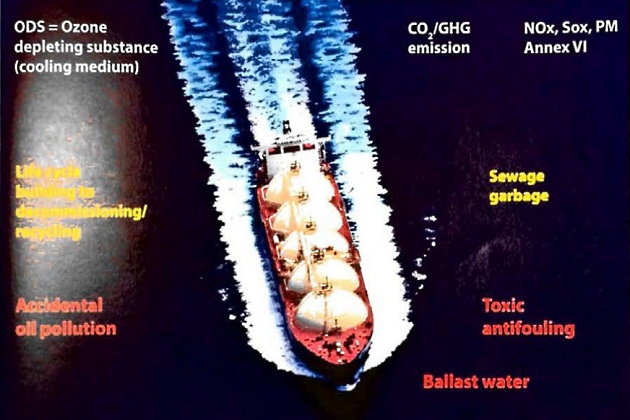

International and Port State regulations exist, among other reasons, to manage the impact of shipping on the marine environment. These environmental regulations cover the range of pollution at sea, air pollution, management of garbage and sewage, aquatic invasive species from both hull coatings and ballast water, recycling, and incidental discharges from ships during normal operations.

Many of these regulations are not unique to liquefied gas carriers and are therefore not discussed in detail in this publication. Information on these general regulations can be found in the various IMO Conventions (MARPOL, Ballast Water Management, Ship Recycling, Ship Anti-Fouling) and national government regulations such as US EPA General Vessel Permit requirements.

Air Emissions

Liquefied Natural Gas Carrier Market InsightsLiquefied gas cargoes are carried in closed systems. Venting of the cargo to maintain cargo tank pressures and temperatures is not acceptable under the IGC Code except in emergency situations, or a may be approved by the Flag Administration and, if applicable, the port authority. Industry best practices during loading, unloading and changing tank atmospheres aim to mitigate emissions from cargo operations.

Pollutants

The MARPOL Convention (Reference 1.7), which was introduced in Chapter 1 of this publication, addresses potential pollution from ships by oil and other harmful substances carried at sea, sewage, garbage, and the prevention of air pollution from ships. MARPOL Annex VI, first adopted in 1997, regulates or prohibits various air emissions from ships. But the MARPOL Annex VI limits on main air pollutants contained in ships exhaust gas, including sulphur oxides (SOx), particulate matter (PM) and nitrous oxides (NOx) are issues that relate to gas carriers and are therefore worth highlighting here.

Greenhouse gases

Greenhouse gases (GHG) are addressed by MARPOL via an Energy Efficiency Design Index (see point “Energy Efficiency Design Index (EEDI)” below) and the Ship Energy Efficient Management Plan (SEEMP). SEEMP is a best practice, onboard management tool, with reporting requirements addressing:

- Energy efficiency;

- speed/power and fuel consumption;

- voyage planning;

- ship handling;

- cargo handling.

Engine emissions

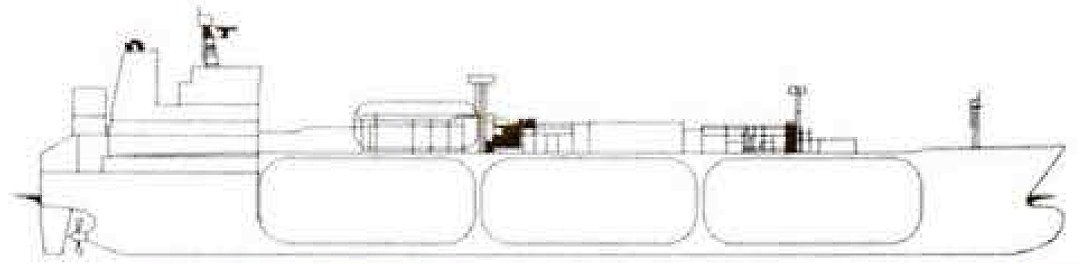

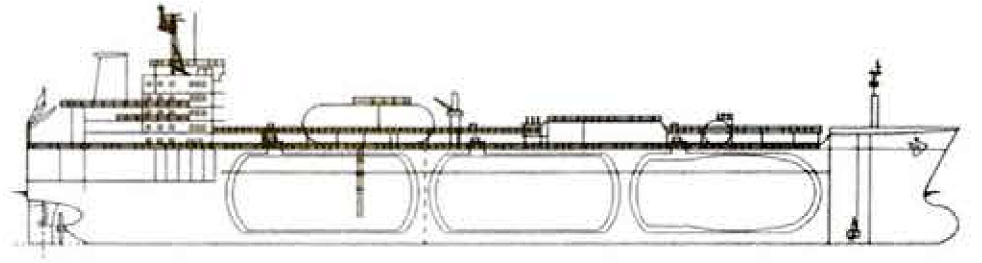

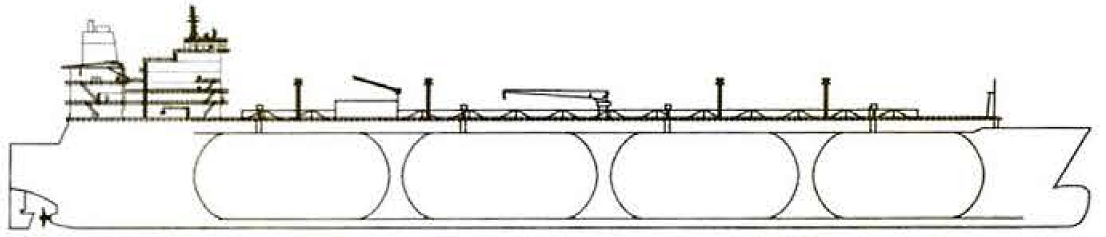

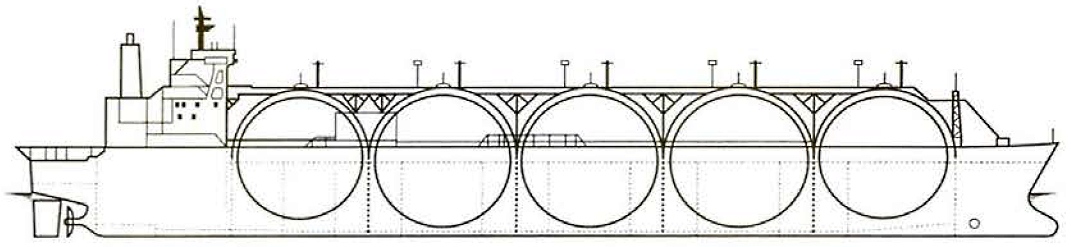

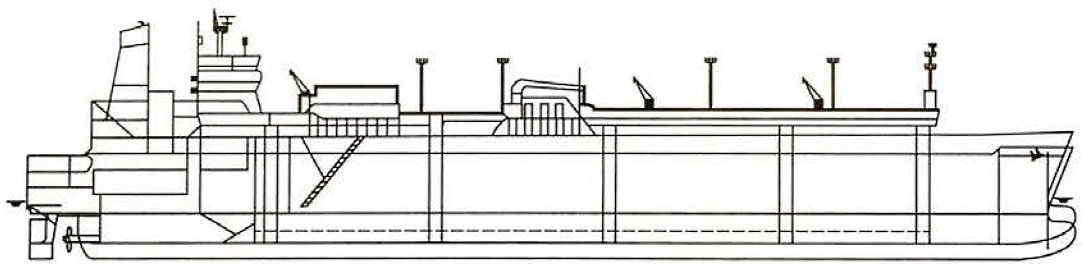

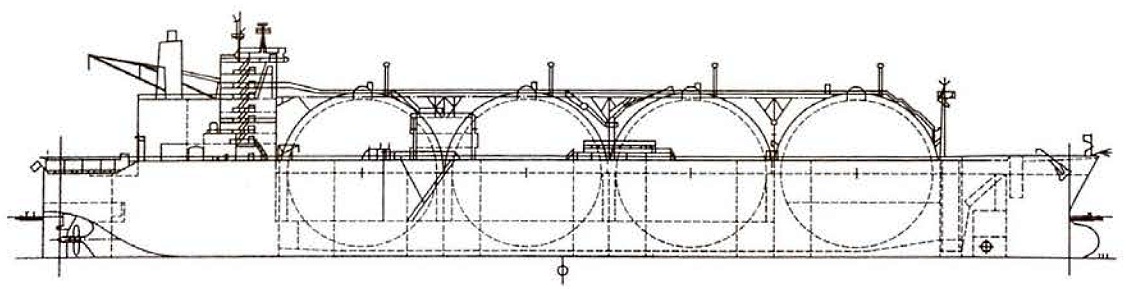

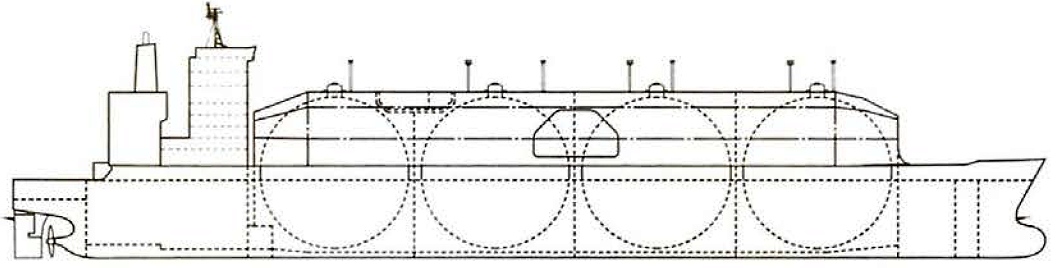

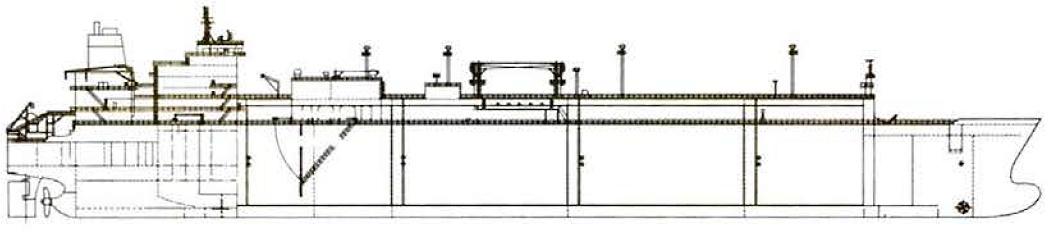

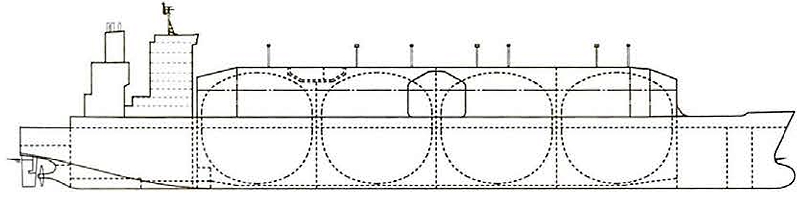

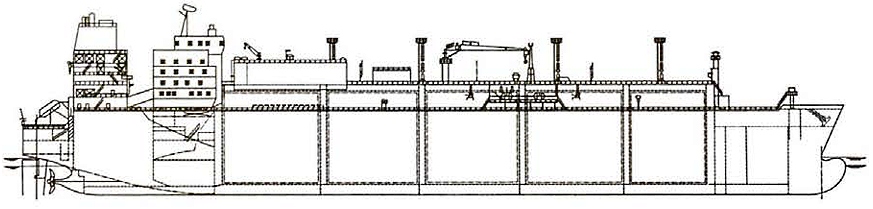

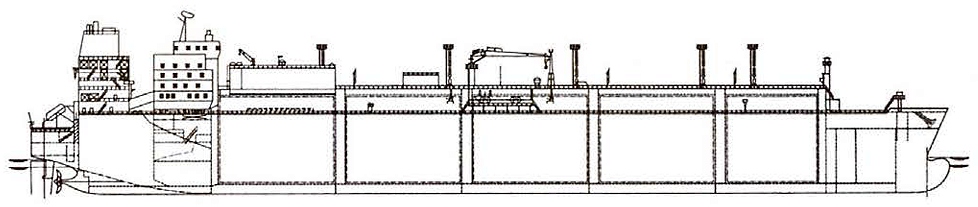

Various propulsion types were discussed in Chapter 3 (c). In all cases, using gas as fuel (ie methane/LNG, ethane, or other liquefied gas fuels approved by Flag Administrations such as LPG) results in significantly reduced emissions, compared to liquid fuels (distillate or heavy fuel oils), for levels of pollutants (NOx, SOx and PM) and GHGs (CO2). The specific reduction in pollutants and GHGs depends on Types of propulsion systems on ships carrying LNGthe type of propulsion system installed (steam, gas turbine, “Otto cycle” internal combustion engines and “Diesel cycle” internal combustion engines).

Energy Efficiency Design Index (EEDI)

EEDI is a technical instrument under MARPOL Annex VI that sets energy efficiency levels for new ships of greater than 400 GT and major conversions. It is intended to reduce the amount of CO2 emissions from ships through non-prescriptive technical and design improvements in energy efficiency. The EEDI regulatory formula is a complex adaptation of:

Where:

- CO2 emissions = Main Engines + Auxiliary Engines – Innovative Technologies.

EEDI works by setting baseline criteria for ship types to be assessed and certified against. It then specifies the amount of energy efficiency that is to be saved (as a percentage comparison).

EEDI is determined at the design stage and verified during ship trials. It represents a design point for the vessel and is not intended to reflect a ship’s energy efficiency under various in-service, operational conditions.

The original EEDI regulations, which entered into force in January 2013, only applied to vessels of “conventional” propulsion types, which means vessels with direct diesel propulsion plants. Therefore, while the regulations applied to LPG and chemical gas carriers, they applied to only a handful of LNG earners as many in operation at the time were powered by “non-conventional” propulsion types of steam turbine or diesel electric systems.

Further work was done by the IMO to address all propulsion types for gas carriers, and new regulations entered into force in September 2015. The result was a division of the baseline criteria into two parts: LNG carriers and all other gas carriers. LNG carriers were considered separately as an added EEDI factor was derived for the handling of BOG. While cargo handling equipment is generally not considered in the EEDI calculation, the equipment associated with BOG management was included for LNG carriers as BOG management is on indispensable arrangement on LNG carriers. Both the management of BOG and the onboard process of LNG reliquefaction requires a considerable amount of energy. The amount of this energy consumption is contained in the auxiliary engine term for propulsion types that do not use BOG as fuel. If a reliquefaction plant is installed for alternative BOG management, in addition to a BOG fuel system the system will be considered as normal “cargo handling equipment“.

Effect of Non-Core Ship/Shore Services

Certain Port States have, in an attempt to reduce or mitigate emissions from ships, made local emissions regulations requiring additional services to be supplied to ships from shore when the ship is in normal service. The ship when alongside a terminal would essentially switch over to shore power supply and services. While various services, including ballast, steam, etc., are envisaged the primary service is shore-supplied power, commonly called “cold-ironing“.

Read also: Personal health and safety crew members on board a gas carrier

While it is outside the scope of this publication to discuss the various systems proposed for non-core ship/shore services, it is important to highlight the potential impact such services may have on a gas carriers. These issues range from compatibility between ship and shore (physical connectivity standards, quality, voltage/frequency, etc.) to ESD considerations.

LEC and LNG Carriers