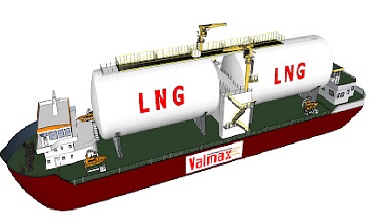

Training of LNGC and ABS Analysis – Gas Carrier Course

The Gas Carrier Course-Training of LNGC and ABS Analysis is an essential program designed for mariners to gain expertise in operating Liquefied Natural Gas Carriers (LNGCs) and performing ABS (American Bureau of Shipping) research. The program makes sure comprehensive knowledge and skills in both practical liquid fuel handling and controlling agreement.

LNGC Coaching

The Liquefied Natural Gas tanker teaching part provides in-depth education on the properties and safe handling of liquefied petroleum gas. Members learn about Liquefied Natural Gas containment systems, cryogenic temperature maintenance and cargo functionings, including loading and unloading procedures. Emphasis is placed on security protocols, emergency response strategies and adherence to international level. Such coaching guarantees that shipmen can manage LNG actions effectively and safely.

ABS Analysis

The ABS research module focuses on understanding and applying ABS levels in Liquefied Natural Gas tanker operations. Candidates are trained in the regulatory requirements set by the American Bureau of Shipping, including protection measures, inspection protocols and maintenance guidelines. The method covers how to confirm compliance with such standards, which are crucial in the direction of maintaining the highest levels of security and operational efficiency.

Integration of Tuition Components

By integrating LNGC teaching with ABS investigations, the preparation offers a holistic approach to LNG carrier functionings. The comprehensive training makes certain that sailors are proficient in the technical aspects of fossil fuel handling while fully understanding the ruling environment. The dual focus enhances the ability to optimize operations, guarantee secure and comply with stringent regulations.

The Gas Carrier Course-Training of LNGC and ABS Analysis is vital to mariners involved in LNG transportation. By combining practical liquid fuel handling skills with detailed ABS official probes, the training program prepares candidates to operate LNG transporters safely and efficiently. The integrated approach supports the industry’s commitment to maintaining high standards of protection, regulatory conformity and operational excellence.