For seamen working on LNG tankers, understanding the hazards associated with liquefied natural gas (LNG) is paramount to ensuring safety at sea. LNG presents unique risks due to its extremely low temperature, flammability, and potential for rapid vaporization in the event of a spill or leak. Seafarers must be trained to recognize these hazards and equipped with the knowledge and procedures necessary to respond effectively in emergency situations, safeguarding both crew members and the environment from potential harm.

Reference SIGTTO “LNG Shipping Suggested Competency Standards”, Sections:

1 Have an awareness of the hazards to personnel and the vessel from LNG and relevant gases:

- Cryogenic;

- Flammability;

- Oxygen deficiency;

- Flash point;

- Auto ignition temperature;

- Data sheets and MFAG for LNG.

2 Know and understand the hazards to personnel and the vessel from LNG and relevant gases and the defences applied:

- LNG;

- Inert gas;

- Nitrogen.

3 Know the first aid action to be taken in the event of personnel contact with LNG:

- Skin contact;

- Inhalation;

- Ingestion.

4 Have an awareness of LNG fire-fighting techniques and equipment:

- Use of high-ex foam;

- Use of dry powder;

- Heat intensity of LNG fires;

- Potential danger of extinguishing a fire prior to stopping the leak.

5 Know and understand LNG fire-fighting techniques and equipment:

- Process isolation and draining;

- Water spray protection.

LNG properties

LNG vapour is colourless, odourless and non-toxic. On release, LNG vapour typically appears as a visible white cloud because its cold temperature condenses the water vapour present in the atmosphere.

Cryogenic temperature. LNG is a cryogenic (very cold temperature) liquid. If spilled on to human flesh, the high rate of vaporisation on the skin would immediately cause cold burns. Similarly, a spill onto a ship’s metal deck, which is not designed for low temperatures, would cause brittle fractures of the metal.

Flammability. Flammability is the measure of the ease with which a substance will ignite, resulting in fire or combustion. Materials that will ignite at temperatures commonly encountered are considered flammable. The lower and upper flammability limits of methane are 5 % and 14 % by volume respectively at a temperature of +25 °C.

O2 deficiency. Normal air contains 20,9 % O2. A space with O2 content below 19,5 % is “O2 deficient” and may have the following effects.

| 19,5-16 % | Fatigue, mild impaired coordination |

| 16-12 % | Increased breathing rate and pulse, impaired coordination, perception or judgement |

| 12-10 % | Further increased breathing rate, blue lips, mental confusion |

| 10-8 % | Fainting, nausea, vomiting, mental confusion within a few minutes |

| 8-6 % | Collapse, death within 8 minutes |

| 6-0 % | Coma within 40 seconds, followed by death |

Flash point. The lowest temperature at which the vapour of a combustible liquid can be made to ignite in air.

Auto ignition temperature. The temperature at which combustible liquid can be made to ignite in air.

Data sheet for LNG. The IGC Code (18.3) states that information should be on board and available to all concerned, providing the necessary data for the safe carriage of cargo. Such information should include, for each product carried:

- A full description of the physical and chemical properties necessary for the safe containment of the cargo.

- Action to be taken in the event of spills or leaks.

- Countermeasures against accidental personal contact.

- Fire-fighting procedures and fire-fighting media.

- Procedures for cargo transfer, gas freeing, ballasting and tank entry.

- Special equipment needed for the safe handling of the particular cargo.

- Minimum allowable inner hull steel temperatures.

- Emergency procedures (contingency plans).

This information is normally supplied for each cargo in the form of a safety data sheet (SDS).

| Example of an LNG SDS | |

|---|---|

| Name | Description |

| Liquefied Natural Gas (LNG) | A complex combination of hydrocarbons consisting of aliphatic hydrocarbons having carbon numbers in the range of C1-C4, predominantly methane and ethane. Uses: – Fuel gas. |

| Methane, refrigerated liquid (cryogenic liquid) | |

| Natural gas, refrigerated liquid (cryogenic liquid) | |

| Formula: Unspecified | |

| CAS number: 68410-63-9 | |

| EINECS: 270-085-9 | |

| TSCA listed | |

| Transport | Properties |

| UN (DOT) number: 1972 | Melting Point (in °C): -182,2 |

| UN (DOT) hazard class: 2.1 | Boiling Point (in °C): -161,2 |

| UN (DOT) hazard class label | Solubility in water, ml/100 ml at 20/C: 3.3 |

| Response Guide: 115 (printed separately) | Relative vapour density (air = 1): 0,6 |

| USCG Flammable/Combustible cargo | Flash point: Flammable Gas |

| USCG Flammability/Combustibility grade: LFG | Auto-ignition temperature: 537/C |

| CHRIS code: LNG | Explosive limits, vol % in air: 5-15 |

| CHRIS Compatibility Group: 31 Paraffins | Octanol/water partition co-efficient as log Pow: 1,09 |

| Hazards | |

| Storage | Keep in a cool, dry, dark location in a tightly sealed container or cylinder.Keep away from incompatible materials, ignition sources and untrained individuals. Secure and label area. Protect containers/cylinders from physical damage. |

| Handling | All chemicals should be considered hazardous. Avoid direct physical contact. Use appropriate, approved safety equipment. Untrained individuals should not handle this chemical or its container. Handling should occur in a chemical fume hood. |

| Protection | Wear appropriate protective gloves,clothing and goggles. Always wear thermal protective clothing when handling refrigerated/cryogenic liquids. |

| Respirators | Wear positive pressure self-contained breathing apparatus (SCBA). |

| Small spill or leak | Make no contact with the spilled material. Eliminate all ignition sources,combustibles and ground all equipment. Take up with sand or other noncombustible absorbent material and place into containers for later disposal. |

| Stability | No data |

| Fire | |

| Fire potential | Keep in a cool, dry,dark location in a tightly sealed container or cylinder.Keep away from incompatible materials, ignition sources and untrained individuals. Secure and label area. Protect containers/cylinders from physical damage. |

| Fire hazards | Vapours from liquefied gas are initially heavier than air and spread along ground. Vapours may travel to source of ignition and flash back. Containers may explode when heated. Ruptured cylinders may rocket. |

| Fire-fighting | Do not extinguish fire unless flow can be stopped. Use water in flooding quantities as fog. Cool all affected containers with flooding quantities of water.Apply water from as far a distance as possible. Auto-ignition temperature (°C): 537 NFPA Flammability: 4 NFPA Health: 1 NFPA Reactivity: 0 |

| Health | |

| Exposure effects – Inhalation | Vapours may cause dizziness or asphyxiation without warning. Some may be irritating if inhaled at high concentration. |

| Exposure effects – Skin | Remove and isolate contaminated clothing and shoes. Clothing frozen to the skin should be thawed before being removed. In case of contact with liquefied gas, thaw frosted parts with lukewarm water. |

| Exposure effects – Eyes | Flush with running water for at least 20 minutes. |

| Important Data | |

| Physical State; Appearance Colourless, compressed or liquefied gas, with no odour. | Routes of exposure The substance can be absorbed into the body by inhalation. |

| Physical dangers The gas is lighter than air. | Inhalation risk On loss of containment, this gas can cause suffocation by lowering the oxygen content of the air in confined areas. |

| Occupational exposure limits TLV: Simple asphyxiant (ACGIH 2000). MAK not established. | Effects of short-term exposure Rapid evaporation of the liquid may cause frostbite. |

Properties of LNG

LNG is considered a hazardous material. The primary safety concerns are the potential consequences of an LNG spill. LNG hazards result from three of its properties:

- Cryogenic temperatures;

- Dispersion characteristics;

- Flammability characteristics.

| Hazards to Personnel from LNG and the Defences Applied | ||

|---|---|---|

| Hazard | Consequence | Defences Applied |

| Cold temp of LNG (approx. -161,5 °C) | Cold burn – severe injury | Cordon off vicinity of leakage – Proven containment systems – Correct medical response – Appropriate drills- All crew and officers made aware of associated dangers – Strategically posted warning notice |

| Asphyxiant | Collapse – possible death | Fixed gas detection systems – Portable gas detection systems – Enclosed space entry procedures – Appropriate drills – SCBA equipment – EEBA equipment |

| Vapour combustible | Riser fire due to lighting strike deteriorating into a serious situation | Remotely operated snuffing/isolating facility – Established response procedure – Appropriate drills – Venting limitations and control – Weather watch and information |

| Vapour explosive | Injury, death or total loss | Proven containment systems – Ignition source control – Smoking regulations – IS equipment and barriers – Gas detection systems – Remote operation of critical valves – Established response procedure – Appropriate drill |

| Minimal undercooling of liquid | Almost inexhaustible fuel supply for a fire resulting in injury or death | Proven containment systems – Ignition source control – Smoking regulations – IS equipment and barriers – Gas detection systems – Remote operation of critical valves – Established response procedure – Appropriate drills |

| High expansion at liquid to vapour phase change (approx. 600x) | Pipeline bursting pressure if trapped between valves with subsequent injury | Where appropriate, self draining pipeline configurations – Pipeline relief valves – Established procedures regarding cargo operations – Pressure sensing instrumentation and high pressure alarms |

| Hazards to Ship from LNG and the Defences Applied | ||

|---|---|---|

| Hazard | Consequence | Defences Applied |

| Cold temp of LNG (approx. -161,5 °C) | Cold/brittle fracture resulting in possible critical failure to the inner hull, main hull, decks and associated equipment | Proven containment systems, with secondary barrier or robust spherical tank design – Contingency planning and drills – Insulation temperature monitoring/alarm system – Inner hull temperature monitoring/alarm system – Permanent gas detection systems – Strategically placed savealls – Experienced operators – Established procedures regarding cargo operations – Emergency means of cargo extraction – Cargo jettison facility |

| High expansion at liquid to vapour phase change (approx. 600x) | Pipeline rupture if liquid LNG or cold vapour trapped between valves | Crack open valves after load and discharge operations to allow any liquid to dissipate safely. Where appropriate, self draining pipeline configurations – Pipeline relief valves – Established procedures regarding cargo operations – Pressure sensing instrumentation and high pressure alarms – Experienced operators |

| Vapour combustible | Riser fire due to lightning strike deteriorating into venting equipment damage | Remotely/locally operated snuffing/isolating facility – Established response procedure – Appropriate drills – Venting limitations and control – Weather watch and information |

| Vapour explosive | Total loss or severe explosive damage to equipment and/or the ship | Proven containment systems – Ignition source control – Smoking regulations – IS equipment and barriers – Gas detection systems – Remote operation of critical valves – Established response procedure – Appropriate drills |

| Minimal undercooling of liquid | Over pressurisation possibility due to continuous vapour generation under all conditions | Numerous means of vapour utilisation, i. e. fuel supply to ship’s power plant – Facility to artificially increase plant load and subsequent BOG utilisation – Manual and automatic venting systems – Alarm/trip over-pressure monitoring systems – Established cargo conditioning procedures – Experienced operators |

| Hazards to Personnel from IG and the Defences Applied | ||

|---|---|---|

| Hazard | Consequence | Defences Applied |

| An inert gas and therefore an asphyxiant | Collapse due to asphyxiation – possible death | Enclosed space entry procedures – Associated drills – O2 meters (fixed and portable) – Personal O2 monitor/alarm – Onboard awareness campaigns – Posted warning notices – Established IG plant |

| Colourless | Detection difficulty by unassisted senses leading to asphyxiation – Collapse possible death | Enclosed space entry procedures – Associated drills – O2 meters (fixed and portable) – Personal O2 monitor/alarm – Onboard awareness campaigns – Posted warning notices – Established IG plant operating procedures |

| Odourless | Detection difficulty by unassisted senses leading to asphyxiation – Collapse possible death | |

| Density close to air | Readily accumulates – Difficulty dispersing in confined spaces | |

| Density close to air | Readily accumulates – Difficulty dispersing in confined spaces | |

| Incombustible gases | Possibility of flame-out in boilers | Automatic CV compensation in boiler combustion control systems |

| SOx/NOx content | Corrosion due to sulphur attack | IG plant efficiently maintained according to an approved PM scheme – Appropriate quality regarding fuel supply |

Properties of nitrogen

| Hazards to Personnel from Nitrogen and the Defences Applied | ||

|---|---|---|

| Hazard | Consequence | Defences Applied |

| An IG and therefore an asphyxiant | Collapse due to asphyxiation – possible death | Enclosed space entry procedures – Associated drills – O2 meters (fixed and portable) – Personal O2 monitor/alarm – Onboard awareness campaigns – Posted warning notices – Established N2 plant operating procedures – Maintenance and monitoring/alarm testing as per an established PM scheme |

| Colourless | Detection difficulty by unassisted senses leading to asphyxiation – Collapse, possible death | |

| Odourless | ||

| Density close to air | Readily accumulates – Difficulty dispersing in confined spaces | |

| High pressure | Rupture/failure of associated plant/equipment or pressurised cylinders, resulting in injury/death | Adherence to COSWP recommended handling procedures – Maintenance and monitoring/alarm testing as per an established PM scheme – Where applicable suitable cylinder stowage facility – N2 plant alarm/monitoring systems – Experienced operators |

| Cryogenic property (for bulk storage systems -196 °C) | Cold burn, frostbite | On a bulk storage system nitrogen is vaporised before entering the consumer’s manifold |

| An incombustible gas | Possibility of flame-out in boilers | Automatic CV compensation in boiler combustion control systems |

| Incondensible under normal operating conditions | Causes a reduction in efficiency in heat exchangers/condensers | Reliquefaction cycle monitoring/alarm/trip systems – Efficient rounds of inspection – Experienced operator |

| High pressure cylinders | Rupture/failure of associated plant/equipment or pressurised cylinders | Adherence to COSWP recommended handling procedures – Maintenance and monitoring/alarm testing as per an established PM scheme – Where applicable, suitable cylinder stowage facility – N2 plant alarm/monitoring systems – Experienced operators |

| Cryogenic property (for bulk storage systems -196 °C) | If spilled on deck brittle fracture | On a bulk storage system nitrogen is vaporised before entering the consumer’s manifold |

First aid actions

Skin contact. Contact with LNG may result in severe injury or a Properties and hazards of shipping LNG, LPGcold burn (frostbite). The symptoms of a cold burn are very similar to those for a thermal burn. If the area of the burn is large then shock will develop.

The symptoms of a cold burn are similar to a hot burn.

When treating a cold burn, the affected part should be warmed with a hand or woollen material. Massage should be prevented as this will cause flesh wounds. Should the victim’s finger or hand be burned, they should hold their hand under their armpit. The affected part should then be placed in warm water, at about +42 °C., and warming may take 15-60 minutes. If this is not practical, then the casualty should be wrapped in blankets and circulation should be allowed to re-establish itself naturally. Pain killers or morphine may be required to control pain during warming.

If it is possible, the casualty should be encouraged to exercise the affected part while it is being warmed. Blisters should never be cut or opened, nor should clothing be removed if it is adhering firmly. The entire affected area should be covered with sterile dressings. In all other ways, the treatment should be as for thermal burns.

If you require further Information, please consult the IMO “Medical First Aid Guide for Use In Accidents Involving Dangerous Goods”.

Inhalation. Vapours may cause dizziness or asphyxiation without warning. Some vapours may be irritating if inhaled at high concentrations.

Ingestion. Seek medical assistance.

LNG fire-fighting techniques and equipment

Use of Hi-Ex foam. LNG does not respond well to water or low expansion foam. Foams that are low expansion are too wet and have a high moisture content that results in a latent heat transfer from the water to the liquid gas, causing the liquid foam to vaporise too quickly.

LNG fires give out 3 times the heat of an oil fire of the same size.

Water and low expansion foam react violently with LNG and should not be used for Fire protection and Fire extinction on Liquefied Gas Carriersfire-fighting. Water should only be used for boundary cooling, but with great caution.

In contrast, high expanding foams designed to produce a thicker, lighter blanket control the vaporisation effect by forcing the vapours to percolate through the layer of ice that is formed above the liquid gas.

Continuous application of high-expansion (Hi-Ex) foam is necessary to maintain a depth of foam of 1-2 m. Hi-Ex foam delivers about 500:1 expansion and is the most effective type for this use.

When applied to a burning gas pool fire, the high expanding foam controls the fire and reduces the heat by as much as 50 %. To extinguish a liquid gas fire, dry chemical powder is needed. However, this should only be done with the fuel source isolated to prevent re-ignition.

It is important that all fire equipment is in good order. Equipment tests at regular intervals are essential if there is to be confidence that a How to Prevent Fire and Explosion or How to Minimize Effects of itleak or fire can be dealt with competently.

Read also: List of the Emergency Situations which can happen on the Liquefied Gas Carrier

Use of dry powder. The main item of fire protection equipment required by the IGC Code is a dry chemical powder system capable of extinguishing the fire (IGC Code 11.4).The dry powder system can be either a monitor or consist of handheld nozzles that must have a discharge rate of at least 3,5 kg of powder per second. The kick back from a nozzle discharging at this rate will be severe and unless the operator is trained in its use, they can easily lose balance or even lose the hose, which could whip like a pneumatic air hose. The hand held gun type applicator requires two people. Where powder monitors are mounted on the ship, the design is such that the nozzle recoil is taken up by the monitor mounting.

When attempting to knock out the fire using dry powder, a decision must be made as to whether or not the deck water spray system, and any Hi-Ex foam that is being used, should be cut off before the powder strike.

Sodium bicarbonate powders. Drypowders based on sodium bicarbonate are normally projected at the base of the fire, but such powders are soluble in water and a proportion of powder may be eliminated if it must pass through a water curtain.

Potassium based powders. Powders based on potassium can be shot through a water curtain to extinguish fire.

Note: dry powders provide no cooling effect and they may be ineffective as a fire extinguished by dry powder can easily re-ignite from the hot metal. With LNG, this is an ever-present possibility.

Personal protective equipment. Chapter 14 of the IGC Code requires that:

- Suitable protective equipment, including eye protection, must be provided for cargo operations. This should be kept in suitable, clearly marked lockers in readily accessible places.

- A stretcher for hoisting an injured person from below deck must be kept in a readily accessible location.

- At least three complete sets of safety equipment must be provided in addition to the firefighter’s outfits. This include an adequate supply of compressed air. Each set must apply for entry and work in a gas-filled space.

- Showers and eyewash stations must be available on deck, taking into account the size and layout of

the ship. They must be operable in all ambient conditions and regularly checked.

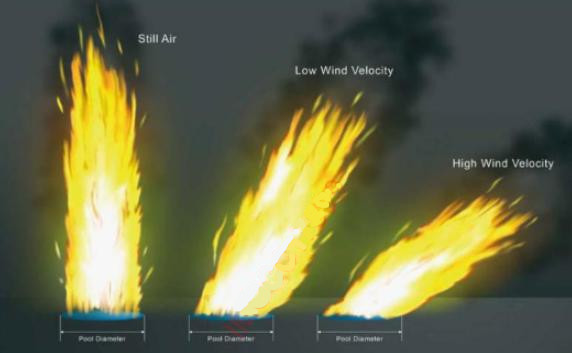

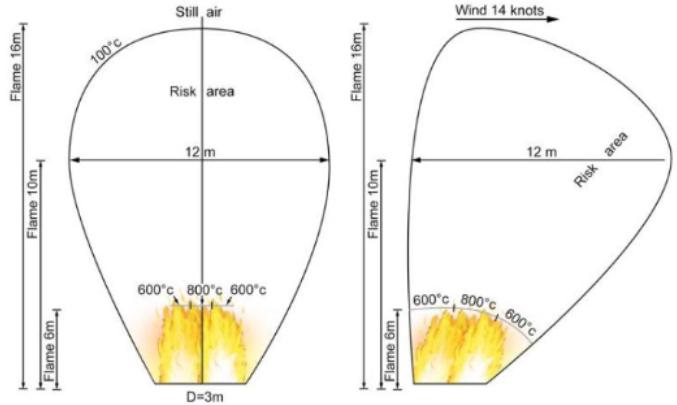

Heat intensity of LNG fires. Fire is a possibility on board in the event of a leak so it is important to know how LNG fires behave and how to fight them.

Fire should always be fought from upwind.

If the ship is alongside a jetty when a fire incident occurs, help may be available from the shore installation fire-fighting facilities.

An LNG fire at night will make the flames seem larger and more Intimidating than during the day.

LNG has an ignition temperature of +540 °C, twice the value for petroleum, so it does not ignite easily.

When almost pure LNG burns without generating smoke, resulting In a fire that generates intense heat.

When a leak has caused a pool to form, vapours will be generated from it for as long as the pool remains. However, vapour generated from LNG acts differently to other hydrocarbons. For example, LPG vapour blankets the ground until it dissipates while, in contrast, LNG vapour rises vertically as it warms.

On liquid gas fires the central core temperature will be 1 000 – 2 000 °C.

When LNG escapes, approximately 30 % will rapidly evaporate to form a vapour cloud and the remainder will fall to the deck to form a pool. If the vapour cloud is ignited, it will be rapidly consumed and the flame will flash to the pool area. Heat from the flames will be radiated onto the surface of the pool, increasing the rate of vaporisation of the liquid. These vapours then, feed the flames and increase the flame height until, when the pool reaches equilibrium, a maximum height is reached.

Pool fires burn at the rate of 15 mm of pool depth per minute.

A further type of fire that could be encountered is the pressure-jet type. This is normally directional and of relatively small influence on surrounding areas, except for equipment within the flame zone.

Water is only to be used for cooling or deflecting the fire.

Potential danger of extinguishing a fire prior to stopping the leak. In LNG fire was extinguished without removing the fuel source (i. e. stopping the leak), there is a large risk that the vapour cloud that forms the leak could suddenly re-ignite.

Process isolation and draining. The most effective way of fighting an LNG fire is to shut off the fuel supply (i. e. the LNG) at source and extinguishing the fire by starvation.

Leaks of LNG must be stopped before extinguishing the fire to remove the source of the fuel. The remaining pool of LNG can then be allowed to burn off or “flash-off” assisted by water sprays, thereby removing the dangers of re-ignition.

The main safety device for shutting off all sources of LNG is the ESOS, but bear In mind that vapour valves are generally manual valves.

Water spray protection. All LNG carriers are fitted with fire protection water sprays over the cargo deck area and on the forward facing area of the accommodation block. This arrangement is designed to protect the cargo and ship’s accommodation from radiated heat in the event of a fire on board. These spray systems are the first line of defence and the water can absorb large quantities of heat, which is its primary objective.

Where there is a leak without a fire, an assessment on whether or not to activate the deck spray system must be taken. If it is activated it could cause the rapid generation of vapours as the liquid in the pool picks up heat from the water. However, this decision is weighted against the potential for brittle fracture of the deck.

When the fire hose is in the full spray nozzle setting and the hydrant is opened there will be less kickback experienced than if the nozzle is set on a jet.

All nozzles should be left at full spray when not in use. This prevents salt encrustation and seizing of the nozzles.

Main targets for protection by cooling with a fire hose are the remotely operated cargo shut-off valves. All measures that can be taken to prevent these valves overheating will give them a greater chance of operating when required, possibly reducing the extent of the incident.

The most common cause of fire on LNG carriers is lightning strike.

Notes for fire-fighting LNG

In any fire involving an escape of LNG:

- The flame should not be extinguished until the source of the leak has been isolated.

- The main efforts of the fire crew are cooling equipment at risk within the flame and radiated heat zone.

- Where possible, approach from upwind of the incident area.

- All nozzles attached to water firehoses should be of the variable spray/jet type. The approaching to the fire should be made with the nozzles at the maximum spray position, protecting the operator from radiated heat. The source of the fire should be isolated. The emphasis should always be on using the spray to fight the fire and protect the fire team. This is because a jet of water directed at a pool of LNG will increase vaporisation and may cause an uncontrolled, violent boil-off.