This article gives the requirements for plates, sections, pipes, forgings, castings and weldments used in the natural gas tank construction, cargo process pressure vessels, cargo and process piping, secondary barriers and contiguous hull structures associated with the transportation of the products. The requirements for rolled materials, forgings and castings are given in “Material requirements” and Tables 1 to 5. The requirements for weldments are given in “Welding and non-destructive testing”.

Natural gas tank construction

With regard to this Section reference is made to the Unified Requirement No. W.1 of the International Association of Classification Societies (I.A.C.S.).

The manufacture, testing, inspection and documentation are to be in accordance with the Rules for Material (Part 1, Vol. V), and the specific requirements given in this article.

Acceptance tests are to include Charpy V-notch toughness tests, unless otherwise specified by the Society. The specified Charpy V-notch requirements are minimum average energy values for three full size (10 mm x 10 mm) specimens and minimum single energy values for individual specimens. Dimensions and tolerances of Charpy V-notch specimens are to be in accordance with the Rules for Material (Part 1, Vol. V) . The testing and requirements for smaller than 5,0 mm size specimens are to be specially considered by the Society. Minimum average values for subsized specimens are to be:

| Charpy V-notch specimen size | Minimum energy average of 3 specimens |

|---|---|

| 10×10,0 mm | E |

| 10×7,5 mm | 5/6 E |

| 10×5,0 mm | 2/3 E |

Where:

- E – the values of energy [J] specified in Tables 1 to 4.

Only one individual value may be below the specified average value, provided it is not less than 70 % of that value.

In all cases, the largest size Charpy specimens possible for the material thickness shall be machined with the specimens located as near as practicable to a point midway between the surface and the centre of the thickness and the length of the notch perpendicular to the surface, (see Pic. 1). If the average value of the three initial Charpy V-notch specimens fails to meet the stated requirements, or the value for more than one specimen is below the required average value, or when the value for one specimen is below the minimum value permitted for a single specimen, three additional specimens from the same material may be tested and the results combined with those previously obtained to form a new average.

If this new average complies with the requirements and if no more than two individual results are lower than the required average and no more than one result is lower than the required value for a single specimen, the piece or batch may be accepted. At the discretion of the Society other types of toughness tests such as a drop weight test may be used. These may be either in addition to or in lieu of the Charpy V-notch test.

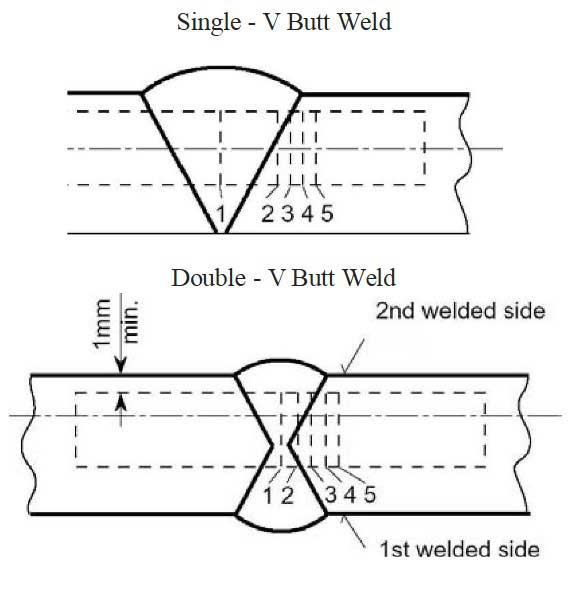

Notch location:

1. Centre of weld.

2. On fusion line.

3. In HAZ, 1 mm from fusion line.

4. In HAZ, 3 mm from fusion line.

5. In HAZ, 5 mm from fusion line HAZ = heat affected zone.

The largest Charpy specimens possible for the material thickness are to be machined with the centre of the specimens located as near as practicable to a point midway between the surface and the centre of the thickness. In all cases, the distance from the surface of the material to the edge of the specimen is to be approximately 1 mm or greater. In addition for double-V butt welds, specimens are to be machined closer to the surface of the second welded side.

Tensile strength, yield stress and elongation are to be approved by the Society. For carbon-manganese steel and other materials with definitive yield points consideration is to be given to the limitation of the yield to tensile ratio.

The bend test may be omitted as a material acceptance test, but is required for weld tests.

Materials with alternative chemical composition or mechanical properties may be accepted by the Society.

Where postweld heat treatment is specified or required the properties of the base material are be determined in the heat treated condition in accordance with the applicable Table of this Section and the weld properties are to be determined in the heat treated condition in accordance with “Welding and non-destructive testing”. In cases where a postweld heat treatment is applied, the test requirements may be modified at the discretion of the Society.

Where reference is made in this Volume to A, B, D, E, AH, DH and EH hull structural steels, these steel grades are hull structural steels according to the Rules for Material (Part 1, Vol. V)

Material requirements for gas tank construction

The requirements for materials of gas tank construction in the Tables are as follows:

- Table 1: Plates, pipes (seamless and welded), sections and forgings for cargo tanks, and process pressure vessels for design temperatures not lower than 0 °C.

- Table 2: Plates, sections and forgings for cargo tanks, secondary barriers and process pressure vessels for design temperatures below 0 °C and down to -55 °C (alloy steels and aluminium alloys).

- Table 3: Plates, sections and forgings for cargo tanks, secondary barriers and process pressure vessels for design temperatures below -55 °C and down to -165 °C.

- Table 4: Pipes (seamless and welded), forgings and castings for cargo and process piping for design temperatures below 0 °C and down to -165 °C.

- Table 5: Plates and sections for hull structures required by “Cargo containment system of gas vessel”Materials and “Cargo containment system of gas carrier”About materials.

| Table 1. Plates, Pipes (seamless and welded) For seamless pipes and fittings normal practice applies. The use of longitudinally and spirally welded pipes is to be specially approved by the Societyx, Sections and Forgings for Cargo Tanks and Process Pressure Vessels for Design Temperatures not lower than 0 °C | ||

|---|---|---|

| Chemical Composition and Heat Treatment | ||

| Carbon Manganese Steel | Fully killed | |

| Fine grain steel when thickness exceeds 20 mm | ||

| Small additions of alloying elements by agreement with the Society | ||

| Composition limits to be approved by the Society | ||

| Normalized or quenched and tempered Thermo-mechanically rolled steels may be accepted as an alternative to normalized or quenched and tempered steels subject to special approval by the Society.x | ||

| Tensile and Toughness (Impact) Test Requirements | ||

| Plates | Each “piece” to be tested | |

| Sections and Forgings | Batch test | |

| Tensile Properties | Specified minimum yield stress not to exceed 410 N/mm Materials with specified minimum yield stress exceeding 410 N/mm2 may be specially approved by the Society. For these materials, particular attention is to be given to the hardness of the weld and heat affected zone.x | |

| Charpy V-notch Test | ||

| Plates | Transverse test pieces. Minimum average energy value (E) 27 J | |

| Sections and Forgings | Longitudinal test pieces. Minumum average energy value (E) 41 J | |

| Test Temperature | Thickness [mm] | Test Temperature [°C] |

| t≤20 | 0 | |

| 20<t≤40 | -20 | |

| Table 2. Plates, Sections and Forgings The Charpy V-notch and chemistry requirements for forgings may be specially considered by the Society.x for Cargo Tanks, Secondary Barriers and Process Pressure Vessels for Design Temperatures below 0 °C and down to -55 °C. Maximum Thickness 25 mm | |||||

|---|---|---|---|---|---|

| Chemical Composition and Heat Treatment | |||||

| Carbon-Manganese Steel | Fully killed | Aluminium treated fine grain steel | |||

| Chemical composition (ladle analysis): | |||||

| C | Mn | Si | S | P | |

| 0,16 % max By special agreement with the Society the carbon content may be increased to 0,18 % maximum provided the design temperature is not lower than –40 °C. x. | 0,70-1,60 % | 0,10-0,50 % | 0,035 % max. | 0,035 % max. | |

| Optional additions: Alloy and grain refining elements may be generally in accordance with the following: | |||||

| Ni | Cr | Mo | Cu | Nb | V |

| 0,80 % max. | 0,25 % max. | 0,08 % max. | 0,35 % max. | 0,05 % max. | 0,10 % max. |

| Normalized or quenched and tempered Thermo-mechanically rolled steels may be accepted as an alternative to normalized or quenched and tempered steels subject to special approval by the Societyx. | |||||

| Tensile and Toughness (Impact) Test Requirements | |||||

| Plates | Each “piece” to be tested | ||||

| Sections and Forgings | Batch test | ||||

| Charpy V-notch Test | Test temperature 5 °C below the design temp. or -20 °C whichever is lower | ||||

| Plates | Transverse test pieces. Minimum average energy value (E) 27 J | ||||

| Sections and forgings | Longitudinal test pieces. Minimum average energy value (E) 41 J | ||||

| For materials exceeding 25 mm in thickness, Charpy V-notch tests are to be conducted as follows: | |||||

| Thickness [mm] | Test Temperature [ °C] | ||||

| 25<t≤30 | 10 ° below design temperature or -20 ° whichever is lower | ||||

| 30<t≤35 | 15 ° below design temperature or -20 ° whichever is lower | ||||

| 35<t≤40 | 20 ° below design temperature | ||||

Notes:

- For materials exceeding 25 mm in thickness for which the test temperature is -60 °C or lower, the application of specially treated steels or steels in accordance with Table 3 may be necessary.

| Table 3. Plates, Sections and Forgings The Impact test requirement for forgings used in critical applications will be subject to special consideration.x for Cargo Tanks, Secondary Barriers and Process Pressure Vessels for Design Temperatures below -55 °C and down to -165 °C The requirements for design temperature below – 165 °C are to be specially agreed with the Society.x. Maximum Thickness 25 mm | ||

|---|---|---|

| Minimum design temperature [ °C] | Chemical composition The chemical composition limits are to be approved by the Society. x and heat treatment | Impact test temperature [ °C] |

| -60 | 1,5 % Nickel steel – normalized | -65 |

| -65 | 2,25 % Nickel steel – normalized or normalized and tempered A lower minimum design temperature for quenched and tempered steels may be specially agreed with the Society.x | -70 |

| -90 | 3,5 % Nickel steel – normalized or normalized and tempered A lower minimum design temperature for quenched and tempered steels may be specially agreed with the Society.x | -95 |

| -105 | 5 % Nickel steel – normalized or normalized and tempered A specially heat treated 5 % Nickel steel, for example a triple heat treated 5 % Nickel steel may be used down to –165 °C upon specialagreement with the Society, provided that the impact tests are carried out at –196 °C. x | -110 |

| -165 | 9 % Nickel steel – normalized and tempered or quenched and tempered | -196 |

| -165 | Austenitic steels (e.g. type 304, 304L, 316, 316L, 321 and 347). Solution treated The impact test may be omitted subject to the agreement with the Society. x | -196 |

| -165 | Aluminium alloys; e.g. type 5083 annealed | Not required |

| -165 | Austenitic Fe-Ni alloy (36 % nickel) heat treatment as agreed | Not required |

| Tensile and Toughness (Impact) Test Requirements | ||

| Plates | Each “piece” to be tested | |

| Sections and Forgings | Batch test | |

| Charpy V-notch Test | ||

| Plates | Transverse test pieces. Minimum average energy value (E) 27 J | |

| Sections and forgings | Longitudinal test pieces. Minimum average energy value (E) 41 J | |

| For materials 1,5 % Ni, 2,25 % Ni, 3,5 % Ni and 5 % Ni, with thickness exceeding 25 mm, the impact tests are to be conducted as follows: | ||

| Thickness [mm] | Test Temperature [ °C] | |

| 25<t≤30 | 10° below design temperature | |

| 30<t≤35 | 15° below design temperature | |

| 35<t≤40 | 20° below design temperature | |

| Table 4. Pipes (seamless and welded) The use of longitudinally or spirally welded pipes is to be specially approved by the Society.x, Forging and Castings The requirements for forgings and castings may be subject to special consideration.x, for Cargo and Process Piping for Design Temperatures below 0 °C and down to -165 °C The requirements for design temperatures below –165 °C are to be specially agreed. x. Maximum thickness 25 mm | |||

|---|---|---|---|

| Minimum design temperature [°C] | Chemical Composition The composition limits are to be approved by the Society.x and Heat Treatment | Impact Test | |

| Test temperature [ °C] | Minimum average energy (E) [J] | ||

| -55 | Carbon-Manganese Steel. Fully killed fine grain. Normalized or as agreed A lower design temperature may be specially agreed for quenched and tempered materials. x | 4 | 27 |

| -65 | 2,25 % Nickel steel. Normalized or normalized and tempered A lower design temperature may be specially agreed for quenched and tempered materials. x | -70 | 34 |

| -90 | 3,5 % Nickel steel. Normalized or normalized and tempered A lower design temperature may be specially agreed for quenched and tempered materials. x | -95 | 34 |

| -165 | 9 % Nickel steel This chemical composition is not suitable for castings.x. Double normalized and tempered or quenched and tempered | -196 | 41 |

| Austenitic steels (e.g. types 304, 304L, 316, 316L, 321 and 347). Solution treated Impact tests may be omitted subject to agreement with the Society.x | -196 | 41 | |

| Aluminum alloys; e.g. type 5083 annealed | |||

| Tensile and Toughness (Impact) Test Requirements | Each batch to be tested | ||

| Impact Test | Longitudinal test pieces | ||

| Table 5. Plates and Sections for Hull Structures by “Cargo containment system of gas vessel”Materials and “Cargo containment system of gas carrier”About materials | |||||||

|---|---|---|---|---|---|---|---|

| Minimum design temperature of hull structures [ °C] | Maximum thickness [mm] for steel grades in accordance with this | ||||||

| A | B | D | E | AH | DH | EH | |

| 0 and above “Cargo containment system of gas carrier”About materials | In accordance with Chapter 1 – Hull Structures, Section 2 | ||||||

| -5 and above “Cargo containment system of gas vessel”Materials | |||||||

| down to -5 | 15 | 25 | 30 | 50 | 25 | 45 | 50 |

| down to -10 | – | 20 | 25 | 50 | 20 | 40 | 50 |

| down to -20 | – | – | 20 | 50 | – | 30 | 50 |

| down to -30 | – | – | – | 40 | – | 20 | 40 |

| down to -30 | In accordance with Table 2 except that the thickness limitation given in Table 2 and the supplementary requirements for thicker material given in “Cargo containment system of gas vessel”Materials of that table do not apply. | ||||||

Welding and non-destructive testing

General

The requirements of this Section are those generally employed for carbon, carbon-manganese, nickel alloy and stainless steels, and may form the basis for acceptance testing of other material. At the discretion of the Society impact testing of stainless steel and aluminum alloy weldments may be omitted and other tests be specially required for any material.

Welding consumables

Welding consumables intended for welding of cargo tanks process pressure vessels and secondary barriers are to be in accordance with the Rules for Welding (Part 1, Vol. VI), unless otherwise agreed with the Society. Deposited weld metal tests and butt weld tests are to be required for all welding consumables, unless otherwise specially agreed with the Society. The results obtained from tensile and Charpy V-notch impact tests are to be in accordance with the Rules for Welding (Part 1, Vol. VI). The chemical composition of the deposited weld metal is to be recorded for information and approval.

Welding procedure tests for cargo tanks, process pressure vessels and secondary barriers

Welding procedure tests for cargo tanks, process pressure vessels and secondary barriers are required for all butt welds and the test assemblies are to be representative of:

- each base material;

- each type of consumable and welding process;

- each welding position.

For butt welds in plates, the test assemblies are to be so prepared that the rolling direction is parallel to the direction of welding. The range of thickness qualified by each welding procedure test is to be approved by the Society. Radiographic or ultrasonic testing may be performed at the option of the manufacturer or the Society. Fillet welding procedure tests are to be in accordance with the Society’s practice. In such cases consumables are to be selected which exhibit satisfactory impact properties.

The following welding procedure tests are required from each test assembly:

1 Cross-weld tensile tests.

2 Transverse bend tests:

- These bend tests may be face, root or side bends at the discretion of the Society. However, longitudinal bend tests may be required in lieu of transverse bend tests in cases where the base material and weld metal have different strength levels.

3 One set of three Charpy V-notch impact tests are be made generally at each of the following locations, as shown in Picture 1:

- Centre line of the welds;

- Fusion line (F.L.);

- 1 mm from the F.L.;

- 3 mm from the F.L.;

- 5 mm from the F.L.

4 Macrosection, microsection and hardness survey may also be required by the Society.

Test requirements

Tensile tests

Generally tensile strength is not to be less than the specified minimum tensile strength for the appropriate parent materials. The Society may also require that the transverse weld tensile strength is not to be less than the specified minimum tensile strength for the weld metal, where the weld metal has a lower tensile strength than that of the parent metal. In every case, the position of fracture is to be reported for information.

Bend tests

No fracture is acceptable after a 180° bend over a former of a diameter four times the thickness of the test pieces, unless otherwise specially required by or agreed with the Society.

Charpy V-notch impact tests

Charpy tests are to be conducted at the temperature prescribed for the base material being joined. The results of weld metal impact tests, minimum average energy (E), are to be not less than 27 J. The weld metal requirements for subsize specimens and single energy values are to be in accordance with this. The results offusion line and heat affected zone impact tests are to have a minimum average energy (E) in accordance with the transverse or longitudinal requirements of the base material, whichever is applicable, and for subsize specimens, the minimum average energy (E) is to be generally in accordance with this. If the material thickness does not permit machining either full size or standard specimens, the testing procedure and acceptance standards are to be approved by the Society.

Welding procedure test for piping

Welding procedure tests for piping are to be carried out and are to be similar to those detailed for cargo tanks in “Welding procedure tests for cargo tanks, process pressure vessels and secondary barriers”. Unless otherwise specially agreed with the Society, the test requirements are to be in accordance with “Test requirements”.

Production weld tests

For all cargo tanks and process pressure vessels except integral and membrane tanks, production tests are generally to be performed for approximately each 50 m of butt weldjoints and are to be representative of each welding position. For secondary barriers, the same type production tests as required for primary tanks are to be performed except that the number of tests may be reduced subject to agreement with the Society.

Tests, other than those specified in list below may be required for cargo tanks or secondary barriers at the discretion of the Society.

The production tests for independent tanks types A and B and semi-membrane tanks are to include the following tests:

- Bend tests, and where required for procedure tests one set of three Charpy V-notch tests is to be made for each 50 m of weld. The specimens having the notch alternately located in the centre of the weld and in the heat affected zone (most critical location based on procedure qualification results). For austenitic stainless steel, all notches are to be in the centre of the weld.

- The test requirements are the same as the applicable test requirements listed in “Test requirements” except that impact tests that do not meet the prescribed energy requirements may still be accepted, upon special consideration of the Society by passing a drop weight test. In such cases, two drop weight specimens are to be tested for each set of Charpy specimens that failed and both must show “no break” performance at the temperature at which the Charpy tests were conducted.

In addition to those tests listed above for type C independent tank and process pressure vessels, transverse weld tensile tests are required. The test requirements are listed in “Test requirements” except that impact tests that do not meet the prescribed energy requirements may still be accepted upon special consideration by the Society, by passing a drop weight test. In such cases, two drop weight specimens are to be tested for each set of Charpy specimens that failed, and both must show “no break” performance at the temperature at which the Charpy tests were conducted.

Production tests for integral and membrane tanks are to be specially agreed with the Society.

Non-destructive testing

For type A independent tanks and semi-membrane tanks where the design temperature is -20 °C or lower, and for independent tanks type B regardless of temperature, all full penetration butt welds of the shell plating of cargo tanks are to be subjected to 100 % radiographic inspection.

- Where the design temperature is higher than -20 °C, all full penetration butt welds in way of intersections and at least 10 % of the remaining full penetration welds of tank structures are to be subjected to radiographic inspection.

- In each case the remaining tank structure including the welding of stiffeners and other fittings and attachments are to be examined by magnetic particle or dye penetrant methods as considered necessary by the Society.

- All testing procedures and acceptance standards are to be approved by the Society. The Society may accept an approved ultrasonic testing procedure in lieu of radiographic inspection, but may in addition require supplementary inspection by radiography at selected locations. Further, the Society may require ultrasonic testing in addition to normal radiographic inspection.

Inspection of independent tanks type C and process pressure vessels are to be carried out in accordance with “Cargo containment system of gas vessel”Independent tanks type C.

For integral and membrane tanks, special weld inspection procedures and acceptance criteria are to be submitted for approval by the Society. The inspection and non-destructive testing of the inner hull or the independent tank structures supporting internal insulation tanks is to take into account the design criteria as given in “Cargo containment system of gas vessel”Internal insulation tanks. The schedule for inspection and non-destructive testing is to be to the satisfaction of the Society.

Inspection of piping is to be carried out in accordance with the requirements of “Piping System of pressure vessels on gas tankers”Piping system

The secondary barrier is to be radiographed as considered necessary by the Society. Where the outer shell of the hull is part of the secondary barrier, all sheer strake butts and the intersections of all butts and seams in the side shell are to be tested radiography.