The article presents the main points of pre-sale preparation of water transport. Discover how to identify, assess, and repair cracks in your boat’s hull or deck with our boat maintenance and repair.

Our comprehensive instructions will help you restore your boat’s structural integrity. Prevent further damage and ensure a safe boating experience. Keep your boat in top shape for smooth, safe sailing.

If you look at many boats at a boat show or in a dealer’s showroom, it becomes obvious why there are price differences when comparing the same length of hull. Maybe the glass fiber hull and deck are the same, but the engines may be different, and the quality of the materials used on the hull interior may be unusual. Certainly, there is a large cost variance between a painted interior and one finished with plastic laminates or with varnished wood trim. All of the prices mentioned in this chapter are just average for manufactured boats of decent quality, and do not represent all of the boating industry. Certainly, custom built boats have prices that may be comparable or may be much higher in initial cost, depending on the type of boat and the builder.

Surprisingly, Manufacturing of Fiberglass Boats and Design Featuressailboats and powerboats of the same length are priced very closely together, but the sailboat cost does not include sails. The cost of large engines in powerboats offset the cost of mast, rigging, and ballast in a sailboat. There are many exceptions to this comparison, but we are discussing average prices only for the purpose of providing comparative information for the new boat buyer.

The following presentation of price comparisons represent a group of average boats. They have been taken from manufacturers’ advertised prices noted at the time of publication.

| Approximate prices of new sailboats and powerboats | |

|---|---|

| Overall Length | Price Range |

| 20 | $18 000 – $29 000 |

| 25 | $28 000 – $48 000 |

| 28 | $40 000 – $68 000 |

| 30 | $70 000 – $120 000 |

| 35 | $120 000 – $168 000 |

| 40 | $180 000 – $350 000 |

We will attempt to analyze where the cost of a boat is distributed. All costs are estimated and vary widely with the size of the boat and the quality of materials.

| Approximate prices of new boat components | ||

|---|---|---|

| Item | 25 FT Boat | 35 FT Boat |

| Hull and framing | 6 000 | 22 500 |

| Deck | 5 000 | 23 000 |

| Bulkheads | 1 000 | 5 000 |

| Rub rails and hand rails | 500 | 3 500 |

| One inboard engine and exhaust | 6 000 | 13 500 |

| Battery and electrical system | 2 000 | 4 500 |

| Shaft, strut and prop | 1 000 | 3 500 |

| Rudder and steering | 1 000 | 3 500 |

| Controls and instruments | 1 000 | 3 500 |

| Seats on deck | 500 | 4 500 |

| Deck hardware | 500 | 2 500 |

| Windshield and deck house | 2 800 | 8 500 |

| Berths | 500 | 3 500 |

| Head and shower | 1 200 | 3 500 |

| Galley | 1 500 | 3 500 |

| Dining table and seats | 1 500 | 3 500 |

| Lockers | 1 000 | 2 500 |

| Tanks and Piping | 2 000 | 8 500 |

| Interior trim and headliner | – | 6 500 |

| Total | 35 000 | 129 500 |

The costs stated in the tables should not be used for replacement estimates. The labor of installation after the boat has been built is much greater than the cost in a manufacturer’s plant. All of the stated prices include the builder’s overhead and profit.

Replacement of Components

Crack in the Hull or Deck

Sometimes, everyone has a bad day. They may approach the dock too fast and have the hull cracked when it hits a piling. Let’s assume the damage is eighteen inches long and three inches wide. The boatyard will have to cut out the damaged laminate to solid glass fiber and taper the inside edge prior to laminating alternate layers of mat and woven roving with epoxy resin.

Just the laminating may take three days of labor plus materials. After the inside glass laminate, the exterior is filled with an epoxy resin putty and the gel coat is applied. This gel coat is covered with a plastic film while wet to assure a smooth, glossy finish. After curing, the repaired area is polished with rubbing compound and waxed. This outside finishing may take another 12 hours of labor.

It would not be unusual to have a repair bill of 36 hours at 40 dollars per hour plus $185 material cost. The collision with the dock may cost a minimum of $1 625 and possibly $500 more if some interior joinerwork has to be removed to gain access to the inside of the damaged area. Molding the hull initially is easy compared with the difficulty of later repairs at a boatyard.

This repair to a glass fiber hull is typical of damage anywhere on the hull or deck. An exception may be in areas where there is a core in the middle of two glass laminates. Any core will be damaged in a collision and some may have absorbed water to an area larger than the cracked glass laminate. In this case, the core will have to be removed to the point of finding completely dry material. Unless the repair is unusually large in area, the core is not usually replaced, and the damaged area is completely rebuilt with solid glass laminate.

Replacement of a Radar

Any electronics replacement is primarily concerned with the antenna and sensor installation. This is always more difficult than just bringing aboard a new black box. In the case of a radar, the cost ranges from $1 500 to $3 000 just for the components, when considering the average 12-mile radar range. In order to be compatible with the new transceiver, the antenna and coaxial cable will have to be replaced, also.

Possibly twenty hours may be necessary for the replacement, and the total installation costs may exceed $3 500. Electronics components are always additional to the new boat price, and the owner should be cognizant of these costs when adding or replacing. Other electronics will involve similar costs, to a greater or lesser degree. Depending on the power of the transmitter, a communications radio may be half, or the same, as a radar installation.

Installing a Fathometer

Prices vary widely with depth finders, as you may have a basic indicator of water depth or it may be a video presentation. The latter uses a screen of varying size that displays the water column to varying depths, depending on the output power at the transducer (the transmitter and receiver of sound signals). Usually, this video presentation is desired by people who fish in deep water, in an attempt to locate schools of fish below the surface.

The transducer may be located on the stem, just below the waterline, or it may be inside the hull. When inboard, it may have its own through hull fitting, or it may be in close contact with a smooth portion of a glass fiber hull, without a through hull fitting. The cost of a depth finder and installation may be as little as three hundred dollars or as much as $1 500 dollars, depending on the manufacturer and the power output of the system.

Inboard Engine Repair

Technical Recommendations for Choosing Engines for a BoatsEngines in a boat are almost like the engine in your car or truck, and you pay the same for parts and hourly rates. Each type of repair requires a different amount of time and you should receive an estimate prior to proceeding. It is always difficult to work on an engine in a boat as it is usually in a very cramped location. Access by hatches in the deck are necessary and these hatches must be supported by posts to take the load of walking on them.

If the engine has to be removed for replacement or major overhaul, there must be access to the top of the engine so a crane can lift it ashore. When there is a roof over the engine, there must be hatches in it also, or it may be removable.

The main engine uses sea water to cool the engine cooling water in most installations, and both circulate in a heat exchanger. It is common to have failure of the water pump or leaks inside the heat exchanger and both problems are detected by a rise in the engine temperature. This should be immediately repaired. If your surveyor notes an engine problem, you should get a repair estimate from the boatyard and the seller may deduct that cost from the agreed boat cost.

Installing a Bilge Pump

Pumps in each bilge area are a must to remove unwanted bilge water from a hull or piping leak. A glass fiber boat is normally absolutely watertight and we see problems only when the deck to hull joint, a hatch, a portlight, or a piping fitting is not properly installed. A pump should be installed between each pair of watertight bulkheads and in a small boat there are usually two bulkheads, just forward, and just aft of the engine space. This means three pumps are necessary; one aft, one forward, and one in the engine space.

It is an easy job for the owner to replace a bilge pump and they can be purchased for about $70. It may cost $125 to have a boatyard do the same job, but the piping to an overboard discharge through hull fitting may be somewhat more difficult. The pump should have a minimum capacity of 25 gallons per minute, and if a float switch is also installed, it should be wired to a warning light at the helm station. This warns the owner when a pump is operating for an extended period and is in danger of draining the boat’s battery.

It is usually not necessary to cut another hole in the hull for a bilge pump discharge, as a T-fitting can be installed in the piping for a sink drain, deck drain, or a cockpit drain. Bilge pumps are often overlooked on a boat, but they are a life saver when there is water in the bilge. Some boats have used a T fitting and valve in the sea water intake line for the inboard engine. This supplemental line leads to the bilge and can be used to pump the bilges in an emergency.

Improve the Appearance of Your Boat

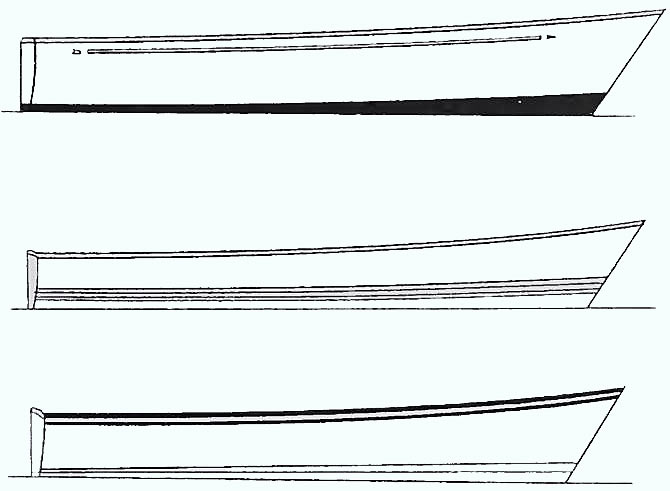

Owners hardly ever think of the boat’s good looks after the day of purchase, but there are always some areas where improvements can be made. Too often, manufactured boats are made with white hulls and white (antique white) deck houses which leaves a very bland impression similar to a ghost in a snowstorm. Some of the outstanding glass fiber boats in the past have had light blue or light gray hulls with a red boot top stripe. See Figure below.

Hulls or decks made with many different colors may be ordered from a manufacturer, at extra cost, depending on the volume of their production. Of course, your hull can be painted by your boatyard with a polyurethane paint. Color schemes can be as plain or fancy as your imagination.

Just above the waterline, a single or double band can be painted at an angle to the waterline. This boot top will improve the appearance of most any hull. The bottom of the boot top may be the top of the antifouling bottom paint, or there may be an area of hull side color visible between the two. There are vinyl tapes available that can be used as a boot top instead of paint, but they must be applied on an absolutely clean surface, and they should be guaranteed not to loosen for two or three years. A stripe at the sheer may also be applied in the same manner, and the contrasting color greatly improves the hull appearance.

A teak or stainless steel pipe handrail secured to the side of a deck house not only improves safety, but the strong horizontal line will provide a better appearance. If you add a vinyl folding top or side curtains over part of the deck, make sure it is white in color. Other colors detract from the lines and shapes of the hull. In general, darker colors should be on the hull, closer to the waterline, and above the main deck the colors should be lighter. Costs for these changes assume the usual boatyard hourly fees plus materials, adding in the work performed by outside suppliers.

Adding a Thruster

It is usual to install a bow or stem thruster on a boat less than 40 feet in length, but they deserve mention as they are becoming very popular. Basically, they are six- to fifteen- inch diameter propellers driven by an electric or hydraulic motor. At the stem, they may be entirely aft of the transom, mounted on a bracket close to the boat’s centerline. Alternately, the propeller is located below the waterline, aft of the transom, and the motor is just forward of the transom, inside the hull. Of course, there is a watertight seal at the hole in the stem and in both cases, there is a circular ring around the propeller to protect the blades from damage. Thrusters can be very valuable when docking with a strong wind blowing off of the dock.

The addition of a bow thruster is much more complicated and expensive. A glass fiber tube is installed from the port to starboard sides of the hull, about 2 feet below the waterline and 4 feet aft of the forefoot (The area where the stem meets the keel). This tube is about 6 inches larger than the propeller diameter and is overlaid with glass mat and woven roving to make it an integral, structural pail of the hull. On centerline, the propeller is mounted at the top of the tube with a watertight seal to the inside of the hull where the motor is mounted. There must be sufficient glass overlay and framing on the inside of the hull to support the weight of the tube and thruster assembly.

It is only preference that determines whether you have a thruster located at the bow or at the stem, although the distance to the center of the waterline area, about which the boat turns, may be greater from the bow thruster location. One can also reason the stem of the boat turns from the mdder force, so it may be logical to have the thruster at the stem. Costs vary widely for the size of thruster and its location. Estimates from a boatyard are always necessary.

Is it Practical to Lengthen the Hull

The question of making a longer hull from a shorter one is often asked, but not usually concerning a hull shorter than 50 feet in length. Mostly, an owner would like to have a fishing cockpit aft to make more recreational space. This addition has been accomplished many times by boat yards in any hull material and involves building a custom boat to exactly match the shape of the existing hull. On a glass fiber hull, 12- to 20- inch wide plywood planks are laid on the existing hull for a length of at least 4 feet and extending aft to the desired length. This plywood is supported with outside framing and must be a fair extension of the present hull. The plywood forms a rough molding surface for the new hull shape. The new construction of molded glass fiber to the existing hull thickness is supported with glass longitudinals and engine girder extensions that extend at least 8 feet into the old hull. A new transom is molded to the new hull shape with solid glass laminate thicker than the old hull. The exterior is sanded and painted to match the existing hull.

The design, weights, and buoyancy of the hull extension must be carefully calculated by an experienced yacht designer to make sure the added weight of the extension, plus all equipment, is equal to the added buoyancy, to keep the boat in trim. In addition:

- the rudders;

- propellers;

- struts;

- shafts;

- shaft tubes;

- and exhausts will have to be relocated.

The engine mounts are changed as the shaft angle will be less than before. The entire process is very expensive and may cost well over $55 000. The alternative, of course, is to look for a longer boat.

Some owners have read articles about the lengthening of ships by cutting in the middle and adding a new section. They ask whether this can be done with recreational yachts. Ships add length to get more cargo space, and with the same engine, they have only a small reduction in cruising speed. It is much more difficult to make this added length on a yacht as there is a large difference in design and construction.

Most ships are designed with constant sections amidships and tapering sections at the bow and stem. These midships sections may comprise thirty percent of the hull length. They are all identical with flat sides and a flat bottom, and with a constant radius at the bilge. The added length on a ship is also flat sided and with all constant sections to match.

The smaller yacht hull does not have constant sections and the hull is a shape of entirely compound curvature. Cutting a boat in the middle and adding a new length has been accomplished, but with a very large expenditure of money and man hours. Of course, the interior joinerwork must be completely rebuilt. The procedure for doing this is similar to the addition at the stem, but with a very important addition. When the hull is cut in two pieces, it is vital the centerline planes of the forward and aft sections be perfectly aligned so the keel, chine, and sheer lines are in the correct location to be faired together.

This type of custom construction is very expensive as it is about the same amount of work as building a new hull. The space in the building yard is occupied for many months, and skilled workers are needed to ensure the new hull is perfectly fair with the existing bow and stem, in addition to having identical lines both port and starboard. It takes a very unusual hull and a special breed of owner to undertake a project of this magnitude and cost.

Adding a Fishing Tower

People who are avid fishermen like the visibility provided by a tower that puts a crew member 10 to 20 feet higher than the main deck. You can usually see further and possibly identify schools of fish that are close to the surface. But the tower height produces two to three times the movement as on the main deck whenever the boat rolls. Often, extra steering and engine controls are located on the tower.

Welded aluminum pipe is used to construct the tower and each one is custom made to fit the main deck. The four legs must be bolted through the deck and there must be reinforcements under the deck to transmit the loads to the hull. Aluminum angles under the deck are bolted to a bulkhead or to a glass fiber knee and to the aluminum backing plate under each leg of the tower. The towers may cost between $5 000 and $10 000 and are usually installed on boats longer than 36 feet. Installation will vary with the type of deck arrangement.

The high weights of the tower and crew reduce the stability of the boat and the tower should be vacated when the boat is traveling in the trough of ocean waves. Only two people should use the tower at one time. Lookout platforms were used on the old sailing ships, but the most extreme example of a tower may have been the old swordfishing boats near the Straits Of Messina in the Mediterranean Sea. Many were about 40 foot hulls with 60 foot masts and 20 feet of bowsprit and stemsprit. The sprits were necessary to secure the rigging that supported the mast.

Adding a Stern Platform

We mentioned earlier the value of a stem platform for getting aboard after swimming or for retrieving an injured person. It is an important addition if there is an inboard engine installation. Often, a stem platform cannot be installed if there are Inboard and Outboard Enginesoutboard motors or an inboard-outboard (stem drive) engine. At times, it may be practical to have just a permanent step installed of narrow width, just outboard of the engines.

The platform may be built from stainless steel pipe, welded to the shape of the transom and located a few inches above the exhaust outlets and usually 9 to 12 inches above the waterline. Above the pipe the platform itself can be glass fiber or a teak grating, about 20 inches wide.

Read also: How to Buy a Used Boat? Essential Tips

The framing, or brackets that support the platform, must be bolted through the transom, using backing plates inside the glass fiber hull. These supports should be spaced not more than 4 feet apart. Some boat yards prefer to use cast bronze brackets and some like stainless steel pipe with welded flanges as a base. If the platform itself is glass fiber, it can be bolted to the framing with flat head stainless steel bolts.

The cost involved is largely dependent on the beam of the boat and may be $400 on a small hull to over $8 000 on a 50 foot boat. The cost will be substantially higher if a door is installed in the transom or if a stainless steel handrail is installed on the aft edge of the swim platform. They can be built as plain or as fancy as the owner’s budget. Some large hulls have had hydraulically operated boarding platforms installed over the swim platform and extending under the aft deck. This can be accomplished at very high cost and usually only on large, custom hulls.