The work on the liquefied gas carrier (LNG or LPG) is fraught with dangers, so crew should clearly understand safety concerns. This article tells about atmosphere evaluation in the enclosed or confined spaces, rules, when worker allowed to enter enclosed space and basic information about safety equipment.

- Atmosphere Evaluation

- Oxygen Analysers

- Combustible Gas Indicator (Explosimeter)

- Hydrocarbon Meter (Tankscope)

- Toxic Meters for Trace Gases

- Entry into Enclosed Spaces

- Personnel Protection

- Filter or Canister Respirator

- Fresh Air Breathing Apparatus (BA)

- Compressed Air Breathing Apparatus (Self Contained SCBA)

- Oxygen Resuscitators

- Protective Clothing in the Presence of Cargo

Atmosphere Evaluation

Atmospheres in enclosed or confined spaces must be assessed using O2 detection equipment, prior to entry by personnel, to ensure 20,9 % O2.

Gas checks of cargo tanks are required during the following operations:

- Gas freeing/purging operations;

- Changing cargo grades;

- Gas freeing prior to dry-dock or repair.

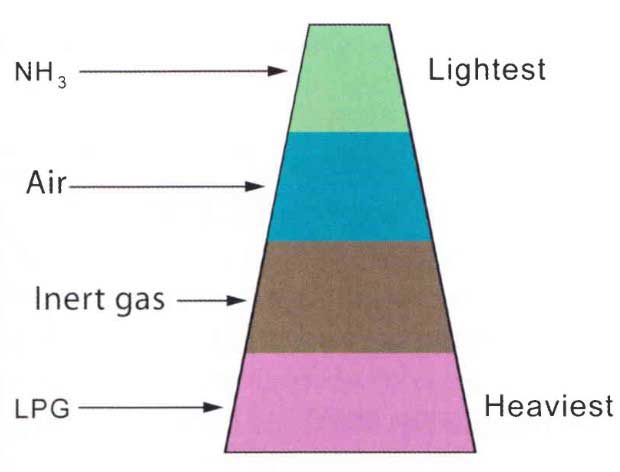

The atmosphere in a cargo tank is rarely constant throughout the tank volume. Most cargo vapours are denser than air, nitrogen or inert gas and this causes layering within the cargo tank. Because of this, samples must be taken at several levels within the tank. (Exceptions to this are the less dense gases, i. e. methane or ammonia vapour when warmed to near ambient temperatures).

On LPG Carriers, the aide memoire “NAIL”, shown in Picture 1, is used to remember the density differences between LPG and ammonia (NH3) cargoes.

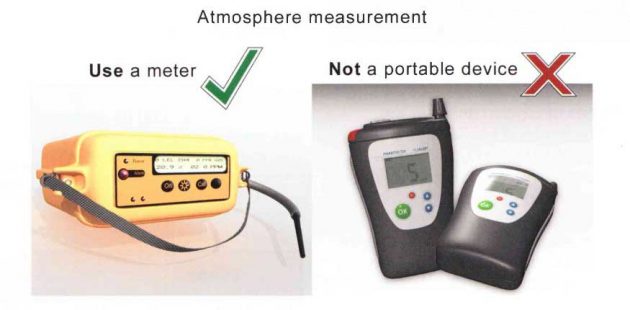

Measurement of an atmosphere is carried out using a meter analysing device and not an alarm (personal or portable) indicator device. It is essential to distinguish between the two.

Note: Many of the manufacturers of explosimeters have models that are designed to operate in air and inert gas.

Oxygen Analysers

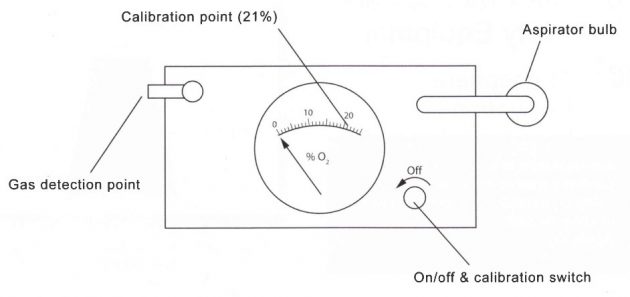

Different types of oxygen analyser are available. The model shown at Picture 3 operates by diffusing the O2, through a teflon membrane, into a potassium chloride solution where the chemical cell is activated. When the switch is closed, current flows around the circuit and can be measured.

The more O2 that is absorbed by the solution the further over the measured deflection, providing an indication of the percentage of O2 in the atmosphere sampled. More sophisticated oxygen detection instruments incorporate dual or triple scales, each of which can be used for different purposes.

For example:

- O2 in air – scale 0 – 25 % O2 by volume.

- O2 in flue gas – scale 0 – 8 % O2 by volume.

- O2 in N2 – scale 0 – 1 % O2 by volume.

Oxygen analysing instruments offering such range scales are extremely sensitive. They use batteries that may be rechargeable.

For a quick check on an O2 analyser, remember that exhaled breath contains approx. 17 % O2.

Oxygen metering instruments should always be calibrated (or spanned) with fresh air (20,9 % O2) and N2 (0 % O2).

Combustible Gas Indicator (Explosimeter)

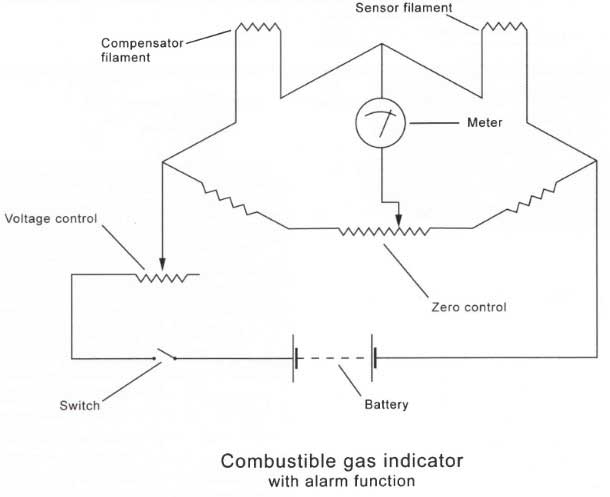

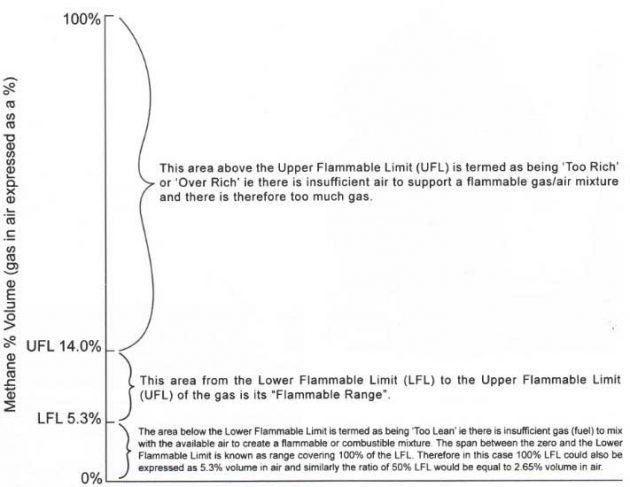

The explosimeter operates on the “Wheatstone bridge” principle. The sensor filament is situated in the gas sampling chamber, protected by a flame arrestor. Gas is aspirated into the chamber, where the hot filament ignites any Flammability, Explosion and other Hazards of Liquefied Gasflammable gas. The heat produced changes the resistance of the sensor filament and throws the bridge out of balance. This condition is indicated by the deflection on the meter. The meter scale is commonly calibrated as 0 – 100 % (or 0 – 10 %) of the lower flammable limit.

The instrument should be calibrated using span gas (normally pentane) and the batteries should be checked before each use.

Hydrocarbon Meter (Tankscope)

The explosimeter is not suitable for measuring hydrocarbon vapours in inerted atmospheres (as combustion cannot take place on the detector filament). Instruments suitable for use in inerted atmospheres should be used, where they operate on a similar Wheatstone Bridge principle, but the gas is not burned in the chamber as is the case in a combustible gas indicator.

Explosimeters cannot be used for measurement in inerted atmospheres. You must use an instrument designed for operation in inerted atmospheres.

Instead, the instrument measures a change in conductivity as hydrocarbon vapour is drawn past the filament.

Toxic Meters for Trace Gases

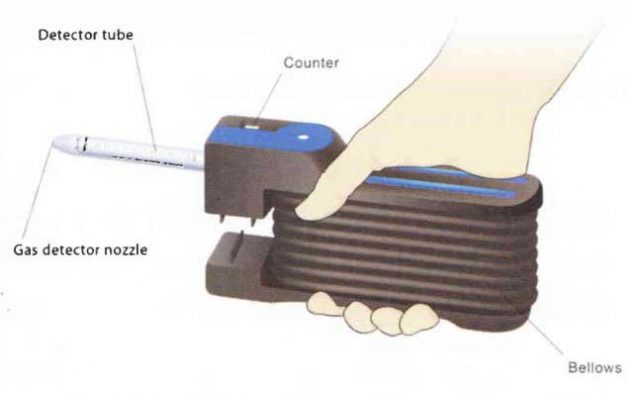

1 Bellows Pump

Toxic meters commonly operate on the principle of absorption of toxic gas in a chemical tube, which results in a colour change. The gas is aspirated through the tube, by means of bellows, until a colour change is achieved.

Both ends of the sealed glass tube must be broken immediately prior to use. The number of aspirations required is indicated on the tube. Detector tubes are date stamped and have an instruction leaflet that lists any interfering gases that may apply. It is important to aspirate the bulb correctly if reliable results are to be obtained. The bellows should be checked for leaks prior to use as they would result in low volumes being aspirated.

The number of aspirations required is indicated on the Dräger tube i. e. “N = 10”.

The bellows arc compressed and the unbroken tube is inserted (only one direction is correct, indicated by an arrow). Should the bellows leak, they will inflate with air that has not passed through the detector tube. If they are found in this condition they should be replaced prior to use. Each inflation sucks 100 cm3 O2 ml into the instrument.

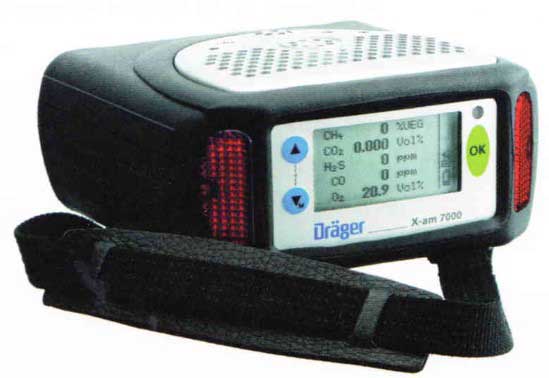

2 Multi sensor detector

Instead of using a bellows pump with tubes for trace gases, a multi-channel sensor detector; such as the X-am 7000 from Dräger; will allow simultaneous and continuous detection of up to five gases.

The functionality of such an instrument is useful where it is necessary to reliably monitor O2, toxic and combustible gases and vapours in ambient air.

Entry into Enclosed Spaces

Enclosed or confined space entry should only be performed when an enclosed space entry permit has been issued by a competent person.

The presence of cargo vapour and/or inert gas should always be suspected in any space adjacent to, or with direct connection to, the cargo or inert gas equipment.

Enclosed spaces should never be entered unless:

- They have been adequately ventilated, and will be ventilated throughout the period of entry;

- O2, flammable and toxic gases have been checked for;

- Protective clothing, including an ELSA escape breathing apparatus, harness and reflective jacket is worn;

- Continuous stand by person, in communication with the entry party and the navigational bridge (or CCR), is at the entrance;

- Emergency equipment is available at the entrance;

- Tally board and official record kept of entrants and exits;

- An emergency team is available to effect rescue.

- 20,9 % O2;

- <1 LFL;

- 0 Toxics.

Entry certificates also require visual inspection to ensure that the tank or enclosed space is liquid-free. Spaces that contain volatile liquids cannot be certified as gas free.

Checks should also be made to determine if there is alternative access and to ensure that there is no interconnection between tanks. Should such connections exist, then both tanks must be gas-freed and certified simultaneously or they must be physically isolated by means of spectacle blinds or spades. Valves are not considered to provide sufficient physical isolation under these circumstances.

Re-do all gas tests for each re-entry, even after coffee break.

Entry certificates are only valid at the time of sampling. Frequent monitoring for be situated near the tank entrance:

- Breathing apparatus lifelines;

- Harnesses and stretchers resuscitator lamps.

It is good practice to have each escape set fitted with a flashing light to aid rapid identification within the space at all times, flammable gases and continuous ventilation are wise precautions and many oxygen analysers and combustible gas indicators incorporate audible and visual alarm functions.

Read also: Hazards, Risks and Controls Available for Operating Boilers and Furnaces

If it is not possible to issue gas free certificates because of the condition of the atmosphere, then further efforts should be made to achieve a gas-free condition.

The following precautionary measures should be taken prior to entry into enclosed spaces:

- Heads of department and members of the navigational bridge should be informed that an entry is about to take place;

- An experienced person should be standing by, with a means of communication agreed;

- Rescue equipment must be prepared.

In addition to normal PPE, such as safety helmet, safety spectacles, coveralls, safety gloves and safety boots or shoes, personnel entering a confined space should have:

- 10-minute escape set (e. g. ELSA Emergency Life Saving Appliance);

- Personal O2/trace gas monitor;

- Hand torch;

- UHF radio.

It is good practice to have each escape set fitted with a flashing light to aid rapid identification within the space at all times.

The following escape and resuscitation equipment should Re-do all gas tests for each re-entry, even after coffee break. Entry certificates are only valid at the time of sampling.

Frequent monitoring for be situated near the tank entrance:

- Breathing apparatus;

- Lifelines, harnesses and stretchers;

- Resuscitator;

- Lamps.

- Never remove their face mask;

- Signal regularly;

- Watch gauges;

- Leave the space by the route used for entry.

In event of a casualty, the following procedure should be followed:

- Raise the alarm;

- Assemble the rescue team and enact the rescue plan;

- Put on breathing apparatus and protective clothing;

- Agree that rescuers will not remove masks in any attempt to assist casualties.

Personnel Protection

Entry using Personal protection of crew on Gas Carriersbreathing apparatus is only to be conducted in extreme circumstances either to effect rescue or after thorough risk assessment.

Respiratory protection includes:

- Filter or canister type respirator;

- Fresh air respirator or distance breather;

- Compressed air breathing apparatus.

Each type of respirator has certain advantages and disadvantages and the choice depends on the atmospheric conditions to be encountered in the enclosed space or tank.

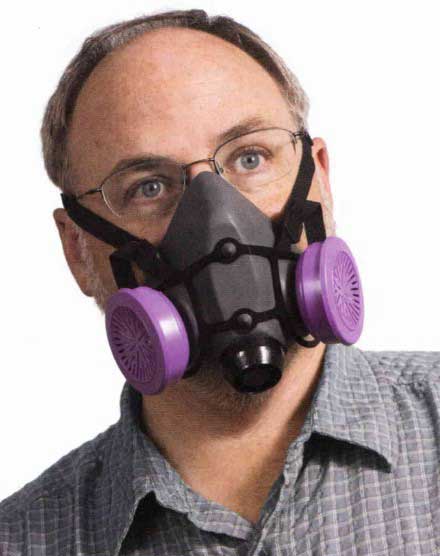

Filter or canister respirators consist of a mask with a filter attached. The toxic air is drawn through the filter and is “cleaned” of any contamination by the normal breathing effort of the wearer.

Filter or Canister Respirator

Canister filters are only to be used in atmospheres of 20,9 % O2.

| Advantages | Disadvantages |

|---|---|

| 1. Freedom of movement | 1. The correct filter must be used for the appropriate toxic gas |

| 2. Simple operation and maintenance | 2. The atmosphere must not be deficient in oxygen because the respirator does not generate oxygen |

| 3. Ability to done quickly for escape purposes | 3. Only suitable for low concentrations of gas (trace gases) |

| 4. Where gas concentrations are known they can be used safely for routine respiratory protection | 4. If strong concentrations of toxic gas, that exceed the canisters rating, are present they can be a danger to the user |

| 5. If the filter has previously been used but there is no indicator |

Fresh Air Breathing Apparatus (BA)

Fresh air breathing apparatus consists of a face mask linked by a flexible tube to an uncontaminated atmosphere (see Picture 12). The wearer either draws clean air into the mask by his own breathing effort or it may be delivered by a rotary blower or bellows.

| Advantages | Disadvantages |

|---|---|

| 1. The operating duration is limited only by the stamina of the operator | 1. Movement may be limited by the weight and length of hose |

| 2. They are simple to operate and maintain | 2. The hose may become entangled in confined areas |

| 3. The air intake position must always be unobstructed and free from toxic and/or oxygen deficient atmospheres |

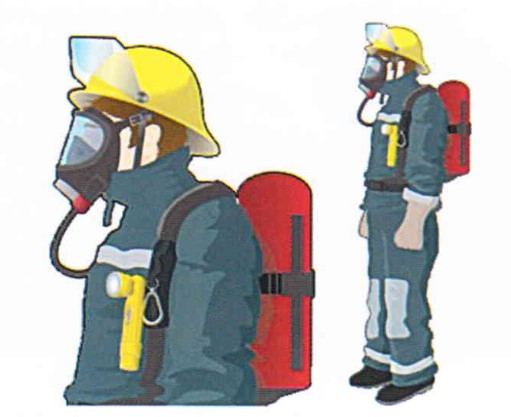

Compressed Air Breathing Apparatus (Self Contained SCBA)

Compressed air breathing apparatus (or Self-Contained Breathing Apparatus SCBA) is the most common respiratory protection used. It consists of a cylinder of compressed air that is filled to a pressure of about 200 bar; which provides a working duration of about 25-30 mins before the alarm whistle sounds.

On SCBA, the alarm whistle sounds at ~50 bar when there is about 10 mins of air left and YOU MUST vacate the space on hearing this.

| Advantages | Disadvantages |

|---|---|

| 1. The user has his own independent cylinder | 1. The half hour set weights about 15 kilos |

| 2. Duration can be varied between 10 minutes and 2 hours, depending on type | 2. Although simple to operate, maintenance requires more skill |

| 3. They can be used in conjunction with a protective suit in atmospheres which are irritant or toxic by skin absorption | |

| 4. They are manoeuvrable in confined spaces |

Certain regulatory bodies control the design of compressed air breathing apparatus and require positive pressure demand valves and masks. This positive pressure keeps a higher pressure in the face mask to prevent the surrounding atmosphere from leaking in. Spectacle wearers, men with beards or persons with long hair must ensure a tight fit of the mask with their face. ln the legislation of certain countries this is now disallowed, i. e. only persons without facial hair may don SCBA.

While compressed air breathing apparatus is generally trouble free, a monthly check on its condition is required and a thorough examination should be conducted annually.

Oxygen Resuscitators

Modern automatic oxygen resuscitators have a lightweight cylinder and control module, making them easy to carry and convenient to use with casualties in confined areas.

Resuscitators are designed so that it is almost impossible for the operator to cause injury to the patient. Pressure release valves and audible warning devices advise the operator if there is any airway obstruction.

Protective Clothing in the Presence of Cargo

Full protective clothing, in addition to breathing apparatus, should be worn when entering an area where contact with cargo is a possibility. This protective clothing would normally comprise a gastight suit that may incorporate gloves and boots. The suit should be constructed from material that is resistant to low temperature and that is not attacked by the solvent action of the cargo. Full protective clothing is particularly important when entering a space that has contained toxic gases such as ammonia, chlorine, ethylene oxide, propylene oxide or VCM.

Most work on the cargo deck of a gas carrier will be carried out in cotton coveralls. However, the potential for liquid splash at tank sample points, cargo manifolds, in the vicinity of cargo compressors, condensers and other specific points must be taken into account. In such work areas, liquid splash resistant clothing, face and eye protection, hand and foot covers should be worn.