Discover everything you need to know about boat outboard motors. Learn about their types, functions, maintenance tips, and how to choose the right outboard motor for your boat. Ideal for boating enthusiasts and first-time buyers.

It’s fascinating to speculate on what things might be like today, if one thing or another had not happened in the past, or had not been invented. How would American history read if the Pilgrims had managed to sail safely past the shoals off Cape Cod in 1620, and went on to carry out their original plan to settle in Virginia?

One Vital Tool

Suppose the Wright brothers had been unable to buy gasoline at Kitty Hawk in North Carolina back in December of 1903? What if the pneumatic tire had never been invented and perfected? Suppose men of today still had not learned how to make cloth out of glass and resin from coal, air and water, and to combine these two unlikely Characteristics of Different Types of Construction Materialsmaterials to form boats? For that matter, suppose the outboard motor still had not been invented?

Well, in the latter case we can be very sure indeed that the sport of fishing would be vastly different than it actually is today! Who can really say? Party boats might be a hundred times more numerous. Fishing from power boats might still be a pastime for the well-to-do. Or, we might see the waters today dotted with millions of dories powered by seagoing versions of cement mixer engines. Techniques for fishing from bridges and beaches might be far more sophisticated than they are now, by reason of vastly more people being obliged to do their fishing that way, and inevitably, coming up with more bright ideas.

We might even be using sailboats for trolling, and at boat shows we would be inspecting fishing sailboats having strange mast and sail layouts designed to hold sails aloft while still leaving clear space below for the manipulation of fishing rods! A group of good friends can while away a long December evening talking with a mixture of amusement and amazement about how things might be today were it not for the outboard motor.

Looking at the salt water fishing scene from this “suppose” point of view helps us to vividly remember and appreciate a fact we tend to overlook—the outboard motor is the modern sports fisherman’s best friend, his seven league boots, his key to new worlds, his most indispensable piece of equipment next to his rod and reel. We can cuss at balky outboards, if we feel like doing so. Admittedly we sometimes feel that way, but the plain and inescapable fact remains that the outboard motor is the kingpin of today’s sport fishing world.

Taken as a whole, outboard motors make the fishing scene what it now is – millions of people in ordinary circumstances enjoying swift transportation on the water to fishing spots both greater in number and farther away than would be possible if we still had to row or sail. The outboard motor made possible the trailered boat, which is to say, it makes possible today’s most common type of fishing craft. You have to admit that the outboard motor is a potent force in the recreational world and has to be accorded a lot of respect. No sense in doing an “ostrich act” and trying to think otherwise!

New outboard motors currently displayed in your local marine dealers’ showrooms are the result of something like eighty years of intensive development. Nobody is really sure when the first genuine outboard was made. The idea actually seems to have formed itself gradually over a period of years. Manually-powered “outboards” in which hand cranks, hand levers and foot pedals turned crude propellers at low speed were sketched and even patented as long ago as the 1860’s and 1870’s. In the 1880’s and 1890’s a variety of outboard motors, presaging today’s electric outboards used for trolling, were designed and built in which battery-supplied Self-Survey Criteria for the Engine and Electrical Systemselectric motors were connected by chains or shafts to propellers.

Late in the 1800’s, a Frenchman was experimenting with a small gasoline engine mounted to the boat, inboard of the transom, and driving the propeller by a shaft system that ran up and over the transom and then down into the water. In 1896, the American Motors Company of New York was actually manfacturing and marketing an outboard motor of crude and bulky appearance, but arranged essentially as are today’s outboards with flywheel at the top, a horizontal cylinder, vertical drive shaft and right-angle drive to the propeller. However, the reason Ole Evinrude is celebrated today as the father of the outboard is that his engine of 1909 was the first to sell in steady volume and result in the establishment of a long-lived manufacturing company.

Compare the racket of an above-water “muffler” of 1920 vintage, consisting of nothing but a brass canister with many small holes drilled in it, with the purr of a well-silenced modern fishing motor. Try your hand at starting with the aid of a wrap-and-yank hand cord one of the big, hairy 50 horsepower speedster-type outboards of 1941 vintage with direct drive to its propeller. Compare your hectic experience with the ease of starting and backing out from a dock that is characteristic of a modern, large outboard with electric starter and gear shift. Such first-hand contact with old-time outboard motors tends to put a guy into a really appreciative mood!

As a good illustrative example of an outboard motor component that has been vastly improved over the years, consider the carburetor. On an outboard of the 1910-1920 period, this component usually amounted to a rough bronze casting somewhat reminiscent of an ordinary sill cock in refinement. It had no float and valve to regulate the fuel level, no carefully calibrated high- and low-speed fuel jets. A single knob operated a needle valve to adjust the fuel-to-air ratio.

With this opened for starting, fuel from the tank flowed by gravity into the carb and trickled out of the valve steadily. If the motor started promptly, air flowing through the carb would pick up the fuel and the motor ran. If the motor didn’t start, the flow of fuel would “load it up,” or flood it, forcing you to shut off the mixing valve and crank the motor to clear it of excess gas. These needle valves worked exactly as do the elementary needle-valve “carburetors” on today’s tiny model airplane engines, and any model fan can tell you how very sensitive such an engine is to valve adjustment!

On one old outboard carburetor I recently examined, there is an “intake valve,” which serves the same purpose reed valves do on modern outboards, to admit fuel-air charge to the crankcase and seal it there preparatory to its going into the combustion chamber. This valve is of a simple poppet type, held closed by a very light coil spring. As the piston moves on its up-stroke and creates a partial vacuum in the crankcase, outside atmospheric pressure pushes this valve open and a slug of air is allowed to rush into the engine, picking up fuel (from the needle valve) on the way.

Timing of this crude valve’s opening and closing was erratic, as air velocity and hence pressure varied with motor speed. Slight manufacturing differences between one spring and another or a little rust on the spring would affect its tension and hence the action of the valve. In cold weather, lubricating oil congealed on the valve’s stem would all but lock it closed, making starting very improbable. You begin to get the idea – a lot of built-in bugs and quirks, requiring the intrepid outboard operator to hold a degree in mechanical engineering in order to fathom his kicker and make it run.

Carburetor and power head design have progressed hand-in-hand. As the heads became larger, more powerful and more accurately machined for higher speeds, the task of the carburetor became more demanding. Early outboards operated at 500 to 1 000 r. p. m.’s. Modern ones will slow down to troll at a few hundred r. p. m.’s, yet will flash to 5000 or 6000 r. p. m.’s in an instant when the throttle is opened. There is tremendous variation in the velocity of air rushing through a carb’s throat. When you take apart a modern outboard carburetor, you’ll find a surprising array of small holes and passageways. An expert will point out what each is for and how they all work together to meter just the right amount of fuel into the airstream at all speeds. Except for the fact that it contains no electronic wizardry, such a carburetor is in effect a miniature computer. It took time and a lot of experimentation to bring outboard carburetors to this stage of development.

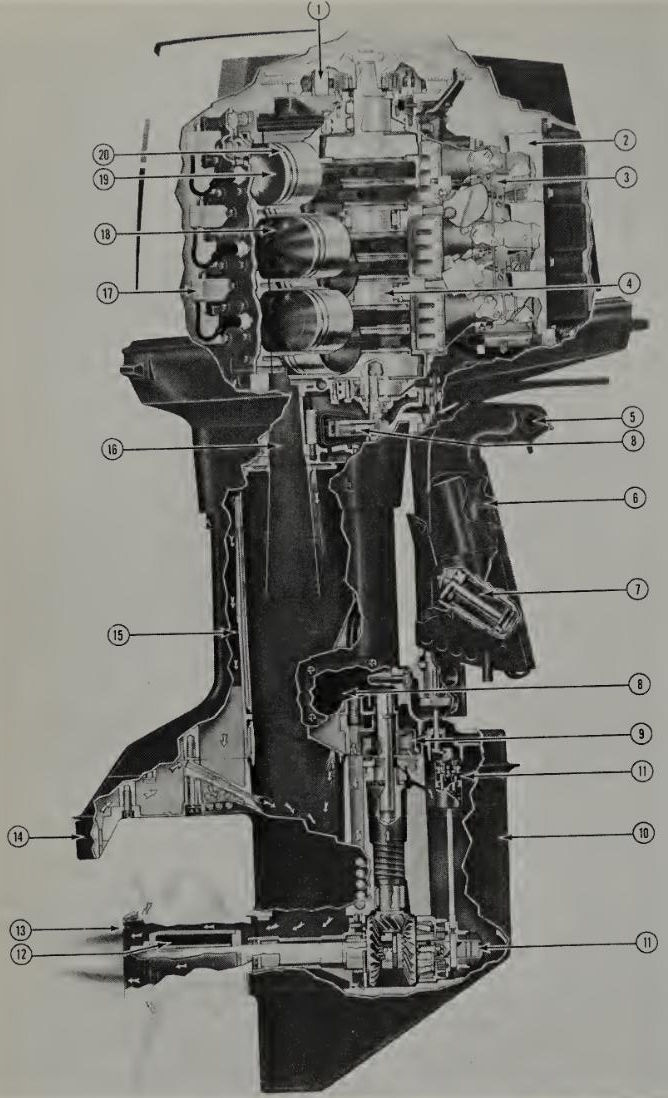

1: 15-amp alternator. 2: Air intake silencer. 3: Dual-barrel carburetor (motor has three such carburetors). 4: Counterweighted crankshaft. 5: Thru tilt pin steering. 6: Single heavy-duty shock absorber. 7: Remote control power trim and tilt. 8: Progressive Isolation rubber mount system. 9: Non-corrosive water pump. 10: Streamlined one-piece lower unit. 11: Power-assisted mechanical shift. 12: Shock-absorbing propeller hub. 13: Thru hub underwater exhaust. 14: Adjustable trim tab. 15: Water-Shield silencing. 16: Tuned exhaust. 17: MagFlash ignition. 18: Double-drilled intake and exhaust ports. 19: Forged aluminum pistons. 20: Pressure-Back piston rings

One fortunate result of this from the fisherman’s point of view is greatly improved running characteristics at trolling speed. Working with these better carburetors are such refinements as thermostats in the cooling system and surface-gap spark plugs, to overcome difficult problems involving low-speed operation. As rotational speed has been steadily upped to get more power from Technical Recommendations for Choosing an Engines for a Boatscompact engines, water pumps have had to be given more and more capacity to keep outboards cooled adequately at high speed. A point was reached where they had excess capacity at lower speeds, and tended to over-cool the motors when trolling. This of course led to sparkplug fouling. Thermostats solved that problem.

Early one-cylinder outboards had appreciable reciprocating vibration, caused by the oscillation of the piston. Manufacturers did not have the forging skill needed to make crankshafts with integral balancing weights and, moreover, a single-cylinder engine cannot be completely balanced against reciprocating vibration by means of counterweights on the crankshaft.

If the counterweights were heavy enough to balance the starting and stopping forces of the piston at each end of the stroke, they would be so heavy that they would set up an entirely new and objectionable shaking of their own when the crankshaft was in the 90 and 180 degree positions. Depending on the kind of engine and service involved, normal running speed, etc., single-cylinder engines are counter-balanced to something less than 100 %, typically some compromise around the 50 % point.

Opposed twin cylinder outboards appeared on the scene early as a solution to the reciprocating vibration problem. The cylinders were set 180 degrees apart, on opposite sides of the crankcase. The two pistons moved inward and outward in unison, thereby canceling out each other’s reciprocating vibration. This was only a partial cure, though, as this layout introduced a new problem called torque vibration.

Since both pistons traveled outward on the compression stroke at the same time, they both fired at the same time and the power strokes occurred simutaneously, giving the crankshaft a vicious twist. The opposite reaction to this made the power head as a whole want to rotate in the opposite direction, requiring a firm grip on the steering handle. Since both pistons had to be pushed up on their compression strokes at the same time, the flywheel had to be quite heavy to provide the needed momentum. If you wanted steady trolling, you had to have a very heavy flywheel to do the job at low speed.

Finally, in the early 1930’s, outboard engineers perfected the now common alternate-firing twin. Both cylinders are on the same side of the crankshaft, one above the other. The two-throw crankshaft has its throws located 180 degrees apart, therefore while one piston is going down on its power stroke the other is going up on its compression stroke. Sparkplugs fire 180 degrees apart and there are two power strokes on each revolution. Torque vibration is substantially reduced although not eliminated, low-speed running is appreciably steadier and more reliable. It was the fisherman’s demand for better trolling that impelled the outboard designers to create this type of power head, which is still used in twin-cylinder outboards from three to as much as fifty or more horsepower.

Read also: The Evolution of Boats with Outboard Motors

We’re so accustomed to such outboards that we forget it was a major engineering achievement to get the first opposed twins into production. They had to design magnetos able to deliver two sparks per revolution. They also had to design carburetors and fuel intake systems able to serve two cylinders alternately. And while alternate firing cut torque vibration, it introduced yet another kind. A rocking vibration created by pistons moving in opposite directions several inches apart. These problems necessitated a lot of experimentation with the first alternate twins.

Today we have outboards that run with remarkable smoothness, and still the experimenting goes on to make them even smoother, quieter and steadier!

It was so hard to get outboards to troll as slowly as desired, or to keep them from fouling up when slowed down that much, that in the 1930’s and for some time thereafter a common accessory sold by marine dealers was the “trolling plate.” This was a steel disc slightly smaller than the propeller for the motor it was meant to be used on. A typical trolling plate had two slots in its center, which mated with the arms of a “U” shaped spring clip. This clip had a hole in it at the bottom of the “U,” this area being suitably flattened. The clip went onto the propeller shaft under the propeller retaining nut. When it was desired to troll, the plate was snapped into place on the clip. With this plate riding a few inches behind the propeller, the propeller’s wash was largely blanketed and even with the motor running at a fairly brisk idle, the boat would just creep along.

It is a tribute to the slow-running ability of modern outboards that trolling plates today are so seldom seen that many sportsmen never even heard of them! Not only do motors run slowly without fouling up, modern wide-beam planing-type hulls have so much drag (due to turbulence behind their wide transoms) at trolling speeds that they themselves help keep speed down.

Another reason for their scarcity is that as outboard boat size increases, it becomes more and more common to see them equipped with a small auxiliary outboard, partly as a get-home safeguard should the big motor break down, and also as a low-powered mill to propel the craft slowly for trolling. Further, at least along the seacoast, it is common for trolling speeds to be fairly high, more or less in proportion to the size of the bait. A fresh water artificial bait two or three inches long represents some kind of creature that naturally moves slowly. A salt water equivalent that is many inches long, represents a creature (such as a squid or an eel) that swims faster. So, many salt water fishermen just don’t see any need to slow down to the snail’s-pace that fresh water fishermen call trolling speed.

Trolling plates in the past took various forms. Some mounted on the motor, behind the propeller. Some were small wooden or metal slides, mounted on the transom of the boat in a couple of simple slotted brackets. When you wanted to troll, you shoved the plate down and when you wanted to move to another spot, you pulled it up.

Older outboards were operated from the stern, since the carburetor often needed manual adjustment to keep an outboard running smoothly at various speeds and suitable cables were not available for remote controls. Moreover, the operator usually wanted to sit near the motor so he could wind the starter rope onto the flywheel. With the skipper in the stern, balance was bad when traveling alone and when passengers were aboard, forward visibility was sometimes obscured.

Reliable, weather-proof, smooth-acting, permanently lubricated push-pull control cables were originally developed for use on industrial, farm and military machinery of many kinds. As soon as outboard engineers had perfected forward-neutral-reverse gears in the late 1940’s, it became feasible to adapt these control cables to outboard use and outboard skippers performed a mass migration to forward positions. We are so accustomed to remote controls today that we tend to overlook how much they have done for outboard fishing boat design. When you are at a boat show, as you look at assorted outboard fishing craft, just ask yourself “Would this layout have been possible without remote engine controls?”

As each new year’s models are introduced, we see that the engineers have thought up yet more detail improvements. One often wonders how even more improvements can be thought of, but rest assured, they are on the way! Outboard Marine and Mercury are both intensively investigating the Wankel rotary engine. This type has received much publicity lately due to its appeal to automobile designers, its space-saving compactness and its ability to burn fuel without producing as many pollutants. It can qualify for higher anti-pollution standards without as many of the elaborate control devices as the piston engine requires.

Outboard engineers view it with interest, partly as a hedge against possible future anti-pollution regulations aimed at marine engines, but also because of its lack of reciprocating parts. The piston engine can reach speeds at which “valve float” – failure of the valves to close fully because they’re being opened so rapidly – becomes a serious problem in trying to coax yet more fuel economy out of a given engine size. Lacking valves, the Wankel can rotate faster without such trouble. We do not know yet when the major manufacturers will start manufacturing Wankel type outboards for public sale.

Fishermen with a strong interest in outboard motors should also keep an eye on the Japanese, as it is quite likely that some interesting news will be coming from them in the near future. Such leading motorcycle firms as Yamaha, Suzuki and Honda already manufacture outboards. Since they produce something like ten million motorcycles a year, they have the talent and facilities to make some interesting outboards.

It is said that the Japanese are holding off largescale export to the U. S. of outboards until they have full lines of motors ranging from small horsepower for prams and canoes to larger models for cruisers and houseboats. The claim is that as soon as they have developed full lines, they will start widespread distribution in the U. S. using their already extensive motorcycle dealership networks as a nucleus. Should this come to happen, the American sportsman will have such a vast array of outboards to choose from that he’ll be bewildered. But once he finally makes his choice, the motor he gets is likely to suit his needs fantastically well!

Huge Outboards

A very good and unusually trusting friend once let me drive his highpowered sports car. My strongest impression of it was the way in which the slightest pressure on the accelerator pedal made it surge ahead effortlessly and instantly. And I experienced exactly the same sensation when I first opened the throttle of one of the new V-6 outboard motors!

One moment the boat was just idling along at the low, no-wake speed posted in the channel. The next moment it had jumped onto plane as if catapulted and was tearing seaward like a cat with a thousand howling dogs on its tail!

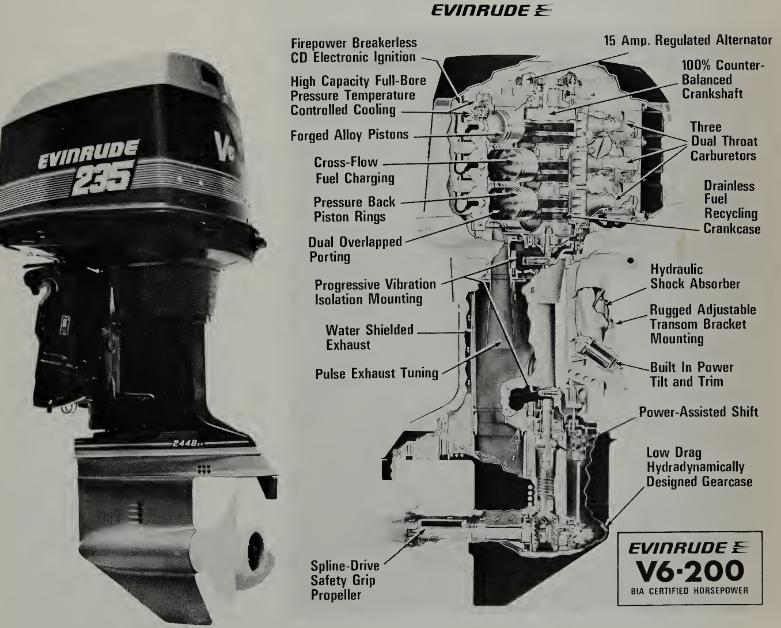

When the news first got around that Mercury, Johnson and Evinrude were going to offer motors rated at 175 and 200 horsepower, most people shook their heads incredulously. “Have the outboard manufacturers gone crazy?,” they asked in amazement. Well, yes, you can say that – with the qualification that they are crazy like foxes!

Most boatmen had assumed that the “horsepower race” had been permanently cancelled by the rising price of gasoline. But here it was, apparently bursting out anew with a vengeance. Who ever dreamed the day would come when outboard motors would reach the 200 h. p. bracket?

Nevertheless, once one understands what these new giant outboards are all about, they make a lot of sense. The power most definitely is not there for the purpose of generating daredevil top speeds, it is there to boost big, heavy boats onto plane – and after that to loaf along easily for mile after mile, running “light” and going surprisingly easy on gasoline.

Consider your car – supposing it is a standard-sized American one, built to travel the long distances common to our vast country. If it has a typical V-8 engine, it will probably attain 90 miles an hour or better flat out, and with some hot rod modification can do even better than that. But you don’t go that fast. It was built to cruise at 60, the usual speed on open roads until the government adopted the 55 m. p. h. limit. You don’t use all the power at that speed. You’ve got a lot of surplus power. It is there to provide acceleration for overtaking and lugging for hillclimbing and trailer-towing. At 55 m. p. h. it is loafing along rather easily and if given recommended periodic maintenance, will last for 100 000 miles before needing an overhaul.

You begin to get the idea. Furthermore, just as auto gasoline consumption rises rapidly as you go above the 60 m. p. h. range, due to rapidly increasing wind resistance, so does outboard motor fuel consumption go up and stay up when its engine is run at or near full throttle. This is done quite commonly, for the sake of maintaining a good cruising speed when the larger, heavier outboard boats are involved.

In recent years the 17 to 24 foot “console” style outboard fishing boats have been becoming steadily more popular for coast fishing. In some areas they range as much as 50 miles offshore. This trend has to be defended as being a useful contribution to boating safety, and even to overall fuel conservation. Obviously, these boats are able to take people out to sea in greater safety than they were in some of the smaller craft formerly used because nothing better was available. And it takes less fuel to propel a lighter outboard boat a considerable distance than it does to propel a much heavier inboard craft. You could say that the big outboard boat (and its motor) represents a happy compromise between craft that are too small for safety on one hand, and too hard on the world’s fossil fuel reserves on the other.

If one agrees that the kind of boats we have been discussing are desirable, one has to admit it is reasonable to say that they deserve the most suitable powerplants that can be devised. Let’s look at a tangible parallel in the automotive field. In the 1960’s, Chevrolet offered a light car called the Chevy II. It was available with either a standard six-cylinder engine or an optional four-cylinder model. One would think the four would give appreciably better fuel mileage than the six, but it didn’t work out that way at all. Under ideal conditions, the four would give a mile or two more per gallon, and that at the cost of noticeably less ability to keep up with traffic and climb hills.

In traffic and hilly country, some owners had to shift into second gear so much to get needed acceleration and power that they ended up using more gas than did drivers whose Cnevy II cars had the six cylinder engine with its greater lugging power. Now in the 1970’s when fuel economy is a much more vital matter, you will observe that the only way Chevrolet and all the other manufacturers are delivering miles per gallon is to install smaller engines in compact and subcompact cars having appreciably less weight and frontal area than the standard-size models. But in the field of big-water boats, we do not want to go into smaller and smaller hulls because that would be going in the wrong direction from the standpoint of safety. The clincher is that you already see newspaper items in which highway safety experts fret that more people will be killed in accidents involving the new, much lighter, smaller cars we are buying for fuel economy.

So, the bigger boats are here to stay for reasons of safety and seagoing ability. That being so, it helps one’s thinking to have a basic grasp of planing hull power requirements.

Beginning from zero at rest, the drag of such hulls increases very steeply until it reaches a high point when they are in the process of “climbing onto plane,” that is, with bow in the air and stern down in the water. Once this point is passed, somewhere around the 10 m. p. h. figure for typical outboard craft, the drag drops off gradually but appreciably. As the boat gains speed, drag caused by the work of climbing onto plane is replaced by drag caused by increasing wind resistance and skin friction of the water against the bottom surface. That is to say, the power used at around 10 m. p. h. to climb onto plane is used from there on to overcome resistances caused by speed.

The amount of power needed to get onto plane is high in these seagoing console boats and similar craft for two reasons. One is that they carry from 30 to 50 gallons of gasoline plus other things incidental to an all-day fishing trip on the ocean. That much gas is heavy. Remember, the boats used for local joy-riding on inland lakes using the same big motors often get by with just one six-gallon tank. So, this extra gas carried by salt water sportsmen does call for a big share of the available power. And also, the deep-vee hulls so popular for a good ride on sea waves take a lot of power to boost them onto plane.

Before the advent of these V-6 outboards, the usual way of getting adequate power was to use twin motors. It is so obvious to anyone that twin motors offer get-you-home safety if one fails, that many persons have overlooked the fact that in many cases the real reason for using them was to get adequate horsepower. It should also be noted that the new V-6 outboards have a built-in safety device that will act like a second motor to get home on. These new motors have what amounts to a compete dual ignition system for each set of three cylinders. So if you have failure on one side of the engine, the other will be able to get you home. This new wiring system combats what was once the most common cause of engine failure, the ignition system.

When two 100 to 135 h. p. outboard motors are put onto a boat, some interesting figures present themselves for your consideration. If happen to be V-4 types, then there are eight cylinders aboard. If they happen to be straight sixes, then you have twelve cylinders. The message is, a lot of parts are moving and creating friction and a lot of fuel has to be used. You begin to realize that a 175 or 200 h. p. V-6 represents an economy of sorts over eight or twelve cylinders.

At present no firm makes an outboard motor rated at exactly 100 h. p., but interpolating from the figures available for various 85, 95 and 115 h. p. motors we can get an average weight for a hypothetical 100 h. p. motor as being 270 lbs. with a selling price of about $2 100. An averaged-out figure for the various V-6 outboards gives us a weight of around 380 lbs. and a selling price of about $3 000, including sales taxes and shipping. Thus, two 100 h. p. motors would put 540 lbs. onto the transom of your boat and take $4 200 out of your checking account.

If you opt for twin outboards in this power range, you also pay for two batteries, possibly two remote control units (or the cost of installing them if they are included in the motor price), dual-motor steering hookup tierod, labor for hooking up controls and wires to two motors, etc. If you get your total of 175 to 200 h. p. in the form on one V-6, you obviously spend considerably less when out shopping! And, one V-6 at about 380 lbs. is a lot less weight to lug around than the 1 000 lbs. which is about average for stern drive powerplants based on cast iron automotive engine blocks. You get a boat that climbs onto plane with less fuel used for the lifting job, and a boat whose stern lifts to following seas better.

The above speeds are at full throttle; cruising speeds in the region of 30 m. p. h. at reduced throttle are mentioned in the manufacturer’s literature. This is a reasonable and practical cruising speed, taking into account typical sea conditions and how much bouncing a boatload of fishermen would want to put up with on a long run. It seems very obvious though that one V-6 running at 30 m. p. h. is going to go easier on gas than one 135 howling at or near full throttle.

Seagoing sportsmen will want to know right away about the safety matter presented by going far out with one motor instead of two. Drive your car at 90 m. p. h. regularly and of course the engine will break down sooner and probably more spectacularly than it will if driven at the 60 it was designed for or the 55 that’s now legal. Cruise a boat capable of 40-plus m. p. h. at 30 and your outboard is rather obviously going to benefit in the dependability department.

You can afford to have one V-6 serviced better and more often than two smaller motors. A used 10 h. p. motor in good condition can be bought at a reasonable price and be carried aboard for a get-home spare. Don’t forget that the light, compact British Seagull outboard is available in models featuring big, slow-turning propellers that can deliver a lot of get-home thrust at the off-plane speeds these motors can develop. It’s the neglected and abused outboards that seem to fail most often at sea, anyway. You won’t see us chewing our fingernails over the possibility of motor failure far at sea with a V-6!

These new motors are full of interesting technical details. As most experienced boatmen know, for years outboard boats have been fitted with transoms either 15” or 20” high. The new V-6 motors come with a choice of legs adapted for either 20” or 25” transoms. Presumably, the boatbuilders will in due time start offering 25” transoms but in the meantime here is an interesting point. A deep-vee hull with transom height designed to take two 20” motors, one to each side of the centerline, will accept a V-6 outboard on the centerline since the 25” length available on these big motors will put the lower unit down deep enough to clear the lowermost point of the deep-vee hull.

They have power tilt mechanisms built in. A touch to a control lever alters the motor tilt on the transom automatically, while under way. One has to experience it to appreciate fully how useful a device this is. Few people stop to realize it but the bigger a motor is – the propellers on these V-6 babies average a whopping nineteen inches in diameter! — the more important tilt adjustment is. One reason is that the cavitation plate just above the propeller is quite large, and if not running parallel to the line of water flow it can develop considerable up- or down-thrust. This in turn affects the boat’s riding angle and steering qualities.

Another is the fact that propeller blade angles vary with boat trim. Draw a horizontal line on a piece of paper. Over this line draw an “X,” with the center of the “X” right on this line. This gives a crude but accurate visualization of a horizontal propeller shaft and the pitches of up-going and down-going blades on the prop. With the line horizontal, both have the same pitch in regard to the water flowing into them. Now tilt the horizontal line and the superimposed “X” to represent the tilted propeller shaft of an outboard (or stern drive) lower unit on a boat whose bow is angled upward.

You will see that, in relationship to the water flowing into them, the up-going blade and the down-going blade have different actual angles of attack to the rushing water. One produces more thrust, one less. This is one reason why you get an exaggerated torque effect when accelerating – this unbalanced force overcomes the straightening force of the trim tab at speeds below that for which the trim tab is set to keep the boat going straight at cruising speed.

Thus, with the automatic tilt adjustment, it is possible to adjust the lower unit’s tilt so the water flows straight into the propeller and all blades have equal thrust at all positions in each complete revolution. As gasoline is burned or people move about, boat balance changes, hull angle changes and so does propeller shaft angle relative to the water rushing past the lower unit. A bit of experimenting with the automatic tilt soon discovers the tilt adjustment that makes the boat go fastest for any given throttle setting. Also, in rough and windy weather the helms¬ man can alter the planing angle slightly, feeling around for that ideal angle that makes the particular hull ride as comfortably as possible or throw the least amount of spray into the cockpit.

Johnson and Evinrude engineers have opted to have a 90-degree angle between the two cylinder banks, Mercury has chosen the 60-degree angle. The reasons involve matters of concern to engineers; the former two claim advantages in fuel passage layout and dynamic balance, the latter make claims a narrower, more compact hood. Regardless of the angle, the average boat owner will find any big V-6 outboard to be a very smooth-running and surprisingly quiet machine.

Owners of big open-water fishing craft are not the only ones who find these huge outboards of interest. The manufacturers find a good market among water skiers, who also appreciate the lower overall costs and fuel costs compared to a pair of large twins. Just as the drivers of ski tow boats find it easier and safer to manipulate a single throttle lever instead of two when it is necessary to maneuver suddenly, so do fishermen find the single lever a boon when pivoting or backing down while playing fish.

Yet another job for the V-6 outboards is propelling houseboats. The more one learns about these new motors, the more obvious it is that going up to 175 and 235 h. p. was not the crazy idea you may have thought it was when you first learned of them.