Ports, terminals and jetties are locations where ships can dock to load or unload cargo, and they often have various facilities like warehouses and cranes. Terminals are specific areas within a port that are designated for handling particular types of cargo, such as containers or oil. Jetties are structures that extend out into the water from the shore and are used for mooring ships or boats.

Ports, terminals and jetties are complex transport enterprises with maritime and land territories under the sovereignty of the coastal state, serving for the loading and unloading of ships involved in foreign trade, boarding and disembarking passengers, and also carrying out certain security supervision shipping and monitoring compliance with international agreements on merchant shipping.

Reducing the level of risks

The shipping industry requires ships to transport goods and ports to provide safe and protected locations in which to load or discharge these goods. Ports must be easily accessible to ships, protected from the weather and must enable easy collection and distribution of the goods being loaded and discharged. This statement is good for all types of shipping and therefore applies to the shipping of liquefied hydrocarbon gases.

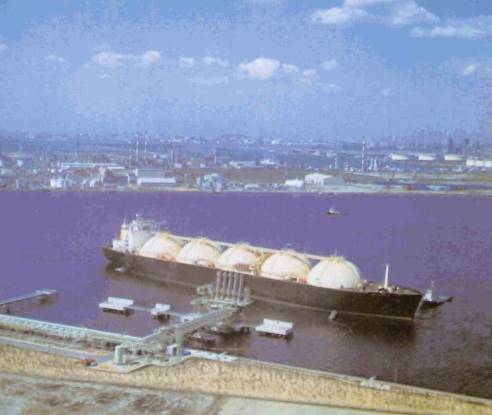

Berths and jetties, specially equipped to load or discharge liquefied hydrocarbon gases, can be located in different types of port. These can be general cargo ports, where a special area is reserved for petroleum products in general or liquefied gases only, or they can be part of a refinery or chemical plant, or within specialised terminals, such as LNG jetties located near LNG liquefaction plants or vaporisation/distribution plants. Loading jetties are, in general, close to production or manufacturing areas, such as production wells, refineries or chemical plants. Discharging jetties are close to distribution points and commercial markets, such as chemical plants, power plants and densely populated areas.

Whatever their location, these facilities must be suitably sited and equipped to allow safe loading and discharging of all products carried by the liquefied gas tankers calling at them. The most critical period of the shipping phase is when the ship approaches the port and berth at the jetty to load or discharge cargo. The frequency of marine accidents is greater in port than on the open sea. From the time the ship approaches the port area until the time she leaves, the responsibility for the various sequences of operation is spread over several groups of people, with different backgrounds and different training. To ensure a continuous safe and reliable operation, extensive planning and preparation are necessary. The level of marine risk must be quantified and risk-reduction methods must be applied to the design, construction and operation of Ship to Shore Access Guidelines for Gas Terminal and Vessel Operatorsliquefied gas terminals and jetties.

Assessments of risk conducted by the industry have concluded that the most significant hazards facing liquefied gas ships and terminals involve releases, both small and large of liquid gas. Vaporised LPG and LNG are not toxic so fire and deflagration are the most important potential consequences of a spillage. Other chemical gases and ammonia, however, can be highly toxic, even in very small quantities, and, in such cases, the danger is increased by their toxicity or corrosive nature.

Available measures to reduce these risks can be summarised as follows:

- The location of the storage facility and of the terminal and jetty must be carefully selected and evaluated when determining the level of risk to be considered for each plant.

- Good design and safe construction, based on reliable experience and on risk calculation methods, are essential factors in the limitation of the risks. High quality materials must be used throughout as a matter of principle and the influence of human judgement should be carefully assessed.

- Operational procedures, including planning, preparation, supervision, maintenance of equipment, training, avoidance of human error and protection against sabotage, must be carefully prepared.

Location, design and construction

When attempting to determine a suitable location for a liquefied gas loading or discharging terminal, marine experts will be particularly concerned about the following points:

- Sheltered water with the required depth.

- Safe access to the sea.

- Protection from the strongest weather effects (wind, waves and current).

- Achieving immediate adjacency to the liquefied gas terminal.

- Good mooring points available for all intended vessels.

- Fender positions and quality.

- Finding an earthquake-free area and using earthquake-proof structures.

- Avoiding close proximity to other industrial areas.

In view of the difficulty of escaping from basic site location factors, it is probably impossible to find an ideal solution. The challenge, however, is to limit marine and natural risks while maintaining the location of storage tanks, terminal and jetty within practicable limits.

When choosing the position of a jetty, sheltered locations must be favoured in order to limit dynamic forces caused by sea-waves. Areas where passing ships present collision or ranging risks must also be avoided.

There are no international rules applicable to the design, construction and equipment of liquefied gas terminals. Designers must rely on national regulations, if any are available, or on publications from international professional organisations. The existing standards provide basic guidelines for securing a safe berth but they are rarely sufficient to afford the assurance required for liquefied gas, therefore risk-related methods addressing the incident probability must be adopted as well.

The type and quantity of equipment to be installed should be carefully considered in the context of risk reduction.

The design of a port receiving liquefied gas carriers must include for the complete passage from the port approaches to the jetty, suitably sized access channels and turning areas to provide the ship with safe transit through the port. Additional facilities such as Vessel Traffic Systems (VTS), escort boats and ship speed-of-approach indicators may, also assist. Each port should be inspected for dangers which would cause critical impact in case of grounding or collision, whether with another ship or a foreign object. When considering collision or grounding hazards for most liquefied gas hull designs, methods are available to estimate what damage may result in a large release of liquid gas. This is achieved by identification of the energy necessary to penetrate the ship’s hull. The position of the cargo tanks at a safe distance from the hull makes their possible damage unlikely. However, based on these results, criteria for accident severity in terms of ship speed can be set to levels where rupture of the cargo containment system is virtually impossible.

The design of liquefied gas jetties should ensure that gas carriers can securely and safely lie alongside while transferring cargo. Fenders and mooring points must be adequately sized and positioned to provide the size of vessel expected to use the berth with good rest positions. Mooring studies should be carried out for all vessels expected to berth at the jetty. This will ensure the loading connections remain secure and will minimise the risk of arm or hose rupture caused by ship movement. The addition of an Emergency Shutdown System (ESDS) on Liquefied Gas CarriersEmergency Shut-Down System (ESDS) and a Powered Emergency Release Coupling (PERC) fitted within the arm will allow safe, quick and automatic disconnection should a liquefied gas carrier move outside predetermined limits in relation to the jetty. This provides an extra level of safety to prevent possible cargo spillage.

The design of the terminal must ensure that the fire protection equipment installed is appropriate to the type and volume of cargo to be transferred and to the environment surrounding the terminal.

The risk of cargo vapour ignition must be evaluated on a port by port basis. In the event of release of liquefied gas, the spread of a gas cloud can cover a considerable distance. When estimating the possible spread:

- of gas clouds;

- the type of gas;

- the spill rate and duration;

- the climatic conditions;

- and the local topography must all be taken into considention.

Ignition controls must be far-reaching and suitable emergency procedures must be in place to prevent contamination of personnel or the public, in cage of leakage of toxic gas.

Terminal design should also include the setting of operating criteria, expressed in terms of wind speed, wave height and current for the maximum forces allowed for the range of liquefied gas carriers planned for that terminal. This should take into account the different characteristics of the vessels and their mooring equipment. Equipment to monitor effectively and accurately the environmental conditions should be available to allow these operating criteria to be properly observed. The same criteria should also be used to determine the number and power of tugs needed for berthing and unberthing manoeuvring.

Human error is unfortunately contributing to the large majority of industrial casualties. In seeking operational solutions for liquefied gas parts, terminals and jetties, the design methods adopted should not, as far as is possible, rely on the sole contribution af human judgement.

Operational procedures

In the same way as there are no international rules governing the design and construction of terminals, the operation of ports, terminals and the training of their personnel are at the discretion of the operators, relying on national regulations, when available, or on publications from international professional organisations. Operating and emergency procedures remain the decision of the operators. Quality certification, such as ISO 9000, provides useful help in this respect. The operational procedures in place at liquefied gas terminals must include accident prevention and control measures focusing on reducing the probability of a collision, grounding or accidental leakage alongside the berth, minimising the effects of any occurrence of these incidents.

IMO has published recommendations for the transit of dangerous goods in port areas, which are a guide for safe operations. These recommendations are directed at the following organisations:

- National and Regional Maritime Bodies.

- Port Authorities.

- Local Fire and Salvage Teams.

- Terminal Management.

- Liquefied Gas Carrier Managers and Crews.

These organisations must be aware of the following:

- The characteristics of liquefied gas carriers.

- The nature of possible accidents.

- The likely consequences.

- The actions that can practically and usefully be taken.

When a liquefied gas carrier calls at a terminal to load or discharge, the terminal must ensure, as part of their responsibility towards the ship, that its personnel possess an adequate understanding of ship procedures and cargo handling processes. Similarly, a liquefied gas carrier crew requires a good appreciation of the systems employed at the terminal, both for cargo handling and safety. General experience throughout the industry shows that a common approach helps improve the safety of operation and reduces the language barriers.

Exchange of information between ship and terminal must start well ahead of the ship’s visit. This exchange of information is generally made easier and more efficient if the ship and the terminal have prepared information manuals to provide both parties with all necessary technical and operational information, including guidelines for both routine and emergency situations. This exchange of information continues after ship berthing, at a pre-operation meeting attended by the two persons responsible for the ship and for the terminal operations. The international safety check-list is completed and discussed during the meeting, as well as such important topics as the language to be used, the communication to be maintained between ship and shore throughout the operation, the basic procedures and the emergency procedures used by both parties.

When a liquefied gas carrier arrives at, departs from, or is alongside a terminal for cargo transfer, three organisations are directly responsible for implementing the measures necessary to ensure a safe operation:

- The Port Authority.

- The Terminal Management.

- The Liquefied Gas Carrier Management.

The Port Authority must have all necessary information on the vessels using the port, the cargo they carry, details of the navigation through the port, the weather conditions and the assistance available to the ships. Based on this information and on local conditions, special regulations and provisions may be introduced. These may include the control of the transit of gas carriers through the port, provision for pilotage, tug and escort boats, confirmation that the terminals are providing facilities appropriate to the cargo and that ships visiting the port are in good condition with well-trained crews. Further regulations and provisions will ensure that, while a liquefied gas carrier is alongside for loading or discharging, adequate precautions are taken to prevent accidents. These should include confirmation that the liquefied gas carriers are fit for cargo operation, that their crews are aware of all port and terminal requirements, that communication with the terminal is well established, that all cargo operating procedures, as well as emergency procedures, are in place and understood by all parties involved.

Read also: General Overview of LNG Cargo Tanks (Typical Operations)

The Terminal Management will wish to consider, in conjunction with the Port Authority, what information is required for an arriving liquefied gas carrier, for example any deficiencies in manoeuvring or mooring capabilities, in addition to the routine operation data. When the liquefied gas carrier is alongside, the Terminal Management is responsible for issuance and enforcement of ship/shore requirements which will maintain safety levels sufficient to ensure the protection of the terminal facilities and to satisfy the requirements of the Port Authority. The Terminal Management should ascertain, in co-operation with the Liquefied Gas Carrier Management, that the ship is ready to proceed with cargo operations, that the procedures for cargo and emergency operations are in place and have been agreed by ship and terminal, that proper channels of communication between ship and terminal have been established and tested and that all necessary safety precautions have been confirmed as recommended by the International Ship/Shore Safety Check List for Gas Carriers.

The Environmental management of ships during transportation of LNG/LPG gasesLiquefied Gas Carrier Management should be fully aware of all information pertaining to the particular port, such as port entry and traffic control requirements, adequate and corrected charts and publications and any other information specifically requested. Liquefied Gas Carrier Management should also consider measures which will ensure their vessels conduct proper passage planning to and from the berth and bridge team-work procedures, especially with regard to liaison with pilots. Liquefied Gas Carrier Management will equally wish to avoid accidents while its gas carrier is alongside. In addition to having an understanding of those items relating to terminal management, they should consider how best to ensure that the liquefied gas carrier personnel is fully experienced in the procedure to be carried out, that they are aware and ready to comply with all the agreed safety precautions, that they maintain permanently open communications with the terminal and that there will always be sufficient personnel on board to cope with any possible emergency, including moving the vessel out, if necessary.