The purpose of this material is to examine the technical problems involved in the transportation of LPG and ammonia cargoes, and various other aspects of the running of LPG Tankers.

The detailed procedures at all stages will depend upon the conditions under which the cargoes are to be loaded, carried and discharged—whether under fully-pressurised, semi-pressurised, or fully-refrigerated at atmospheric pressure conditions.

- Preparation: At the point of loading, the cargo tanks should have been prepared, so far as is possible, for the reception of the cargo to be carried. The procedure involved, and the degree of readiness would depend upon whether the vessel is loading:

- a consecutive cargo of the same type;

- a cargo of a different nature, but compatible with the previous cargo, e.g. butane after propane;

- a cargo of a different nature, and incompatible with the previous cargo (e.g. to load propane after discharging ammonia would involve gas-freeing); or

- a first cargo;

- Loading: This involves differing procedures, depending upon the facilities offered at the loading terminal, e.g. whether or not a vapour return line (see Glossary) is provided. It covers calculations for ascertaining the correct soundings (depths of liquid) to load either a full cargo or a given quantity (part cargo), and to calculate afterwards as accurately as possible the quantity in fact loaded;

- Transportation: This covers care of the cargo in transit to guard against loss of product; the running of the reliquifaction plant and ensuring that the cargo tanks do not become over-full due to the incorrect operation of the condensate returns from the reliquifaction plant; and the routine checking of tank pressures and adjusting the degree of refrigeration accordingly so that the vessel is ready to discharge on arrival at the terminal;

- Discharging: The method of discharge will depend upon the facilities for discharge available at the receiving terminal, and the type of discharge required—if direct into fully-refrigerated storage or via the cargo heater into pressure storage.

- Special Safety Precautions

- Part I pressurised ships

- General description

- General operating principles

- Loading

- Discharging

- Refrigeration

- Gas-freeing

- Cargo handling equipment

- Worthington Cargo Pumps

- Loire Compressors (6-cylinder)

- Condensers (Figs. 8 and 9)

- Heat Exchanger (fig. 8)

- Cargo Heater

- Conduct of cargo operations

- Semi-refrigerated or pressure cargoes

- Loading

- Discharging

- Refrigerating the Cargo (Figs. 8 and 9)

- Gas-freeing

- Fully-refrigerated cargoes at atmospheric pressure

- Loading

- Discharging

- Two-stage Refrigeration

- Precautions to be observed when starting a compressor

- Points to watch whilst the compressor is running

Special Safety Precautions

Due to the hazardous nature of the cargoes carried, those responsible for the conduct of Liquified Gas Tanker operations have a particular responsibility, not only to preserve the lives of those on board, but particularly to preserve the environment at the terminals and their approaches. A fire, once it gets a firm hold, and particularly if it spreads to the cargo tanks, would present a very serious hazard, since it would be extremely difficult to extinguish. So fire prevention is of the greatest importance. The chapter on Safety lays particular emphasis on this and covers:

- safe navigation;

- safe practice (incorporated in the chapters dealing with the operating procedures);

- efficient detection of an accumulation of gas before it reaches a flammable mixture;

- rapid fire detection so that a fire can be tackled in its early stages;

- fire fighting.

The chapter also covers the special dangers which may be encountered when entering a compartment which has previously been inerted with nitrogen even though it has since been ventilated, and the precautions which should be taken. This is fully explained in Chapter X.

One of the peculiarities of operating Liquified Gas Carriers is that the cargo is completely unseen whilst it is being loaded, carried and discharged. A firm knowledge of the scientific laws relating to the behaviour of gases, both in the vapour and liquid form, is therefore essential because the successful operator must be able rapidly to recognise symptoms, diagnose the trouble and take action to cure the problem without delay. The gas behaviour laws also have a great significance with regard to safe working practice.

Although the gas behaviour laws are invariable, their application when used in respect of fully-pressurised/semi-pressurised ships, as opposed to fully-refrigerated gas tankers, is very different. This affects both the design of the two different types of gas carriers, as well as their respective method of operation, to such an extent that the book is divided into two main parts. Part I covers the fully-pressurised semi-pressurised types of carriers, and Part II the fully-refrigerated type. which always carry their cargoes at about atmospheric pressure. Part III deals with such general matters as Cargo Calculations and Safety.

The book concludes with suggestions horn of experience for improvements which would free the operators of much of the embarrassment they now frequently experience. They are particularly directed to the attention of those responsible for the design of the ships, higher management and the legislature.

Part I pressurised ships

General description

Pressure ships can be divided into two types, namely fully-pressurised and semi-pressurised (semi-refrigerated). In practice, the designation of the two types of vessels has been contracted to Pressure Ships to describe fully-pressurised LPG tankers, and semi-refrigerated to describe semi-pressurised ships. From this point on, this terminology will be used.

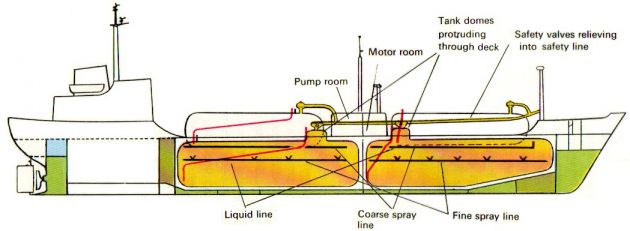

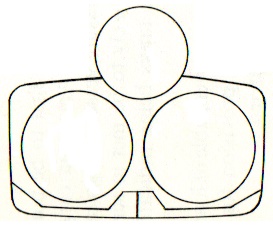

Pressure ships are the simplest vessels, and were the first to be built or converted, for the specific purpose of carrying LPG/Ammonia cargoes. The cargo is carried in a number of cylindrical pressure vessels (cargo tanks) capable of withstanding the maximum pressure likely to be met in service, (usually about 17 bars), the arrangement of the tanks being indicated in fig. 1.

In order to act as a liquified gas carrier, the ship must be capable of loading, carrying and discharging its cargoes, as well as having provision for gas-freeing for repairs or when changing types of cargo to be carried.

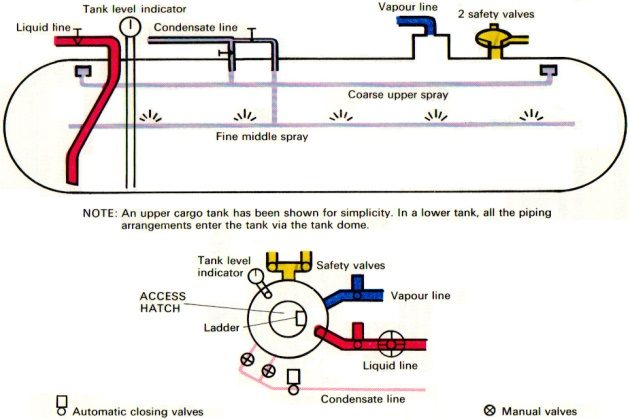

In liquified gas vessels, no joints, glands, etc., are permitted below decks, in order to exclude the possibility of liquified gas or vapour leaking unnoticed below decks, so special arrangements have to be made to conform to this requirement. This means that the loading/discharging (liquid) lines have to penetrate the tank through the tank dome protruding through the deck. The arrangement is shown in fig. 3.

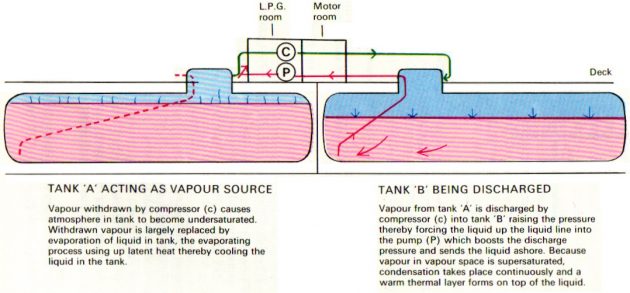

To drive the liquified gas from the bottom of the tank to the cargo pump suction, compressors are installed which, by taking vapour from a tank not being discharged (or from shore through a vapour return line), pressurise the tanks being emptied and drive the liquid to the pump suction. Therefore a pressure type liquified gas tanker is provided with:

- strong tanks (or pressure vessels) into which the cargo is loaded;

- a liquid line leading from the top of the cargo tank to the bottom through which the liquid gas cargo is loaded and discharged (these are also used for gas-freeing);

- compressors with which to pressurise the tanks being discharged in order to blow the cargo from the bottom of the tank to the cargo pump suction;

- a vapour line leading to the top of the cargo tanks which is used by the compressors to pressurise the tanks being discharged;

- cargo pumps to raise the discharge pressure and so pump the cargo ashore; and

- a liquid manifold to which the shore loading/discharge lines are connected, and linked to the ship’s liquid line system, together with a vapour line connection which can be linked to the shore vapour line (if provided) and used either as a vapour source when discharging or pressure relief when loading.

The principal advantage of semi-refrigerated ships (semi-pressurised) is that the tanks containing the cargo need not be so strong because the pressure of the cargo is very much reduced by lowering its temperature. As a result, the following benefits are derived:

- more cargo can be carried in a tank of the same capacity (see Chapter IX—Cargo Calculations);

- a tank of the same capacity is lighter and cheaper to construct; and

- much larger and more economical tanks can be constructed.

Pressure ships usually range from very small capacity up to 2,000 cubic metres capacity. The capacity of semi-refrigerated ships usually range from between 1,000 to over 10,000 cubic metres. The cargo in the tanks is usually maintained at about 0 °C. by a process of refrigeration, and the tanks themselves are thermally insulated.

The loading and discharging procedures are generally similar in both types, the main operating difference being the addition in the semi-refrigerated ship of a reliquifaction (refrigerating) plant to cool the cargo on passage, and also under certain circumstances, to assist with loading.

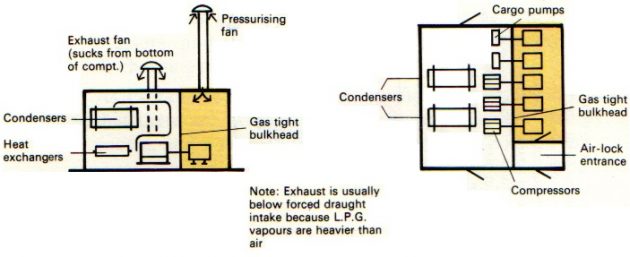

In most vessels of both types, the cargo handling equipment is located in a deckhouse divided into two compartments by a gas-tight bulkhead. In the one half are located the electric motors to drive the compressors and pumps, which are separately housed in the other section, the driving shafts passing through the gas-tight bulkhead via gas-tight seals (see fig. 4). The motor room is kept pressurised with air by powerful fans to exclude the possibility of gas entering the motor room, so avoiding a fire hazard.

The tanks are usually discharged two at a time by blowing the liquid gas to the cargo pump suction, where the discharge pressure is greatly increased by the cargo pump.

To blow the liquid gas to the pump, one or more compressors are started up. sucking vapour from one or more tanks not being discharged and sending it into the tanks being emptied. This is shown in fig. 6. A simple vapour line arrangement to do this shown in fig. 5, but in more advanced ships (particularly the semi-refrigerated ships) different arrangements are made to achieve the same result, often using different piping arrangements, hut the principle of pressurising the tanks being discharged and blowing the product to the pump suction remains the same.

The latest development is to make semi-refrigerated ships capable of carrying fully-refrigerated cargoes at atmospheric pressure, which gives them greater versatility with regard to the cargoes that can be carried. Hence, a simple general description of the all-purpose ship will cover individual types.

General operating principles

The cargo system of a typical semi-refrigerated gas carrier consists of a number of cylindrical tanks strong enough to withstand the maximum pressure of the cargo it is intended to carry at the maximum carrying temperature envisaged. If, for any reason, the pressure rises above this limit, then safety valves lift and relieve the excess pressure.

The arrangement of the pipework in the cargo tanks is depicted in fig. 2 and consists of:

- A liquid line through which the liquid gas is loaded and discharged. It leads to the bottom of the tank.

- A vapour line through which vapour is withdrawn from the top of the tank, and which leads to the compressor suction.

- A condensate spray line which has the multiple function of:

- Returning condensate from the condenser to the tank when it is being refrigerated. The returned condensate is usually sprayed into the tank through the upper spray.

- As a vapour line connected to the discharge side of the compressors, and through which the tank can be pressurised for discharging purposes.

- As a spray line to reduce pressure when loading. It will be noticed that there are two spray lines—the upper spray which is fairly coarse, and a much finer middle spray. The holes in the middle spray line are directed upwards, and the middle spray line is used to pre-cool the tanks when it is intended to load a very cold cargo.

- A relief line which leads up the mast, and to which at least 2 safety valves are placed in parallel to relieve excess pressure from the tank up the mast.

The general nature of the operation is to ensure that the ship may be loaded and discharged, the cargo cooled on passage, and the system be gas-freed, either for drydock, or when it is decided to change the type of cargo to be carried, and to this end, the vessel is fitted with compressors, cargo pumps, condensers and heat exchangers in the pumproom.

Loading

This is effected by loading via the liquid line into the bottom of the cargo tanks. As each tank fills up, the vapour trapped in the space above the incoming liquid is compressed, becomes supersaturated and condenses. However, in order to condense, it must condense on to something—usually the tank sides—but, particularly in the last stages of filling a tank when the space above the liquid is rapidly diminishing, the rate of condensation may not keep pace with the rate of compression, and the pressure in the tank starts to rise quickly. This build-up of pressure can be relieved by spraying liquid into the tank through the spray line which will provide myriads of small droplets and vastly increase the surface area upon which the supersaturated vapour can condense, or the pressure can be relieved by refrigeration. If all else fails, the excess pressure can be allowed to escape into another tank. In this latter case, the usual cause is the unsuspected presence of incondensibles.

Discharging

To discharge the ship, one (or more) compressor is started up in the pumproom, and the tank to be discharged is pressurised with vapour withdrawn from another tank or tanks, not being discharged, and sent via the condensate line to the tank being discharged whose liquid is blown “soda-water syphon fashion” to the cargo pump suction.

When the vessel arrives alongside after a period at sea, the “on arrival” tank pressures may be taken as very closely corresponding to the SVP (saturated vapour pressure) of the product in the tank at the “on arrival” temperature. When, due to pressurisation, the pressure on the pump suction has been increased to about one bar above the “on arrival” pressure, the pump is started up. As the pump begins to operate, the pressure on the pump suction drops slightly. If there is any risk of the pressure on the pump suction falling below the SVP of the product being discharged, the pump must be slowed down. If the pressure on the pump suction does fall below the SVP, the liquid in the pump suction will “flash” (vaporise), and the pump gas-up, which is the equivalent of an ordinary pump becoming “air-locked”.

During the discharge, the vapour in the tank being pressurised for discharging purposes, will be super-saturated, so that condensation will take place continuously. Heat will be released, and the cargo will be steadily warmed. Fortunately, the heating effect due to the release of latent heat of condensation warms the top of the liquid in the tank, and as the specific gravity of the heated liquid will be less than that of the colder cargo, the warm

liquid will tend to float on top and not to circulate by convection, so that it forms a thermal barrier about 30 centimetres thick. Nevertheless, the temperature of the cargo before it enters the pump suction should be watched—if no thermometer is fitted before the pump suction, then the one at the liquid discharge manifold will give an equally good indication—and an allowance made for an increase of the SVP, if the temperature does rise.

When the warmer last 30 centimetres of liquid reaches the pump suction, the pump frequently gases-up. If this occurs, the warmer liquid should be transferred by difference of pressure to another tank (preferably the smallest and highest tank in the ship) which has sufficient space to receive the drainings (see Chapter IV). This is easy because, being pressurised, the liquid remaining will quickly move to an unpressurised tank. A small elevated tank is nearly always used because the concentration of warm drainings in this tank will:

- give the maximum sounding (depth) of liquid, which makes for easier priming of the cargo pump;

- if necessary, it can easily be refrigerated by using this tank as a vapour supply source to supply any other tank being pressurised for discharge purposes;

- being relatively elevated, it is easier to discharge (if it were situated above the cargo pump, it would not require pressurising).

If a vapour return line is provided at the discharge terminal, then vapour from shore can be used to pressurise the tanks being discharged instead of taking vapour from tanks not being discharged.

Refrigeration

In this operation, vapour is withdrawn from the top of the tank being cooled, compressed, condensed and returned as a liquid via the condensate line to the same tank. The withdrawal of vapour from the tank being cooled reduces the vapour pressure in this tank to below the SVP of the liquid in the tank. As a result of this, the liquid inside the tank boils to replace the withdrawn vapour, latent heat is given up and the liquid in the tank, so cooled.

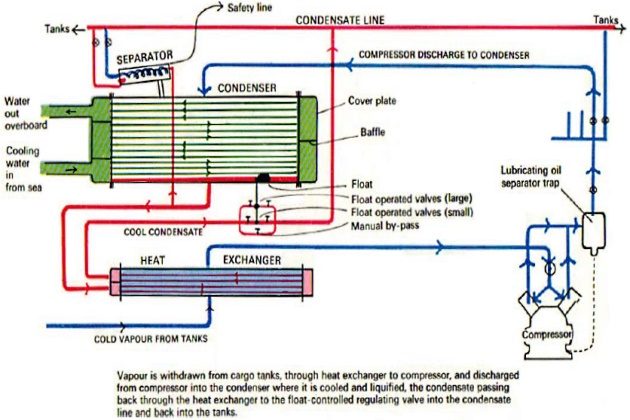

The withdrawn vapour will be roughly at tank temperature, and is sucked through a heat exchanger, which also acts as a liquid trap. (It is essential that no liquid enters the compressor suction, because, being non-compressible, on the compression stroke damage could be done to the compressor when the piston suddenly hits the liquid.) From the heat exchanger, the vapour then goes to the compressor, compressed and discharged into the condenser, where it condenses. Due to the adiabatic increase in temperature due to compression, the temperature of the vapour discharged is usually between 100 °C. and 130 °C., and is undersaturated. When it passes into the condenser the cooling water (seawater) first removes “sensible heat” from the hot vapour until it becomes supersaturated. The supersaturated vapour now condenses and surrenders latent heat. The cooling water is heated by the surrendered sensible and latent heat and is then discharged over the side to be continuously replaced by fresh cold water supplied by the condenser pump/s (usually situated in the engine room).

The resultant condensate will be at a temperature somewhat above sea temperature. (In fact its temperature will conform to the condenser pressure, but this in turn is affected by the efficiency of the coolant.) The condensate then passes through a number of tubes inside the heat exchanger where it is cooled by the incoming cold vapour withdrawn from the tank, which, in turn, is warmed by the condensate. The cool condensate is then allowed to pass back to the tank being refrigerated via a float-operated control valve into the condensate line, and so back to the tank by the sprays.

It would be possible to cool the cargo by allowing the vapour to escape up the mast (which would be wasteful and harmful to the environment), or, as in the case of methane carriers, to burn the “boil-off” in the ship’s boilers.

Reliquifaction of the vapour is really a product-recovery system. Refrigeration takes place inside the tank and reliquifaction is an essential part of the process. However, in practice, reliquifaction is so closely bound up with refrigeration that the term refrigeration is often used instead of reliquifaction.

Gas-freeing

To gas-free the ship, the first step is to expel all trace of liquid from the tanks, pipe lines, cargo pumps and condensers by purging them over the side (i.e. allowing the residual vapour pressure in the tanks to blow out all traces of liquid). When this is done, the compressors are used to create a vacuum in the cargo tanks, lines, condensers, etc., after which the vacuum is broken by allowing air to enter the tanks. The tanks are then flushed through with air until each tank indicates that it is gas-free on the explosiometer. A second vacuum is then created and the whole system flushed through again. The procedure is then repeated, after which the ship may safely be considered gas-free.

Cargo handling equipment

The cargo handling equipment comprises:

- Cargo pumps;

- Compressors;

- Condensers;

- Heat exchangers;

- Vaporisers;

- Cargo heater.

The pumps and compressors are driven by electric motors situated in the motor room—a compartment pressurised with fresh air provided by one or more fans to exclude the possibility of the entry of gas from the pumproom. An electrical trip combined with a timer switch prevents the starting of any of the cargo handling equipment unless the ventilation has been in service for a specified length of time, and stops the plant if for any reason the ventilation is stopped. In the descriptions that follow, particular types of pumps and compressors etc. are described though the general principles are the same for all.

Worthington Cargo Pumps

The cargo pump, of which there will be more than one, is driven by an electric motor in the motor room, driving through a hydraulic clutch coupling, situated in the motor room, but with the control lever in the pumproom. The drive passes through a gas-tight bulkhead seal into the pumproom itself where it drives a multiplier gearing which drives the pump.

The multiplier has its own lubricating system supplied by an electric pump in the motor room, which must be started prior to starting the main cargo pump.

The cargo pump’s main bearings and the multiplier gearing system are water cooled; the pump main bearings are lubricated by a small lubricator. The pump seal is methanol cooled, and the cargo pump itself is cooled by the liquid it is pumping. For this reason, on no account should the pump be run unless it is actually pumping, not even at slow speed for test purposes.

The safety devices fitted are a high-pressure cut-out which will stop the pump if the discharge pressure exceeds 19 bars, and the pump cannot be started if the lubricating pump is not already running.

There is no over-speed cut-out, so that if the pump races (cavitates due to loss of suction), it must be stopped immediately.

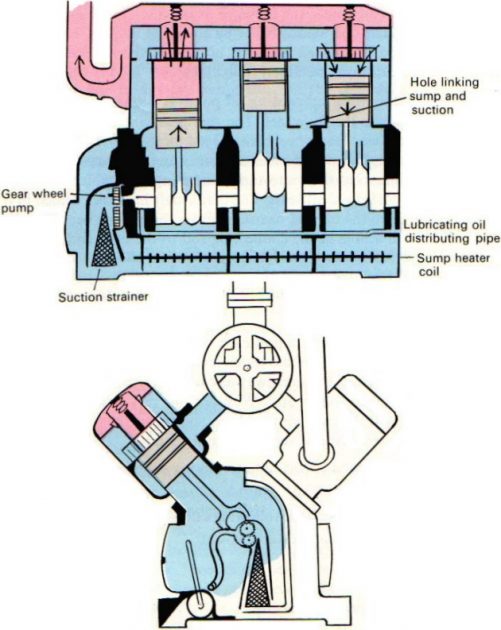

Loire Compressors (6-cylinder)

A schematic arrangement of the compressor showing the suction and delivery arrangements is shown in fig. 7. The suction and delivery valves are on separate plates which are concentrically arranged, the suction plate being on the outside, and the delivery valves in the centre. The two sets of valves are separated by a sleeve so that the lower gallery acts as a suction gallery, and the upper gallery acts as a delivery gallery. A series of dished washers act as a strong spring which, together with a strong pin, holds the delivery plate in position. In the event of a “slug” of liquid entering the compressor, the washers will be flattened, permitting the whole delivery plate assembly to lift, and so save the cylinder head from shattering.

The cylinder block is hollow into which the cylinder sleeves are fitted. This cylinder block acts as a suction chamber for the gas handled by the compressor. The cool gas coming from the tanks flows around and over the cylinder sleeves thereby cooling them. Two holes bored through the cylinder block in the vicinity of the centre cylinder sleeve connects the suction with the crankcase so that the pressure in the crankcase always approximates to the pressure at the compressor suction, thus obviating any build-up of pressure in the crankcase due to slack piston rings.

Each compressor is fitted with 4 cylinder off-loaders which make it possible to run the compressor using 2, 3, 4, 5 or all 6 cylinders. These off-loaders work by holding open the suction valves when the cylinder is being off-loaded. They are operated by oil pressure.

An automatic-starting by-pass enables the compressor to be started up without any load. It is situated on top of the compressor between the “V” of the cylinders. It consists of a piston in a cylinder which acts as a circulating valve when in the open position by connecting the suction and discharge sides of the compressor. The piston is held in the open position by a spring, and lubricating oil acting on the other side of the piston opposes the spring. When the compressor is started up, the lubricating oil pressure is zero, so the spring holds open the circulating valve. As the oil pressure builds up, the oil pressure opposing the spring overcomes the spring tension and forces the piston back, thereby closing the circulating valve and putting the compressor on load.

The compressor discharges through an oil separator which traps any oil which is carried over by the discharged gas. The oil so saved is returned to the compressor crankcase under the pressure of the discharged gas through either an automatic float-operated valve or by a manual by-pass, but neither of these valves should be opened until the bottom of the separator is hot (see section on Lubrication, immediately following).

Lubrication. A gear wheel lubricating oil pump is situated at the end of the compressor opposite the fly-wheel. The two gear wheels are fitted one above the other, the lower gear wheel being keyed directly to the crankshaft. The oil is sucked through a conical suction strainer and discharged via an oil cooler, through a filter, and then into the distributing pipe which feeds the crankshaft bearings and the shaft seals. The crankshaft has holes drilled in it which conduct the oil to the big end bearings. From the big end bearings, the oil passes up through a hole in the connecting rod to the little end bearings at the top. The cylinder itself is splash-lubricated. The oil pressure is regulated by a spring-loaded relief valve which is externally operated. The excess oil pressure is relieved by spilling back into the crankcase and is so adjusted as to maintain the oil pressure at about 2 bars above the crankcase pressure.

An oil heater is fitted in the sump of each compressor. Its function is, by heating the oil, to drive off the vapours which tend to dissolve into the oil when it is under pressure, in much the same way as carbon dioxide dissolves under pressure in water to make soda-water. With hot oil, very much less vapour can be absorbed than is the case with cold oil, and this is the reason why oil should not be returned from the oil separator until it is hot.

The oil heater is a finned coiled radiator and is supplied with hot water from a steam-heated tank.

Each compressor is fitted with the following safety devices:

- lubricating oil differential pressure cut-out;

- overheat cut-out;

- high-pressure cut-out;

- lubricating oil temperature cut-out;

- safety disc.

- Lubricating Oil Differential Pressure Cut-out. This device stops the compressor if the oil differential pressure falls below a safe limit (usually set at 1-5 bars).

- Overheat Cut-out. The sensor for this device is attached to the compressor’s discharge pipe, and stops the compressor if the discharge temperature exceeds 130 °C.

- High-pressure Cut-out. This stops the compressor if the discharge pressure becomes excessive, generally due to a valve being shut on the discharge side. The actual setting can be adjusted but is usually at about 17 bars.

- Lubricating Oil Temperature Cut-out. This prevents the compressor from being started if the oil temperature is below 30 °C. and stops the compressor if the oil temperature rises above 70 °C.

- Safety Disc. This device virtually duplicates the high-pressure cut-out. It replaces the older type “bursting disc” and is a spring-loaded valve between the suction and the discharge sides of the compressor. It operates on a pressure differential between the suction and discharge sides of the compressor, When the disc operates, it causes the compressor to circulate and will stop the compressor on the over-heat cut-out.

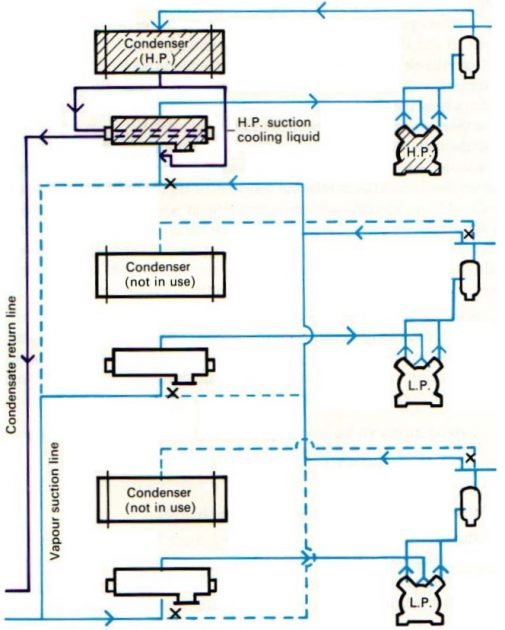

Condensers (Figs. 8 and 9)

A condenser consists of an outer vapour shell, through which pass a large number of small galvanised steel tubes. On the vapour shell are bolted the end plates into which are incorporated baffle plates so that the seawater coolant zig-zags its way through the tubes.

The hot vapour discharged under pressure from the compressor is cooled by the seawater passing through the condenser tubes, and when it becomes supersaturated, condenses and forms a liquid at the bottom of the condenser. The sensible heat surrendered by cooling the vapour and the latent heat surrendered by the condensing vapour heats up the seawater, which passes over the side. Most of the heat given up is latent heat due to the vapour condensing, and not the sensible heat occasioned by a reduction of the vapour temperature. As the condenser works on the vapour almost exclusively, and has little effect upon the condensate, the level of liquid in the condenser should be kept as low as is practicable.

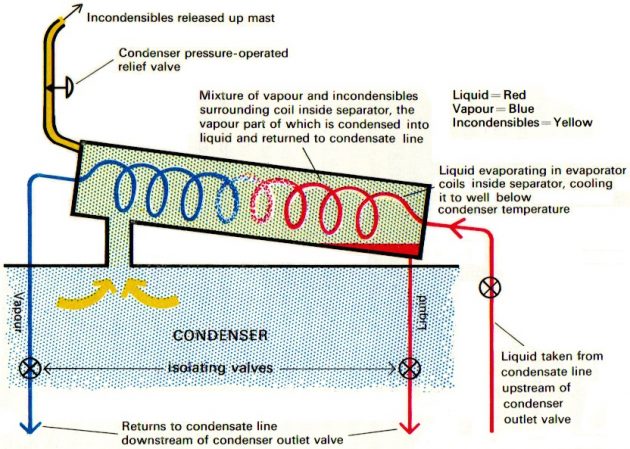

An incondensible separator is fitted on top of the condenser. The most likely incondensible to be met is air or nitrogen. As both air and nitrogen are lighter than most of the products carried (butane, propane, propylene etc.) the air tends to collect at the top of the condenser, and so passes up into the incondensible separator. A small quantity of liquid taken from the condenser outlet is evaporated in a coil inside the separator, thereby cooling it. Any condensible vapour which may be intermixed with the incondensible, will condense into a liquid and is returned to the tank which is being refrigerated by the condensate line. As the temperature in the incondensible separator will be much lower than in the condenser, even semi-incondensibles such as ethane can be recovered in this way, and dissolved back into the cargo from which they originated. (This particularly applies when fully-refrigerated cargoes are carried, when the temperature in the separator can be expected to be very low.) This leaves only incondensibles in the separator. The presence of an undue quantity of incondensibles is indicated by a rise in the condenser pressure, and a reduction in the quantity of condensate made. When this occurs, the excess pressure due to the presence of incondensibles is released up the mast.

In “normal” circumstances, when few if any incondensibles are present, then the mast relief valve is kept shut, but the liquid return valve to the condensate line is kept slightly open. If this tank return valve were to be kept shut, any small quantity of incondensibles would get trapped in the condenser simply because they would not condense, and would have nowhere to go. Over a period of time, the condenser would tend to fill up with incondensibles. With the tank return valve slightly open, any small quantities of incondensibles would be returned to the tank with the liquid condensate. The mast relief valve is only used when the quantity of incondensibles is excessive, and is indicated by the pressure in the condenser rising well above normal.

Heat Exchanger (fig. 8)

The heat exchanger is similar in construction to a condenser. Essentially it consists of a number of tubes enclosed in a shell. The condensate from the condenser passes through the tubes, and the vapour from the tanks through the shell around them.

The heat exchanger is situated immediately under the condenser. Its main functions are:

- to act as a liquid droplet separator (liquid trap);

- to exchange heat between the warm condensate coming from the condenser, and the cold vapour coming from the tank, so that the condensate is cooled, and the incoming vapour warmed and dried.

The vapour coming from the tanks enters the heat exchanger at the bottom and leaves from the top, depositing any liquid droplets in the heat exchanger. Unless there is an undue quantity of liquid entrained with the incoming vapour, the warm condensate should evaporate them. A sight glass is fitted so that any build-up of liquid in the heat exchanger can be seen, and in some, cases, a float-operated compressor cut-out switch is fitted which stops the compressor should the level of liquid rise sufficiently to actuate it.

When the vessel is two-stage, refrigerating an atmospheric cargo (using 3 compressors, 3 heat exchangers and 1 condenser), additional arrangements must be made to control further the temperature of the vapour before it goes to the suctions of the compressors so that:

- very cold vapour coming from the tank is heated; and

- hot vapour discharged from the first stage compressors is cooled before going to the suction of the second stage compressor. (In this case, the heat exchanger is acting as an inter-stage cooler.)

The very cold vapour corning from the tanks is warmed by conducting a small quantity of hot vapour from the first stage compressor discharge, and passing it through the inner tubes of the heat exchanger. The cold incoming vapour from the tanks liquifies the warm vapour (which is under pressure from the compressor) and the liquid so formed passed back to the tank via the condensate line, and the cold incoming gases warmed.

To cool down the hot vapours discharged from the first stage compressors before they enter the second stage (HP) compressor suction, some liquid is taken from the condenser and sprayed into the vapour line just before it enters the second stage heat exchanger (inter-stage cooler) to allow a small quantity of liquid to form in the bottom of the heat exchanger itself, but in such a manner as not to rise above a safe level. The temperature will conform to the pressure in the heat exchanger (usually between 3-5 and 4 bars). The level in the heat exchanger is regulated by a simple float valve. (See Two-Stage Refrigeration, Chapter IV.)

Cargo Heater

The cargo heater permits the discharge of a cold cargo at atmospheric pressure into pressure storage ashore. It is in effect a heat exchanger where the cold product is warmed as it passes through the inner tubes by seawater which zig-zags its way through the outer shell of the heater. 540 tons of water per hour are passed through the cargo heater and the cargo speed is adjusted so that the outlet temperature of the product being discharged is satisfactory. If the outlet temperature of the seawater falls below 5 °C., the cargo pump is stopped to prevent the risk of the heater icing up. (See Chapter VII for diagram and further information.)

Conduct of cargo operations

All cargo operations must be conducted within the framework of the General Principles described earlier. Cargo operations fall into two main categories, namely, semi-refrigerated and fully-refrigerated at atmospheric pressure.

Semi-refrigerated or pressure cargoes

Loading

This operation follows the general principles very closely. The shore loading hose, and, if available, the vapour return line hose, are connected 10 the liquid and vapour line connections at the cargo manifold. Loading is effected through the liquid line, and pressure relief, etc., through the vapour return line. When the vessel arrives at the loading terminal, her tanks should be:

- empty of liquid, but under suitable pressure of vapour from her previous cargo (gassed-up); or

- gas-free, but under the maximum vacuum possible (usually in the vicinity of 80 per cent). An increasing number of terminals insist that the vessel’s cargo tanks be inerted before the final vacuum is created prior to loading.

If the vessel’s cargo tanks are full of vapour at a suitable pressure (gassed-up). loading can start at once. This being the simpler of the two cases given above, it will be described first. As the liquid enters the tank, the vapour trapped in the space above the liquid will be compressed, become supersaturated and condense. If a vapour return line has been provided, any excess pressure can be returned ashore. If no vapour return line is provided, then the pressure can be relieved in the following ways: firstly, by spraying part of the cargo into the tank, secondly by refrigeration and finally, if these methods fail, by allowing the excess pressure to escape into another tank. In this connection, it is not advisable to attempt loading all the cargo through the sprays because 10 do so places an unnecessary restriction on the line. The sprays should be used only for the purpose of providing a larger surface area upon which the supersaturated vapour condenses.

In the second case, when the vessel arrives alongside gas-free and under an 80 per cent. vacuum, the first step is to break the vacuum with vapour taken from shore, and raise the pressure within the tanks to a suitable level. If a vapour return line is provided, this is simple. If no vapour return line is provided, the cargo tanks can be gassed-up by either using the vaporiser, or by spraying very small quantities of liquid into the tank via the fine spray line in such a manner that the liquid droplets evaporate before they come into contact with the tank’s sides.

This effectively gasses-up the tank, but if the ship arrived with an 80 per cent. vacuum, 20 per cent. of the ship’s capacity will be occupied by incondensibles at atmospheric pressure, the incondensibles being either air or inert gas (usually nitrogen).

However, under pressure, the physical space occupied by these incondensibles is much less. For example, under 3 bars pressure (gauge) they would occupy a quarter of the space they would occupy at atmospheric pressure. If the incondensibles remaining in the tanks consist of air, the atmosphere within the tank will be very “over-rich” after gassing-up, but to dispose of the incondensibles by the separator using the reliquifaction process involves putting a gas/air mixture through the compressors which involves a risk, however small, of an explosive mixture being passed through the compressors.

For this reason, some refineries insist on the cargo tanks being inerted prior to creating the final vacuum before loading, but many loadings have taken place over a long-period without any accident being attributed to this cause, and the danger may be more theoretical than real.

The usual loading programme is to load the lower tanks first, and to complete loading in the upper tanks. The loading rate depends upon the diameter of the liquid lines and the number of valves open. When the number of valves opened towards the completion of cargo is reduced, the loading rate should be reduced accordingly. Soundings of all tanks should be checked at regular intervals to ascertain the loading rate, and also to ensure that no liquid is entering a tank which has been completed, or not started. This is very important because it is an old maxim that it is the unwatched tank which always overflows.

To load a very warm cargo from fully pressurised storage at ambient temperature into a semi-refrigerated ship, the reliquifaction plant must be started up and run at its maximum capacity to cool the cargo as it comes on board. The usual technique is so to adjust the loading rate as to maintain a pressure in the tanks below the safety valve relief setting. This can be achieved by maintaining a constant pressure at the loading manifold by frequently adjusting the manifold valve. Experience will soon show the best pressure to maintain and it is usually very close to the maximum pressure at which it is intended to load the product. The loading manifold pressure gives a much better indication of the valve adjustment needed, than watching the tank pressures, and adjusting the loading rate by guesswork.

Discharging

The pressures in the tanks at the time of arrival at the discharging berth are noted, and these can be taken as approximating very closely to the saturated vapour pressure for the product. If the product has been refrigerated on passage, the liquid in the deck lines may be at a far higher temperature than the product in the tank. The most practical way to cool the product in the deck lines is to open the valve of one of the tanks before pressurising it. The drop in pressure in the deck line will cause the liquid in that line to boil and use up latent heat until its temperature falls to the same level as the temperature of the liquid in the tank.

While the discharge hose and vapour return line, if available, are being connected to the cargo manifold, the tank soundings, pressures and temperatures are checked and recorded by the cargo receiver’s representative. When all is ready, one or more compressors are started up, and taking vapour either from the vapour return line, or from a tank or tanks it is not intended to discharge right away, the first tanks to be discharged (usually the two upper ones) are pressurised. Their tank valves and the pump suction valve are opened, and the liquid in the tanks forced to the pump suction. Any vapour trapped in the liquid line is released up the mast through the pump purges until the pump is full of liquid. When the pressure on the pump suction is about 1 bar above the SVP of the product in the tanks, the discharge valve on the cargo manifold is opened and the vessel ready to discharge, and the shore advised. The pump is started with the discharge valve shut. As the pressure on the discharge side of the pump builds up, the discharge valve is opened slowly and the pump speed slowly increased. At the start, slugs of hot liquid and vapour can be expected. These are indicated by a nickering of the discharge gauge needle, but this steadies up once the cold liquid from the tank arrives, and the pump settles down.

The needle sometimes nickers towards the end of discharging a tank. This is due either to a shortage of vapour with which to keep the tank pressurised, or to a rise in the temperature of the product in the tank being discharged caused by condensation and release of latent heat in the tank. In either case, the pump should be slowed down, and, if possible, the pressure increased on the pump suction by putting an additional compressor into service.

Occasionally, it is very difficult to get the cargo going ashore at all. Everything is going correctly until the moment the discharge valve is opened, when the pump gasses-up. This is usually due to a very high back pressure ashore, combined with a large quantity of vapour in the shore discharge line. The best way to overcome this problem is to shut the liquid discharge valve on the cargo manifold, and then pump for a few seconds, transferring some liquid from one tank to another. This fills the line on the discharge side of the pump with liquid which, when the cargo manifold is next opened, will act as a buffer and prevent the pump being gassed. Because the tanks are almost full, only the smallest quantity of liquid should be transferred, but a well-trained operator can usually change over from discharging into a tank to discharging ashore without stopping the pump.

The tanks are drained by difference of pressure using the compressors, usually into one of the upper tanks. For this reason, the tank selected to receive the drainings from the other tanks is not completely discharged. It is then used as one of the vapour sources from which vapour is withdrawn by the compressors to pressurise the tanks being discharged, so that it is kept cool and at a low pressure, which will facilitate the transfer of drainings. This is done as soon as a pair of tanks has been discharged as far as the pump is capable, and whilst they are still pressurised.

The tank containing the drainings is pumped out at the end of the discharge, and if reasonably elevated, empties almost completely before the cargo pump loses its suction.

The routines for measuring the cargo, and the methods of calculating the quantities loaded or discharged are discussed in Chapter IX—Cargo Calculations.

Refrigerating the Cargo (Figs. 8 and 9)

After ensuring that water is passing through the condenser, and there is no liquid in the heat exchanger, the vapour lines are set to suck vapour from the tank to be refrigerated for discharge into the condenser. If the presence of incondensibles is suspected, any excess pressure in the condenser must be at once relieved up the mast via the incondensible separator. If there is no sudden build-up in pressure in the condenser and liquid forms readily, it is usually sufficient to allow what few incondensibles that may be present to circulate back to the tank by leaving the incondensate circulating valve slightly open.

The compressor is started with the discharge valve open, and the suction valve shut. The pressure on the compressor suction is allowed to come down to a vacuum, and then the suction valve is opened slowly. The rise in pressure in the condenser is closely observed (see end of this Chapter). Once the condenser pressure has steadied and is reasonable, liquid should start to form in the condenser. The condenser outlet valve (expansion or regulating valve) is set to “automatic”. The condensate will then start to pass back to the tank being refrigerated via the condensate line. If during the refrigeration process, an undue quantity of incondensibles arrives in the condenser, this is indicated by a rise in the condenser pressure, and a fall in the production of condensate made. The excess pressure occasioned by the presence of incondensibles must then be relieved up the mast.

In this connection, some vessels are provided with an automatic incondensible relief valve. The relief setting can be varied and is set at between 0-5 and 1 bar above the normal operating pressure of the condenser, which varies with the temperature of the cooling water for any given product and between different products.

In a vessel capable of both semi-refrigeration and full refrigeration, it is normal for the condenser to be provided with two liquid outlet valves (usually referred to as expansion valves, although this is not their true function, the expression “expansion valve” being taken from the refrigeration terminology), each controlled by the same float controller. These outlet valves are of two different sizes. The large valve is used when semi-refrigerating, the smaller when using two-stage refrigeration. This is because much more condensate is made with a relatively high suction pressure (semi-refrigerating) than with a low suction pressure (two-stage) because, although the volume passed by the compressor is constant, if the suction pressure is greater, then a greater quantity of vapour is passed through.

Gas-freeing

The first step is to check that the condensers are empty of liquid (blown down). Then a flexible hose is rigged over the stern, connected to the stern liquid line.

The object of the next stage is to free the ship of all residual liquid lying in the tanks, pumps, liquid lines, etc. This can be done in two ways. If there is sufficient vapour pressure remaining in the ship, the first way is the quickest, which is to open all the pump suction valves, cargo heater isolating valves, all valves in the liquid line, and the cargo tank valves, and allow the pressure in the cargo tanks to blow all the liquid remaining in the ship over the stern.

If there is insufficient pressure in the cargo tanks to do this (e.g. after discharging a fully refrigerated cargo at about atmospheric pressure), then the second method must be used. In this method, the cargo tanks are warmed by using the compressors to circulate vapour by withdrawing it from the top of the tanks, and by discharging it into the liquid line, return it to the bottom of the same tanks. The vapour is warmed by passing through the compressors, and the warm vapour evaporates the small quantity of liquid remaining in the bottom of the cargo tanks.

However, before this part of the operation is commenced, the liquid remaining in the liquid line is first blown over the stern by the compressors discharging into the liquid line and out through the flexible hose connected to the stern liquid line. If this is omitted, then the liquid remaining in the liquid lines after discharge will be swept into the cargo tanks, and the tank warming operation prolonged. To change over from blowing over the stern to tank warming, the tank liquid valves are opened and the stern discharge valve shut.

It is usual to warm the tanks in pairs, and it takes from 4 to 6 hours to evaporate the residual liquid in each pair of tanks. The evaporating process will cause a slight rise in pressure in the cargo tanks. When all the liquid in the tanks has been evaporated, any excess pressure is released over the stern, the stern valve shut, and the flexible hose recovered.

The next stage is to create a vacuum on the whole cargo system by arranging for the compressors to draw vapour from the tanks and discharge up the mast to atmosphere. This is done to expel the bulk of the vapour. Once the vacuum has been created, it is broken with air by opening one of the valves on the cargo manifold. Here, the technique varies according to the product previously carried — LPG or ammonia.

Because LPG vapour is heavier than air, the compressors, sucking air from the atmosphere via the vapour line connection on the cargo manifold, discharge it into the tops of the cargo tanks, and flush out the LPG vapour from the bottom via the liquid line, and over the side via the lee liquid valve at the cargo manifold. It is a good scheme to open the condenser valves so that part of the air flows through the condensers and gas-frees them. At the start of this operation, that part of the vapour line between the manifold and the compressor suction will contain a gas/air mixture which will have to pass through the compressor. It is vitally important that this gas/air mixture is discharged freely and not be subject to compression. For this reason, it is advisable to discharge for a few minutes up the mast until that section of the line and the compressors have gas-freed themselves. A constriction on the compressor discharge (due to a valve having been left shut inadvertently), will cause a pressure build-up, and it has been calculated that, at 14 bars discharge pressure, the adiabatic increase in temperature due to compression equals the ignition temperature of LPG gases, and combined with a “flash back” into the condenser, a serious explosion has been attributed to this cause. Gas tanker operators refer to an explosion brought about by the adiabatic rise in temperature due to compression as “the diesel effect”.

After the tanks have been flushed through for some time each tank is ventilated separately and the outflow tested at the liquid line outlet until it shows gas-free on the explosiometer, the explosiometer being a portable instrument which measures the percentage concentration of gas in air. When each tank in turn shows that it is gas-free, a second vacuum is created, the vacuum broken and the tanks flushed through again and a third vacuum created, when the ship may be said to be gas-free. The second and third vacuums are created in order to diminish the strength of any gas/air mixture lurking in a cul-de-sac and which has escaped dispersal during the flushing-through operations.

Although the vessel is gas-free, it is usual to ventilate daily to disperse any gas concentrations forming in the bottoms of the tanks due to subsidence.

In the case of ammonia, two 70 per cent. vacuums are created and broken in succession. The first vacuum reduces the vapour/air mixture to 30 per cent, which is over-rich. The second vacuum reduces the ammonia concentration to 9 per cent, which is too lean to cause an explosion. The tanks are then ventilated by sucking from the top of the tanks, and allowing the air to enter the tanks at the bottom via the liquid line by opening the liquid valve on the cargo manifold. The vacuums can be created and broken and the tanks ventilated merely by operating this one valve, without stopping the compressors. This tank ventilation is continued until the concentration of ammonia in the tank atmosphere is below 100 p.p.m. (100 parts per million). Such a low concentration, although very easily smelt, can only be measured by crystals changing colour chemically, using the same principle as a “breathalyser” and the instrument frequently used is the “Draeger”.

Two more vacuums are then created and broken and the tanks ventilated for the same reasons as are given for gas-freeing from LPG, but with ammonia, due to its contaminating influence upon other cargoes, shippers of LPG cargoes demand virtually a total absence of ammonia vapour— in the region of 5 to 20 p.p.m.

Fully-refrigerated cargoes at atmospheric pressure

Loading

This operation falls into two parts: pre-cooling and then loading. The procedure for a ship arriving at the loading terminal under vacuum, or for a consecutive cargo, are essentially the same, except that, when arriving under vacuum, the tanks will be warm and the cooling down procedure will take longer. The tanks must be cooled prior to loading because the tanks shrink during the cooling process, and this shrinking (contracting) process must take place whilst the tanks are empty. Whilst shrinking, the tanks will have to move in the support cradles, and to avoid placing unnecessary strain on the tank support system whilst this movement is taking place, the tanks should have no weight in them.

The tanks must also be cooled evenly and slowly (the cooling rate for any ship will be specified and can be expected to be about 6 °C. per hour for this type of ship).

To cool the tanks prior to loading, liquid taken from shore is sprayed into the tanks via the fine spray line. The holes in this spray line are directed upwards so that the holes in them are less likely to get clogged, and the droplets of liquid moving first upwards and then downwards have more time to evaporate than would be the case if the holes were directed downwards. Incondensibles present the same problem as described in previous paragraphs concerning loading semi-refrigerated cargoes. The spraying process is continued until liquid is firmly established at the bottom of the tank. The coarse sprays at the top of the tank should not be used for cooling purposes because the liquid droplets, being larger, will not evaporate so easily and liquid at the bottom of the tank form too quickly, causing uneven cooling and also create a cold thermal barrier at the bottom of the tank and prevent convection by subsidence.

If the shore do not provide a vapour return line, the reliquifaction plant can be used to relieve any build-up in pressure during the pre-cooling and loading processes, and to release any incondensibles to the atmosphere.

When liquid is firmly established at the bottom of the tank, loading in bulk through the main liquid line may commence and procedure from this point is the same as for loading a semi-refrigerated cargo.

Discharging

With very low temperature cargoes, the liquid lines on deck must be cooled down prior to discharge, in the same manner described for cooling the lines described in the Section dealing with loading semi-refrigerated cargoes (i.e. to open a tank valve and allow the liquid in the line on deck to boil and so cool itself down to the same temperature as the product in the tank).

The principal difficulties to be overcome or minimised when discharging a fully-refrigerated cargo, as opposed to a semi-refrigerated cargo, are:

- to minimise the heating effect of pressurising the cargo tanks in order to discharge them, due to the release of latent heat by condensation; and

- the insufficiency of vapour available in the tanks not being discharged to act as a vapour source with which to pressurise the tanks being discharged. This particularly applies when no vapour return line is provided.

To commence the discharge, the first tank or pair of tanks is pressurised and the discharge commenced in the same manner as is used for semi-refrigerated cargoes. If no vapour return line is provided, the available vapour supply may be inadequate to keep the tank being discharged pressurised and if this occurs, the vaporiser must be placed in service to supplement the work of the compressors. The vaporiser produces large quantities of vapour, the temperature of which is determined by the pressure in the vaporiser, which will be a little higher than that of the tanks being pressurised.

Due to the heating effect of pressurisation and the limited supply of vapour available to keep the tanks being discharged pressurised, it is usually necessary to discharge the larger lower tanks half-way at first, then, using the pressurised tank as a vapour source, pressurise the second set of tanks and then discharge them half-way. Although the tank being discharged is heated by condensation, the tank or tanks being used as a vapour source are being cooled.

To keep the cargo as cold as possible whilst discharging, the general rule is to take vapour from the tanks not being discharged whilst it is at all possible, and to take vapour from the shore, or use the vaporiser, as little as possible.

The order of discharge, therefore, usually works out as follows: first, discharge the two upper tanks, one of them completely, the other (which is reserved for receiving the drainings) about three-quarters. Then half-empty the two forward lower tanks using all the other tanks as a vapour source. After that, half-empty the two after-lower tanks and then go back to the two forward-lower tanks and completely discharge and drain them. After this, discharge and drain the two after-lower tanks and complete the discharge by emptying the tank used for draining.

Two-stage Refrigeration

In two-stage reliquifaction, one or more compressors in the first or LP stage discharges vapour into the heat exchanger of the HP or second stage compressor, which further raises the pressure and discharges into the condenser where the vapour is condensed and returned to the tank/s as a liquid being refrigerated in the normal manner. See fig. 10.

If the vapour coming from the tanks being refrigerated is very cold, it must be warmed, and this is done by taking some of the hot gases discharged from the first stage compressor/s and feed them back into the inner tubes of the heat exchanger where, being under the pressure of discharge (about 3-4 bars), they liquify and return to the tank via the condensate line.

The hot vapour from the discharge of the first stage compressors is discharged into the heat exchanger of the second stage compressor and is cooled by injecting a small quantity of liquid taken from the condenser. Therefore, the second stage heat exchanger acts as an inter-stage cooler. If this were not done, the second stage (HP) compressor would soon overheat.

When the liquid taken from the condenser is injected into the vapour line just before it enters the heat exchanger, most of it evaporates at once, so cooling the HP or second stage vapour suction. After a time, not all the liquid will evaporate, and a small quantity will appear in the heat exchanger. As soon as an appreciable quantity of liquid gathers in the heat exchanger (or inter-cooler), a float-controlled valve shuts off the liquid, but opens again as soon as the level of the liquid falls, thus acting as a regulating valve.

Because the second stage (HP) compressor will quickly overheat if the vapour suction is not cooled, it is important to spray in the liquid as soon as possible. For this reason, the condenser should not be emptied of liquid if refrigeration is suspended, in order that liquid will be readily available when refrigeration is resumed.

In two-stage refrigeration, it is usual to use two compressors in the first (or LP) stage, feeding one compressor using 2-4 cylinders in the second or HP stage. To commence two-stage refrigeration, the second stage (HP) compressor, is started, followed by at least one compressor in the first stage (LP) as quickly as possible. It takes at least one compressor in each stage to make the system viable, because the HP compressor, by itself, has no suction, and the discharge side of the LP stage is “blocked” unless the second stage compressor is running.

The principal cause of compressors cutting-out and stopping themselves during two-stage refrigeration is overheating. The best way to prevent this is to control the temperature on the suction side of both the first and second stage compressors. Although it is usually necessary to warm the very cold vapour coming from the tank being refrigerated before it enters the suctions of the first stage compressors, this is by no means always the case. For example, at the start of refrigeration, particularly when releasing incondensibles from the ship when the ship is being loaded after having been gas-freed, the temperature of the vapour arriving at the first stage suction may be too warm, causing the first stage compressors to overheat. In this case, liquid must be taken from the condenser and sprayed into the vapour suction before it enters the heat exchanger in a manner similar to that used to cool the suction of the second stage, except that, in this case, only the manual by-pass valve should be used, and the minimum amount of liquid used to do the job; this valve should be shut off as soon as the system settles down. The reason for using the manual by-pass and not the automatic system is that the suction pressure being about atmospheric, the incoming vapour would be over-cooled if sufficient liquid were sprayed in so as to form liquid in the heat exchanger in order for the automatic controller to work.

Another method of relieving over-heating is to off-load some of the cylinders on the compressor which is over-heating, but this imposes more work on the compressor in the opposite stage, and this may start to overheat. Also, off-loading cylinders (particularly in the first stage) reduces the amount of useful work done, and should only be used as a last resort.

Precautions to be observed when starting a compressor

- the lubricating oil heater must be working and the oil be at the correct temperature;

- there must be no liquid in the heat exchanger;

- the lubricating oil level in the sump must be at the correct level and the bulkhead seal-lubricating cups full arid the cocks open;

- cooling water must be available for the lubricating oil coolers and the lubricating oil returns from the separator must be shut.

The general set-up of the vapour line for the intended operation must be checked and, if satisfactory, the compressor discharge valve opened and the suction valve shut. The compressor may then be started. As soon as the pressure gauge on the suction side shows a vacuum, the suction valve is slowly opened, observing that the-lubricating oil pressure rises as the suction pressure rises. The pressure indicated on the compressor discharge pressure gauge must be watched to ensure that there is no constriction. If the discharge pressure rises abnormally, the compressor suction must be shut and the compressor stopped.

Points to watch whilst the compressor is running

In addition to recording the suction and discharge pressures and temperatures, lubricating oil pressure, condenser pressure, seawater temperature, etc., the temperature of the compressor heads should be closely observed (by touch). If one of the heads is hotter than the others, this usually indicates that the compressor suction or discharge valves inside the compressor are failing. If the cylinder head is unduly cool, this indicates a “wet suction”. A “wet suction” means that droplets of liquid are entering the compressor as a result of carry-over from the heat exchanger, which will be found to contain too much liquid. The droplets of liquid entering the compressor evaporate and remove most of the heat gained by the adiabatic process due to compression. The compressor must be stopped and the source of the liquid traced and corrected.

After the compressor has been running for some time, and when the bottom of the lubricating separator is warm, the automatic oil return valve should be opened. If the return valve is opened too soon, then cold oil, saturated with vapour, will be returned to the sump.