Aluminum alloys are known for their unique characteristics that make them ideal for various applications. They possess a combination of properties such as high strength-to-weight ratio, excellent corrosion resistance, and good formability, which make them a popular choice in industries such as aerospace, automotive and construction.

One of the key characteristics of aluminum alloys is their strength-to-weight ratio. They are much lighter than other metals such as steel, yet still maintain high levels of strength. This makes them ideal for applications where weight is a critical factor, such as in the aerospace industry where fuel efficiency is of utmost importance. Additionally, aluminum alloys have excellent corrosion resistance due to the formation of a protective oxide layer on their surface. This makes them suitable for use in harsh environments, such as in the construction of buildings near the coast where there is exposure to saltwater.

Characteristics of Aluminum Alloys

Aluminum and Aluminum Alloys

Pure aluminum is a silvery-white metal with many desirable characteristics:

- it is light, non-toxic, non-magnetic and non-sparking;

- it is easily formed, machined, and cast;

- although softer and with less strength than steel, alloys with copper, magnesium, silicon, manganese improve mechanical properties, making aluminum extremely versatile;

- it is not found in the same raw form in nature (as with iron ore) and is to be refined from bauxite, and aluminum ore, which are found abundantly.

The main characteristics of aluminum alloys are:

- CORROSION RESISTANCE. Aluminum is chemically resistant to seawater and acids.

- STRENGTH. Certain alloys strength levels approach steel’s mechanical strength.

- LIGHT WEIGHT. Strength to weight ratio is higher than steel.

- HIGH TOUGHNESS. Aluminum possesses excellent toughness properties at low temperatures, making it a well-suited cryogenic material.

- EASE OF FABRICATION.

Aluminum and aluminum alloys are not new to Managing Liquefied Natural Gas Risks in the Marine Industrythe marine construction industry. Aluminum alloys have been extensively used for:

- naval amphibious craft;

- naval patrol boats;

- gas carriers cargo containment systems;

- offshore supply vessels;

- commercial barges;

- cruise ships: top side structure.

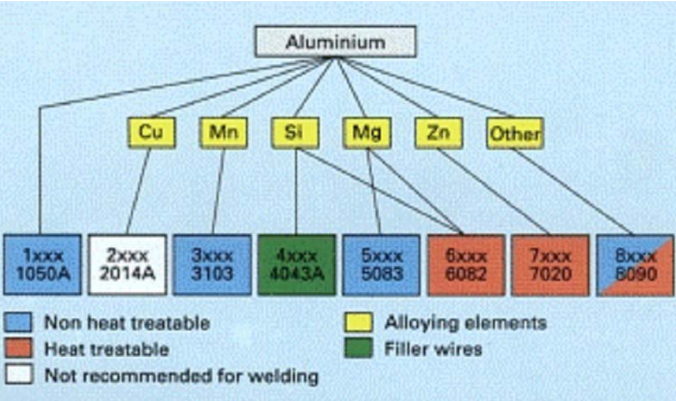

Aluminum Alloy Series

Figure below shows the aluminum alloy families and their main characteristics, based on the most important element of the alloy. The most interesting alloys for Boat Development & Ancient Historyshipbuilding are the series 5 000 and 6 000.

Alloys distinguished by name 5XXX (5 000 series alloys) are corrosion resistant in marine environments and readily weldable since the 1950’s.

5 000 series alloys are non-heat treatable aluminum-magnesium alloys. They have excellent corrosion resistance and good “as-welded” strength. There are no measurable corrosion losses after decades of use.

6 000 series alloys are heat treatable aluminum-magnesium-silicon alloys. These are used frequently as extruded shapes and sections.

6 000 series alloys need to be protected from seawater.

The most popular base metal for shipbuilding is 5083. The 5083 base alloy was registered with the Aluminum Association in 1954. Advantages for shipbuilding are the following characteristics:

- availability;

- excellent strength;

- corrosion resistance;

- formability;

- weldability.

While 5083 has been predominant in construction of oceangoing vessels, lower-strength alloys (such as for instance 5052 and 5086) have been used for smaller, lower-stressed typically inland lake boats.

In recent years, aluminum producers have developed “improved” aluminum alloys specifically targeted at the shipbuilding industry. In 1995, Pechiney (now ALCAN) registered the aluminum Alloy 5383 and has promoted this alloy as having improvements over 5083.

These improvements provided potential for significant weight savings in the design of aluminum vessels and included a minimum of 15 % increase in post-weld yield strength, improvements in corrosion properties, and 10 % increase in fatigue strength. In 1999, the aluminum manufacturer Corus Aluminum, registered the aluminum base Alloy 5059 (Alustar). This alloy was also developed as an advanced material for the shipbuilding industry, claiming significant improvements in strength over the traditional 5083 alloy and promoted by Corus as having a 26 % increase in yield strength before welding and a 28 % increase in yield strength (with respect to Alloy 5083) after welding.

It is to be noted that at the present moment, neither Alloy 5383 nor Alloy 5059 has been approved by Presentation on ABS Advanced AnalysisABS as yet.

Problems with Aluminum Alloys 5086

Exfoliation corrosion and fracturing problems have recently been observed on several high-speed vessels built with Aluminum Alloy 5083 H321.

Therefore, ASTM B928 – 5083 H321 cold rolled plate is susceptible to corrosion and not guaranteed for marine application by the manufacturer.

This has raised concern for use of this material, when it is considered for marine use.

Mechanical Properties

The mechanical properties of heat treatable aluminum depend upon:

- the combination of alloying elements;

- he thermal (heat treatment) processing;

- the mechanical processing (stretched, rolled, etc.).

The mechanical properties of non-heat treatable alloy depend upon:

- the alloying elements;

- the amount of strain hardening or cold work.

Tables 1 and 2 show the mechanical properties of non-heat-treated as-welded aluminum alloys and of heat-treated as-welded aluminum alloys respectively.

| Table 1. Minimum Mechanical properties for Butt-Welded Aluminum Alloys (not heat-treated) | ||

|---|---|---|

| Alloy | Ultimate tensile strength (Ual) | Yield strength (Yal) |

| N/mm2 (psi) | N/mm2 (psi) | |

| 5083 – H111 | 269 (39 000) | 145 (21 000) |

| 5083 – H116, H321 | 276 (40 000) | 165 (24 000) |

| 5083 – H323, H343 | 276 (40 000) | 165 (24 000) |

| Table 2. Minimum Mechanical properties for Butt-Welded Aluminum Alloys (heat-treated) | ||

|---|---|---|

| Alloy | Ultimate tensile strength (Ual) | Yield strength (Yal) |

| N/mm2 (psi) | N/mm2 (psi) | |

| 6061-T6 under 9,5 mm (0,375 in) | 165 (24 000) | 138 (20 000) |

| 6061-T6 over 9,5 mm (0,375 in) | 165 (24 000) | 103 (15 000) |

Key Concept for Welded Alloys

For welded construction, allowances must be made for reduced-as-welded strength and ductility, as compared to the properties of the heat-treated (un-welded) base metal (base metal mill certificate).

The as-welded strength of heat-treated aluminum weld varies as a function of time and temperature in the heat affected zone (HAZ).

The main heat treatable alloys used are 6061 & 6005A. They are mainly used as extrusions for structural members.