Foundational Principles of Pipeline Transmission Networks

The engineering discipline governing high-pressure NG-transmission focuses on the movement of hydrocarbons from extraction zones to end-user distribution grids. The architectural planning and operational management of these extensive infrastructures are vital for ensuring an uninterrupted and dependable energy supply. Critical architectural elements include compressor stations, which are tactically located to sustain pressure and guarantee consistent flow over vast distances. Ensuring the structural integrity and security of the entire pipeline network is of utmost importance, necessitating sophisticated monitoring and control mechanisms to handle the substantial operational pressures and volumetric throughput.

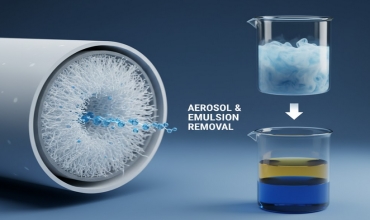

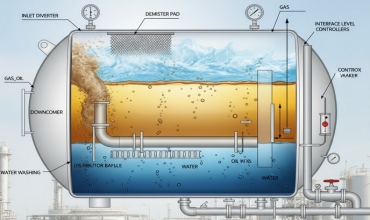

The Interdependence of Gas Treatment and Transport Infrastructure

The operational efficacy of any long-distance pipeline network is fundamentally connected to upstream treatment technologies. Prior to entry into the high-pressure transmission conduits, the hydrocarbon stream must undergo purification to eliminate contaminants such as water vapour, carbon dioxide and hydrogen sulphide to comply with rigorous pipeline quality standards. This purification process is indispensable for preventing corrosive degradation, hydrate crystallization and structural impairment to the infrastructure itself. Consequently, the engineering of treatment facilities requires meticulous coordination with the operational frameworks of the transportation system to assure both product stream quality and the preservation of pipeline assets.

Innovative Progress in Transport System Management

Contemporary technological developments are persistently transforming the operational paradigm of gas logistics. The deployment of advanced Supervisory Control and Data Acquisition (SCADA) systems enables comprehensive real-time operational command over extensive pipeline networks, thereby augmenting both security and operational efficiency. Moreover, the creation of progressive inline diagnostic instruments, commonly referred to as “smart pigs,” facilitates preemptive integrity management within the transmission pathways, enabling the identification of potential complications prior to their maturation. These technological developments are indispensable for the strategic modernization and performance optimization of worldwide gas transportation infrastructure.