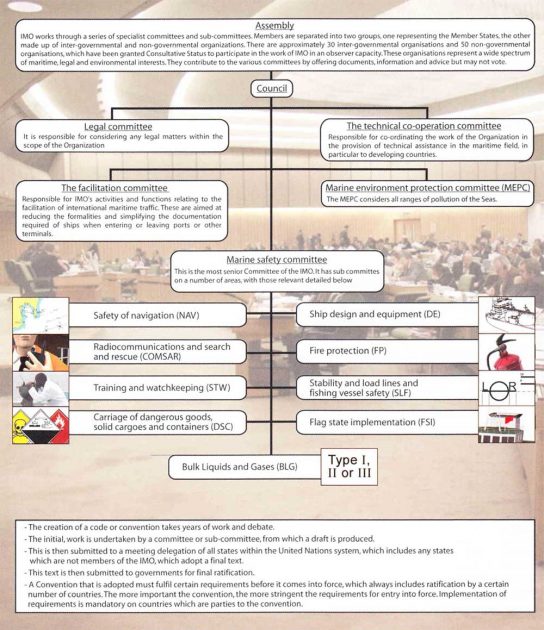

Vessels, which carry LNG or LPG should follow rules and regulations. It is the IMO’s global responsibility to develop international standards and adopt conventions on many aspects of marine operations, including shipping liquefied gas. This responsibility is discharged through a number of codes, recommendations, treaties and guidelines.

- The IMO Codes for Liquefied Gas Tankers

- Background

- The International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk (IGC Code)

- International Convention on Safety of Life at Sea (SOLAS-74)

- International Convention for the Prevention of Pollution from Ships (MARPOL-73)

- International Convention on Standards of Training, Certification and Watch keeping for Seafarers, 1978 (STCW) as amended 1995

- Inter-Industry Organisations

- International Chamber of Shipping (ICS)

- Oil Companies International Marine Forum (OCIMF)

- Society of International Gas Tankers and Terminal Operators (SIGTTO)

- The Classification Societies

- Ship Inspectorate Groups: SIRE and CDI

- Form “C”

The main conventions that apply to all vessels, including gas carriers, are:

- International Conference on Load Lines, 1966.

- International Convention on Safety of Life at Sea, 1974, as amended (SOLAS-1974).

- International Convention on Marine Pollution 1973/78 (MARPOL 73/78).

- International Convention on, Training and Certification of Seafarers, 1978 (STCW’78), as amended in 1995 (STCW’95).

Ships built before 1986 were recommended to comply with the IMO Gas Carrier Code (GC) and before 1976 with the Existing Gas Carrier Code (EGC) in addition to a “Certificate of Fitness”.

Ships built after 1986 are required to comply with the “International Gas Carrier Code” (IGC) and its applicable “International Certificate of Fitness”. This compliance is necessary to gain entry to a foreign port.

Packaged gases carried on other ship types e. g. Ro/Ro’s or Container ships are covered in the IMDG Code Glass 2.

The IMO Codes for Liquefied Gas Tankers

Background

The terms of reference of the IMO sub-committee on Ship Design and Equipment for Gas Carriers includes the following:

“To consider the construction and equipment of dangerous chemical substances other than petroleum and other similar flammable products normally carried in tankers, and to recommend suitable design criteria, construction standards and other safety measures to minimise the risk involved in loading, carrying and discharging such cargoes.”

Meeting this requirement, the subcommittee has considered:

- The hazards of each product in respect of the ship, its crew and the neighbourhood.

- Special hazards affecting the design or modification of the ship, such as specific gravity and the pressure and temperature at which the cargo is carried.

- The influence of hazards on the design, construction or modification of the ships carrying each class of product.

There are three IMO Codes currently in force for liquefied gas carriers:

- The Code for Existing Ships Carrying Liquefied Gases in Bulk (Resolution A. 329(ix) adopted 12 November 1975), which applies to gas carriers built or contracted before the 31st October 1976 (The EGC Code).

- The Code for the Construction and Equipment for Ships Carrying Liquefied Gases in Bulk (Resolution A.328 (ix) adopted 12th November 1975), which applies to gas carriers built between the 31st October 1976 and the 30th June 1986. (The GC Code).

- The International Code for the Construction and Equipment of Ships Carrying Liquefied Gas in Bulk (The IGC code) (Resolution MSC 5(48) adopted 17th June 1983 as amendment to SOLAS convention), which applies to gas carriers built on or after the 1st July 1986.

The IGC Code was made mandatory by amendments to SOLAS which required the code to be included in flag state legislation for all contracting governments that had gas fleets.

The International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk (IGC Code)

The underpinning philosophy of the IGC Code is to relate the ship type to the hazards of each of the products covered the Code, including cargoes transported under cryogenic or pressured conditions.

The code is based on established naval architectural and engineering principles, together with the best understanding available of product hazards. The Code is not a static document as it reflects the continuing development of gas carrier technology.

The IGC Code applies to all ships, regardless of their size.

A brief summary of each chapter in the IGC Code now follows. Further information will be found through reference to the full text.

1 Chapter 1 – General

This chapter deals with:

- Requirements for the specification of the Code;

- Date of entry (1st July 1986);

- Definitions of hazards, etc;

- Survey and certification;

- Survey requirements;

- Maintenance after survey so that the ship is maintained to conform with the provisions of the Code.

If the safety of a ship or the efficiency or completeness of its lifesaving appliances are affected by an accident or discovered defect, the Master or the owner of the ship should, at the earliest opportunity, report the matter to the administration or organisation responsible for issuing the relevant certificate.

An International Certificate of Fitness for the Carriage of Liquefied Gases in Bulk is valid for 5 years.

2 Chapter 2 – Ship Survival Capability and Location of Cargo Tanks

For each cargo, the Code aims to achieve a high level of safety by specifying the criteria for ship survivability after damage and the tank location and Liquefied Natural Gas and Liquefied Petroleum Gas Cargo Containment Systemcargo containment standards.

Ships subject to the Code are classed as either Type 1G, 2G, 2PG or 3G. Further details of these clarifications can be found in Types, Layouts and Designs of the Liquefied Gas Carriers (LNG/LPG)Understanding of the Liquefied Gas Carrier Types (LNG/LPG).

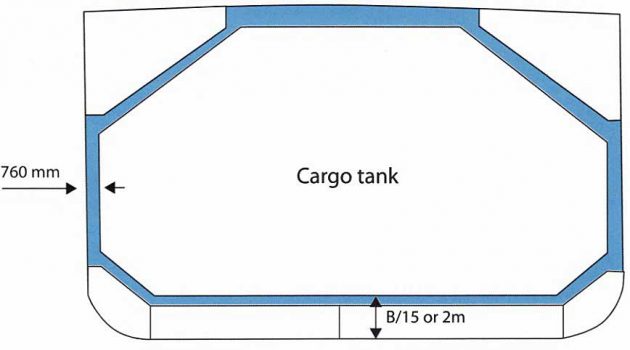

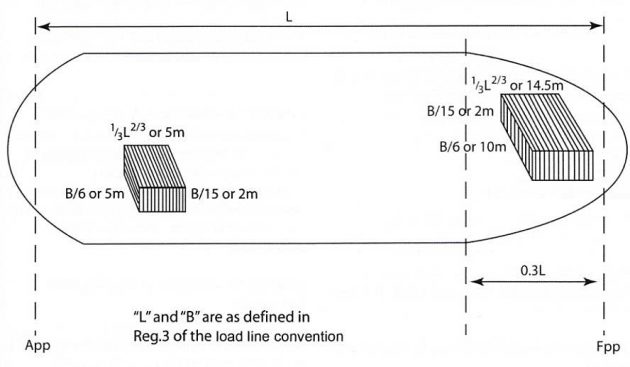

The intact stability of gas carriers in all conditions, including damage stability, should be positive (GM 0,15 m). The bottom and side damage that a gas carrier should be able to survive are as shown in Pictures 4.3 and 4.4.

3 Chapter 3 – Ship Arrangements

This chapter outlines the segregation standards for the ship, covering:

- Cargo tanks;

- Hold spaces;

- Cargo piping;

- Accommodation;

- Compressor rooms;

- Motor rooms, etc.

4 Chapter 4 – Cargo Containment

This chapter details the requirements for the cargo containment systems and types of tank including:

- Integral;

- Membrane;

- The Types, Layouts and Designs of the Liquefied Gas Carriers (LNG/LPG)independent tanks of Types “A”, “B” and “C”.

It includes specific details for design loads, structural analysis, allowable design stress, secondary barrier thermal calculations, materials, construction and testing.

All categories of tanks, except for independent type “C”, are generally restricted to a maximum vapour pressure of 0,25 bar although type “B” may be allowed to hold slightly more pressure.

| For all types of tanks, requirements are set for the provision of secondary barriers: | |

|---|---|

| For temperatures between -10 °C and -55 °C | The hull may act as a secondary barrier |

| For temperatures below -55 °C | A separate secondary barrier is required |

| When cargoes are carried at a temperature below -10 °C | Suitable insulation around the tank is required |

Integral tanks are usually limited to the carriage of cargoes that have a temperature of -10 °C or higher at atmospheric pressure.

5 Chapter 5 – Process Pressure Vessels and Liquid and Pressure Piping System

This chapter details the requirements for the design, construction and testing of cargo piping systems.

6 Chapter 6 – Materials

This chapter gives the requirements for plates, sections, pipes, forgings, castings and elements used in the construction of cargo tanks, cargo process tanks, cargo and process piping, secondary barriers and the hull structure.

7 Chapter 7 – Cargo Pressure/Temperature Control

This chapter covers the equipment and arrangements necessary for containment when the cargo is carried al a pressure below that corresponding to the ambient temperature. It covers boil-off gas by either reliquefaction or by combustion in the ships boilers, engines and similar equipment.

Only LNG can be used in the ship’s boilers as the vapour is lighter than air and any leaks would rise out of the E/R.

8 Chapter 8 – Cargo Tank Vent System

The requirements are given for pressure relief systems serving cargo tanks, spaces surrounding cargo tanks and cargo piping. This includes the capacity and arrangements of relief valves. Unless the tank is smaller than 20 m3, each cargo tank must be fitted with two pressure relief valves.

9 Chapter 9 – Environment Control

This chapter provides standards for the environmental control of:

- Cargo tanks and piping systems;

- Interbarrier spaces and void spaces;

- Vapour spaces of loaded cargo tanks;

- Holds, when inerting is not required.

The quality and control of the inert gas produced on board is also covered in this chapter.

10 Chapter 10 – Electrical Arrangements

This chapter defines the hazardous zones created by the products and the class of electrical equipment, including instrumentation that is required in them. Requirements for cargo pump rooms and electric motor rooms are specifically addressed.

11 Chapter 11 – Fire Protection and Fire Extinction

This chapter details standards for structural fire protection, fire protection arrangements in cargo handling spaces, sea water extinguishing systems and water spray systems in the cargo tank area.

A dry powder extinguishing system is specified for small flammable gas fires, recognising that extinction of a major gas fire would not be possible unless the source of gas is secured. Requirements for firemen’s protective clothing and outfits is included.

12 Chapter 12 – Mechanical Ventilation in the Cargo Area

This chapter covers the spaces normally entered during cargo handling operations and the spaces that are not normally entered. Location of intakes and exhaust, number of air changes and materials of construction for fans are also covered.

13 Chapter 13 – Instrumentation

Requirements are given for cargo tank level indicators and alarms, pressure gauges and temperature indicators in cargo systems and vapour detection equipment.

14 Chapter 14 – Personnel Protection

This chapter discusses requirements for protective clothing, gas masks and breathing apparatus, first aid and resuscitation equipment, decontamination showers and eye wash facilities and personnel rescue equipment.

15 Chapter 15 – Filling Limits for Cargo Tanks

Limits are specified to prevent a tank becoming liquid full by thermal expansion after loading. The maximum limit is considered to be 98 % (of the volume of the tank) liquid full at the reference temperature.

Some administrations allow for greater tank volume when carrying LNG, with some ships permitted to fill to 99 % volume. This limit takes account of the expected boil-off of vapours from the cargo tanks during the loaded voyage.

16 Chapter 16 – Use of Cargo as Fuel

This chapter describes the conditions under which LNG boil-off gas may be used as fuel. The necessary arrangements of piping, Valves and gas detecting equipment for safe delivery of the gas to the machinery are specified, as are the ventilation systems to ensure that there is no accumulation of hazardous vapours.

17 Chapter 17 – Special Requirements

The code incorporates special requirements for cargoes that have unusual characteristics.

18 Chapter 18 – Operating Requirements

This chapter deals with the operation of a gas carrier it highlights the regulations in other chapters that are operational in nature and includes other requirements unique to gas ship operation.

19 Chapter 19 – Summary of Minimum Requirements

This chapter links the product hazards to the ship design. For example, in determining the applicable ship type requirements, products are categorised as high hazard, medium hazards or low hazard.

International Convention on Safety of Life at Sea (SOLAS-74)

SOLAS-74 was adopted October 1974. SOLAS 1974 as amended represents the latest edition of a document kept under continuous revision.

SOLAS main objective is to lay down the basic design and equipment requirements to ensure that all ships comply with basic safety standards.

The following provides an overview of SOLAS, highlighting the specific items that are relevant to gas carriers:

SOLAS Chapter II-1: Construction – Subdivision and Stability, Machinery and Electrical Installations.

This chapter is about the soundness of the construction, permeability of the hull, sub- division of the hull and stability of the ship, particularly in damaged conditions. The provisions are primarily for passenger ships but also cover the requirements for cargo ships.

Read also: The Gases and Their Properties, Liquefaction Process (LNG/LPG)

Gas carrier sub-division and stability, as well as survival capability, are covered by the Gas Code. Other requirements for machinery and electrical installations are applicable to all ships.

SOLAS Chapter II-2: Construction, Fire Protection, Fire Detection and Fire Extinction

The pressure in the fire main on gas carriers should meet at least 5,0 bar (instead of 2,8) because of the installation of a water spray system.

Fire hoses must not have hose lengths that exceed 33 m.

The fire main on gas carriers should be capable of at least 5,0 bar to adequately supply the water spray system.

Gas carriers will be provided with firemen’s outfits and protective clothing, as required, plus some additional equipment as stated in the Gas Code. The requirements are determined by the gas carrier’s size.

The safety equipment for personnel protection that must be provided is specified. However; it should be noted that the Gas Code requires gas carriers to be provided with at least 3 additional sets to those required by SOLAS.

SOLAS Chapter III: LifeSaving Appliances

Lifesaving appliance requirements are covered by this chapter; including:

- lifeboats,

- life rafts,

- lifebuoys,

- lifejackets and muster lists.

SOLAS Chapter IV: Radio Communications

Details of the radio communication equipment required on board are provided.

SOLAS Chapter V: Safety of Navigation

In addition to the specification of the navigational equipment to be installed on ships, this chapter details recommendations on ship manning and nautical publications that are to be carried on board.

It requires all Masters to inform all ships in the vicinity, and also the competent authorities at the first contactable point on the coast, about all dangers to navigation they may encounter.

SOLAS Chapter VII: Carriage of Dangerous Goods

This chapter introduces, as supplements to the SOLAS Convention, the “IMO International Code for the Construction and Equipment for Ships Carrying Liquefied Gases in Bulk” (IGC) and the “IMO International Code for the Construction and Equipment of Ships Carrying Dangerous Chemicals in Bulk” (IBC).

SOLAS Chapter IX: Management for the Safe Operation of Ships

This chapter provides a basic introduction to the International Safety and Pollution Prevention Management of Ships (the ISM Code).

SOLAS Chapter XI-1 and XI-2: Special Measures to Enhance Maritime Safety

The final chapter discusses enhanced surveys of bulkers and oil tankers, identification numbers of all ships and the practice of Port State Control for ships visiting foreign ports.

International Convention for the Prevention of Pollution from Ships (MARPOL-73)

The International Conference on Marine Pollution was convened in 1973. It is commonly referred to as MARPOL.

The convention, integrated with two Protocols, has six annexes (with dates of international entry into force):

Annex I

Regulations for the Prevention of Pollution by Oil (2nd October 1983).

Annex II

Regulations for the Control of Pollution by Noxious Liquid Substances in Bulk (6th April 1987).

Annex III

Regulations for the Prevention of Pollution by Harmful Substances Carried by Sea in Packaged Form (1st January 1992).

Annex IV

Regulations for the Prevention of Pollution by Sewage from Ships (not yet international).

Annex V

Regulations for the Prevention of Pollution by Garbage from Ships (31st December 1988).

Annex VI

Controlling atmospheric pollution by the prevention of release of volatile organic compounds and NOX or SOX engine exhausts. (19th May 2005).

Gas carriers are affected by the provisions of Annex I, Regulation 9 (b) where it states that any ships above 400 gross register tons (other than oil tankers) are prohibited from discharging into the sea, oil or oily mixtures from machinery space bilges, except when the following conditions are satisfied:

- The ship is not within a special area (Mediterranean Sea, the Baltic Sea, the Black Sea, the Red Sea, the gulfs area, Gulf of Aden, North West European waters and Antarctic waters, with reference to Regulation 10).

- The ship is more than 12 nautical miles from the nearest land.

- The ship is proceeding en-route.

- The oil content of the effluent is less than 15 parts per million.

- The ship has in operation an oil discharge monitoring and control system (for ships above 10 000 gross register tons), oily-water separating equipment, oil filtering system or other installations as required by Regulation 16 and 17 of this Annex.

Regulation 16 specifies that the oil-water separating equipment can be substituted by an “effective” oil filtering system, the design of which must be approved by the Administration.

In addition, every ship of 400 GRT must be provided with a tank or tanks of adequate capacity to receive oil sludge’s that cannot be dealt with in another manner.

Every ship of 400 GRT and above must be provided with an Oil Record Book, either as part of the ship’s official log book or in the form specified by the Convention (Appendix III to Annex I). The Oil Record Book must be completed on each occasion, on a tank-to-tank basis, whenever any of the following operations take place in the ship:

- Ballasting or cleaning of fuel-oil tanks or oil cargo spaces;

- Discharge of ballast or cleaning water from tanks above;

- Disposal of residues;

- Discharge overboard of bilge water that has accumulated in machinery spaces while in port, and the routine discharge at sea of bilge water that has accumulated in machinery spaces.

International Convention on Standards of Training, Certification and Watch keeping for Seafarers, 1978 (STCW) as amended 1995

The convention establishes agreed international standards of training, certification and watch keeping for seafarers.

In its Annex, the convention covers all of the qualifications required for:

- Masters;

- Chief Engineers;

- Deck and Engine Officers;

- Radio Operators and Ratings.

Special requirements are laid down for the training and qualifications required to serve as Masters, Officers and ratings on Oil Tankers (Regulation V/1) on Chemical Tankers (Regulation V/2) and Liquefied Gas Tankers (Regulation V/3).

Regulation V/3 specifies:

Officers and ratings who are to have specific defies and responsibilities in connection with cargo and cargo equipment on liquefied gas tankers, and who have not serye d on board a liquefied gas tanker as part of the regular complement, shall have completed an appropriate shore-based fire-fighting course. They will also have:

- An appropriate period of supervised shipboard service in order to acquire adequate knowledge of safe operational practices;

- An appropriate liquefied gas tanker familiarisation course which includes basic safety and pollution prevention precautions and procedures, the layout of different types of liquefied gas carriers, types of cargo, their hazards and their handling equipment, general operational sequence and liquefied gas tanker terminology.

Masters, Chief Engineer Officers, Chief Mates, Second Engineer Officers and any person with the immediate responsibility for loading, discharging and care in the transit or handling of cargo, in addition to the provisions stated above shall have:

- Relevant experience appropriate to their duties on liquefied gas tankers;

- Completed a specialised training programme appropriate to their duties including liquefied gas tanker safety, fire safety measures and systems, pollution prevention and control, operational practice and obligations under applicable laws and regulations.

According to the Convention requirements, every officer who has completed a specialised level training course must have his licence “endorsed” to serve either on an oil, chemical or liquefied gas carrier; depending on the nature of cargo being carried.

Complete revision of the annex to the 1978 STCW Convention became necessary in 1995. No amendment was made to the articles of the Convention.

STCW-95 was a revision to the existing annex, no change was made to the 1978 convention.

STCW-95 provided a complete, consolidated text of the STCW Convention, including its original articles, a revised Annex and the supporting STCW Code.

Mandatory technical standards are contained in part A of the STCW Code. Part B of the Code provides guidance to assist those involved in educating, training or assessing the competence of seafarers or those who are otherwise involved in applying STCW Convention provisions.

Inter-Industry Organisations

All existing international conventions, codes and regulations deal with the legislation of the ships. The right equipment and qualifications are recommended to achieve safe operations, but it should be noted that no operational guidance or recommendation is given.

A number of inter-industry organisations are involved in producing “codes of practice” that support the operator in complying with legislation, including:

- ICS – International Chamber of Shipping.

- OCIMF – Oil Companies International Marine Forum.

- SIGTTO – Society of International Gas Tanker and Terminal Operators

International Chamber of Shipping (ICS)

The ICS is made up of and supported by the ship owner’s associations of the member countries.

The structure of ICS is based on committees and sub-committees that deal with the various branches of maritime activity such as the:

- Nautical,

- Construction,

- Tanker Safety,

- Operational Pollution Sub-Committees,

- Liquefied Gas and Chemical Panels, etc.

Among the various codes of practice produced by ICS, the following are of specific interest to gas carriers:

- Tanker Safety Guide (Liquefied gases);

- International Safety Guide for Oil Tankers and Terminals (ISGOTT), produced in collaboration with OCIMF and IAPH;

- Ship to Ship Transfer Guide (Liquefied Gases), produced in collaboration with OCIMF.

Oil Companies International Marine Forum (OCIMF)

Membership of this organisation is granted only to oil companies. The primary aim of OCIMF is to foster safe and pollution free operations for all types of tankers at sea and in port.

Of the various codes of practice prepared by OCIMF, or by OCIMF in partnership with other international industry organisations, the following are specifically related to Liquefied Gas Carriers.

- Safety Inspection Guidelines and Terminal Safety Check-list for Gas Carriers;

- Standardisation of Manifolds for Refrigerated Liquefied Gas Carriers (LNG);

- Standardisation of Manifolds for Refrigerated Liquefied Gas Carriers for Cargoes from 0 °C to -104 °C;

- Design and Constructional Specifications for Marine Loading Arms;

- Safety Guide for Terminals Handling Ships Carrying Liquefied Gases in Bulk.

The main OCIMF publication is the International Safety Guide on Tankers and Terminals (ISGOTT), produced in collaboration with ICS and IAPH.

Society of International Gas Tankers and Terminal Operators (SIGTTO)

Almost all of the main gas companies are members of SIGTTO, covering gas carrier owners as well as liquefied gas producers and users.

The main SIGTTO publication is “Liquefied Gas Handling Principles on Ships and Terminals”.

The Classification Societies

Originally intended to assure the insurer, classification societies are organisations that establish and apply technical standards in relation to the design, construction and survey of marine related facilities, including ships and offshore structures. The standards are issued by the classification society as published rules. A vessel that has been designed and built to the appropriate rules of a society may apply for a Certificate of Classification from it. The society issues this certificate on completion of relevant classification surveys.

Such a certificate does not imply, and should not be construed as, an express warranty of safety, fitness for purpose or seaworthiness of the ship. It is only an attestation that the vessel is in compliance with the standards developed and published by the society issuing the classification certificate.

As an independent and self-regulating body, a classification society has no commercial interests related to:

- ship design,

- ship building,

- ship ownership,

- ship operation,

- ship management,

- ship maintenance or repairs,

- insurance or chartering.

In establishing its rules, each classification society may draw upon the advice and review of members of the industry who are considered expert in their field.

A ship is maintained in class provided that the relevant rules have, in the opinion of the society concerned, been complied with and surveys have been carried out in accordance with its rules. Classification societies also maintain significant research departments that contribute towards the on-going development of appropriate, advanced technical standards.

Ship Inspectorate Groups: SIRE and CDI

Within the operation of Liquefied Gas Carrying Ships, there are commercial inspectorate groups who act on behalf of the charterers. Perhaps the most widely known example is the “Ship Inspecting and Reporting: SIRE” body, who are mainly involved with oil and LPG carriage. A slightly older and perhaps more demanding group is the “Chemical Distribution Institute: CDI”, who concern themselves with chemical tankers and those gas carriers carrying cargoes such as butadiene vinyl chloride and other “chemicals”. The standards of both SIRE and CDI are very demanding and have resulted in the exclusion of sub- standard shipping from these trades.

Form “C”

This is a document (that is rarely shown to ship’s staff) that ship owners use to provide information to prospective charterers. Form “C” describes the ship’s trading parameters and operating details.