A Material Safety Data Sheet (MSDS) is a document that provides information about the properties, hazards, handling, storage, and emergency procedures related to a specific chemical or product. It includes details such as chemical composition, physical and chemical properties, health hazards, safety precautions, and first aid measures in case of exposure. MSDSs are important for ensuring the safe handling and use of chemicals in workplaces and for emergency responders to have vital information in case of accidents or spills.

MSDS‘s are important for ensuring the safe handling and use of chemicals in workplaces and for emergency responders to have vital information in case of accidents or spills.

A Knowledge and understanding of tanker safety culture and safety managementMaterial Safety Data Sheet (MSDS) provides basic information on a cargo carried on board gas Carriers. This includes the properties and potential hazards of the material, how to use it safely and what to do in an emergency.

The MSDS is an essential starting point for the development of a complete health and safety program for the material. MSDS are prepared by the manufacturer or supplier of the material. They tend to be general in nature, since they provide summarized information which tries to address all reasonably anticipated uses of the material.

The information on MSDS‘s is organized into sections. The specific names and content of these sections can vary from one supplier’s MSDS to another, but are often similar to the 16 sections of the ANSI Standard MSDS. The MSDS are also included in the CHRIS Code and the ICS data sheets appended in part D2.

As per Chapter 18 – «Operating requirements» of IGC Code, Information should be on board and available to all concerned, giving the necessary data for the safe carriage of cargo. Such information should include for each product carried:

- A full description of the physical and chemical properties necessary for the safe containment of the cargo.

- Action to be taken in the event of spills or leaks.

- Counter-measures against accidental personal contact, fire-fighting procedures and fire-fighting media.

- Procedures for cargo transfer, gas-freeing, ballasting, tank cleaning and changing cargoes.

- Special equipment needed for the safe handling of the particular cargo; x Minimum allowable inner hull steel temperatures,

- and emergency procedures.

Additionally products required to be inhibited should be refused if a certificate from the manufacturer stating the below information is not provided:

- name and amount of inhibitor added;

- date inhibitor was added and the normally expected duration of its effectiveness;

- any temperature limitations affecting the inhibitor;

- and the action to be taken should the length of the voyage exceed the effective lifetime of the inhibitors.

Function and Proper use of Gas Measuring Instruments and Similar Equipment, Proper use of Safety Equipment and Protective Devices

Safety equipment & protection of personnel

General

All tanker vessel are designed, constructed and equipped under the strict supervision and control of their respective classification society. This is to ensure the personnel onboard should not be exposed to the hazards inherent during cargo handling. But in certain circumstances, such as scheduled maintenance or emergency danger arises. It is essential to know the operating principles and limitations of this equipment.

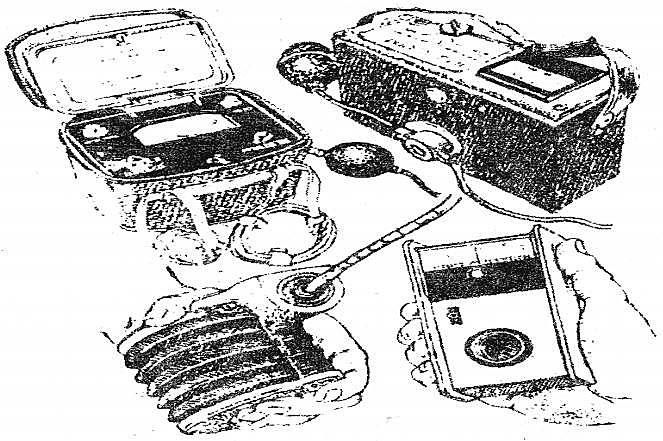

I Gas Measuring instrument

a) Oxygen Meter/Analyzer – An instrument for determining the percentage of oxygen in a sample of the atmosphere drawn from the tank, pipelines or compartment.

Calibration:

- Zero – Nitrogen.

- Span – Normal air (Atmosphere).

b) Explosimeter/Combustible Gas Indicator – An instrument for measuring the composition of hydrocarbon gas/air mixtures, usually giving the result as a percentage of the lower flammable limit.

Calibration:

- Zero Nitrogen (atmosphere).

- Span – Combustible Gas Propane/Butane).

c) Toximeter/Gas Absorption Detector – An instrument used for the detection of gases or vapours which works on a principle of discolouring a chemical agent in the apparatus.

Calibration:

- Change the chemical agent.

- (Dragger Tube).

- Clear the instrument from gases previously tested.

II Fire Extinguishing Appliances

Fire Extinguishing

- Water (jet, spray , fog).

- Foam (chemical foam {(A+B)/mechanical foam (AFFF)}.

- Dry Powder.

- Dry Chemical.

- CO2.

- Halon (inhibits the fire) contains CFC.

- Steam.

- IG System (Tanker with operational IGS).

- Sand (smalls fire).

Correct media in Different types of Tanker Cargoes

Oil Fires

- Foam.

- CO2.

- Halon.

- Water Fog.

- Steam.

- Dry Powder (small fires).

- Sand (small fire).

Liquefied Gas Fires

- Dry Powder.

- Foam.

- Inert gas (IGS).

Water should never be applied on Safety Liquefied Gas of Marine Transportationburning Liquefied Gas Pool since it will provide a heat source for more vaporization of the liquid.

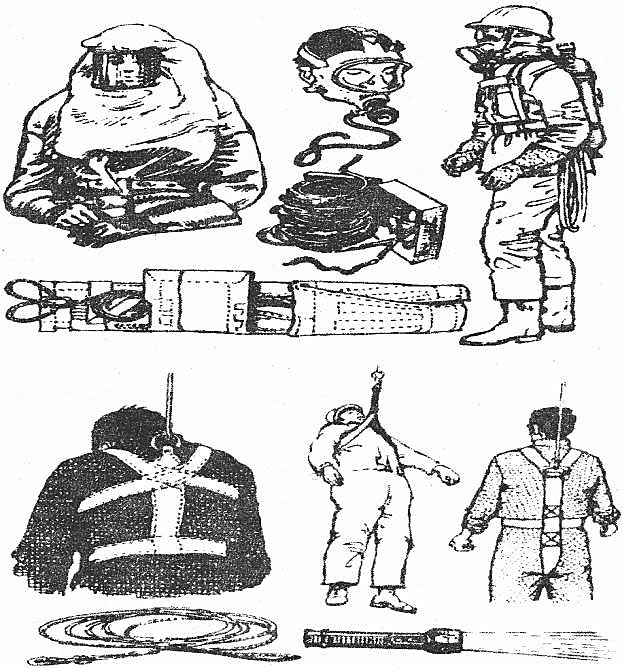

III Breathing Apparatus

- Oxygen Breathing apparatus (OBA).

- Fresh Air Respirators.

- Canister Filter Respirators.

- Compressed Air Breathing Appliances (CABA).

- Self – Contained Breathing Apparatus (SCBA).

IV Resuscitators

Use of Resuscitators

People overcome by smoke in a fire or those deprived of oxygen in an enclosed space will have immediately require resuscitation. Personnel should be instructed in the technique of artificial resuscitation (AR) as the most important and effective means of resuscitation. Responsible personnel should also be instructed in the use of resuscitation apparatus.

Read also: Custody Transfer Measurement System (CTMS) on Liquefied Gas Carriers

V Tanker Evacuating Equipment

- Escape/Emergency Life Saving Apparatus (ELSA).

- Self-Contained Breathing Apparatus (SCBA).

VI Rescue and Escape Equipment

- Escape/Emergency Life Saving Apparatus (ELSA).

- Canister Filter Respirators.

- Oxygen Breathing Apparatus (OBA).

- Self-Contained Breathing Apparatus (SCBA).

- Emergency Escape Breathing Device (EEBD).

VII Safe Use of Protective Clothing & Equipment (PPE)

Personal Protective Equipment

- Safety Helmets/Hard Hat.

- Safety Boots/Shoe.

- Coveralls/Boiler suits.

- Gloves.

- Ear Defenders.

- Safety Goggles.

- Safety Spectacles.

- Safety Harness.

- Buoyancy Aids.

- Visor.

- Respiratory Filters (Filter Mask/Gas Mask).

- Chemical Suits.

- Enclosed Space Entry Jacket.