This article covers the following learning outcome: identify the main hazards of, and suitable controls for, land transport (road tankers) in the oil and gas industries.

- Road tankers

- Introduction

- Road transportation of hazardous materials

- Protection of plant and equipment against being struck by vehicles

- General principles for avoiding plant being struck by vehicles

- Driver training for transportation of dangerous goods

- Loading and discharging arrangements

- Traffic management

- Vehicle movements on site

- Vehicle movements off site

- Rail

- Questions and answers

Road tankers

Introduction

Oil and gas have become essential elements in just about every aspect of the way we live and the products we produce. They fuel our transport systems, provide heat and energy to our homes and businesses, and they provide the building blocks for many of the materials and chemicals we use in everyday life.

Consequently, in order to feed this insatiable appetite for oil and gas, vast amounts have to be transported from one location to another at various stages of their transformation to a finished product.

The type of transportation used can vary, and this will depend to a great extent on where the material is coming from and where it is destined to go. Global transportation of hydrocarbons is usually by seagoing tankers, although pipelines are used for some well- established routes. Locally, transportation is by road and rail, and it’s these two types of transportation we shall be looking at in this article.

Road transportation of hazardous materials

As these products are volatile, and potentially very hazardous, transporting them on public roads needs to be regulated so that safe working practices and procedures, which will help safeguard the public, are universally imposed.

The first step in the safe carriage of hazardous material is to be able to:

- Identify exactly what it is that is being carried;

- Identify what the precise hazards are that this product presents;

- Identify the best means of controlling those hazards Conveying this information instantly to those with a vested interest, especially the emergency services, is essential. It also needs to be conveyed in a standard format that is universally recognized by those interested parties.

The UN classification and labelling system for the transportation of dangerous goods, which is now universally accepted, is the means by which this information is made available on all vehicles carrying dangerous goods.

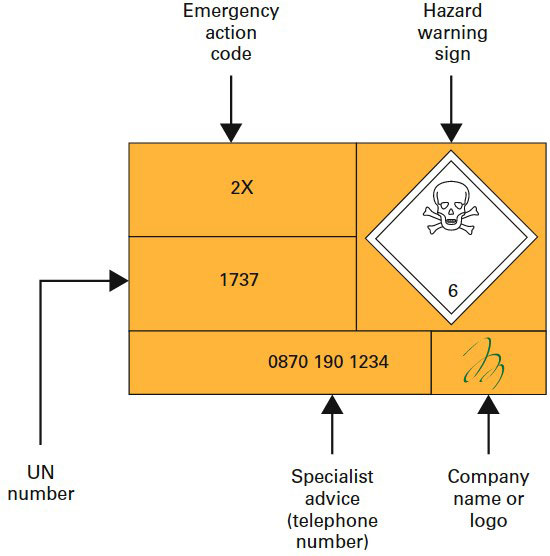

The system uses a standard signboard fixed to the vehicle in a designated position or positions. On this signboard are a number of internationally accepted series of codes and symbols to show what is being transported, the hazards it represents and the correct preventative actions to be taken when required.

Read also: Safety while Working on Marine Transport Over Water and Under Water

Figure 1 shows an example of the type of signboard used on vehicles. In this case, the hazard warning sign shows a skull and crossbones, which indicates the product being carried is a toxic substance. The number 6 also indicates it is toxic or there is a risk of infection.

Source: Wise Global Training

The UN classification number 1737 shows the substance being carried in this case is benzyl bromide.

The emergency action code 2X shows the following. The number 2 indicates that the emergency services should use a “fog or fine spray” when dealing with this substance. The letter X indicates that “full liquid-tight personal protective equipment” should be worn by the emergency service personnel.

Additional to these information boxes is the telephone number, which will give access to specialist advice if needed. With regards to transporting hazardous materials, there are nine types of substance classed as hazardous.

These are:

- Explosive substances;

- Flammable gas;

- Flammable liquid;

- Flammable solid;

- Oxidizing agents;

- Toxic substances;

- Radioactive substances;

- Corrosive substances;

- Miscellaneous substances.

Figures 2 and 3 show the hazard warning panel in situ. This panel will be positioned on both sides of the tanker and, as in this case, on the rear of the vehicle as well.

Source: Wise Global Training

Protection of plant and equipment against being struck by vehicles

Vehicles travelling at any speed carry the potential to cause significant damage to any object they strike. When that object, or indeed the vehicle itself, contains a hazardous or flammable liquid or gas, the results can be catastrophic.

Source: Wise Global Training

Consequently, it is essential that all possible measures are taken to Common Hazards and Risk Assessment in Oil and Gas Industryreduce this hazard as far as possible.

General principles for avoiding plant being struck by vehicles

- Traffic routes should be wide enough for the safe movement of the largest vehicle permitted to use them (including visiting vehicles).

- Traffic routes should have enough height clearance for the tallest vehicle permitted to use them (including visiting vehicles).

- Potentially dangerous obstructions, such as overhead electric cables, or pipes containing hazardous chemicals, need to be protected using goalposts, height gauge posts or barriers.

- Traffic routes should be planned to give the safest routes between calling places.

- Routes should avoid passing close to such things as unprotected fuel or chemical tanks or pipelines.

- All potentially vulnerable plant should be protected from errant vehicles by collision barriers.

- All routes should be well lit.

- Any hazardous sections of the route, such as sharp bends or adverse cambers, should be clearly signed.

- A person should be appointed to be responsible for, and oversee, site traffic movements on site.

- Drivers should be trained and authorized to drive vehicles on site.

- Visiting drivers should be briefed about site traffic movement rules.

- Reversing of vehicles should be avoided or controlled.

Driver training for transportation of dangerous goods

The main objectives of driver training, in relation to carrying dangerous goods, are to ensure drivers:

- Are aware of the hazards arising when they are driving a vehicle which is carrying dangerous goods.

- Know what steps to take in order to reduce the likelihood of an incident taking place.

- Know what necessary measures they need to take when driving a vehicle which is carrying dangerous goods with regard to ensuring their own safety, that of the public and of the environment; also, if an incident does occur, how to limit the effects of that incident.

- Have practical experience, attained during the course of training, of what actions they will need to take in the case of an incident occurring.

The regulations in some countries require drivers of road tankers to hold a Vocational Training Certificate (VCT) which certifies that the holder has attended appropriate training courses and has passed an examination on the requirements to be met when carrying dangerous goods by road.

The basic course content includes:

- General requirements covering the carriage of dangerous goods.

- The main hazards associated with the carriage of dangerous goods.

- Preventative and safety measures regarding various hazards related to the carriage of dangerous goods.

- Actions to be taken in the case of an accident.

- Marking, labelling, placarding and hazard warning panels.

- What not to do as a driver of a vehicle carrying dangerous goods.

- Reasons for, and operation of, technical equipment on vehicles carrying dangerous goods.

- Precautions to be taken when loading and unloading dangerous goods from vehicles.

- Restrictions and instructions on driving vehicles carrying dangerous goods through tunnels.

Beyond the basic course, tanker drivers will be required to partake in a specialist course which will include:

- Behaviour of loaded tankers, including load movement, whilst being driven.

- Knowledge of different filling and discharge arrangements for tankers.

- Specific requirements for tankers, including knowledge of certificates of approval for tankers, approval marking, hazard warning panels, etc.

Loading and discharging arrangements

Whenever hydrocarbons are transferred from one location to another, as when tankers are loaded or unloaded, there is an increased risk of fire or explosion from a number of sources. Knowing what these sources are, and implementing pre-emptive safety and control measures, helps to keep the risk to a minimum.

Source: Dreamstime

The following control measures should be implemented when the loading and unloading of hydrocarbon materials takes place.

- The area designated for loading and unloading should be situated away from general traffic routes. It should also be situated on level ground.

- There should be sufficient space to allow the largest planned-for vehicles to easily manoeuvre into and out of the loading/unloading area.

- Loading/unloading areas should be adequately lit when in use.

- A system should be implemented that ensures a vehicle cannot be driven away from the loading/unloading point before authorized to do so. An example of this control would be to have the driver hand over the ignition key to the transfer supervisor on arrival, who would only returning the key once he/she was satisfied the loading/unloading operation had finished and it was safe for the vehicle to depart.

- When the loading/unloading operation has been completed, drivers must ensure all tank openings, including valves and caps, are closed before starting their journey.

- No tank should be overfilled, as most tanks require room for expansion of the liquid. Information on what is the prescribed level of filling may be affixed to the tank or the vehicle’s chassis. Most modern road tankers use a device known as a “Scully” to protect against overfilling when loading. This device uses a series of probes inside the compartments of the road tanker to detect when the correct amount of product has been loaded and bring the filling operation to an end.

- When filling tanks, the pressure in the tank must be monitored to ensure it does not exceed its maximum working pressure. Tanks should be fitted with pressure relief valves.

- When discharging tanks, the pressure in the tank must be monitored to ensure a vacuum is not created. Tanks should be fitted with vacuum breaker valves.

- All external vents should be fitted with flame arrestors.

- The rate of filling or discharge must be limited. This is to reduce the risk of static electricity build-up, which can be caused by splashing and liquid being circulated unduly.

- Suitable drip trays should be placed beneath hose connection points when loading/unloading operations are being set up or are being ended. This is because these points have the potential to spill product when connection is made or broken.

- Where product with a flash point of 60 °C or less is being loaded/unloaded, a bonding wire should be connected between the vehicle and an earthing point before loading/unloading commences.

- A no smoking policy should be established and maintained on site.

- There should be two opposing emergency exits from the loading/unloading area.

- Exits should be clearly marked and open outwards.

- Vapours which are displaced during the transfer operation should be returned to the donor tank via a vapour-tight connection line.

- The vapour return line should have a different connection fitting compared to that of the product transfer hose. This is to ensure there can be no misconnection;

- The vapour return line should be connected before the product transfer hose is connected.

- There should be a device on the vehicle which locks the brakes in the “on” position when the vapour recovery line is connected.

- A competent person shall be given the responsibility to monitor all the hose connections during loading/unloading operations.

- Any uncontrolled release of vapour should be recorded in the vehicle log book and reported to the authorities.

- There should be a pre-formulated spillage plan ready to deal with any spillages, and a spillage kit at the ready. This kit should include bunding.

Traffic management

Vehicle movements on site

There is always a need for vehicles to be properly managed and supervised whilst they are on site. Vehicle movements can be managed on site by implementing the following controls:

- A person should be appointed to be responsible for and oversee site traffic movements on site.

- All routes should be well lit.

- Any hazardous sections of the route, such as sharp bends or adverse cambers, should be clearly signed.

- Drivers should be trained and authorized to drive vehicles on site.

- Visiting drivers should be briefed about site traffic movement rules.

- Reversing of vehicles should be avoided or controlled.

- A contingency plan, and the resources to implement it, must be in place in case of adverse weather conditions such as snow and ice.

- Periodic surveys and safety tours should be conducted to ensure traffic rules are being complied with.

Vehicle movements off site

It is equally as important to manage traffic while it’s an route by applying control measures which will reduce the chances of an accident or incident occurring. These include the following.

Prior to leaving the site, check that:

- All hoses are secure.

- There are no leaks from the hoses.

- Blanking caps are fitted.

- The load is not leaking.

- The load is not overheating.

- For liquefied petroleum gas tanks, the pressure is within prescribed limits.

- The brakes and tyres on the vehicle are OK.

- All documents are in order and available.

- The markings are correct and in place.

When planning the route, employ the following controls:

- Avoid built up areas.

- Avoid roads with low bridges.

- Obey any restrictions relating to the transport of dangerous goods.

During the journey, check that:

- The load is still secure.

- There are no leaks.

- There is no overheating on the vehicle, i. e. from tyres, bearings, brakes, etc., that could lead to a fire.

- Any control temperature is not exceeded.

- Markings are still in place, clean and visible.

Employ driving techniques to:

- Maintain concentration.

- Anticipate situations wherever possible.

- Plan ahead.

- Drive defensively.

- Keep to the speed limit and drive at a safe speed, especially at roundabouts, motorway slip roads and site entrances.

- Always allow a margin of safety.

Load behaviour

Drivers must adjust their driving techniques according to the load on board. They must be aware that product will surge backwards under acceleration, will surge forward when braking and will surge from side to side when cornering. Also, any sudden steering movement may well cause instability.

Rail

The international carriage of dangerous goods by rail within Europe is governed by Annex I of the Convention Concerning International Carriage by Rail. This is known by the letters RID. However, the principles of these regulations form a sound basis for the transport of hydrocarbon products by rail anywhere in the world.

Source: Dreamstime

In order to transport hydrocarbon products by rail, a number of duties must be complied with. These include the following:

- Any dangerous goods being transported by rail must be clearly marked and labelled with their name, description and UN number, just as with road transport.

- Only carriers with the appropriate resources and experience should be engaged to carry hydrocarbon products.

- All temporary storage of rail traffic carrying hydrocarbon products should be secure.

- Rail staff engaged in the transportation of hydrocarbon products should undergo awareness training programmes.

- There should be an emergency plan in place where hydrocarbon products are involved.

When transporting hydrocarbon products by rail, all the safety systems which apply to the safe transportation by road, also apply to rail.

Source: Dreamstime

Rail loading/unloading operations present hazards that are very similar to those experienced by road transportation methods. However, there are several additional hazards that are unique to rail. These are:

- The movement of trains through entrances and exits of rail sidings should be supervised by a competent person.

- Sidings should be isolated from any main line.

- During loading/unloading operations, warning signs should be displayed on the train if open to access.

These will include:- Red flag during the day;

- Red light at night;

- A warning sign that the rail cars are connected.

- Loading/unloading operations must be monitored throughout the operation.

- Rail cars which have been disconnected from the locomotive must be prevented from moving.

- There should be a 15-metre exclusion zone around any loading/unloading point. This exclusion zone will prohibit any potential source of ignition.

- Where tools have to be used, these should be non-sparking tools.

- Prior to loading/unloading operations commencing, a system of vapour control should be established.

- The closure of all foot valves, lids and the removal of hoses, etc. must be overseen by a competent person.

- If rail tankers are fitted with product heaters, these must not be used if flammable vapours are present during loading and discharge operations.

- When work involves working on top of rail cars, working at height regulations should be adhered to.

- Weather conditions (the potential for lightning) should be taken into consideration prior to the commencement of loading/unloading.

Questions and answers

Answer 1

- There is a hazard warning sign/symbol which shows the internationally recognized diamond shaped symbol to indicate what hazard the product presents and its classification.

- There is the UN classification number which indicates exactly what the product is.

- There is the emergency action code indicating what actions and precautions the emergency services should take if they have to deal with an incident involving the product.

- There is a telephone number to contact if specialist advice is required.

Answer 2

- The area designated for loading and unloading should be situated away from general traffic routes. It should also be situated on level ground.

- There should be sufficient space to allow the largest planned-for vehicles to easily manoeuvre into and out of the loading/unloading area.

- Loading/unloading areas should be adequately lit when in use.

- A system should be implemented that ensures a vehicle cannot be driven away from the loading/unloading point before authorized to do so. An example of this control would be to have the driver hand over the ignition key to the transfer supervisor on arrival, who would only returning the key once he/she was satisfied the loading/unloading operation had finished and it was safe for the vehicle to depart.

- When the loading/unloading operation has been completed, drivers must ensure all tank openings, including valves and caps, are closed before starting their journey.

- No tank should be overfilled, as most tanks require room for expansion of the liquid. Information on what is the prescribed level of filling may be affixed to the tank or the vehicle’s chassis. Most modern road tankers use a device known as a “Scully” to protect against overfilling when loading. This device uses a series of probes inside the compartments of the road tanker to detect when the correct amount of product has been loaded and bring the filling operation to an end.

- When filling tanks, the pressure in the tank must be monitored to ensure it does not exceed its maximum working pressure. Tanks should be fitted with pressure relief valves.

- When discharging tanks, the pressure in the tank must be monitored to ensure a vacuum is not created. Tanks should be fitted with vacuum breaker valves.

- All external vents should be fitted with flame arrestors.

- The rate of filling or discharge must be limited. This is to reduce the risk of static electricity build-up, which can be caused by splashing and liquid being circulated unduly.

- Suitable drip trays should be placed beneath hose connection points when loading/unloading operations are being set up or are being ended. This is because these points have the potential to spill product when connection is made or broken.

- Where product with a flash point of 60 °C or less is being loaded/unloaded, a bonding wire should be connected between the vehicle and an earthing point before loading/unloading commences.

- A no smoking policy should be established and maintained on site.

- There should be two opposing emergency exits from the loading/unloading area.

- Exits should be clearly marked and open outwards.

- Vapours which are displaced during the transfer operation should be returned to the donor tank via a vapour-tight connection line.

- The vapour return line should have a different connection fitting compared to that of the product transfer hose. This is to ensure there can be no misconnection;

- The vapour return line should be connected before the product transfer hose is connected.

- There should be a device on the vehicle which locks the brakes in the “on” position when the vapour recovery line is connected.

- A competent person shall be given the responsibility to monitor all the hose connections during loading/unloading operations.

- Any uncontrolled release of vapour should be recorded in the vehicle log book and reported to the authorities.

- There should be a pre-formulated spillage plan ready to deal with any spillages, and a spillage kit at the ready. This kit should include bunding.