Use the search below to find question.

Amount of questions: 172 .

Right answers marked with this sign

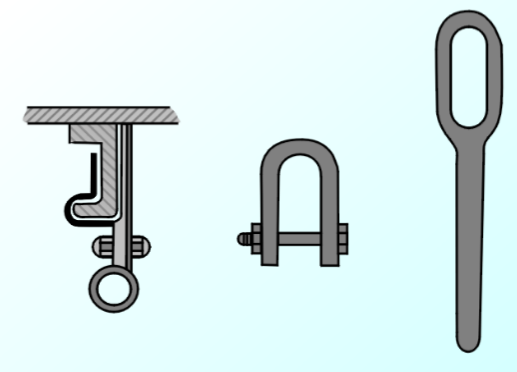

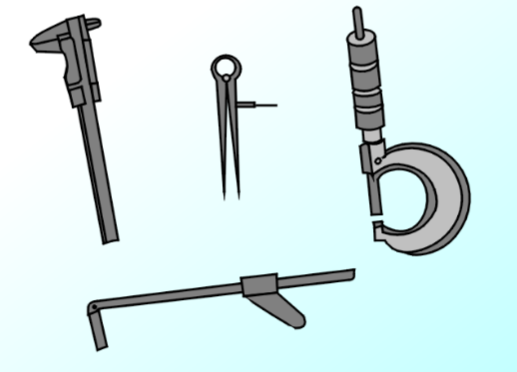

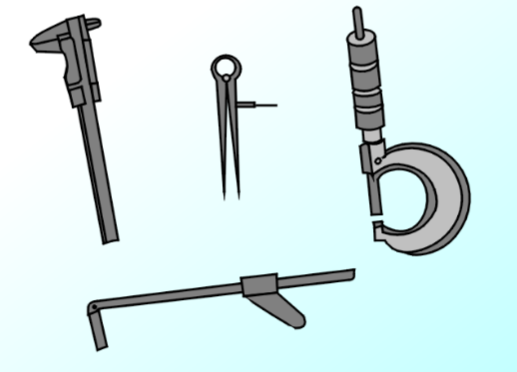

What is the fastening device shown at the left side of the drawing?

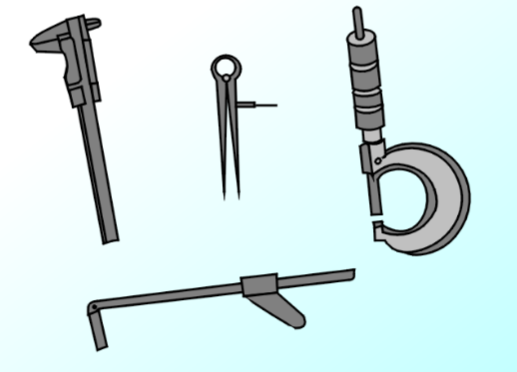

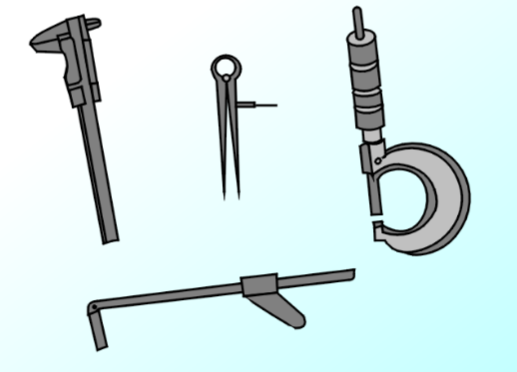

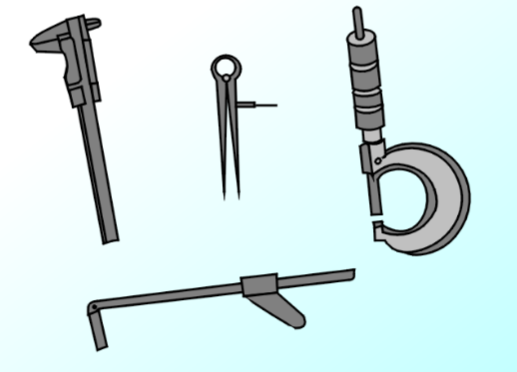

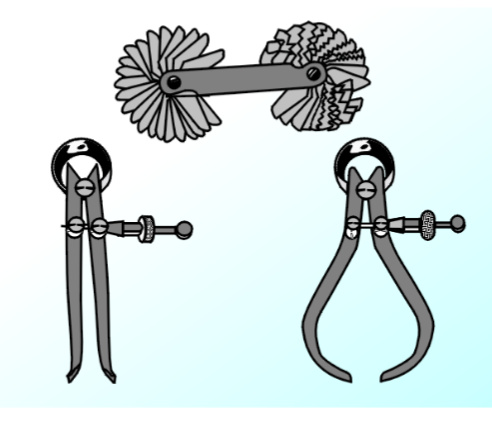

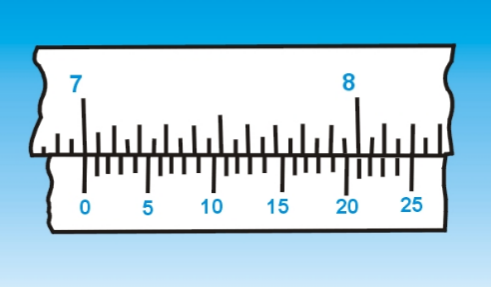

What is the measuring instrument shown on the left top?

What is the accuracy of the measuring instrument shown on the top left?

millimetre .

millimetre .

millimetre .

millimetre .

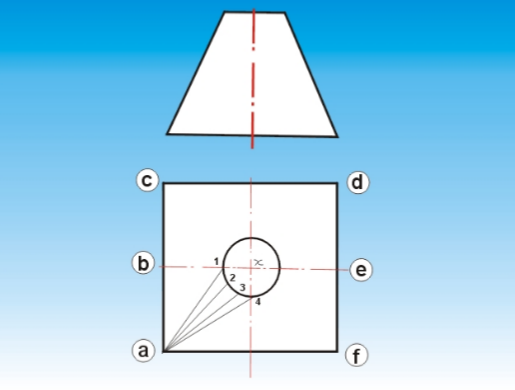

Suppose you need to draw a circle of 186 mm diameter on metal or on a packing sheet. How would you do this using the compass shown top centre?

mm on packing, draw 2 lines through the centre.

mm using a steel ruler.

mm , 93 mm and 186 mm on packing.

What is the accuracy of a micrometer shown top right?

millimetres .

millimetres .

millimetres .

millimetres .

What is the measuring device shown at the bottom?

degree angle projector.

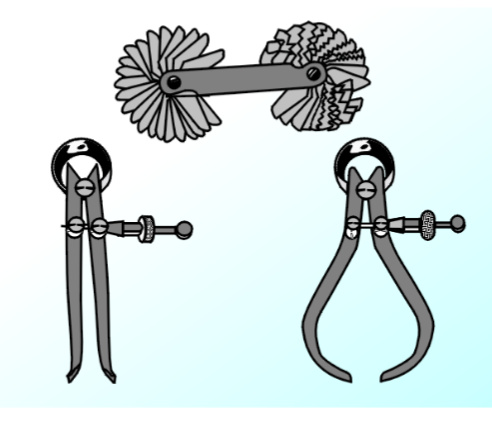

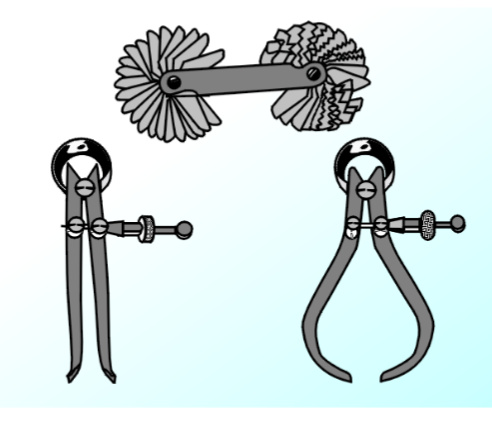

What is the measuring device shown in the top and what is it used for?

What measuring device is shown in the bottom left corner?

What is the purpose of the calliper shown in the bottom left corner?

What is the measuring device shown in the right bottom corner?

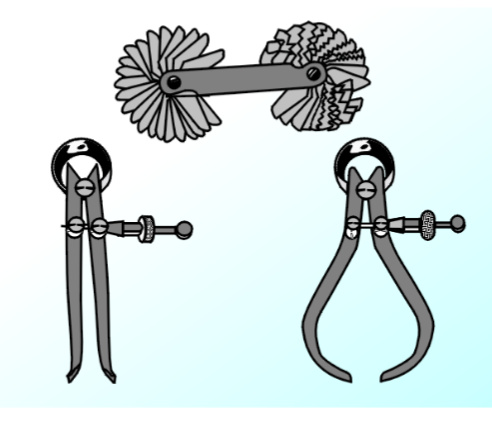

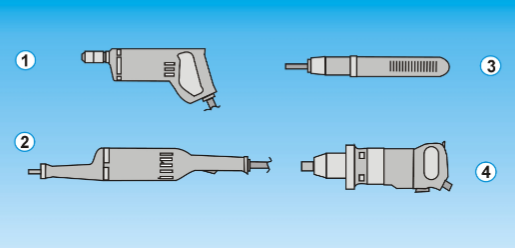

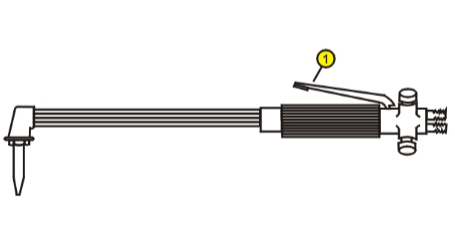

How will the tool shown at the top be powered if it is to be used on tankers?

Volt maximum.

AC power 110 Volt , 60 Hz maximum.

kg/cm2 maximum.

kg/cm2 maximum.

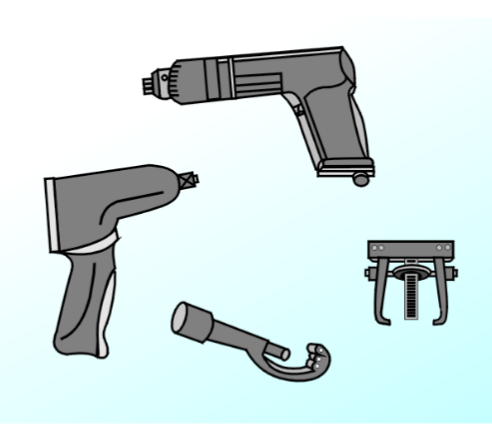

For what are RECOIL-LESS HAMMERS used?

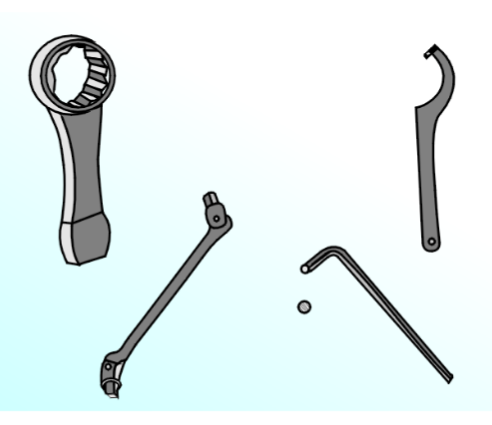

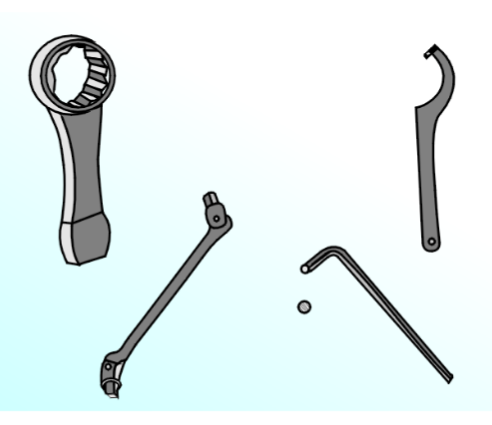

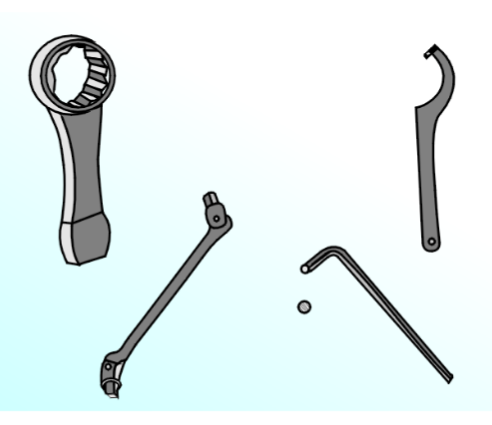

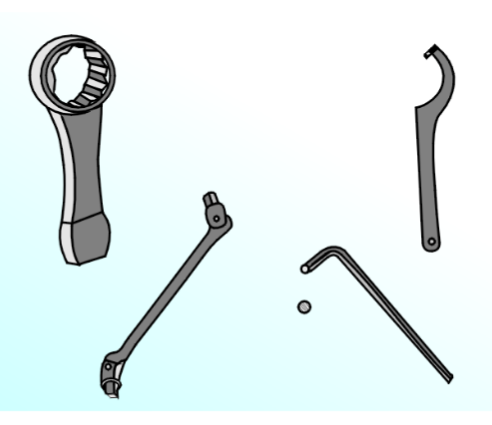

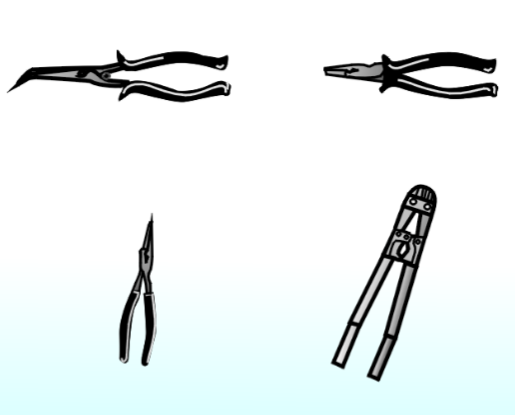

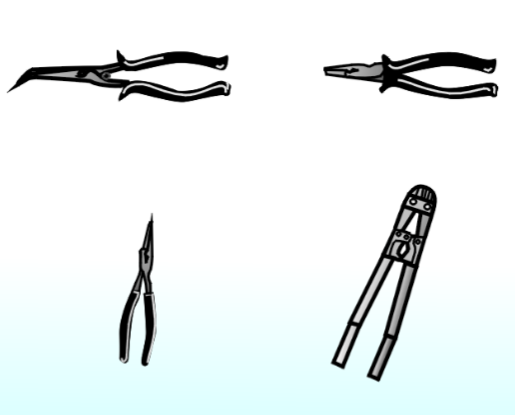

What kind of tool is shown top left and for what is it used?

What is the tool shown upper right?

What tool is shown bottom left and for what is it used?

degree out of line wrench.

What kind of tool is shown right bottom and into what does it fit?

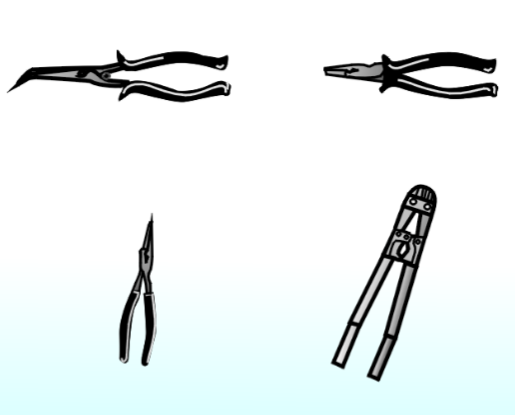

What kind of wrench is shown upper left?

What kind of tool is shown upper right?

What is the tool shown bottom left?

What kind of tool is shown top right?

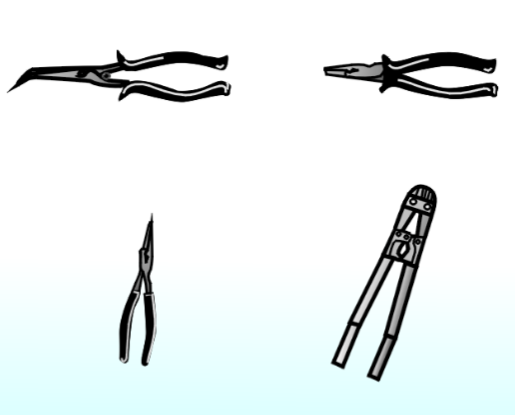

What is the tool shown top left?

What kind of tool is shown bottom left? How can it be extended?

What kind of tool is shown bottom right bottom?

What kind of assembly does the upper left piece and the upper centre piece make?

What kind of tool is shown on the bottom left corner of the picture and when is it used?

What kind of tool is shown bottom centre?

On what equipment should the wrench shown bottom right be used?

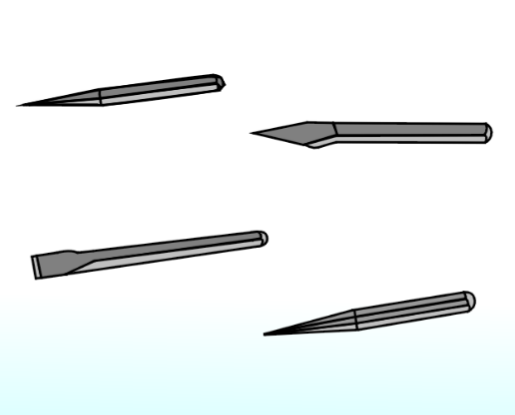

The tools shown here are …………….?

What is the tool shown top left called and by whom is it mostly used?

What is the tool shown top right and by whom is it used?

What is the tool shown bottom left and by whom is it used?

What kind of tool is shown bottom left? What is its use?

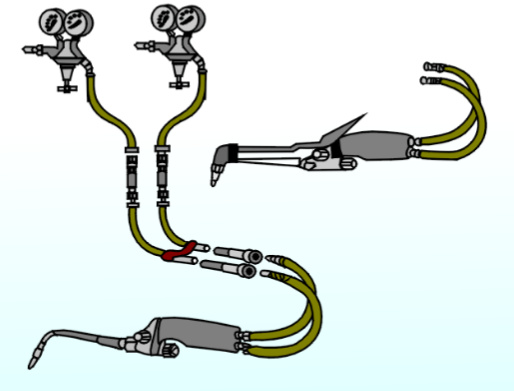

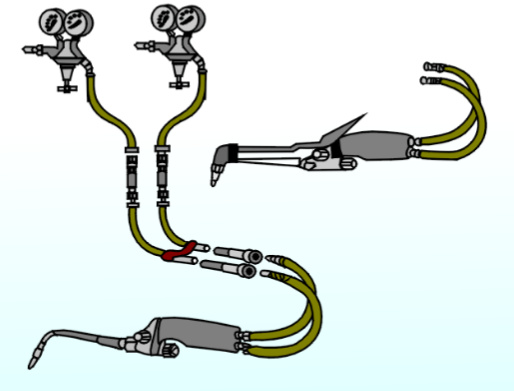

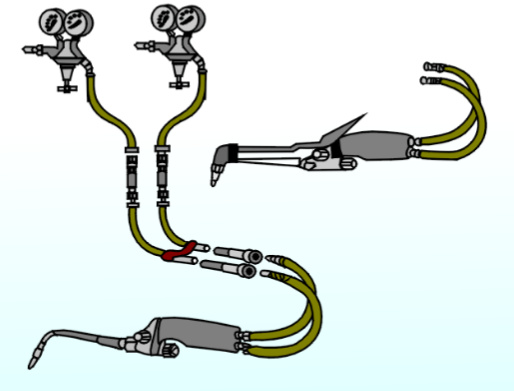

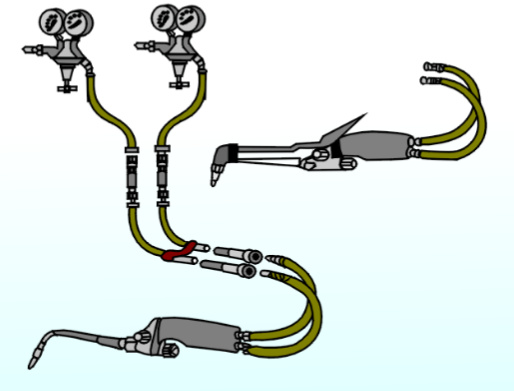

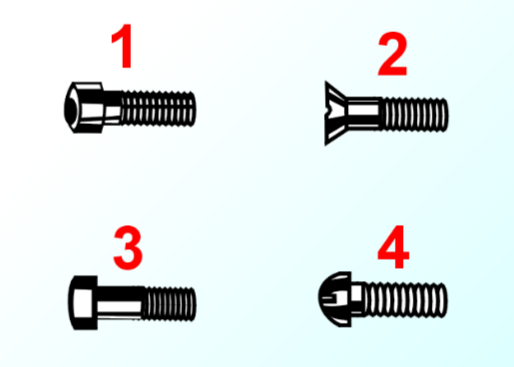

If the welding torch and the oxygen/acetylene pressure regulators are fitted in the engine room workshop, to what should they be connected?

When igniting the welding torch, how would you proceed?

What is the gas welding equipment shown right side?

How should oxygen and acetylene bottles be transported?

Depending on the plate thickness to be cut you should increase …………….?

If you are welding in the workshop, you must ensure in advance that the bridge is told and that:

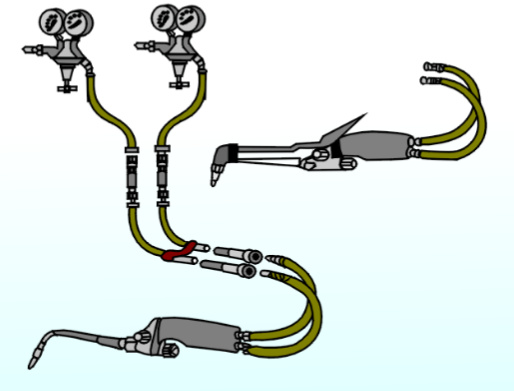

What is the function of this hydraulic stressing tool when fastening and unfastening bolts/nuts on an engine?

The “scleroscope ” is used to determining:

hardness ” of a metal.

thickness ” of a metal.

brittleness ” of a metal.

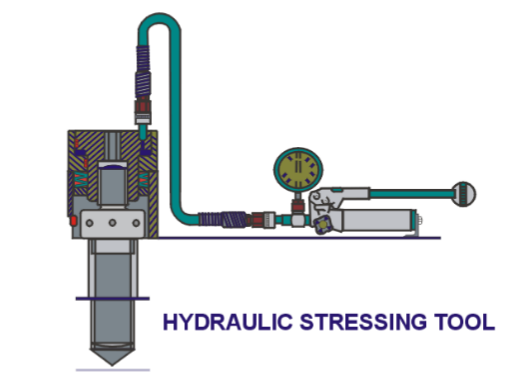

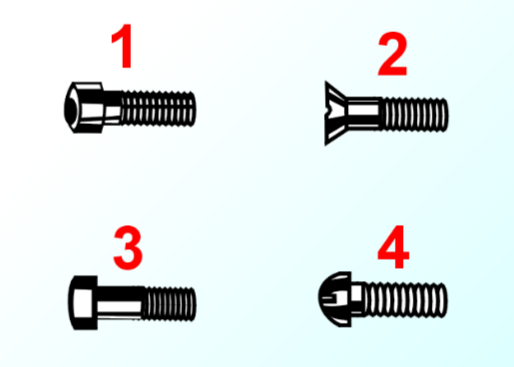

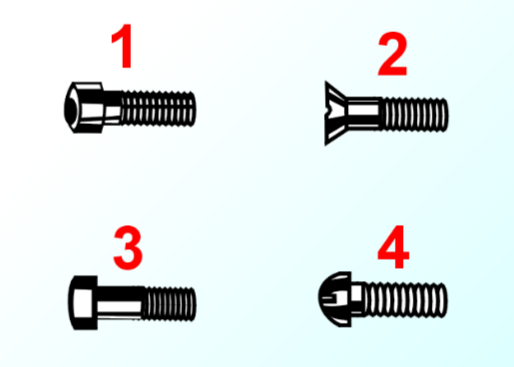

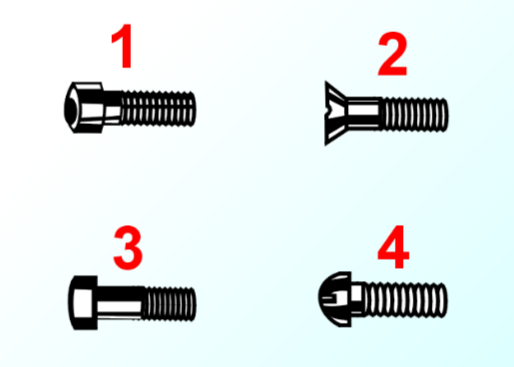

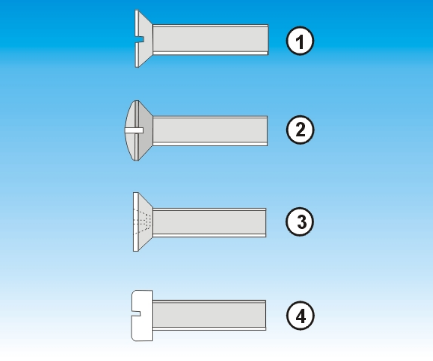

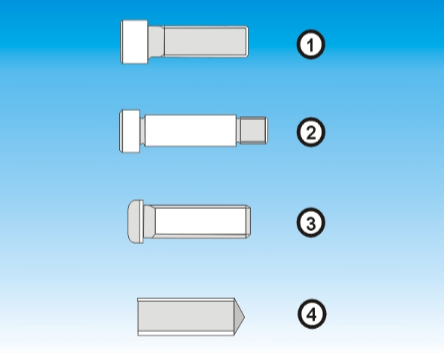

Which of these four screws is a fillister head screw?

What type of screw is No. 2?

What type of screw is No. 3?

What type of screw is No. 4?

For cutting hard materials, metal saws with ……. blades should be used?

When starting to tap a hole, how is the process checked for perpendicularity?

What general name is given to files which remove maximum metal in the shortest time?

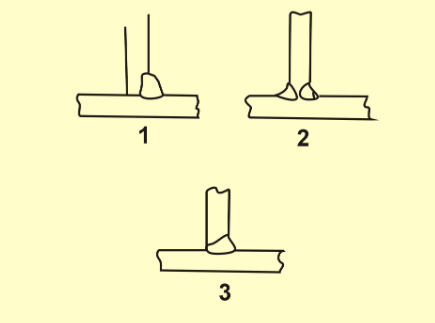

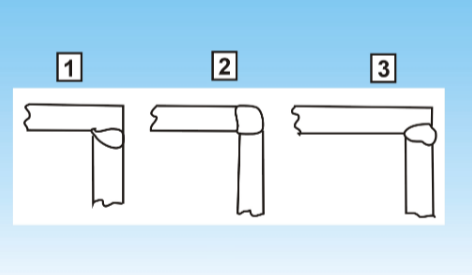

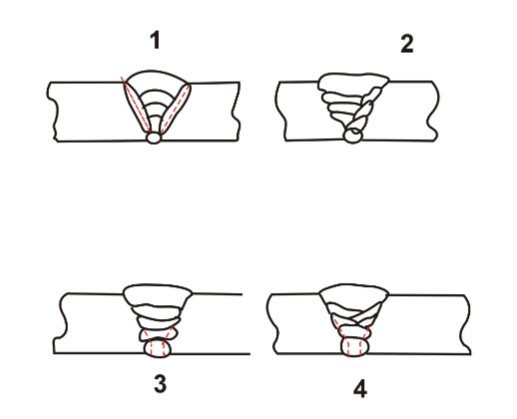

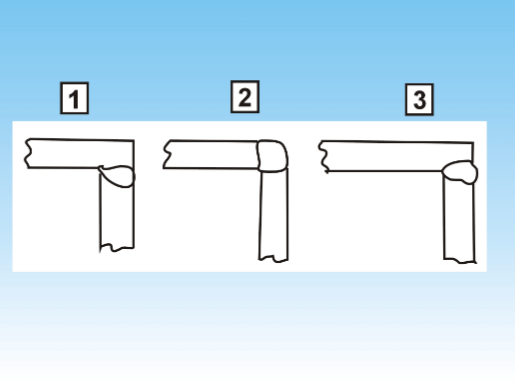

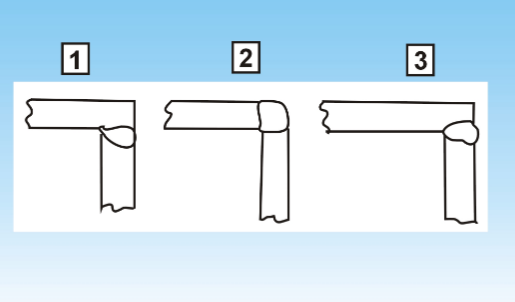

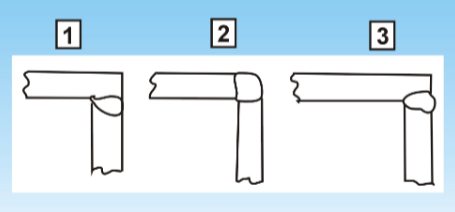

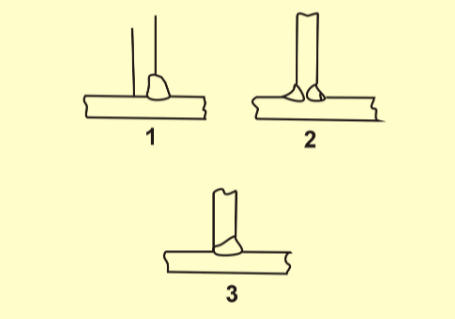

The figure shows welded tee joints. What preparation is required for No. 2?

When fitting new bottom ends to a small diesel engine, the bottom end bolts have no locking devices. Which of the following should be fitted.

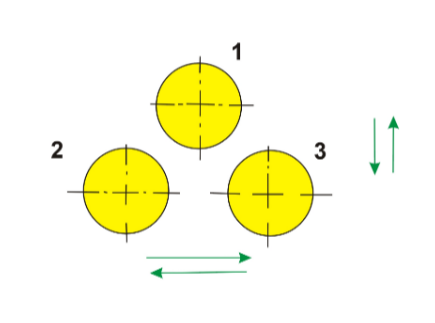

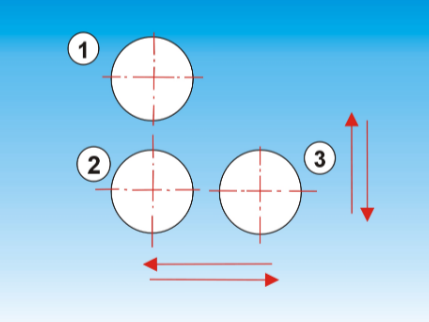

The sketch shows the rollers for a pyramid rolling machine. Which is the idler?

What device is fitted to prevent component gases mixing in hoses?

The diagram shows four types of machine screws. Identify the cheese head screw.

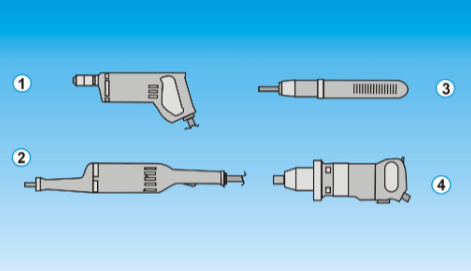

Identify the powered hand tool No. 2?

Perspex is an example of a thermoplastic, how is this best heated prior to bending?

It is required to make a drip tray. What machine would be used?

In readiness for use, a good scraper would have it’s cutting edges?

A method of joining two plastics together is by solvent welding. What is this process?

When gas cutting a mild steel plate, what does the size of nozzle used depend upon?

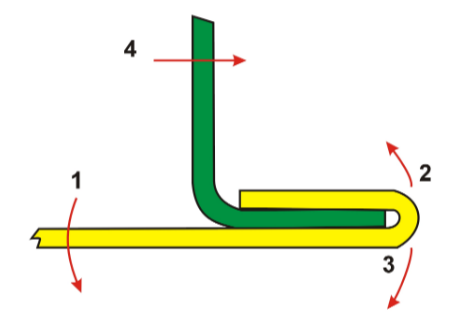

The sketch shows a partially completed knocked up joint made from 0,5 mm plate. Which direction of bending completes the joint?

A short box girder is fabricated from 8 mm steel plate. What edge preparation is required for No. 2?

Welding fumes can be dangerous. When welding in the workshop how is welding rendered safe?

Which set of equipment is required to mark out the keyway of a 30 mm diameter shaft?

A blind hole in a valve casing requires to be tapped 12 mm . Which tap(s) would be used?

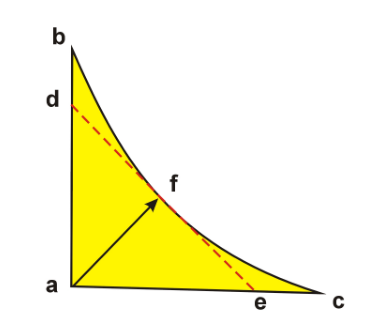

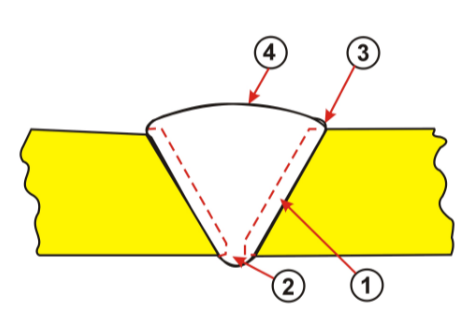

For the fillet weld shown, what is the throat length?

A crankcase weld requires detailed inspection while on passage. How would this be carried out?

Which gas is NOT commonly used as a fuel when cutting steel plate?

When bonding together two metal components, what is the correct sequence?

When gas welding, which is the most likely cause of a serious accident?

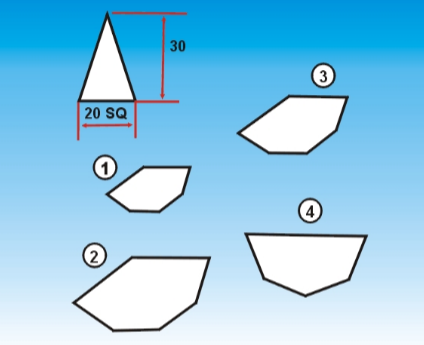

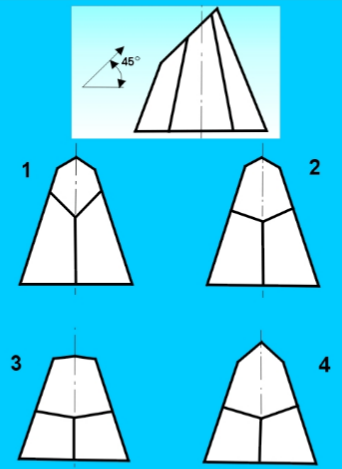

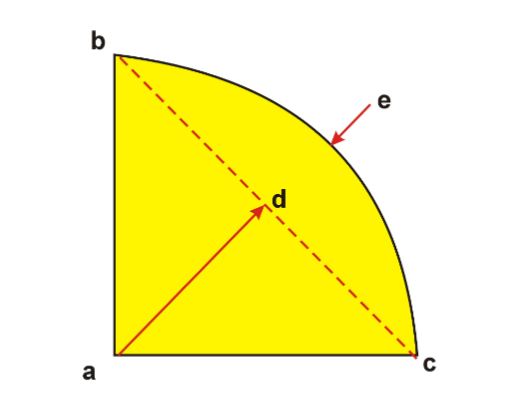

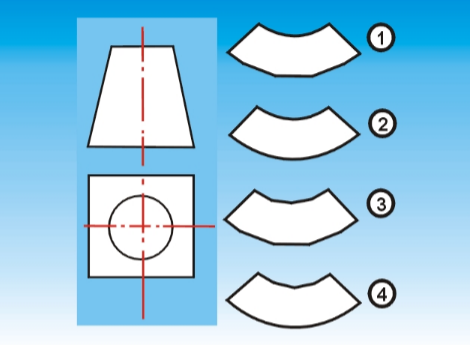

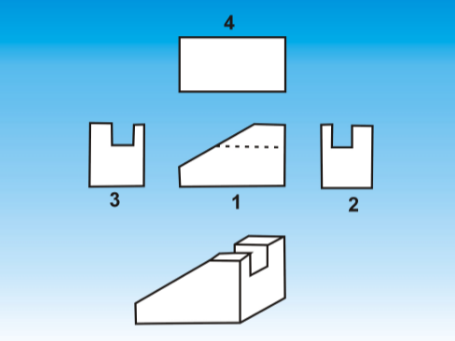

For the square pyramid float component shown, which is the correct development?

Which of the materials listed can be cut using an oxygen fuel gas mixture?

What is the limiting factor of a visual inspection of a weld?

When working with bonded resins what is their useable pot life?

minutes .

minutes .

minutes .

minutes .

What general name is given to files used for finishing?

Which column gives the correct factors for a clean cut edge preparation?

Which of the following size nominations is most commonly used?

What is the plate thickness limit for hand-operated folding machines?

mm .

mm .

mm .

mm .

Which system uses a tungsten electrode, causing an arc between itself and the metal to be cut?

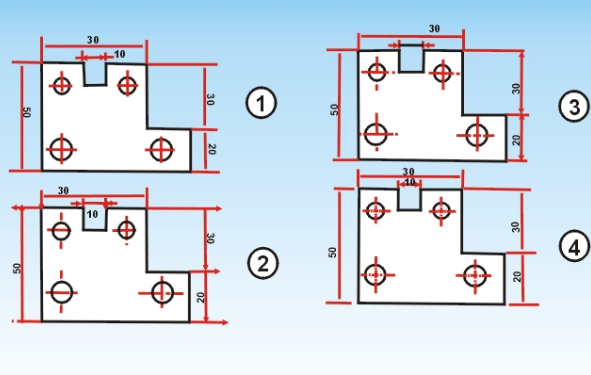

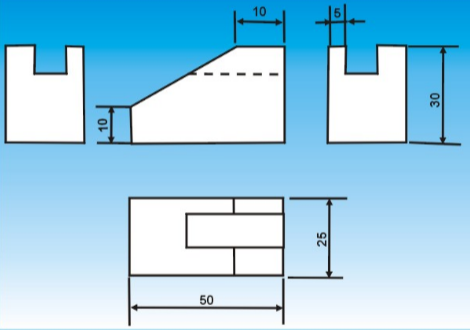

A repair to a compressor requires a plate of the form illustrated to be designed. Which illustration is dimensioned to be the correct standard.

The speed and feed for a 20 mm diameter reamer would be?

A scriber should not be used for marking out?

Hoses are easily damaged and require special care for long life, but what are they reinforced with?

The diagram shows four types of socket head screws. Identify the socket shoulder screw.

What dictates the size of drill hole required prior to cutting an internal thread?

When welding at a bench, which list of equipment would be used?

Which of the following effects could be reduced if hand powered tools were used?

What effect will an undersized vee width have on the form produced?

Which correctly identifies a full acetylene cylinder?

bar right hand thread black colour.

bar right hand thread blue colour.

bar left hand thread maroon colour.

bar left hand thread red colour.

Which material is difficult to weld due to porosity?

When out of use temporarily, how should the workshop surface plate be stored?

A 1,3 m long slot is to be marked off on the floor plate but only a 300 mm straight edge is available. How is this overcome?

What is the softening temperature for PVC ?

Which type of examination reveals pin holes, slag inclusion and lack of fusion?

What is a trammel used for?

A frustrum of a hexagonal pyramid is shown. Which drawing goes to the left of the figure in third angle projection?

What is the effect of low pressure cutting oxygen?

The Vernier protractor gives an angular accuracy of?

minutes of angle.

minutes of angle.

minute of angle.

minute of angle.

Dimensions are read from the bottom of the drawing but if this is not possible what is the next choice?

RH side.

RH side.

LH side.

RH side.

After sharpening a twist drill, which points are the most important to check?

When fitting a blade into a hacksaw, which direction should the teeth be pointing relative to the handle?

degrees to normal.

degrees to normal.

In the following gas flame temperatures, which is the oxy-acetylene?

During a plasma cutting process the workpiece was not totally penetrated. What would be the most likely problem?

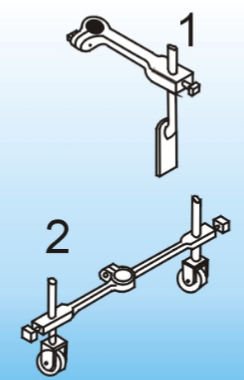

What is shown in No. 1?

How does the brake press differ from the other forming machines?

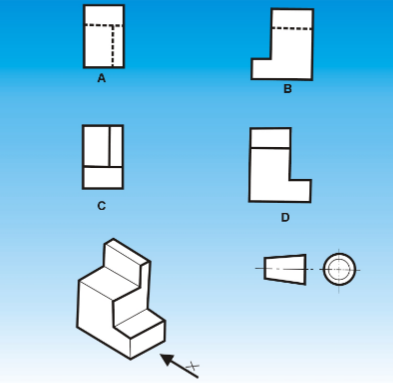

When using third angle projection, viewing the component from x, which drawing will be above the front elevation?

A flashback arrester has been triggered. Which is the correct sequence to follow after this event?

When self-secured joints are to be made, which tool is most useful?

Which table best describes the flexible hacksaw blade?

If a gas pressure gauge is over-pressured and bursts, what feature minimizes damage?

The sketch shows the two scales of a Vernier caliper. What degree of accuracy will a measurement have?

When two pieces of metal at right-angles are welded together, what weld is used?

What condition must exist in order to cut using an oxygen fuel gas mixture?

Why is a high pressure blow pipe unsuitable for use in a low pressure system?

The engine room workshop carries different types of hacksaw blades. Which blade should be used to cut sheet metal?

cm .

cm .

cm .

cm .

A centre punch has a 60° point for?

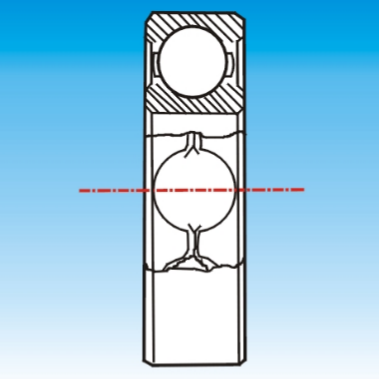

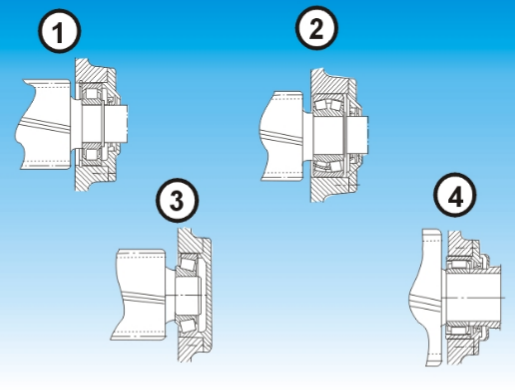

What type of ball-bearing is shown in the illustration?

If two pieces of metal are welded together while laying in the same plane, this is known as?

Which table would give the best checklist following an arc welding process, checking for:

In the system of limits and fits shown, on what basis has the drawing been made?

A white metal lined bearing is to be fitted on to a shaft. Which combination would be used?

For the fillet weld shown, what is the throat length?

What is the greatest danger when working with sheet metal?

A flat chisel requires tempering; which temperature and colour is correct for this process?

Thick plates require a multi-run weld. Which type of runs are used?

Identify the powered hand tool in No. 1?

The square to round section shown requires a template. What forms the triangular base line from which the true lengths are obtained?

How is the emergency stop button indented on workshop machinery, for example, the lathe?

In electric arc welding, what purpose does the the electrode coating serve?

Which of the four bearings shown provides positive location?

The figure shows welded tee joints. What preparation is required for No. 3?

All mechanical cutting devices have the same basic features. These are?

The engine room workshop has a bench shear. What is the maximum thickness of mild steel it will cut?

mm .

mm .

mm .

mm .

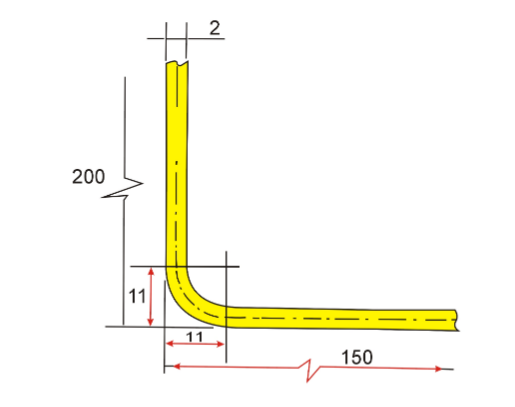

For the cover shown, what length of plate is required?

mm .

mm .

mm .

mm .

How does a two-stage pressure regulator give precise control?

When using a centre lathe what operation could a hacksaw be used for?

A chisel is refurbished and requires the cutting end to be tempered after hardening. How is this achieved?

In the following, which gives advantages only for adhesive bonding?

What is significant about the spring-back hacksaw blade?

The drawing of an engine mechanism component gives some surfaces as angles. How would these angles be marked out?

An acetylene welding cylinder is packed with charcoal and charged with acetone. At 15 bar by how many times will it absorb its own volume?

A short box girder is fabricated from 8 mm thick steel plate. What edge preparation is required for No. 1?

Which of the tables of defects would lead to porosity in a welded joint?

What feature of a good weld is indicated by No. 4?

Mild steel plate 2 mm thick bent in vees would produce an approximate inside bend radius of?

mm .

mm .

mm .

mm .

What is the system called which gives explicit instructions on drawings which cannot be misinterpreted?

When carrying out a repair using a bonded resin what precautions should be observed?

Looking at the drawing, can this component be made?

Which is the preferred table to be checked to ensure a sound weld is produced during an arc welding process?

What presents the greatest danger when sharpening a chisel on a grinding machine?

When tempering a cold chisel, at which part of the chisel is the flame directed?

What may be done to improve the finished appearance of a self-secured joint?

What special care do an engineer’s dividers need:

Thermoplastic type adhesives soften when subject to heat, are fusible and soluble. They are not suitable for?

The ventilation trunk shown goes from square to round section. What does its development look like?

To make a single grooved seam from 1 mm plate, in what order would the following operations be carried out?

In the method of datum dimensioning (sometimes known as parallel dimensioning), what is the advantage over conventional dimensioning?

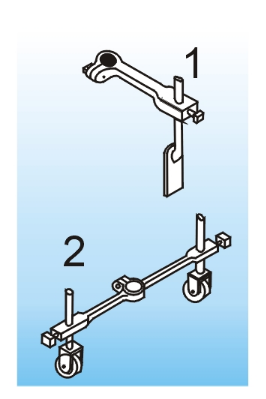

What is the attachment shown in No. 2?

The safety features for a welded acetylene gas cylinder are?

The sketch shows the configuration of a pinch bending roll. How does this operate?

A short box girder is fabricated from 18 mm thick steel plate. What edge preparation is necessary for No. 3?

A component with a working temperature of 325 °C is to be joined using epoxy resin. Which of the following is suitable?

The figures show welded tee joints. What preparation is required for No. 1?

Prior to welding, plate edges are prepared to?

Which system of welding uses a shield of Argon and a non-consumable electrode?

For a particular welding arrangement, the decision is to use a manifold system. Why would this be chosen?

Plates of less than 6 mm thickness (T) have no edge preparation but what ratio of (T) is the gap?

When tempering use is made of the microscopic oxide film formed on the surface, in what sequence does change occur?

A 90° centre punch is specifically designed to?

Given a set of odd-leg calipers and a small cork, what use is the cork?

In the sketches, which view is incomplete?

If a view is projected in a direction which is not horizontal or vertical, what name is given to the view?

Sketch shows a gas cutting blowpipe. What is control No. 1 used for?

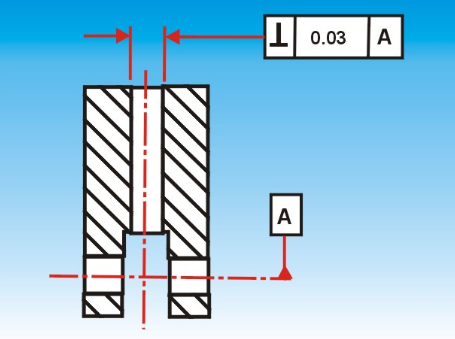

What does the geometrical tolerancing shown in the drawing refer to?