Types of Gas Tankers

LNG Tankers

1) Membrane Tankers

These vessels use a thin, flexible membrane to contain the LNG. The membrane is supported by insulation layers and the ship’s hull, allowing for efficient use of space and reduced boil-off rates.

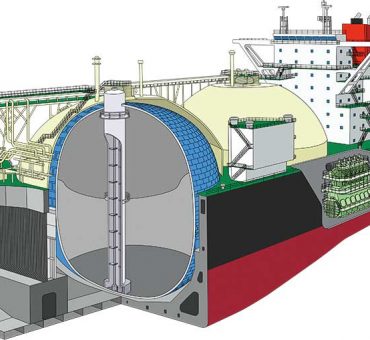

2) Moss-Type Tankers

Named after the Norwegian company Moss Maritime, these tankers feature spherical tanks made of aluminum or nickel steel. The spherical shape evenly distributes the internal pressure and provides robust containment.

3) SPB (Self-supporting Prismatic Shape IMO Type B) Tankers

These have prismatic tanks that fit the hull shape more effectively, maximizing cargo capacity. The tanks are self-supporting and designed to handle the stresses of the liquid cargo.

LPG Tankers

1) Fully Pressurized Tankers

These smaller vessels transport LPG at ambient temperature under high pressure, typically up to 18 bar. They are simpler in design and used for shorter routes.

2) Semi-Pressurized/Refrigerated Tankers

These vessels can carry LPG at intermediate pressures and temperatures, offering flexibility in operations. They can adjust the pressure and temperature to optimize cargo volume and stability.

3) Fully Refrigerated Tankers

Designed to transport LPG at atmospheric pressure and very low temperatures (around -42 degrees Celsius), these tankers are used for long-distance voyages and can carry larger quantities of LPG.

Familiarization with Gas Tankers

Familiarization with gas tankers involves understanding their specific operational procedures, safety protocols and the technologies employed to handle liquefied gases. Crew members and maritime professionals must be well-versed in the unique characteristics of the cargo, including its physical properties, handling requirements and potential hazards.

Training for gas tanker operations typically includes:

a) Safety Training

Emphasizing emergency response procedures, fire suppression techniques, and the use of personal protective equipment (PPE).

b) Operational Procedures

Covering the loading and unloading processes, maintenance of containment systems, and monitoring of cargo conditions during transit.

c) Technical Knowledge

Understanding the design and functionality of the containment systems, including the insulation, pressure relief valves and temperature control mechanisms.

d) Regulatory Compliance

Familiarity with international regulations and standards, such as those set by the International Maritime Organization (IMO), which govern the safe transport of liquefied gases.

By gaining a comprehensive understanding of the types of gas tankers and the principles of their operation, maritime professionals can ensure the safe and efficient transportation of LNG and LPG, contributing to the overall reliability and sustainability of the global energy supply chain.