From 2026: Widespread Adoption of Laser Cutting in Shipbuilding

In 2023, the marine industry began exploring the use of laser technology for metal cutting. At that time, the situation was mixed: smaller shipyards were already actively purchasing new equipment, while larger production facilities upgraded more slowly. Nearly two years later, the situation has changed – regulatory documents have been introduced that allow for the use of laser cutting, and a major potential customer from the OSC group plans to implement such equipment starting next year.

The company STM continues to collaborate with shipbuilding enterprises and jointly develop technical specifications with factories for equipping production lines with laser cutting machines. The main obstacle to the adoption of this innovative technology was the lack of a regulatory framework and standards.

Source: STM

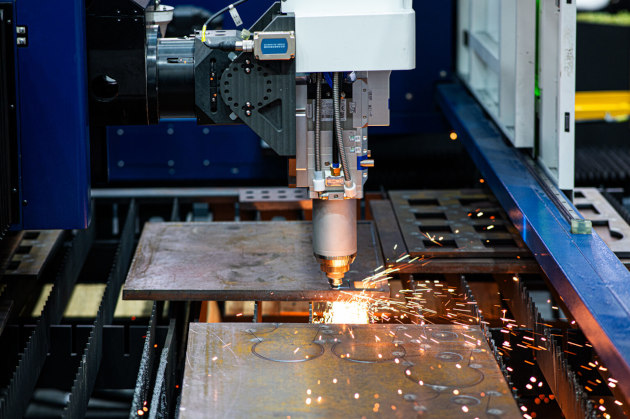

Previously, laser cutting was low-powered and unsuitable for processing the thick metals used in shipbuilding. However, over the past decade, the shift to fiber lasers has dramatically increased power (up to 60 kW), opening up opportunities for applying lasers not only to sheet metal but also to various profiles (such as channels, I-beams, girders, etc.).

Key advantages of laser cutting compared to traditional methods (plasma or gas cutting) include a high cutting speed, improved edge quality (with less heat-affected zones and structural changes in the metal), and reduced costs for subsequent mechanical processing. Moreover, laser equipment can process sheet metal as well as create parts with complex geometrical shapes.

Source: STM

The primary barrier to the widespread adoption of laser technology in shipbuilding remains the bureaucratic process involved in forming and updating regulatory documentation. For government contracts, enterprises must strictly adhere to established GOST standards and technological charts, making it difficult to implement more modern methods even if they are economically viable. Nevertheless, smaller private companies, such as those producing yachts or small craft, have more flexible standards and are already actively using laser cutting.

Read also: Global Shipbuilding — 2024 Results and 2025 Trends

Another important aspect is the selection of the right equipment, which depends on factors such as the size of the workpieces, material thickness, production volumes, and workshop space. Modern technologies continue to evolve: hybrid systems are emerging, intelligent control systems are being implemented, warehouse automation is progressing, and even laser cutting with water guidance is being developed to minimize thermal impact. In addition to cutting metallurgical structures, lasers are being used for cleaning ship surfaces before repair.

In summary, despite the gradual regulatory changes and bureaucratic challenges, the development of laser technologies in shipbuilding promises to enhance productivity, quality, and cost-effectiveness in shipbuilding processes.