LNG project management encompasses a multifaceted approach to overseeing the planning, execution, and Regulations and Rules for Vessels to Carry Liquefied Gasdelivery of liquefied natural gas (LNG) projects from inception to completion. This involves coordinating various stakeholders, managing resources, mitigating risks, and ensuring compliance with regulatory requirements. Effective project management in the LNG sector requires a deep understanding of technical, commercial, and regulatory aspects, as well as the ability to adapt to dynamic market conditions and emerging technologies. ABS (American Bureau of Shipping) Quality Assurance (QA) system plays a crucial role in LNG project management by providing a framework for ensuring that projects meet industry standards, regulatory requirements, and client specifications. ABS’ QA system encompasses comprehensive processes for quality control, documentation management, risk assessment, and performance monitoring throughout the project lifecycle. By adhering to ABS’ QA system, LNG project managers can enhance efficiency, minimize errors, and deliver projects on time and within budget while upholding safety and environmental standards.

For Korean projects, the location of plan review holds significant importance in LNG project management. Given the substantial involvement of Korean shipyards and engineering firms in LNG projects, plan review activities often take place at designated locations in South Korea. These locations typically include major shipbuilding hubs such as Ulsan, Geoje and Busan, where leading shipyards like Hyundai Heavy Industries, Samsung Heavy Industries, and Daewoo Shipbuilding & Marine Engineering are based. Conducting plan reviews at these strategic locations allows ABS and other stakeholders to collaborate closely with Korean partners, expedite communication, and ensure alignment with local regulations and industry practices. Additionally, proximity to shipyard facilities enables efficient coordination of inspection activities, prototype testing, and project milestones, contributing to the overall success of LNG projects managed in partnership with Korean entities.

ABS QA System and Project Managment

All ABS engineering, survey and management activities are governed by our quality system which includes documented procedures and detailed work instructions for each activity. The ABS quality system is designed and certified to meet all aspects of both the IACS Quality System Certification Scheme (IACS QSCS) and ISO 9001-2000 requirements as well as additional quality objectives of ABS.

Project management is an essential element to the success of any program of the magnitude of LNG projects. Therefore, in keeping with our quality policy, establishment of an effective project management team is a key element to ABS’s approach.

Read also: Safety, Risks and Security Aspects in Liquefied Natural Gas Industry

Once the formal agreement for classification is signed, ABS project management will consist of two aspects.

First, Engineering Project Managers will be assigned for each of Hull and Machinery to provide sources for coordinating drawings and analyses. The Engineering Project Managers provide periodical reports on plan review status and analyses. The duties of each Engineering Project Manager are extended to the major shipyard equipment and materials suppliers.

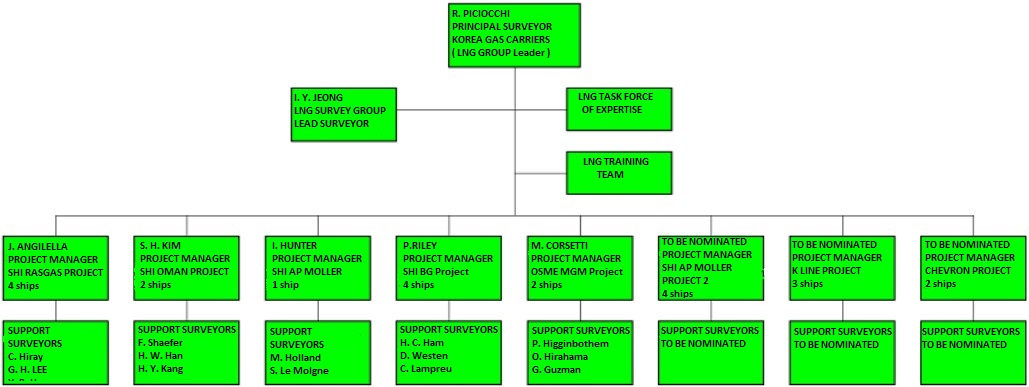

Second, due to the emphasis ABS places on classification of LNG Carriers (LNGC) and our understanding of the level of technical expertise required for fabrication of these vessels, a specialist LNG Survey Team under the direction of a Project Manager Gas Carriers has been created as part of ABS Korea Operations. The Project Manager – Gas Carriers is assisted by the LNG Task Force that gives him technical advice any time there is the necessity.

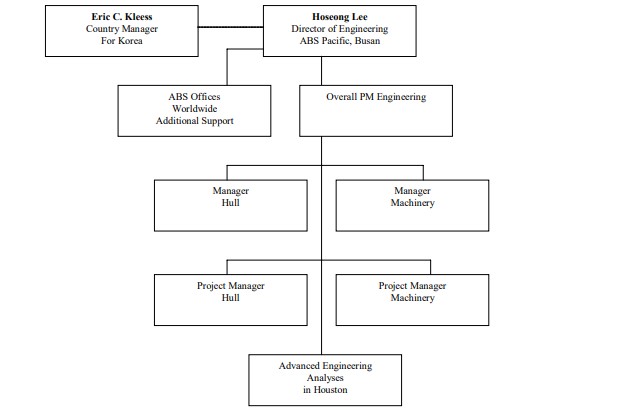

Project Organization – Engineering

Engineering Organization Chart for a LNG project is outlined in Figure 1.

Project Organization – Surveys

Survey Organization Chart for all current

Location of Plan Review for Korean Projects

Plan approval takes place at the ABS Pacific Busan Office by resident assigned ABS engineers certified to carry out the appropriate review. However in some cases part of the project may be assigned to another ABS office where there is the necessary expertise or where the geographical location may render easier the contacts with the designer of particular equipment or systems.

Each regional office involved will co – ordinate with the Project Manager, who will remain the single point of contact for the entire project and will reside in Korea.

Location of Detailed Engineering Analysis

Performance and review of detailed Det Norske Veritas Fatigue Analysis of Natural Gas Carriersengineering analysis, such as seakeeping analyses, structural analyses, spectral fatigue analyses, sloshing analyses, etc.; will take place either in Busan or in the ABS Americas Houston office by the Advanced Analysis Department.

Project Personnel (Engineering / Technical Advice)

For each LNG carrier to be built in Korea with ABS class, a number of lead engineers and surveyors for the noted disciplines are selected. Other professional staff will be assigned to the project, as warranted during the various design / survey phases of the project from the ABS Corporate Office and ABS Marine Operating Divisions.

The following tables list the names of key engineers from ABS Busan office that will be assigned to a LNG project, plus some of the available worldwide supports for advanced analysis and technical advice.

| Hull Structures, Cargo Containment System | ||

|---|---|---|

| NAME | TITLE | OFFICE |

| L. G. Motta | Manager – Hull | Busan |

| J. H. Yoon | Senior Engineering Specialist | Busan |

| I. T. Choi | Senior Engineering Specialist | Busan |

| M. Y. Hwang | Engineering Specialist | Busan |

| I. H. Ryu | Engineer | Busan |

| Ship Machinery, Equipment , Piping and Cargo Handling System | ||

|---|---|---|

| NAME | TITLE | OFFICE |

| S. K. Byun | Manager – Machinery | Busan |

| H. M. Kim | Principal Engineer | Busan |

| J. Y. Kim | Senior Engineer | Busan |

| S. H. Shon | Engineering Specialist | Busan |

| Additional Worldwide Support Service – Seakeping Analysis, Structural Analysis, Spectral Fatigue Analysis, Sloshing Analysis | ||

|---|---|---|

| NAME | TITLE | OFFICE |

| R. I. Basu | Manager | Houston (USA) |

| E. H. Kotte | Chief Engineer | Houston (USA) |

| H. S. Lee | Staff Consultant | Houston (USA) |

| Additional Worldwide Support Service – Technical Advice | ||

|---|---|---|

| NAME | TITLE | OFFICE |

| M. A. McGrath | Regional V. P. | Yokohama |

| T. Kaibara | V. P. of Engineering | Yokohama |

| S. Bond | Principle Engineer SED London | London |

| S. Penso | Country Manager | Genoa |

The ABS LNG Focus Group

Due to the importance of the LNG projects ABS has established a special working group named LNG FOCUS GROUP. The main purpose of this group is to devote efforts to increase the LNG market share. Other purposes are to support the ABS Divisions giving presentations, collecting data, identifying the necessities of new Rules, Guides, Instructions, and helping to develop them. Some members are also members of Industry forums, such as SIGTTO and NFPA.The Group is chaired by Bud Roth and is actually composed as indicated in the following table:

| NAME | TITLE | OFFICE |

|---|---|---|

| Bud Roth | Senior Vice – President and Chief of Staff | Corporate |

| Bill Senber | Vice President – Energy Project Development | Corporate |

| Jim Gaughan | Senior consultant | New York |

| Mumtaz Mahmmod | Director – Technology Development | London |

| Akira Akijama | Vice President – Technology & Business Development | Yokohama |

| Haseong Lee | Director of Engineering | Busan |

| A. K. Seah | Vice President – Technology & Business Development | Singapore |

| Rick Nelson | Vice President – Technology & Business Development | Houston |

| Young Shin | Manager | Corporate |

| Raffaele Piciocchi | Principal Surveyor – Project Manager Gas Carriers | Koje |