Discover essential tips and techniques of loading and unloading boat on trailer, to ensure a smooth and secure process, whether you’re a beginner or an experienced boater. Perfect for making your boating adventures hassle-free.

Every year at boat show time you read of some company or organization giving an award to somebody or other for his contributions to the progress of pleasure boating. All well and good. However, this business of honoring the most prolific authors, the most active safety crusaders, the fastest race drivers and so on tends to overlook many unsung heroes whose obscure deeds mean a great deal to the sport. In fact, without these diligent ones, the sports of boating and fishing would amount to very little indeed.

Therefore, I am happy to announce the establishment of Boating’s Unsung Hero Award. The trophy will be mounted on a polished marble base to which will be affixed a gold plaque engraved with the recipient’s name and the service for which he is being honored.

As the years pass, it will be awarded according to the judgment of a select committee of sportsmen to such unsung heroes as the sea worm digger of Maine whose backbreaking efforts are vital to salt water sport fishing as we know it, to the draftsman who designs the gears for fishing reels without whose smooth and sure performance our sport would be almost as much fun as shaving with a 25-cent jacknife, and to a representative of the employees of Use of Fiberglass in Boat Constructionfiberglass boat factories whose tedious labor with smelly resin pots and sticky laminating rollers gives us the boats without which we’d be sunk – and honest, I mean no pun!

As originator of this fine and commendable award, I reserve the right to choose the first recipient.

“La-dees and gennul-men, it is now my grrrreat pleasure to introduce Mr. Modulus O. Elasticiti, an engineer from a boat trailer factory. Mr. Elasticiti, please step up to the podium and take a bow.”

After several minutes of tumultuous applause from the admiring crowd, I will motion for silence and proudly read the citation:

“To Modulus O. Elasticiti, designer of modern and worthy boat trailers, we present this Unsung Hero Award in deep appreciation for his tireless and able efforts in developing and improving the faithful but silent workhorses which carry our boats millions of trailer-miles each year from inland home to seaside launching ramp.”

There now, justice has been done. Unfortunately, I must confess that Boating’s Unsung Hero Award is, alas, but a figment of my imagination. But I think the idea of having it is a good way to dramatize the fact that we do tend to take boat trailers too much for granted. And, the old saying has it that familiarity breeds contempt. This leads to another cliche; pride cometh before a fall.

Make a long automobile trip in the summertime and observe how often you see broken-down boat trailers sitting forlornly beside the highway while their owners have driven off into unfamiliar communities in search of needed parts with which to effect repairs – often a frustrating and timeconsuming activity. Trailer breakdowns are usually the direct outcome of unfamiliarity with trailers and trailering. Victims of trailer breakdowns tend to be chaps who thought they knew all they needed to know about trailering, which in their minds amounts to “Hitch it up and drive off.”

Many boaters still do not understand basic principles of trailer balance, don’t realize trailer tires are different from car tires, that trailer wheel bearings live a life that is much different from that of their brothers inside car wheel hubs.

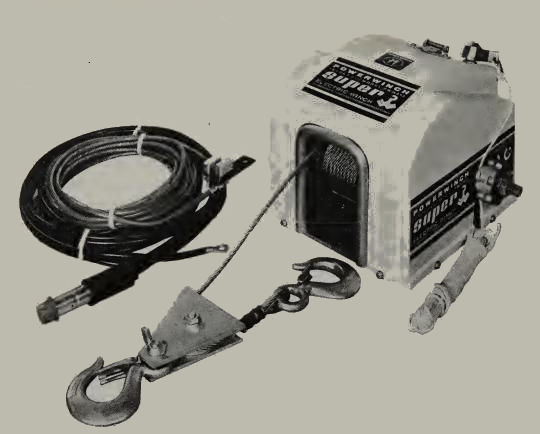

Before World War II, a handful of pioneer manufacturers produced a piddling number of boat trailers. The business boomed enormously in the late 1940’s when today’s boating boom began to gain momentum. In those days trailer builders often had to improvise, because they could not get all the parts they needed from specialist firms – things like wheel hubs specially designed for the task, keel rollers of rubber molded into a wide variety of shapes, winches engineered to suit various loads, hitches for small and large trailers, and so on. They had to make their own, or make do with purchased items of mediocre suitability.

Have you ever noticed that when some new type of product comes on the market and begins to gain wide acceptance, inventors and suppliers are quick to come out with new items specially tailored to meet the needs of the new product? When manufacturers of the new product find themselves able to purchase these improved items, they stop fudging up makeshift components and eagerly adopt these items made available by specialty firms.

The equipment used to form and weld up a good trailer frame is not adaptable to making winch gears, or rubber rollers, for example. So it is that today most boat trailers incorporate highly-developed components produced outside the trailer makers’ own factories. The result is overall better trailers for American boat owners.

Another fortunate development is that as the years have passed, trailer designers have learned many lessons. Most boat trailer manufacturers now belong to a trade association which was established as a division of the Boating Industry Association for their benefit – and yours. At regular meetings designers from various firms get together and swap ideas and information. You might be very surprised at how much these men know about why trailers behave as they do on the highway and how to make sure a new one will be roadworthy.

Let’s take a look at trailer springs as a means of gaining a good practical understanding and appreciation of their knowledge. If you were designing a trailer to be the cheapest and lightest one in your imaginary trailer company’s line, you might suppose that a single, transverse leaf spring would provide the lightest and cheapest suspension. So, you’d sketch out the proposed trailer. You’d attach the thick middle section of the spring to the backbone of the trailer with a pair of U-bolts, and you’d connect the outboard ends of the spring to the axle by means of two sets of shackles, which would allow for flexing and consequent change of length of the spring.

As soon as you begin the actual working drawings, it will occur to you that the location of the fittings on the axle to hold the shackles, will be a matter to ponder. Common sense might suggest they should be located so that the shackles will sit in a vertical position when the trailer is carrying its rated load, the lower end of each shackle attaching to eyes in each end of the spring, and the upper ends of the shackles suspended from the attachment fittings. This will put a straight downward pull on the shackles, which seems right.

But during early road tests, your prototype trailer proves to have a dismaying tendency to oscillate from side to side, threatening to tear the boat loose from its tiedowns and making the tow car shake from side to side.

You’ll eventually figure out what is happening. The shackles are “swinging” from side to side in unison, like a pair of synchronized children’s swings. A twist from the tow car, a bump or centrifugal force in a fast turn starts the action and the faster you go the worse it gets.

So, you move the spring fittings outboard on the axle an inch or two, so that now instead of hanging vertical, both shackles angle inward. Thus angled, each will tend to pull against the other and resist “swinging.” Now the trailer should not oscillate. But, just how much should the shackles angle inward? If too much, they will tend to pull inward very forcibly on the shackle support fittings on the axle, requiring these parts to be made stronger and more expensive. Will there now be excessive wear on the bolts and bushings that hold the shackles? Will the new angle make the trailer bounce more under certain load or road conditions?

Now you see why men like our fictitious Modulus O. Elasticiti, with their knowledge of mechanical calculations, are employed to take over when Old Joe the local welder finds that rule-of-thumb methods won’t produce a good, workable, economical answer to the shackle angle problem – and many other problems like it.

Faced with this shackle problem, Mr. Elasticiti will make calculations, perhaps rig a mockup to duplicate varying shackle angles and make tests on it. Or, after due consideration and some figuring, he may point out that to use a single transverse spring, we’ll have to install radius rods on both sides of the trailer to position the axle against drag loads; that it would be cheaper to use a pair of leaf springs of some stock size bought from a spring specialist in large quantities, than it would be to buy half the number of longer transverse springs and make jigs in the trailer shop on which to build the radius rods ourselves. Also, he’ll add, the two springs mounted fore-and-aft on each side of the trailer’s frame will offer more resistance against heeling on fast turns than would the transverse spring.

Read also: How to Purchase the Perfect Boat: Evaluation to Final Sale

So you see, the men who design trailers meet and solve all kinds of design problems. All to the benefit of Joe Boater. Leaf springs have a lot of “interleaf friction” when they flex, enough to appreciably snub the spring’s tendency to vibrate after striking a pothole and causing the trailer to bounce and bounce. Some trailers use coil springs – water does not get between their leaves and cause rusting, for they have no leaves. But in such springs there is no interleaf friction and they will flex and bounce easily. So shock absorbers have to be installed. Actually, the name “shock absorber” is a misnomer. In England they’re called “snubbers” and this describes their true purpose more accurately – to snub spring oscillations and prevent wild bouncing and swaying.

Trouble is, when the widely-available piston-type shock absorbers are installed, salt water eats hell out of them in a hurry because that’s one condition they were never designed to meet. Automotive leaf springs used on rear ends are engineered to be quite flexible so as to work in tune with the very flexible coil springs now almost universal on front ends. Therefore, if widely-available and cheap auto leaf springs were used on a boat trailer, they might let it lean over too much on a fast curve and threaten to topple your boat onto the ground. So boat trailer springs tend to be on the short, stiff side.

We’re now cruising into “how to choose a trailer” territory. Knowing the foregoing bit of information about trailer springs, it’s easy to understand that any boat trailer is bound to have a harsher ride than its tow car. You don’t want too harsh a ride, for that would give your boat a beating, possibly open some seams or strain parts of it in contact with the keel and bilge supports. It’s obviously a mistake to buy a trailer of too little rated load capacity, for it will be overloaded and its life expectancy will not be good.

But, beware of the “I want a good, solid, heavy trailer that won’t break down!” point of view. If you have a 1 500-pound boat and get a 3 000-pound trailer, you may in the end outwit yourself because its overly hard ride with its springs designed for twice your load will in time have deleterious effects on both boat and trailer. Tail lights, for example, may be forever blowing out – because the white-hot and therefore soft filaments can’t stand the jolting of the trailer’s hard ride.

Good boat trailers are deliberately designed with a factor of safety in their load ratings. If you put 1 501 pounds onto a trailer rated at 1 500 lbs. capacity, it won’t collapse. In fact, if you put 2 000 pounds onto it it still won’t collapse. But its reliability on the expressway and life expectancy will be reduced. The point to know is that you do have reasonable leeway to both sides of the rated load figure. Your marine dealer carries a line of trailers that includes one model rated for 1 800 lbs. and another rated for 2 400 lbs.

Your boat with its motor, full fuel tanks and normal load of gear weighs 2 100 lbs., so which trailer? If your trips will be short ones or good roads, three hundred pounds overload won’t be enough to worry about. On the other hand,the springs on the 2 400 lb. model won’t be so much stiffer as to justify fear of a harder ride hurting the boat – especially if you will be using it on smooth expressways. And its moderate amount of extra “beef” will tend to make it more reliable on long, fast runs. Plain horse sense is the name of the game when choosing trailers.

After buying the boat, motor, controls, PFDs and all the other things that go aboard, you and a million other men are apt to be watching your bank balance very nervously. This is the time to avoid falling into the trap of automatically buying the cheapest available trailer. It might be all right, if you’re going to use it on slow, local, intermittemt trips. But it could also end up costing you more than the deluxe model, if it lets you down in the middle of nowhere on frequent long-distance trips.

Typically, the cheaper models are easy enough to recognize – fewer and more widely-spaced hull support rollers, lighter-duty wheels and tires, fewer conveniences such as walk boards to facilitate reaching the bow of the boat during haul-out, lighter frame construction, plainer finish and so on. They’re roadworthy and serviceable but built for economy and less well adapted to fast, long trips. Another source of confusion is that today there are on the market trailers made for conventional-bottom boats and for deep-vee boats. The latter are easily spotted by the vee shape of their cross members; don’t get one of these if yours is a conventional hull.

The reason why most boat trailers have wheels smaller than those on a car is not for the sake of cheapness – if you’ve bought a pair of extra car wheels for your winter snow tread tires you know such a wheel gives you plenty of change from a $10 bill. Smaller trailer wheels are a bit cheaper but not much. The real reason is so that wheels and fenders will not project very far above the “deck” level of the trailer and get in the way of whatever wider hull an owner might want to carry on his boat trailer. The few trailers using car-size wheels tend to have wider tracks to put the higher wheels farther outboard so as to clear the boat bottom. It is very desirable to keep a trailer as low as possible for steadiness on fast curves.

Small-diameter trailer wheels naturally rotate faster – as much as 400 r. p. m. faster! The bearings spin faster, generating more heat. Arriving at a launching site, the trailer wheel hubs are usually fairly warm to the touch. This is normal and no worry on the highway, provided the proper amount of lubricating grease is in each hub. Car wheel hubs are concealed under hubcaps, we seldom think about them, and unwittingly pull a boo-boo involving our trailer bearings. Warmed trailer wheel hubs put into chilly sea water causes air in the hubs to contract. This creates a slight vacuum, and sometimes it’s strong enough to suck sea water into the hubs past the grease seals.

Better grease seals, running on very smooth chrome-plated surfaces instead of on somewhat roughly machined axle surfaces, have helped a lot, but we still see water get into hubs. Salt water takes only a short time to start pitting the bare steel surfaces of roller bearings. At this stage, the bearings begin to encounter much more friction, they get hotter and hotter, the grease breaks down, friction increases, the rollers bind, the inner race starts spinning on the outboard end of the axle, the axle gets red hot and then white hot and then melts – and there goes your wheel as your axle drops to the pavement amidst a comet-tail of sparks.

Hub greases compounded especially for boat trailer use contain corrosion-inhibiting compounds that have some benefit in preventing salt water from corroding bare steel at once. But they don’t give everlasting protection. It’s a chore to pull trailer wheels off for drying-out every time the wheels have been dunked in sea water and might possibly have pulled some of it into the hubs. Some trailer owners think the answer is simply to install grease fittings on their hubs to they can quickly re-grease the hubs at a gas station on their way home from the sea.

The rub here is, grease guns found at service stations are capable of developing surprisingly high pressure in order to force grease into dry automobile suspension surfaces. They can easily blow out the delicate-edged grease seals in a wheel hub. When that happens, grease runs out under the effect of centrifugal force and a breakdown is then not too far down the old superhighway.

A number of devices are on the market to solve the trailer hub lubrication problem. In one, a special lubricating oil replaces the hub grease and a transparent hub cap enables the boater to keep constant watch on oil level. In another, a spring-loaded grease reservoir built into the device keeps the hub constantly filled 100 % with grease and this presumably makes it impossible for water to enter.

Because they rotate faster, trailer tires generate more heat than do your car’s tires. To keep heat build-up to a minimum, trailer tires are run at appreciably higher pressures – commonly from 50 to 80 lbs. per sq. in. To enable them to contain such pressure, they are thus normally built with more plies than car tires – four, six, even eight. When you neglect to check pressure and it drops off, or some ignoramus blows off the “excessive” pressure in them, you get added sidewall flexing – and with all those extra plies flexing rapidly, a lot more heat is generated. Low pressure in trailer tires is a wide open invitation to a blowout. Trailer and tire dealers have charts on which you can look up the pressure that is correct for the tires on your particular trailer.

Car and trailer weight are interrelated. The general rule is that gross weight of the trailer and its load should not exceed gross weight of the tow car, on the theory that a trailer heavier than the tow car might take charge of matters during hard braking. As far as pulling power is concerned, this rule pretty much evens things up since a light car of modest power would be used to tow a lighter boat and trailer. Towing a trailer doesn’t really overstrain a car, it just slows things down a little. It’s going up and down hills that strains things – the transmission when climbing, the brakes when descending. You can get away with trailer weights on flat roads that would give your car severe strain on hilly roads.

When trailer weight equals car weight, each square inch of brake lining has to do twice as much work. Brakes heat up faster. Doing a lot of braking can bring them up to a heat where they will “fade” and lose their stopping power. That’s bad, on fast expressways or going down long hills. Many states require brakes on all trailers weighing over 1 500 lbs. loaded.

Trailer brakes are a big and involved subject. Number One fact about them is that if they get dipped in salt water, trouble is not far over the horizon. Built to keep splashed water out, they are hard to flush with a hose. Most major trailer makers are located well inland and I suppose they don’t worry about what to them seems like a remote and minor problem. One would think that the new disc brakes used on many cars would be fine for salt water areas, as their working parts are much more exposed and presumably easier to flush of salt water.

But thus far I have seen no sign or word in the marine trade of their being adapted to boat trailers. I couldn’t begin to delve into the ramifications of electric and hydraulic trailer brakes here; if the subject interests you deeply, visit shops or friends who are involved in hot rodding automobiles and track down Volume No. 2, “Basic Chassis, Suspension & Brakes,” a soft cover textbook published by Hot Rod Magazine. It has a well-detailed chapter on trailer brakes including pros and cons of the various types of controls.

In regard to your car’s transmission, cooling system, shock absorbers, tires and other parts directly involved in trailer towing capability, visit your local car dealer. Every automobile manufacturer has a booklet of some kind which will tell you a lot of useful things about outfitting your make and model of car to do the best possible job of trailer towing. It’s even possible to order your brand new car with assorted heavy-duty components to suit it for towing a larger boat trailer as efficiently as possible.

The day is long gone, praise King Neptune, when a man had to cobble up his own trailer hitch with the aid of the local welding shop. Ready-to-install frame hitches are now available to fit practically every make and model of car and just by bolting such a hitch on you assure yourself of having a reliable, trouble-free one. If yours is a really heavy boat, investigate a “load equalizer” type hitch. By means of a system of levers, it distributes the down-load of the trailer’s boom onto both front and rear wheels of the tow car, preventing rear-end-sag and making the car ever so much easier to drive and manage.

Load equalizer hitches are more commonly seen in the trailer coach field than in the boat trailer field, so if you plan on towing a larger boat go to a local trailer coach dealer for information on such hitches.