Liquefied Natural Gas carriers are tankers designed to carry different liquefied gases. This article will talk about most of the kind of gas tankers, like fully/semi pressurised ships, fully/semi refrigerated ships, LPG and LNG carrier types.

Gas tanker types

Gas carriers can be grouped into six different categories according to the cargo carried and the carriage condition, i.e.

- Fully pressurised ships.

- Semi-refrigerated/semi-pressurised ship.

- Semi-pressurised/fully refrigerated ships.

- Fully refrigerated LPG ships.

- Ethylene ships.

- LNG ships.

Ship types (1), (2) and (3) are most suitable for the shipment of smaller-size cargoes of LPG and chemical gases on short-sea and near-sea routes whereas ship type (4) is used extensively for the carriage of large-size cargoes of LPG and ammonia on the deep-sea routes.

Fully pressurised ships

These ships are the simplest of all gas carriers in terms of containment systems and cargo-handling equipment and carry their cargoes at ambient temperature. Type C tanks – pressure vessels fabricated in carbon steel with a typical design pressure of 17,5 barg, corresponding to the vapour pressure of propane at 45 °C, must be used. Ships with higher design pressures are in service: 18 barg is quite common – a few ships can accept up to 20 barg.

No thermal insulation or reliquefaction plant is necessary and cargo can be discharged using either pumps or compressors. Because of their design pressure the tanks are extremely heavy. As a result, fully pressurised ships tend to be small with maximum cargo capacities of about 4,000 m3 and they are used to carry primarily LPG and ammonia. Ballast is carried in double bottoms and in top wing tanks. Because these ships utilise Type C containment systems, no secondary barrier is required and the hold space may be ventilated with air. Picture “Type C tanks as found on fully pressurised gas carriers”Cargo Containment Systems of LPG and LNG shows a section through a typical fully pressurised ship.

Semi-refrigerated ships

These ships are similar to fully pressurised ships in that they incorporate Type C tanks – in this case pressure vessels designed typically for a maximum working pressure of 5-7 barg. The ships range in size up to 7,500 m3 and are primarily used to carry LPG. Compared to fully pressurised ships, a reduction in tank thickness is possible due to the reduced pressure, but at the cost of the addition of refrigeration plant and tank insulation. Tanks on these ships are constructed of steels capable of withstanding temperatures as low as -10 °C. They can be cylindrical, conical or spherical in shape.

Semi-pressurised/fully refrigerated ships

Constructed in the size range 1,500 to 30,000 m3, this type of gas carrier has evolved as the optimum means of transporting the wide variety of gases, from LPG and VCM to propylene and butadiene, found in the busy coastal gas trades around the Mediterranean and Northern Europe. Like the previous two types of ship, SP/FR gas tankers use Type C pressure vessel tanks and therefore do not require a secondary barrier.

The tanks are made either from low temperature steels to provide for carriage temperatures of -48 °C which is suitable for most LPG and chemical gas cargoes or from special alloyed steels or aluminium to allow the carriage of ethylene at -104 °C (see also ethylene ships). The SP/FR ship’s flexible cargo handling system is designed to be able to load from, or discharge to, both pressurised and refrigerated storage facilities. A typical SP/FR ship section is shown in Picture “Type C tanks as utilised on semi-pressured/fully refrigerated gas carriers”Cargo Containment Systems of LPG and LNG.

Fully refrigerated LPG ships

Fully refrigerated (FR) ships carry their cargoes at approximately atmospheric pressure and are generally designed to transport large quantities of LPG and ammonia. Four different cargo containment systems have been used in FR ships: independent tanks with double hull, independent tanks with single side shell but double bottom and hopper tanks, integral tanks and semi-membrane tanks, both these latter having a double hull. The most widely used arrangement is the independent tank with single side shell with the tank itself a Type A prismatic free-standing unit capable of withstanding a maximum working pressure of 0,7 barg (Picture “Prismatic self-supporting Type A tank for a fully refrigerated LPG carrier”Cargo Containment Systems of LPG and LNG).

The tanks are constructed of low-temperature steels to permit carriage temperatures as low as -48 °C. FR ships range in size from 10,000 to 100,000 m3. A typical fully refrigerated LPG carrier would have up to six cargo tanks, each tank fitted with transverse wash plates, and a centre line longitudinal bulkhead to improve stability. The tanks are usually supported on wooden chocks and are keyed to the hull to allow expansion and contraction as well as prevent tank movement under static and dynamic loads.

The tanks are also provided with anti-flotation chocks. Because of the low-temperature carriage conditions, thermal insulation and reliquefaction plant must be fitted. The FR gas carrier is limited with respect to operational flexibility. However, cargo heaters and booster pumps are often used to allow discharge into pressurised storage facilities. Where Type A tanks are fitted, a complete secondary barrier is required. The hold spaces must be inerted when carrying flammable cargoes. Ballast is carried in double bottoms and in top-side tanks or, when fitted, side ballast tanks.

Ethylene ships

Ethylene ships tend to be built for specific trades and have capacities ranging from 1,000 to 30,000 m3. This gas is normally carried fully refrigerated at its atmospheric pressure boiling point of -104 °C.

If Type C pressure vessel tanks are used, no secondary barrier is required; Type B tanks require a partial secondary barrier; Type A tanks require a full secondary barrier and because of the cargo carriage temperature of -104 °C the hull cannot be used as a secondary barrier, so in this case a separate secondary barrier must be fitted. Thermal insulation and a high capacity reliquefaction plant are fitted on this type of vessel. As mentioned, many ethylene carriers can also carry LPG cargoes thus increasing their versatility. Ballast is carried in the double bottom and wing ballast tanks and a complete double hull are required for all cargoes carried below -55 °C whether the tanks are of Type A, B or C.

LNG ships

LNG carriers are specialised vessels built to transport large volumes of LNG at its atmospheric pressure boiling point of -163 °C. These ships are now typically of between 120,000 and 130,000 m3 capacity and are normally dedicated to a specific project where they will remain for their entire contract life, which may be between 20-25 years.

Apart from a few notable exceptions built during the early years of LNG commercial transportation these ships are of three types:

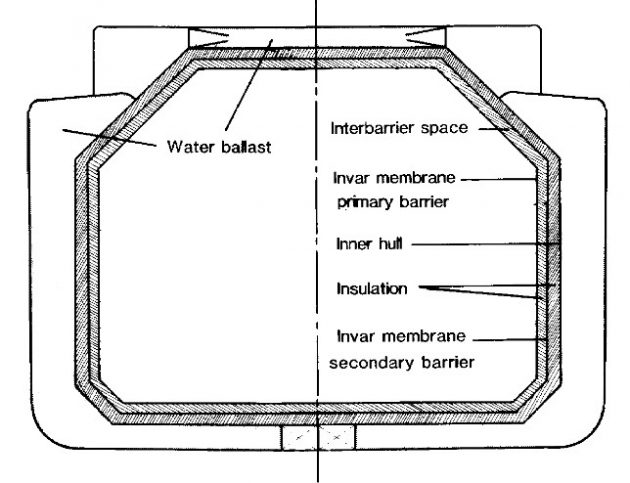

- Gaz Transport membrane (Picture 1);

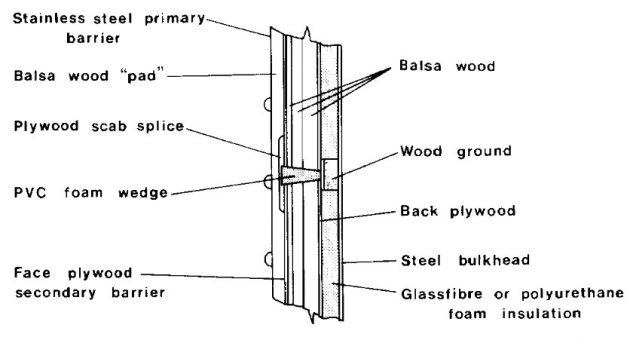

- Technigaz membrane (Picture 2);

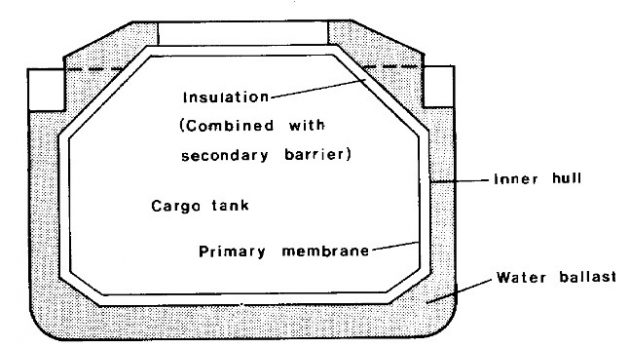

- Kvaerner Moss spherical independent Type B.

All LNG ships have double hulls throughout their cargo length, which provides adequate space for ballast; the membranes have a full secondary barrier, the spheres a drip-pan type protection. Another characteristic common to all is that they burn the cargo boil-off as fuel (permitted with methane cargo, being lighter than air at ambient temperature – but not propane or butane which are heavier than air gases).

Hold spaces around the cargo tanks are continuously inerted except in the case of spherical Type B containment where hold spaces may be filled with dry air provided that there are adequate means for inerting such spaces in the event of cargo leakage being detected. Continuous gas monitoring of all hold spaces is required.

To date, reliquefaction plants have not been fitted to LNG vessels because, being a much colder cargo than LPG, the necessary equipment is much more costly and it has been more economic to burn the boil-off gas in steam turbine propulsion plants. However, due to the rising cost of oil fuel and increasing value accredited to LNG, future designs of LNG ships tend towards the provision of greater tank insulation (to reduce boil-off), a reliquefaction plant and diesel engine main propulsion.

Layout of a general gas carrier

Liquefied Gas tankers are designed, built and operated so they obey rules and regulations. These rules and regulations are defined by the Governments of the countries in which the ships are registered, and are based on rules made Internationally and recommended by IMO. The rules are strictly applied, and ships are inspected throughout the world to make sure that they conform. These rules protect you, the ship, the environment and the cargo, and help to make the operation safe.

It is not permitted for a cargo pump-room to be placed below the upper deck; nor may cargo pipework be run beneath deck level; therefore, deepwell or submersible pumps must be used for cargo discharge. Cargo pipework to tanks beneath deck level must be taken through a cargo tank dome, which penetrates the deck.

Where a gas tanker is fitted with a reliquefaction plant, this plant is housed in a compressor house on deck.

Contiguous to this compressor house is an electric motor room, which contains the motors for driving the compressors of the reliquefaction plant and booster pumps when fitted. A gastight bulkhead must separate the electric motor room and compressor room.

The IMO codes detail the requirements for mechanical ventilation of these rooms. Positive pressure ventilation must be provided for the electric motor room with negative pressure ventilation for the cargo compressor area, thus ensuring a positive pressure differential between the rooms. An airlock entrance to the electric motor room from the weather deck, with two gastight doors at least 1.5 metres apart, prevents loss of this pressure differential on entry into the motor room.

To ensure that both doors are not opened simultaneously they must be self-closing with audible and visual alarms on both sides of the airlock. In addition, loss of over-pressure in the motor room should trip the electric motors within. The importance of these protective systems is fundamental to the safety of the gas tanker.

Another safety feature associated with the motor/compressor room area concerns sealing of the driving shafts penetrating the gastight bulkhead between the compressor and motor room. The cargo tanks cannot be used for ballast purposes on gas carriers and therefore separate ballast tanks are required.

The cargo containment and handling systems must be completely separate from accommodation spaces, machinery spaces, etc., with cofferdam separation or other means of gastight segregation between the cargo area and the engine room, fuel tanks and chain lockers.

The IMO codes also give specific recommendations for positioning of doors leading from accommodation spaces into cargo areas. In addition, air intakes for accommodation and engine spaces must be sited at a minimum distance from ventilation outlets associated with gas dangerous areas. All air intakes into accommodation and service spaces should be fitted with closing devices.

Gas tankers are fitted with a fixed water spray system for fire protection purposes. This covers:

- cargo tank domes;

- cargo tank areas above deck;

- manifold areas;

- the front of the accommodation area;

- boundaries of control rooms facing the cargo area, etc.

Minimum water flow rates of 10 litre/m2 per minute for horizontal surfaces and 4 litre/m2 per minute for vertical surfaces should be achieved. In addition to this fixed water spray system, all gas tankers must be fitted with a fixed dry powder installation capable of fighting local cargo area fires. At least two hand hose lines must be provided to cover the deck area. The dry powder installation is activated by nitrogen, which is stored in pressure vessels adjacent to the powder containers.

Survival capability and tank location

The IMO codes divide gas carriers into four categories, ship types IG, IIG, IIPG and IIIG, which reflect the hazard rating of the cargoes to be carried.

For example, Type IG ships, where the cargo tanks are located at the greatest distance from the side shell (and may also be restricted in capacity), must be used for cargoes representing the greatest hazard, eg., chlorine.

Ship types IIG/IIPG and IIIG can carry cargoes which represent progressively decreasing environmental hazards and therefore progressively less stringent constructional requirements in respect of damage survival capability in the event of collision or grounding. A fully refrigerated ship, say with Type A tanks, designed for LPG must comply with the requirements for tank location and survival capability of a category IIG ship whereas a semi-refrigerated ship with Type C tanks carrying LPG can comply with the requirements either of a IIG or a IIPG ship.

For the latter case the Type C pressure vessels must be designed for a design vapour pressure of at least 7 barg, and a design temperature of not lower than -55 °C. The IIPG category takes into account the fact that the pressure vessel design provides increased survival capability when the ship is damaged by collision or grounding. The IMO codes and classification rules should be referred to for the detailed construction requirements for each category of ship.