Floating LNG terminals represent a significant advancement in the natural gas industry, offering flexible solutions for gas processing and distribution. These floating LNG terminals combine storage, regasification and transfer capabilities in a single offshore facility. Modern floating LNG terminals are designed to operate in various marine environments, providing an efficient alternative to land-based terminals.

- Floating LNG Terminals

- General Considerations

- Floating, Progressing, Storage, Off-Loading (FPSO) (Concrete Structure)

- Floating, Storage, Processing, Off-Loading Floating Steel Structure Self Supported Prismatic IMO Type B Tanks

- Gravity Based Concrete LNG Storage Barge

- Evolution of the Concrete Barge Concept

- GBS Concept: Gravity Base Structure – Prismatic Storage Tanks

- Summary

Floating LNG terminals have revolutionized the way natural gas is processed and distributed globally. The operational flexibility of floating LNG terminals allows them to be relocated based on market demands, while their advanced safety systems ensure reliable performance. Furthermore, floating LNG terminals demonstrate cost-effectiveness compared to conventional onshore facilities, making them an increasingly popular choice in the LNG industry.

Floating LNG Terminals

General Considerations

Floating terminals have numerous advantages over their land-based counterparts.

Some of these advantages are:

- Larger Ships (200 000 + m3) / Deeper draft (12 + mtrs).

- No traffic restrictions – as compared to existing terminals.

- Events of 9/11, Authorities & Government, reluctant to take risk of even larger LNGC’s coming into port.

- Offshore within the territorial waters.

- Secure with dedicated crew – security implementation easier.

- Cost comparison between Shore terminal & offshore terminals.

- Easy access by the trading Surveys on Existing LNG ShipsLNG ships – no jetties required.

- Facilitates changing locations as & when needed.

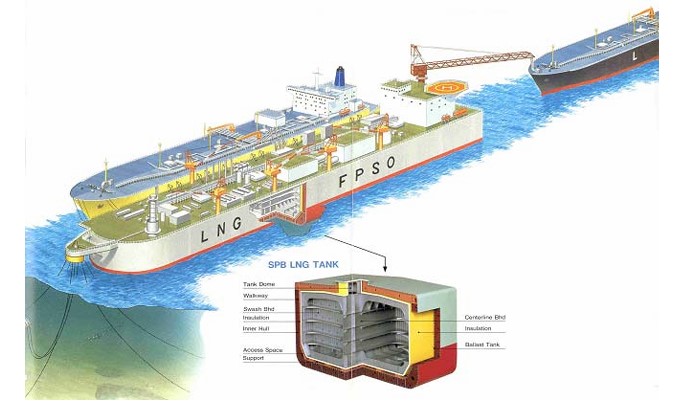

LNG – Floating, Processing, Storage, Offloading (LNG-FPSO) – (Steel or concrete).

Figure 1 illustrates concept of LNG – FPSO, which is nearly identical in function to its petroleum counterparts.

The choice of steel or concrete requires consideration of Membrane Sheet Welding Procedure for LNG Containment Systemsthe containment system, size of terminal, etc.

Floating, Progressing, Storage, Off-Loading (FPSO) (Concrete Structure)

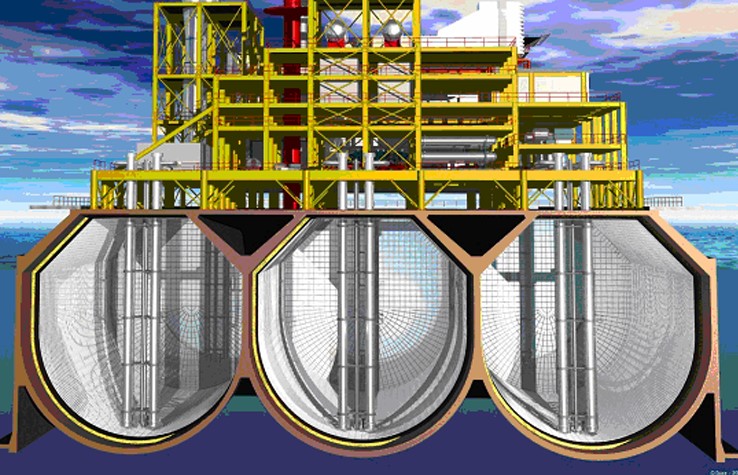

The versatility of concrete allows for the casting or spraying of the concrete to form irregular shapes such as these round bottom, semi-prismatic tanks. (See Figure 2).

The proposed containment system is TG Mark-III, or could soon be GTT CS-1. (See Figure 3).

Floating, Storage, Processing, Off-Loading Floating Steel Structure Self Supported Prismatic IMO Type B Tanks

As it can be seen from Figures 4, 5 and the preceding figures, the choice for containment systems is as varied as it is for LNGC new building.

Gravity Based Concrete LNG Storage Barge

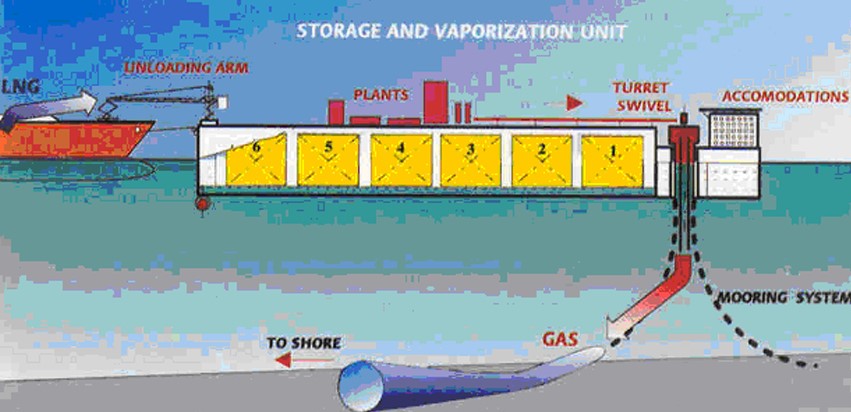

Larger LNG–FPSO’s (Figure 6) offer an economy of scale, but also present related problems with regard to hull stress, etc.

One consideration was to fabricate the FPSO large enough so that it could be set on the bottom. In this manner, it could actually be used as a breakwater to protect the discharging vessel from prevailing weather and sea conditions.

Figure 7 depicts the send-out Piping System of pressure vessels on gas tankerspiping arrangement.

In this instance, it is probably similar to the LNGC-RV’s in that the “GAS” Line is probably a high-pressure fluid line. That is, methane is above its supercritical temperature and pressure.

Evolution of the Concrete Barge Concept

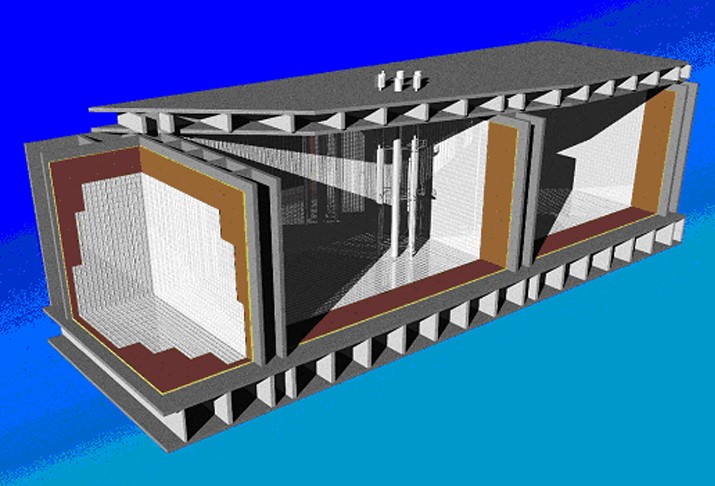

Concrete, when properly cured and insulated, has excellent cryogenic properties. In the case of an LNGC–FPSO, it offers reasonable economy if multiple casting can be made with the same mold system. Figure 8 illustrates a large amount of flat panel construction without a lot of complex rounded shapes as seen in earlier slides.

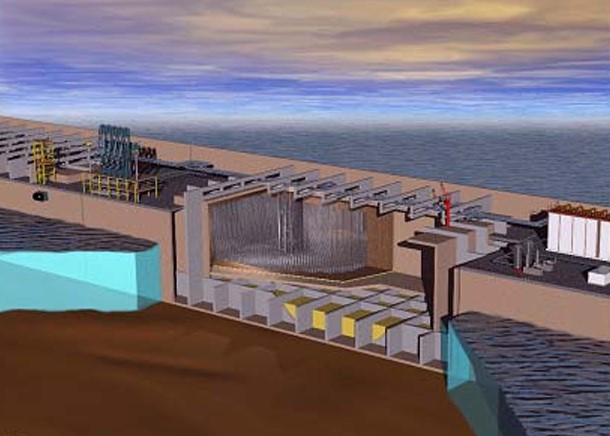

GBS Concept: Gravity Base Structure – Prismatic Storage Tanks

In this instance, the GBS facility can actually be set on the bottom. This would seem to provide the utmost in stability and eliminate the cost of expensive mooring systems. (See Figure 9).

Summary

The increasing demand for LNG coupled with a shortage of existing terminals makes the case for considering LNG–FPSO and the associated variations. Costs and versatility also favor the LNG-FPSO.