This article covers the terminal operations of a gas carrier from the point of her arrival in port. Liquefied gas terminals designed to accommodate large LNG or LPG carrier ships designed to load, carry and unload gas.

It includes:

- Berthing;

- Mooring;

- Pre-cargo operations;

- Cargo transfer;

- Post-cargo transfers operations;

- Unbearthing;

- Departure.

Joint co-operation and good communication is key in a successful ship/shore interface.

The Ship/Shore Interface

The ship/shore interface is defined as an area where two different parties with defined responsibilities must work together and where any action taken by one party affects the other.

Both parties must work together in close co-operation, while understanding their respective challenges in achieving a Essential Operations with Gas for a Modern LNG Carriers in Typical Trading Cyclesafe ship/shore operation.

Communications

Many items of information will be exchanged prior to, and at the time of, chartering the ship. In addition to these, communications between the ship and the terminal should start before arrival as delay can occur if the ship waits to exchange all the relevant information once alongside.

Items for consideration include:

- Does the manifold comply with the position standards for gas carriers, as determined by OCIMF;

- Draught on arrival and departure and if this meets berth approval;

- ESD system closure time and any effect this may have on the maximum loading rate;

- Whether the ship is fitted with controllable closing-time actuators;

- If a refrigerated cargo is to be discharged to a non-refrigerated shore system, whether or not the minimum temperature acceptable been established and an evaluation of the cargo heating requirements has been made to estimate the discharge time;

- If a pressurised cargo at ambient temperature is to be loaded onto a refrigerated ship, whether the reliquefaction plant capacity is known for the loading rate to be determined;

- If a vapour return line is available where the conditions require;

- Whether or not inerting and purging operations will be allowed alongside;

- Terminal regulations and requirements.

These issues require exchange of information between the ship (through her owners/charterers) and the terminal. Effective communication saves time.

Pre-Arrival

1 Operational Equipment

Prior to arrival at the terminal, the ship should verify that the cargo system and transfer equipment has been inspected and tested.

Similar checks should be carried out on terminal equipment before cargo operations.

These checks should include:

- Remotely operated valves run through a complete open/close cycle. This ensures proper functioning at the correct closure times;

- Operation of the gas detection system;

- Activation of ESDS from all locations to ensure correct operation of all associated alarms and interlocks;

- Testing of the operation of the tank high and low pressure alarms and where possible high, high-high and low low-low liquid alarms;

- Testing of fire-fighting equipment, water spray systems and emergency equipment.

2 Navigational Equipment

Prior to entry into the harbour, the port authority may ask the ship to confirm that all navigational equipment and propulsion machinery is fully operational.

3 Berthing Requirements

- The terminal will have established berthing/unberthing criteria, including environmental limits, e. g. maximum wind, current, waves, vessel size/displacement, vessel approach angle/velocity;

- The terminal will have an established set of criteria for stopping cargo operations, e. g. maximum wind and/or waves, other ship movements, etc.;

- Tug requirements should be established to ensure that the correct number and size of tugs are used for berthing and unberthing. Tug availability for emergency situations should be established;

- A mooring plan should be prepared by the terminal and sent to the ship in advance of berthing. The ship should try to comply to that plan as closely as possible.

4 Mooring

Good mooring is one of the most important aspects of terminal operations. It ensures that the ship is secured alongside, allowing minimal movement.

This “minimal movement” is important to remain within the design criteria of the cargo transfer equipment, preventing damage to the shore Cargo Handling Systems and Specialised Equipment on LNG LPG Carrierscargo handling facilities and the berth.

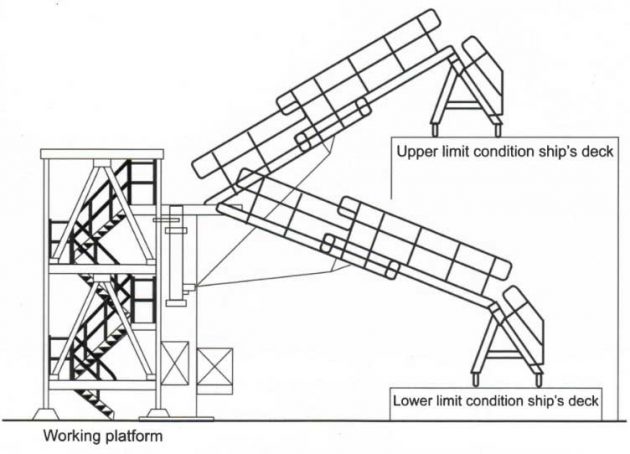

5 Cargo Transfer Equipment

As with all tankers, if the position of the cargo and vapour manifolds on board gas carriers did not conform to standards, operating difficulties would be met when connecting hard arms.

OCIMF publishes the following guidelines:

- “Standardisation of Manifolds for Refrigerated Liquefied Gas Carriers for Cargoes from 0 °C to minus 104 °C”.

- “Standardisation of Manifold for Refrigerated Liquefied Gas Carriers (LNG)”.

Both of these serve as guidelines to owners, operators, builders of liquefied gas carriers and jetty designers.

The following pre-arrival information related to ship manifold characteristics should be obtained by the terminal:

- Size of the connection flange;

- Distance of manifold from bow;

- Height above uppermost continuous deck;

- Distance of manifold from ship’s side;

- Height above waterline when loaded;

- Height above waterline in ballast;

- Distance from face to support stanchion;

- Height of manifold above keel.

General Precautions while the Ship is at Berth

1 Operational Limits

Criteria that is based on maximum wind velocity and the possibility of severe veering or backing changes in wind direction should be established for stopping cargo operations. Height and frequency of waves can be a major factor and the interaction with other ship movements in the vicinity of the gas ship can cause severe water movement against the hull and suction effects under the hull.

When preparing the operational limits for a terminal, the following are considered.

- Gas carriers present a larger “windage” area than other tankers in both the loaded and ballast conditions and so are more sensitive to wind effect;

- The maximum wind limits of hard arms, when connected;

- The time required to stop operations and disconnect cargo transfer equipment.

Operational limits must then be assessed on a case by case basis for each vessel, covering:

- Mooring standard, quality/type of mooring lines;

- Cantilever effect of hard arms over the ship’s manifold;

- Relative position of the ship’s manifold in relation to the envelope of the chiksan arms;

- Quality of the ship and crew;

- Frequency of ships passing in the vicinity of berth.

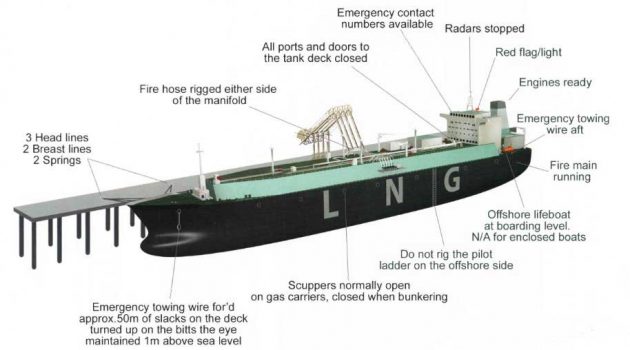

2 Summary of Safety Precautions Alongside the Berth

3 Moorings

Attention should regularly be given to the ship’s moorings to ensure that the ship remains in compliance with the berth plan and any deviation must be promptly rectified.

In berths open to the sea or swell, ranging of the ship alongside should be prevented by keeping all mooring lines taut and the ship firmly against the fenders.

Tides and currents and their potential effect on the vessel should be anticipated for the duration of the vessel’s stay.

Wire and fibre ropes should not be used together in the same direction (i. e. breasts, springs, head or stern) because of the differences in their elastic properties.

Ships fitted with automatic tension winches should not use such winches in the automatic mode.

In 2006, an LNG carrier with her winches in automatic mode was sucked off the berth by a passing ship.

Means should be provided to enable quick and safe release of the ship in the case of an emergency and the emergency release operation should be agreed.

Anchors not in use should be properly secured, either in or out of the hawse pipe, to prevent sudden release and generation of sparks.

4 Access and Security

The ship/shore access should be positioned as far away from the manifolds as practicable.

Access to the ship must be safe and should consist of an appropriate shore or ship’s gangway. Particular attention to safe access should be given where the difference in level between the points of access on the vessel and the jetty or quay is large or likely to become large.

When using the ship’s gangway rig a safety net.

When a shore gangway is not available and a ship’s gangway is used, there should be an adequate landing area on the berth that maintains a safe and convenient access to the ship at all states of tide and any changes in the ship’s freeboard.

A lifebuoy fitted with a line and a light should be available near the gangway at accommodation ladder. The ship/shore access point should be safely and properly illuminated during periods of darkness.

Anyone admitted on board will have to adhere to all ship security procedures. The terminal and port facility Security Officer should control access to the jetty or berth in agreement with the ship Security Officer.

5 Immobilisation of Main Engines

The ship should be able to move under its own power at short notice unless permission to immobilise the ship has been granted by the Harbourmaster and the Terminal Manager, which is rare and only with the precaution of tugs standing by (not alongside – see “Other Craft” below).

6 Supervision

Operations should be under constant control, both on ship and ashore, to prevent the development of any hazardous situations. If such a situation arises, supervisory personnel should have adequate means and the responsibility to take corrective action.

Personnel in charge on the ship and ashore must maintain constant and effective communications with each other.

All personnel connected with operations should be familiar with the dangers of the substances handled and have easy access to cargo information such as a Material Safety Data Sheet (MSDS).

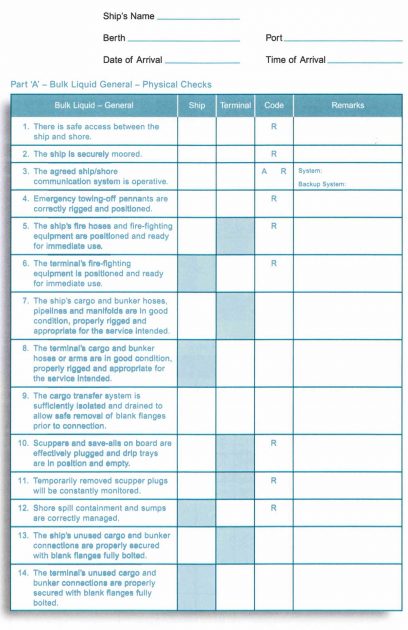

7 The Cargo Transfer Meeting

The Ship/Shore Safety check-list allows the terminal and the ship to exchange necessary information prior to loading or discharging cargo.

Terminal personnel, in their visits on board the ship, will satisfy themselves that the cargo handling plan is being closely followed.

One section of this check-list is dedicated to the “ship’s cargo handling plan”. The cargo handling plan should be thoroughly discussed and agreed by both the ship and terminal representatives.

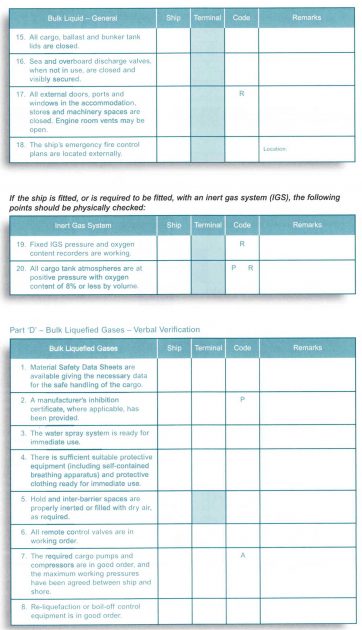

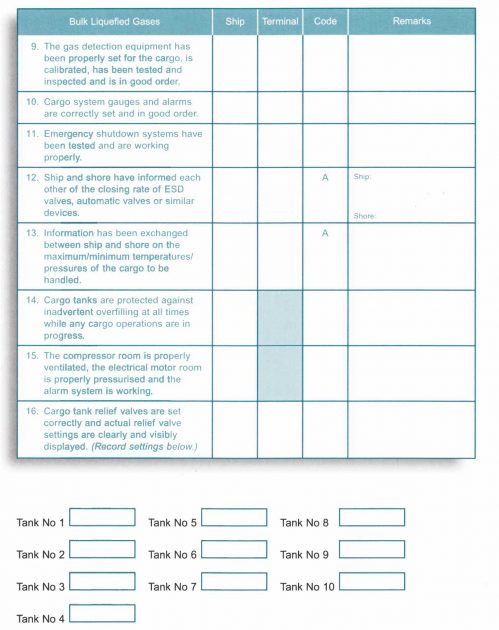

8 Ship-Shore Safety Check-Lists

Cargo operations alongside should not be started until all parties have confirmed they can be safely carried out.

The ship-shore safety checklist fulfils this purpose. For gas carriers, the general checklist for tankers and the specific checklist for gas carriers are both followed. These check-lists are based on ISGOTT (International Safety Guide for Oil Tankers and Terminal operators) and you are recommended to adhere closely to this publication.

All ship/shore check-lists should be carried out jointly by a responsible ship’s officer and responsible terminal representative, with signatures obtained from both parties to indicate agreement.

9 Material Safety Data Sheet (MSDS)

The MSDS for the cargo to be loaded or discharged should be available in the cargo control room, on the ship’s notice board and at the gangway.

USCG requires the MSDS to be available at the gangway and on each tank where different grades are carried.

The MSDS details all chemical and physical data, hazards and product incompatibility and actions to be taken in the event of an emergency.

When de-icing, if chemicals such as methanol are used the MSDS for this substance should also be displayed.

Cargo Inhibitors are usually toxic.

For any cargo containing an additive such as a polymerising inhibitor, the MSDS relating to it should also be available.

10 Fire-fighting Equipment

Fire-fighting equipment, both on board and ashore, should be correctly positioned and ready for immediate use.

11 Connecting and Disconnecting Hose Hard Arms

During the connection/disconnection of hoses and hard arms, care should be taken to prevent air entering the system.

The easiest way to ensure this is to inert the connection with nitrogen by inserting a plug valve for a nitrogen line connection near the ship’s end of the hose/hard arm.

Before removing the cargo blind or flange, care must be taken to release any possible pressure existing in the system.

When connecting the hard arm to the ships manifold, the nuts & bolts should be tightened to a torque of 65 kgf.m.

Before opening the ship’s manifold valve, the shore may thoroughly purge the hose/hard arm with nitrogen, venting through the bleeder/breaker.

Purging with nitrogen is not required when handling ammonia, but pressure should be released from the bleeder/breaker.

12 Disconnecting Hoses/Hard Arms

When loading/discharging is complete and the main cargo supply line ashore has been closed, hoses/hard arms should be purged of liquid.

Read also: Liquefied Natural Gas and Liquefied Petroleum Gas Cargo Containment System

After loading, the shore may blow the lines clear of liquid into the ship’s tanks using either hot gas from their compressors or nitrogen.

After discharge, the ship may blow the lines clear of liquid ashore using the ship’s compressors.

13 Checking Ship’s Tank Atmosphere

Before loading/discharging, the oxygen (O2) content in the ship’s cargo tank vapour space may be checked.

It is recommended that no more than 2 % O2 by volume ls accepted. Ensure that the O2 content in the entire cargo system has an even distribution. Lower O2 levels may be required for commercial or specific reasons related to the chemical properties of the cargo.

O2 analysers should be calibrated at regular intervals.

Samples from the vapour space of ship’s tanks may be taken by the terminal to test for O2 content. This may be done:

- After inerting and purging;

- Before loading;

- After loading;

- Before discharging.

If the O2 content exceeds acceptable limits the ship will be instructed to remedy the situation.

Cargo Handling

1 Cargo Loading

Whenever cargo operations must be stopped, to change shore tanks for example, the manifold valves must be closed until operations are resumed. As the possibility of stopping cargo operations is generally known in advance, the ship should be informed during the pre-cargo transfer meeting to enable it to properly pre-plan.

The ship should be informed of any alteration that may occur in the flow rate, for terminal technical reasons, during loading operations.

Venting alongside is not permitted during loading operations.

Fixed gas detection equipment should be in operation throughout loading.

2 Cargo Discharge

The ship will be instructed by the terminal whenever the discharge flow is interrupted due to equipment failure or activation of automatic shut-off devices. Such stoppages must be reported to the terminal and discharge operations cannot be resumed without terminal authorisation.

Cargo and vapour manifolds must be closed for the entire time if discharge is interrupted.

Venting alongside is not permitted during discharge operations and fixed gas detection equipment should be continuously working throughout the discharge.

3 Loading from Pressurised Storage into a Refrigerated Ship

When cargo from pressurised storage is loaded into a semi-pressurised or refrigerated ship, the loading rate should always be compatible with the capacity of the shipboard reliquefaction plant.

4 Discharging Refrigerated Cargo into Pressurised Storage

When a semi-refrigerated or fully refrigerated LPG carrier has to discharge into pressurised storage, the ship should be informed in advance so that the cargo can be heated to the correct temperature during discharge.

Cargo Vapour Handling

During cargo operations it is recommended that a vapour return line should be connected. Where the vapour return line is not available during discharge, the ship can use the cargo vapouriser to replace the cargo vapour in the tanks. On semi-pressurised/refrigerated ships, the capacity of the ships reliquefaction plant will determine the loading rate.

1 Pressure Surges

A pressure surge known as a “liquid hammer” can result from rapid closure of valves. This is a hazard that all personnel involved in cargo transfer operations should be aware of.

If there is an ESD, to prevent pressure surge when loading activate the shore ESD before the ship’s.

Pressure surges are created when the flow in a liquid line is stopped too quickly. The hazard is greatest when cargo is transferred over long distances and at high velocity. If a valve is shut too quickly under these conditions, the deceleration of the large column of liquid in the line sets up shock waves that can travel down the line, causing extremely high surge pressures. The cargo hose/hard arm is most vulnerable to failure in these circumstances and the upper joint or swivel, if ruptured, would release liquid over the entire working area of the ship and shore manifolds.

A pressure surge is like a Tsunami travelling hose/hard arm is most vulnerable to failure in these circumstances and the upper joint or swivel, if ruptured, would release liquid through the pipe.

Surge pressures are most likely to be created during cargo transfer as a result of one of the following occurrences:

- Closure of a quick-closing shut-off valve;

- Rapid closure (or opening) of a manually or power-operated valve;

- Suddenly slamming shut a non-return valve;

- Starting or stopping a pump.

Potential hazards from pressure surge may be overcome by reducing the pipeline flow- rate during cargo transfer; according to the closing time of the quick-closing valve. Unless appropriate equipment has been installed (surge pressure drums, ship/shore umbilical cord, etc).

The 30 seconds it takes for remote operated valves to close is to prevent pressure surge.

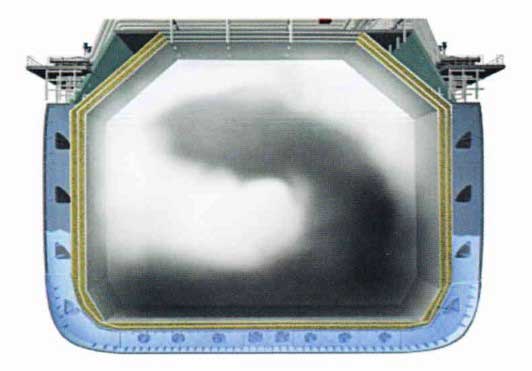

2 Rollover

If a cargo is stored for any length of time and the boil-off is removed to maintain tank pressure, evaporation will cause an increase in density and reduction of temperature near the liquid surface. The static head will create a higher pressure, causing an increase in temperature and lower density at the tank bottom.

This unstable equilibrium will exist until some disturbance occurs, such as the addition of new liquid. Spontaneous mixing will then take place with the violent production of large quantities of vapours. This phenomenon is called “rollover”. If such a situation is foreseen the tank contents should be circulated or mixed at regular intervals.

Until recently the only documented case of rollover was in a shore storage tank. However, ship reports indicate it happened on an LNG Carrier in 2006.

Rollover can occur if the same or compatible cargoes of different densities are put into the tank. Rollover may also occur when two part-cargoes are pumped into the same tank (e. g. propane and butane). In this case there will be a large boil-off from the temperature difference between the two.

Additional Procedures

1 Ship Work Permit, Chipping and Use of Power Tools

Only under exceptional circumstances should hot work or cold work that involves welding, burning, hammering, chipping, or any operations that involve the use of power tools, be undertaken while the ship is alongside.

In the event that such work must be carried out, the most stringent precautions must be taken and written agreement from the Port Authority and/or Terminal Manager be obtained before starting.

2 Terminal Work when Ship Alongside

In the event that such work must be carried out, a work permit will be issued by the terminal once environmental conditions have been properly assessed and operations in progress stopped for the duration of the work. The Master of the berthed ship should be informed of all details of such work and agreement reached before work starts, including the safety precautions to be taken.

3 Other Craft

Craft supplying services to the ship should only be permitted to moor alongside with the express permission of the Master and with the agreement of the terminal.

Craft should not be permitted alongside during cargo transfer, purging or inerting.

4 Protective Equipment and Protective Clothing

Suitable protective equipment, including Self-Contained Breathing Apparatus (SCBA) and protective clothing appropriate to the specific dangers of the product handled, should be readily available in sufficient numbers for operational personnel on board and ashore.

All personnel directly involved in the operation should utilise this protective equipment and clothing whenever necessary.

Personnel who need to use breathing apparatus during operations should be physically fit and fully trained in its use.

5 Non-Cargo Spaces

O2 readings in spaces that need to be inerted should be logged by ship’s personnel prior to arrival.

6 Remote Control Valves

All ship and shore cargo system remote control valves and their position-indicating systems should be regularly tested. Details of the last tests should be exchanged.

If any such valves, either on the ship or in the terminal, are not working correctly the alternative arrangements should be clearly understood and agreed by those responsible for the transfer.

7 Safety Relief Valves

If the ship venting system is fitted with relief valve by-passes they must be closed.

When different grades of cargo are carried simultaneously, independent venting systems must be available and segregation arrangements between the systems should be checked.

Relief valves normally have two settings on Fully Refr LPG/C: Harbour setting (higher relief setting) typically 350/385 mbarg Sea Setting typically 200/225 mbarg.

In cases where ship cargo tanks are permitted to have more than one relief valve setting, it should be verified that the relief valves are set as required by the cargo to be handled and that the actual setting of the relief valves are clearly and visibly displayed.

8 Working Pressures

Agreement should be reached on the maximum allowable working pressure in the cargo-line system during operations. The agreed pressure should be entered in the ship/shore operational arrangement form. Details of safe working pressures should be clearly displayed on the ship’s lines.

9 Reliquefaction

It should be verified that reliquefaction and boil-off control systems are in order before the start of operations.

At the loading port, if the ship uses its reliquefaction plant it should be confirmed that the equipment is in good working order. If the vessel is unable to cope with the quantity of displaced and boil-off vapour; the rate at which the return vapour can be accepted ashore should be advised, or cargo liquid transfer ceased with all isolation precautions taken while the ship continues to control vapour pressures.

In some LPG loading ports the VRL is connected but remains closed and is only to be used in an emergency.

At the discharge port it should be agreed whether vapour will be returned to the vessel from the shore tank or if the ship will be required to use its own vapouriser to maintain the vapour pressure in its tanks.

10 Venting to Atmosphere

Vapour displaced from cargo tanks during loading should be returned either to the shore via the VRL or, if possible, reliquefied and returned to the ship’s cargo tanks.

In most circumstances, venting of cargo vapours to the atmosphere from the ship should be avoided.

Venting to the atmosphere may occur if the ship’s pressure relief valves lift. The mast risers will be in a relatively safe location but, under certain climatic conditions, a hazardous situation could develop. If accidental venting occurs it will be necessary to stop cargo operations.

11 Vapour Return Line

A vapour return line to the shore tank, or shore vent stack, will enable the vessel to dispose of surplus gas (particularly in an emergency) without venting to the atmosphere in the vicinity of the ship’s deck area.

If gassing-up alongside, the surplus vapours going ashore will frequently go to a vent stack flare with an igniter.

For safety reasons it is strongly recommended that a vapour return line be available at all loading terminals.

12 Port Information Booklet

All terminals handling liquefied gases should prepare a port information booklet to be distributed to ships and ship owners. This will enable the Masters to pre-plan their stay alongside the terminal’s jetty.

Ship/Shore Safety Check-List

The ship may have a specific Ship/Shore safety check-list that has been created by the company. Alternatively it may use the generic tanker check-lists in ISGOTT.

THIS CHECK-LIST SECTION TAKEN FROM ISGOTT IS BY THE KIND PERMISSION OF ICS AND OCIMF

INTERNATIONAL SAFETY GUIDE FOR OIL TANKERS AND TERMINALS

Ship-to-Ship (STS) Cargo Transfer of Liquefied Gas

For a long time offshore ship-to-ship gas transfer of liquefied gas was thought to be too hazardous an operation for a ship’s crew to undertake. However, several loading stations that transfer LPG into liquefied gas ships have now been in use for a substantial period of time. Emergency relief transfers of gas cargoes have also been carried out at times when a “victim” ship has run aground or met with other disaster scenarios. LPG, ethylene, butadiene and other gases have all been safely transferred in this manner and the first commercial LNG STS operation was successfully completed in 2006.

The gas industry is, therefore, well prepared and experienced in the offshore transfer of liquefied gas cargoes. Offshore transfer of liquefied gas may be conducted because of:

- Emergency conditions;

- Geographical or political preference for handling these cargoes away from port areas that are liable to environmental protest and/or possible terrorist threat;

- Economic factors of handling the cargoes on smaller ships, rather than constructing complex port structures;

- Terminal/port requirements to have product available off port, providing additional backstop capacity to the shore tanks in times of greater demand for the cargo.

The publication: “Ship-to-Ship Transfer Guide (Liquefied Gas)”, jointly issued by the International Chamber of Shipping (lCS), Oil Companies International Marine Forum (OCIMF) and the Society of International Gas Tanker and Terminal Operators Ltd (SIGTTO), is the main guidance document for this type of operation.

Within the STS guide there are a series of checklists:

- Pre fixture information for each ship, between the ship operator charterer and organise;

- Before operations commence;

- Before run in and mooring;

- Before cargo transfer;

- Before unmooring.

The check-lists detail each distinct phase of the operation and are in addition to the normal preparations for a ship/shore cargo transfer.

Favourable weather and sea conditions are of prime importance to this operation and a major difference from ship/shore transfer is that an STS operation requires a single individual to have overall control, i. e. the Mooring Master.

The appointment of the Mooring Master and the “organiser” agency must be clearly agreed between the two ships prior to commencement. Generally, they will be from the ship that is being loaded, which is often local and dedicated to this purpose.

It is normal practice that extra equipment, such as patented “Yokohama” fenders and hoses, will be provided by the organiser agency. This type of cargo transfer demands extra manning effort in mooring, hose handling, derrick and crane control and careful watch keeping throughout the procedure.