Fire on vessel are a serious and potentially life-threatening emergency. In the event of a fire, it is crucial to immediately notify the crew and follow the designated emergency procedures to ensure the safety of all passengers and crew members. Adequate fire prevention measures should always be in place and practiced regularly to minimize the risk of fires on board a ship.

Fire on vessel a ship can occur due to various reasons such as electrical faults, machinery malfunctions, human error, fuel leaks, or even cooking accidents. It is essential for ships to have proper fire prevention measures in place, regular maintenance checks, and well-trained crew members to minimize the risk of fires at sea.

To date there has been no incident involving uncontrolled loss of containment on an LNG carrier and the largest LNG pool fire tests carried out at Montoir and Maplin were only a maximum of 35 m diameter. Therefore, there is no experience to draw upon to estimate the effects of a release and subsequent ignition of a large quantity of LNG engulfing an LNG carrier.

There are however, numerous well documented incidents involving conventional tankers and LPG carriers and these can give us an insight into the effects of an engulfing fire on the structure of a ship and also the characteristics of fires involving large quantities of refrigerated liquefied gases in insulated tanks.

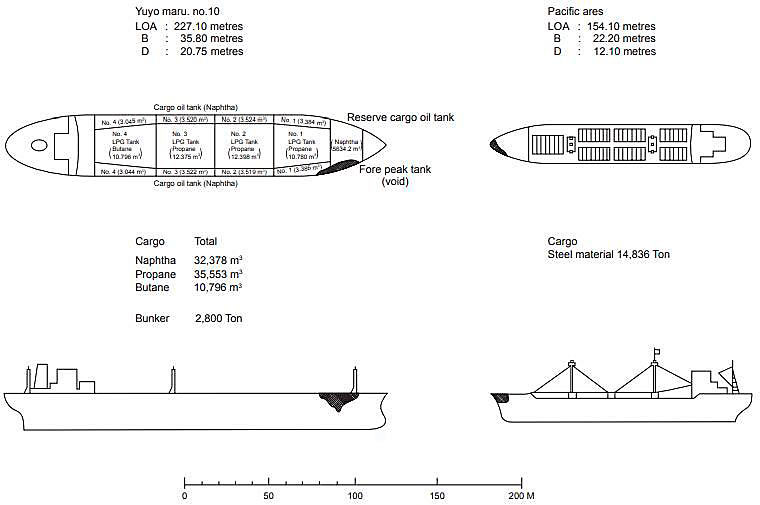

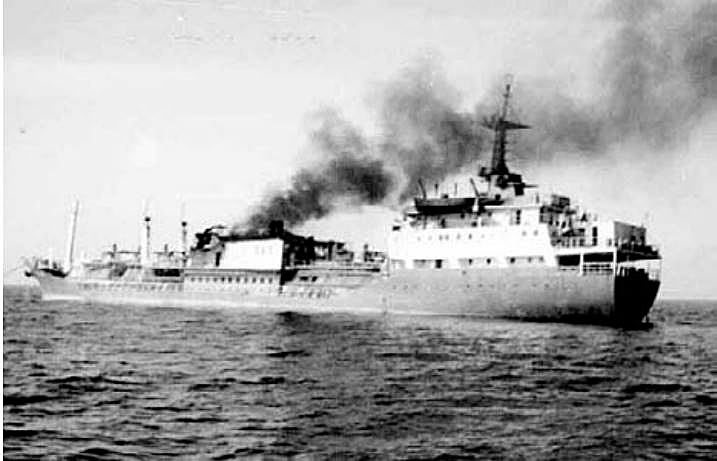

«Yuyo Maru» No.10

«Yuyo Maru» was of a design no longer permissible under the IGC Code (see diagram) whereby LPG was carried in the centre tanks and light naphtha in the wing tanks (MARPOL Regulation 13G, 1994, prohibits the carriage of petroleum products in tanks adjacent to the sea). In November 1974 the vessel was involved in a collision with a bulk carrier, resulting in a serious fire and the death of most of the crew of the bulk carrier and 5 members of the «Yuyo Marus» crew. The information below comes from the Japanese Maritime Safety Agency report.

Hazards of LNG and Relevant GasesThe vessel burned for 10 days after which time it was boarded and a survey carried out to ascertain if it could be towed. It was estimated that approximately 25 % of the naphtha and an unknown amount of propane and butane had been consumed in the fire. Most of the butterworth plates were missing on the wing tanks, but otherwise the deck was intact. The damage to the LPG tanks was «the safety valves and part of the hatch covers where the float gauges were installed» (sic). The vessel was towed out to sea, during which time the fire flared up again, and was eventually sunk by a combination of gun-fire, bombs and, eventually, a torpedo, 19 days after the collision.

«Gaz Fountain»

«Gaz Fountain» was a fully refrigerated LPG carrier with a cargo-carrying capacity of 40,232 m3. Her 3 free-standing prismatic cargo tanks were insulated with loose fill perlite. On 12 October 1984, during the height of the Iran-Iraq war and while carrying 6 300 tonnes of propane and 12 140 tonnes of butane from Ras Tanura to Fujairah, the ship was attacked by an Iranian aircraft and suffered three hits from air-to-ground, armour-piercing missiles. The crew shut down the propulsion and cargo refrigeration systems and abandoned ship. The following account describes how a salvage team quenched the fires and salvaged the vessel and over 93 % of her cargo.

One missile exploded on deck above № 2 cargo tank, severely damaging much of the pipe work in this area and setting off fires fuelled by escaping gas. The other two missiles hit the vessel’s deck in the vicinity of № 3, or aftermost, tank. One of these penetrated the deck and blew a hole of several square metres in the roof of № 3 tank. A severe fire resulted, fed by the butane in № 3 tank. This quickly spread to the accommodation block, gutting it but, luckily, leaving the engine room relatively undamaged.

The following day a salvage tug approached «Gaz Fountain» and started cooling the main fire areas. The salvors later experimented with dousing the torch fires using powerful water jets. This was an unconventional procedure, but one which was the only option as there was no means of isolating the ruptured tank and pipe work.

The salvage crew used various combinations of wooden plugs, canvas patches, cement boxes and sandbags to stop the gas leaks in the damaged deck and pipe work. However, it was impossible to plug the hole in № 3 tank and the hold space around the tank effectively became the cargo tank. A temporary gas vent was rigged to control tank pressures and the vessel, which by now had been anchored, was towed across the wind to aid the safe dispersal of gas.

A ship-to-ship transfer was started a month after the missile attack and 17 200 tonnes of cargo were successfully transferred over. On 12 December the operation, including the lengthy gas-freeing of № 3 hold, was concluded and the vessel was handed back to her owners.

25 000 dwt Single Hull Product Carrier

A single hull 25 000 dwt product carrier, owned and operated by a major oil company was involved in a collision in the southern North Sea. The vessel was carrying a full cargo of gasoline, which ignited and burned for over 24 hours before the fire was extinguished and the vessel boarded. Bronze butterworth plates and PV valves had melted in the intensity of the fire, and deck pipelines were badly buckled, but there was no serious buckling or distortion of the vessel’s structure.

«Val Rosandra» Propylene Fire

On 28 April 1990 the 3 990 m3 ethylene carrier «Val Rosandra», laden with 2 250 tonnes of fully refrigerated propylene at minus 47 deg C, was discharging at Brindisi in Italy when a violent explosion occurred in the cargo compressor motor room.

Read also: Risk Assessment in the Liquefied Natural Gas Bunkering Operations, Hazard Identification

The motor room was so severely damaged that a switch panel was blown onto the deck and cargo pipe work outside the room ruptured. In addition, the port and starboard domes of № 3 cargo tank also ruptured. As a result of the explosion the escaping propylene ignited and the fire continued to be fed by cargo evaporating from the damaged domes.

As local emergency services responded to the incident, the crew abandoned ship. The vessel was subsequently towed to the edge of the port limits where the fire was monitored from a safe distance. Although the fire showed no signs of escalation over a number of days, it was decided not to attempt to salvage the vessel or her cargo. Instead, charges were detonated around the domes of the remaining four tanks to allow the propylene cargo to escape gradually and burn off. It was agreed that once this had been accomplished, the vessel would be scuttled.

On 21 May 1990, over 3 weeks after the initial explosion and with the fire still burning at № 3 tank, the vessel was towed out to sea. The tank domes of the 4 undamaged tanks were breached with explosive charges. Although this resulted in some escalation of the fire, it was not to the extent the authorities had anticipated. The slow burn rate was attributed to the fact that the cargo was fully refrigerated and would only burn as fast as heat penetrated the insulated tank walls and domes and evaporated the propylene. On 8 June 1990, 41 days after the initial explosion and fire, a large quantity of explosive was detonated on «Val Rosandras» hull and, on this occasion, the ethylene carrier’s demise was not long in coming.