Explore the differences between inboard and outboard boat engines. Learn about their advantages, disadvantages, installation processes, and which type of engine is best suited for your boating needs. Perfect for boat owners and enthusiasts looking to make an informed decision.

A funny thing will happen to you on your way to the fishing grounds some day in the not too distant future. You’re going to see a boat go whizzing across a slightly-submerged sand bar where you know from experience that boats cannot operate!

Trends in Power

Or, you may see an outboard motor whose shape, styling or sound is rather different from anything you are familiar with. Yet again, the thing that will shake you up is to suddenly realize the fact that the “stern drive” boat you are gazing at from a dock does not have the familiar outboard driving unit showing on its transom, even though it has an engine box in the aft part of the cockpit.

All of these things will be on-the-water manifestations of boat and engine manufacturers’ increasing amount of activity in the field of unusual marine propulsion methods.

Once limited to use in a few scattered special-purpose, custombuilt boats, tunnel-stern hulls are now being produced in substantial numbers by one well-known boat builder. Interest in water-jet drives, somewhat passive for several years, is picking up appreciably. Awareness of the expense involved in replacing corrosion-damaged parts of stern drive lower units used in salt water areas is leading to renewed interest in what are called vee drives.

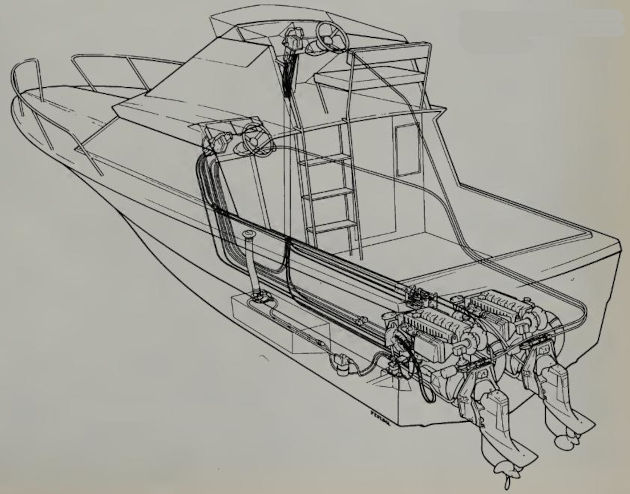

In these, the engine is mounted in the stern where a stern drive engine would go, but it’s put in with its drive shaft facing forward. A gearbox bolted to the reverse gear housing in place of the normal inboard propeller shaft, feeds engine power to a propeller shaft that angles downward and backward through the boat’s bottom. Seen from above, a vee-drive boat looks like a stern drive (minus the outboard parts), but seen from below it looks like a conventional inboard.

Why all these efforts? Isn’t what we’ve already got adequate and versatile enough to fill the boatman’s needs? Evidently some manufacturers don’t think so! What has happened is that in a comparatively short span of time the sport of boating has grown immensely. A great many people now own and use boats for many purposes, in many kinds of waters, and under a wide variety of operating conditions. Enough boating is now going on to show up clearly the shortcomings of standardized types of boats. This spurs development of new ideas. At the same time, the steadily growing market for pleasure craft makes this development an economically feasible and attractive matter.

It could accurately be said that pleasure boating today is where American automobiling was in 1940. At that time an overwhelming majority of cars in use in this country were of conventional size and type. Sports cars, four-wheel-drive utility vehicles, compact cars and motor homes were either unknown, or used in such very limited numbers that they were looked upon as curiosities when they chanced to appear on Main Street. But today it’s commonplace to see such specialized automotive products, and they’re big business. So it is with boats and motors – the pleasure boat industry has realized that no matter how fine they might be, relatively conventional boats and motors simply cannot do all the jobs that need doing in this vast and varied land.

Tunnel stern boats are nothing new. This writer has seen magazine plans for build-it-yourself craft of this type dating 25 and 35 years ago. But it was only 10 years ago that a recognized boat manufacturing company decided the time had come when it would be possible to make and sell in good volume stock boats incorporating this feature. It must have taken a lot of courage for them to go ahead with the venture! But the fact that they have been marketing them for over 10 years now, and that new models are being introduced regularly, shows that Penn Yan Boats, Inc., of Penn Yan, N. Y. has made a success of it. Early-day tunnel sterns had the propeller tunnel built up of many pieces of wood and were hard to make and keep leak-tight; the one-piece contstruction of the Penn Yan hull and tunnel is made possible by today’s most versatile boatbuilding material, fiberglass. The firm offers both open-cockpit and cabin craft, with single and twin engines.

In the seaside town where this writer lives, the local harbormaster has been using a runabout of this type for nine summers now and reports himself pleased with it. The bay experiences a nine-foot rise and fall of the tide, and extensive mud flats make it necessary for conventional powerboats to take very roundabout courses to get from one point to another except near the time of high tide. But it’s a common sight to see this harbormaster go scooting across the flats, headed directly to the scene of reported trouble, any time there’s enough water to float the boat itself over the shoals.

Knowing that your tunnel stern boat can keep going in as little water as this can be most helpful to the salt water sportsman. We have ridden in a few of these boats and have made some observations. The hulls have the deep-vee section currently so popular which gives a good ride on open water. Deep-vee hulls always have more draft when at rest than do shallow-vee ones. When going slowly, they tend to put their bows up and sterns down, which further increases draft at the stern. However, once such a hull has accelerated onto plane and is running freely, it has lifted bodily in the water so that draft is substantially reduced. Then one of these boats can go places other craft have to avoid.

There are times and places in which this can be most valuable to the fisherman. Getting back to dock after dark in a shallow bay or inlet full of meandering channels. Operating in coastal areas characterized by hundreds of small islands with shallow channels between them. Exploring tidal inlets with water so muddy that depth cannot be estimated visually. Keeping a boat moored in a protected inlet that is separated from the ocean by a passage that has an ever-shifting sand bar.

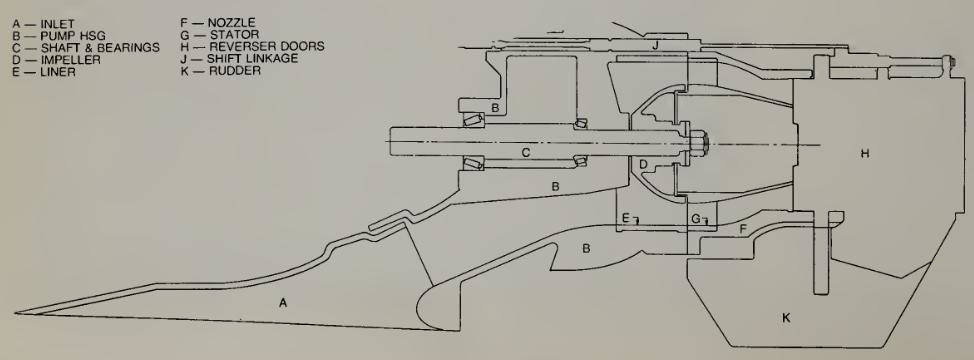

It’s quite surprising to realize that, all of a sudden, five or six companies are now manufacturing jet drives, another method of obtaining shallow-water operating ability. Although this type of propulsion has been on the market for several years, and has been displayed at boat shows quite often, fishermen have not seen too much of it. There has probably been a tendency to take one quick look at the elaborate pump units with their multiple-stage rotors, visualize what salt water and ingested gravel might do to them, and give up on them then and there as practical salt water fishing rigs. But things change!

There has been a trend toward replacing multi-stage impellers with single-stage ones, which amount to nothing but a propeller with the profile and number of blades designed to fit the conditions experienced while running inside the jet’s body. The blades are fewer in number, larger, and more rugged. Makers using this type claim that sea shells, pebbles and other hard objects likely to be picked up when skimming over sand bars are “cushioned” in the stream of water and tend to slip through without doing harm.

Designing the protective grille over the water intake opening calls for the inevitable compromise. If it were made of relatively fine mesh screening able to keep small pebbles from being drawn in, there is a strong possiblity that weeds would tend to pack against it and stop water flow. A lot depends on the boat’s forward speed – at low speed something like that can happen, but at high speed it might not as there would either be insufficient time for such material to rise against the screen, or the water flow might tend to swish it off the screen.

The trend is to make the grill of a moderate number of fairly strong bars, able to stand up to the punishment of occasional groundings and of beaching, and let the ruggedness of the impeller take care of the problem of ingested hard objects. Since weeds or floating rope are occasionally picked up, well-designed jet units have inspection openings that can be taken off to allow one to inspect the impeller and pull free any entanglement. One has to study each make individually, and after choosing one well, operate it so as to avoid whatever type or types of use are apt to be harmful to it. A jet that will do an excellent job of propelling a boat on a boulder-strewn mountain river may not survive prolonged use in a shallow, gravel-bottomed river in which it keeps picking up pebbles and stones by the thousands.

Makers of jet drives mention all kinds of interesting advantages. Some models are bolted direct to the engine, which must therefore be located well aft in a hull. But others are connected via short shafts and there’s no reason why the shaft can’t be made long enough to enable the engine to be located amidships. This gives better boat balance, both for minimum draft when running slowly in shallow water and for best sea¬ worthiness on open water. A craft that has a big, heavy engine in its stern is a poor sea boat under some conditions, such as when running with big waves, or when slowed down to work its way carefully into steep, wind-driven waves.

With nothing projecting below the keel line, a jet boat can be very easy to launch and load on a trailer. There is nothing to dig into the bottom while launching, and the jet can actually be used to push the boat onto its trailer when returning from an outing! Of course, keeping a moderate-sized jet boat on a trailer takes care of the electrolysis problem that would bedevil the same craft were it left moored all summer in the briny.

Reversing is accomplished by clamshell-style devices that close into the water stream emerging from the jet nozzle, reversing its direction. Because there are no gears and no whirling propeller involved in reversing, it is possible to slam a jet into reverse even at speed, without mechanical damage. This provides a built-in “water brake.”

In many areas, “dry land marinas” are becoming more common. At such places, fork-lift trucks position boats on storage racks two, three and even four tiers high in big metal storage sheds. Keeping such a boat out of the sun and rain at such a place also keeps its jet unit out of salt water while not in use, so the electrolysis problem is going away. Also, in places like Florida where more and more homes have man-made channels in their back yards, boats are often kept hoisted out of water on davits to avoid the problem of bottom fouling, so again more people see the jet as a practicable propulsion system for salt water use.

Now let us deal with vee drives. An ever-increasing amount of pleasure boating is being done on inland waters. Driftwood, sand bars, and floating debris of endless types can be real hazards on many such waters. The tilt-up feature of the stern drive is very valuable to boaters in such localities. Because a stern drive lower unit is hinged at a point well down on a boat’s transom, some cannot tilt completely out of water as is the case with an outboard, since an outboard pivots from a point much higher on the transom. In the early days of stern drives, this led to serious corrosion problems. Better metals and anti-corrosion and electrolysis devices have largely solved these problems.

Since a vast majority of larger pleasure boats intended for stern drive engines are Use of Fiberglass in Boat Constructionmade of fiberglass, it is very expensive to make changes in their basic layouts. Once it has been decided to use stern drive in such a craft, the cabin layout and the high cost of the molds from which the various parts of the boat are made renders it economically out of the question to install amidships inboard engines in them. The aft area of the cockpit has been designed with a motor space, the molds incorporate this space, and you’re stuck with it.

Here’s where the vee drive comes in. The engine itself will fit into the space meant for a stern drive engine. It’s more within economic and practical reason to make comparatively minor changes in the mold to install the shaft, stuffing box and strut for a vee drive’s underwater parts. There are various tricks up the sleeves of good fiberglass men for doing this kind of thing.

So, for people who cast off and head straight for deep water and who can therefore get along without the tilt-up feature of the stern drive, the vee drive is an easy way to power a modern fiberglass boat in such a way as to have a highly corrosion-resistant propeller and shaft assembly.

Power at Sea

Any experienced boatbuilder can tell you something interesting. Satisfying the customers in a women’s shoe store is easy compared to trying to satisfy people who are shopping for a boat!

For a good example of what the boat seller has to cope with, take the matter of propulsion. “Why don’t you make a really good seagoing outboard boat?” is a question often asked of boatbuilders by visitors to boat shows. Every so often, a boatbuilder takes this plea seriously and after a considerable amount of effort comes up with just such a boat.

And guess what happens as soon as he shows his new creation to the public? People look it over carefully and a large percentage of them then gravely ask one of these questions:

“Is this boat available with a stern drive engine?”

“It’s a nice boat, but why don’t you offer it with an inboard engine?”

Maybe the reason why so many boat salesmen are not as outgoing and aggressive as good salesmen are supposed to be is that they are always on their guard, having learned to be wary of each stranger who approaches them. They never know what he is going to say that is sure to shake them up!

Analyzing the questions put to boat salesmen, it really does seem as if a considerable number of people have things figured out thusly:

- Outboard motors are inherently unreliable.

- Inboard motors are inherently reliable.

- Stern drive motors are reliable because they are inside the boat.

It might be helpful to discuss the subject of powerplants in such a way as to put things into sensible perspective. What might at one time have been true is not necessarily true today. There was an interesting article in the August, 1971 issue of Reader’s Digest, entitled “Coping With Future Shock.” It pointed out that in our highly technological society, new things come along with steadily increasing rapidity and in ever greater variety, and that as a consequence one of the big challenges to people’s emotional stability today is to learn how to keep up with the ever more complex matter of choosing, using and finally discarding manufactured goods. The boatman who is bewildered by marine power-plants is by no means a poor soul in an unusual position! The cheerful view to take of the situation is that today’s proliferation of products means that factories are busy and this is what keeps the economy healthy.

A commonly heard statement is “Inboards are more expensive than outboards.” That may have been generally true in the days when 7 1/2 and 10 h. p. outboards were by far the most common in general use and they sold for between $175 and $275 compared to the several hundreds for the typical inboard engine. But today we have 130 and 140 h. p. outboards selling for prices like $2 000, while at the same time we have four-cylinder inboard engines selling for around $1 500. The point is that today, there are so many different kinds and makes of powerplants that flat statements just cannot be made. Each case has to be individually evaluated.

Dwellers in coastal states often cling to the idea that pleasure boating is native to and appropriate to coastal waters, and find it very hard to realize that things have changed drastically. The plain fact is that the boating boom that has taken place in the last score of years has switched things around so that today, a substantial majority of all pleasure boating is done on fresh water far inland.

As a consequence, profound changes have resulted in pleasure boat design and construction. Marine hardware stores in coastal areas still carry many items of galvanized iron deck hardware. You simply never see any of these things on the boats displayed at major boat shows, however. The inlanders rule the market, they don’t need galvanized ware and much prefer chrome plated hardware. More and more of the things we see at boat shows originated in the midwest and southwest. John boats and fiberglass houseboats, for example.

The squarish “cathedral hull” style of boat also developed inland—a major reason for its shape being that a larger dollar volume of such boats can be loaded into a freight car or trailer for long-distance shipment than is possible with boats of more conventional shape. Aluminum-framed windshields also originated inland. Large volume boatbuilders located inland realized varnished mahogany frames involved too much hand work and too many finishing operations, so they turned to firms making aluminum windows for houses, trailers and trucks for finished, ready-to-install boat windshields. And so it goes.

In regard to marine powerplants, all this rearranging of things has resulted in a picture that is rather kaleidoscopic and hard to sort out with any degree of neatness. One fact does stand out clearly – no longer can different kinds of engines be arbitrarily classed as “reliable” and “unreliable.”

It can reasonably be said that we have traded one set of problems for another. In the past, breakdowns at sea were very often caused by failure of basic parts like crankshafts, pistons and connecting rods, traceable to a lower level of experience with design technique, metallurgy and manufacturing methods. Vast improvement in these matters has been made.

But meanwhile, the public has consistently and clearly shown a strong tendency to want to buy products that were ahead of the competition in performance and convenience of operation. In order to stay in business, manufacturers have had to add all kinds of features to marine power plants. Look at the stark simplicity of a 1940 outboard motor’s power head and compare it with the mass of controls and electricals festooning the powerhead of a modern outboard.

A generation ago, The Evolution of Boats with Outboard Motorsoutboard motor connecting rods were often made of die cast aluminum. It was fairly common for such rods to let go suddenly, leaving one adrift at sea. Nobody went very far offshore in those days with outboards! The forged steel connecting rods of today have rendered connecting rod failure at sea almost as scarce as fresh dinosaur footprints. It used to be a common happening for spring steel reed valves to crack and drop away from their mountings, thus causing motor stoppage. A vast amount of research and development has given us crack-resistant but springy metals for these parts, as well as knowledge of how to shape them to make them perform well at all motor speeds.

Early outboard motors had carburetors so rudimentary that a schoolboy could take one apart, clean it, and get it together correctly. But because of their crude design, they could not meter fuel accurately at all speeds. Motors started hard and ran erratically. Modern carburetors meter fuel efficiently at all speeds. To do this, they have to be complicated. This sophistication gives John Q. Public what he demands in the way of performance and conveneince. Considering the large number of parts and the many critical adjustments in them, modern power plants are amazingly dependable what with all the little things on them that can potentially go wrong. When something does go wrong, it is not particularly mature to damn the power plant and hurl accusations of incompetence at its maker.

Men who spend a lot of time at the waterfront have noticed that while boatmen are very apt to curse engine manufacturers when a motor quits at sea for some mechanical reason, they are apt to be very quiet when the same motor quits because somebody forgot to keep track of the gasoline supply! Around any waterfront one can see boats that have obviously been very poorly taken care of. I’m not a psychologist so cannot come up with a highfalootin’ explanation for it. All I know is, people will talk for hours about whether an inboard is more reliable than an outboard, and then go ahead and invite the motor of their choice to fail at sea by taking very poor care of it!

In regards to outboards, a situation exists today to which the motor makers would love to find a workable answer. They’ve got the basic moving parts so well refined that they seldom give trouble. But the features that sell outboard motors like gear shift, remote controls, sophisticated fuel and electrical systems, are of necessity complicated and also somewhat on the delicate side because they have to fit into the limited space inside a motor’s streamlined hood.

Some of these motors are bought by men who are at home with mechanical things. Such men can size up this maze of parts readily enough and figure out for themselves what’s wrong when something goes awry.

But other motors are bought by people who don’t know a spark plug from an expansion plug. When something doesn’t go as it should, they’re helpless. The outboard manufacturers would like to have somebody tell them how to build highly sophisticated motors that at the same time can’t be misunderstood or mistreated by the duffers.

The seacoast is lined with people who have “had it” with outboards and are in the market for a reliable inboard. But alas, today the inboard scene is a rather complicated one too and unless one is well informed on the subject, the simple act of purchasing an inboard is by no means the end of one’s powerplant problems.

Back when today’s middle-aged men were kids, most marine engines were out-and-out marine engines. It did not cost so much to set up a factory in those days, one reason being that the needed machinery was a lot simpler. So many, many firms manufactured engines designed expressly for boat use. A large proportion of their output went into use in the salt water “yachting” areas, the inlanders not yet having discovered boating. These old engines tended to be heavily built. Most went into displacement boats where dead weight was not the handicap it is in planing hulls. The thick cylinder and water jacket walls inherent in these heavily-made engines could stand salt water for a long time.

Read also: Self-Survey Criteria for the Engine and Electrical Systems

Today, the only engines being built to this formula are a few one- and two-cylinder kickers intended for auxiliary power in sailboats. They are of scant interest to fishermen. There are several four-cylinder engines of from 20 to 60 h. p. that are based on fairly heavy tractor and industrial engine blocks. These are simple, economical and durable, but lack the power needed to plane out today’s popular wide-beamed planing hull.

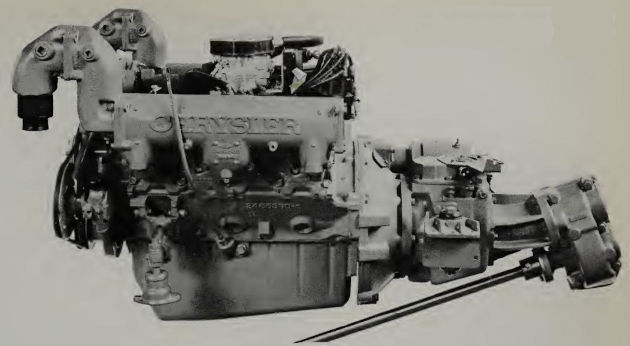

Modern inboard engines having enough power to drive planing hulls are practically all built around popular six- and eight-cylinder automobile blocks. There are very good reasons for this. Such blocks bring the boatman the benefit of the automotive industry’s vast investment in engineering, quality control and mass production equipment.

There are things one needs to know about them, though. One reason old-time engine blocks had a lot of thick metal in them was because some margin had to be allowed to take care of possible shifting of cores during the pouring operation in the foundry. Modern casting methods make it possible to control metal thickness much more accurately. Designers of auto engines have taken advantage of this to make blocks that are more compact while at the same time having generous cooling water passageways to keep temperatures within limits in high-speed, high-compression engines. The thin cylinder walls and water jackets of these engines can’t stand salt water for long. So more and more, it is regular practice for such engines to be equipped with fresh water cooling systems as standard equipment. This adds something to the first cost.

When a car is going fast, its engine is revolving at high r. p. m. but it is running comparatively light and free. A water propeller loads down an engine heavily, so when running at the same high r. p. m. in a boat the same engine may be lugging rather hard. In normal automobile operations, an engine runs well below its top speed a large percentage of the time. But in a boat, it often runs at high speed under heavy load for hours on end.

As used by an automobile factory, a particular engine block finds its way into a handful of automobile models, for which it was specifically designed and tested. Converted to marine use, examples of the same block can and often do end up powering a wide variety of hulls featuring good, mediocre and bad installations. Lubrication and cooling problems can crop up. Wander around some boatyeard and observe the interesting number of late-model marine engines laying around in the shops with burned-out main and connecting rod bearings, broken pistons and other failures caused by severe operating conditions.

What it amounts to is, just because an engine is an inboard does not automatically make it more reliable than an outboard. Provided the de¬ signer of an inboard boat knows engines well, makes a wise choice and works out a good installation, an inboard can be very reliable. You can also find fudged-up rigs on the market today, which will give you plenty of woe. A nice thing about an outboard motor is that if it needs repairs, it can be taken off the boat quickly and be put on a convenient work stand right beside the mechanic’s bench. If it fails and the failure is covered by the guarantee, a replacement motor can be clamped on quickly. But the mechanic has to go down to the dock and clamber into the boat to service are inboard, and if there is something wrong with it that requires its removal, a lot of work may be involved.

There are things very much in the inboard’s favor. When installed amidships and low in a hull, engine weight is most advantageously located for best hull riding qualities and seagoing ability. There’s nothing better able to withstand salt water than the simple arrangement of bronze and Monel parts in the shaft, strut and propeller installation. In a smaller inboards, an engine box occupying the middle of a cockpit can take up an objectionable amount of space; in a larger cabin cruiser the engine or engines may be Complete Guide to Below Deck Sailboat Systems: Ventilation, Marine Heads, Water Systems and morebelow deck level and completely out of the way. The explosion hazard in outboards is so small as to be negligible, but is so great in inboards that constant attention must be given to bilge ventilation and safe refueling procedures.

The growth of boating inland has put the smaller conventional inboard at a disadvantage. More and more people want to, or have to, trailer their boats, A skeg and propeller below the hull make beaching and winching out very awkward. Fewer and fewer firms make conventional inboard runabouts and utilities. You’ll notice that Penn Yan and Lyman, the two most active firms in this field, are both located in a part of the country handy to several large, deep lakes where the need to trailer isn’t as great as it is on many other inland waters. The output of the few other firms still making small conventional inboards is so small that mass-production economies are not possible so they find customers to be rather few and far between.

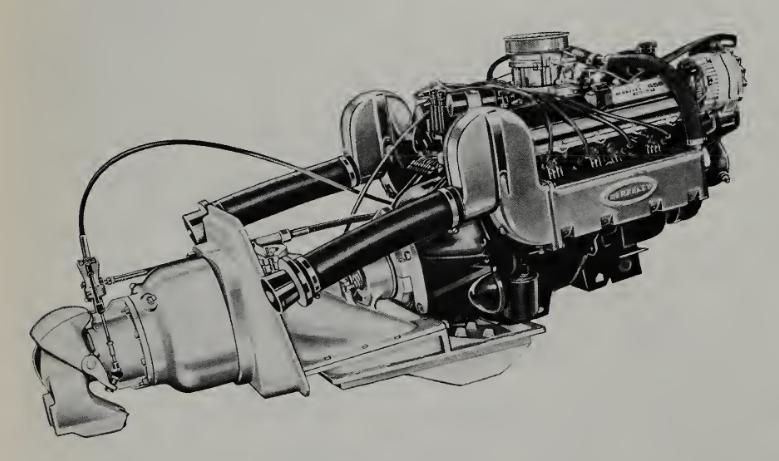

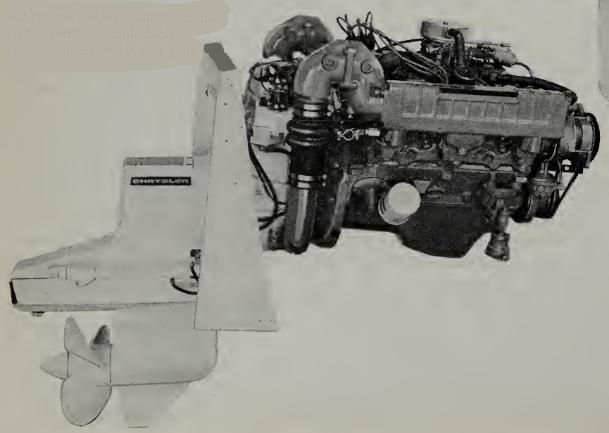

The inboard-outboard is obviously an excellent thing for medium and large boats that operate in shallow or obstruction-infested waters, such as the big rivers of the midwest and the artificial lakes of the west. But it also has big advantages from the boatbuilder’s point of view, and these explain why the type is really so popular. Shaft alignment is built in by the engine manufacturer; there is no need to entrust fussy engine-to-shaft alignment work to workmen not having years of boatbuilding experience. The inboard-outboard is also a logical way for boatbuilders to offer a choice of inboard or outboard power without undue expense.

Fiberglass is now the leading Characteristics of Different Types of Construction Materialsboatbuilding material. Once you have your molds, you cannot make changes in your boat without spending a lot of time and money on new molds. A company can develop a good outboard hull. The forward deck, windshield, dashboard, seats and overall hull balance are arranged on the assumption that the powerplant will be in the stern. Often it is not possible to put an inboard engine into such a boat without spending thousands of dollars for a new deck mold with completely rearranged layout to fit around that big engine box amidships. As the demand for conventional inboards is small due to the trailering problem, many firms just don’t see any point in offering their outboard hulls with conventional inboard power. For them, the stern drive is the answer. All they have to do is make the side decks and motor well of the outboard in such a way that it’s easy to leave out the well and put in a motor box.

The inboard-outboard is also a logical way for outboard motor manufacturers to enter the market for powerplants bigger and heavier than is practical for outboard motors.

Outboard motors pivot at a point well above the water. It is normal for all the parts of an outboard motor to be completely out of the water when it is tilted up on a well-designed boat. In this position, electrolysis is no problem at all to the outboard on a boat moored in salt water.

And although an inboard-outboard’s lower unit will tilt for beaching or trailering, because the pivot point is so low on the transom the unit will not lift completely out of the water when tilted at a mooring. All this aluminum down in the salt water opens the door to attack by electrolysis, but aid can be had through the use of electrolysis blocks and electronic anti-electrolysis devices.

Stern drives are normally heavier than outboards. This much weight so far aft has to be taken into account. There are pros and cons to it. It’s obviously better for inboard engine weight to be in the stern of 60 m. p. h. offshore racing boats that leap from wave to wave, but in 25 m. p. h. pleasure boats the ride is better and the stern lifts to following seas better when engine weight is amidships.

As between different makes of outboards and inboard-outboards, one will find noticeable difference in the number of degrees to which they can pivot up and down and port to starboard. In the inboard-outboards, sometimes the type of universal joint used at the top of the lower unit limits steering. Not much steering motion is needed at normal cruising speeds on swift planing boats, but as between a lower unit that can pivot only 30 degrees port and starboard and one that can pivot 40 or 45 degrees, you will notice a difference in low-speed maneuverability.

A variety of engine blocks are found in stern drives. Because these engines are normally used in fast planing hulls, their weight cannot be excessive. In order to find engine blocks of moderate weight for the smaller inboard-outboards, manufacturers have gone to Europe in search of four-cycle oder automotive blocks suitable for marine conversion. When you get one of these you get an engine built to metric measurements and when servicing is needed that means a new set of tools.

As with some conventional inboards, inboard-outboards run at high r. p. m. under heavy loads and can develop lubrication and cooling problems. Rubber bellows used at various joints to allow steering and tilting must be watched carefully for signs of deterioration, for if salt water gets in through even a small crack the damage to finely machined universal joints can be rapid and expensive to repair.

It all comes down to the fact that today, it just is not possible to say categorically that one kind of engine is more reliable or more durable than another. Each case has to be evaluated individually. The man who understands motors and treats them well will have less trouble with any kind of power plant than will the man who does not understand them and who abuses them, however unintentionally.

A motor well-chosen for the job is bound to be more reliable than one ill-suited to a particular application, and it makes little difference whether it is an outboard, inboard or stern drive. If one is very much concerned about motor dependability, perhaps the best advice is – buy the motor from a dealer with a good shop and a good reputation for servicing what he sells.