Type “C” tanks are a specialized type of cargo tank that has been designed for the safe transportation and storage of liquids and gases. These tanks are characterized by their unique design features, which include a robust structure, advanced insulation, and a sophisticated system of valves and pipes. Type “C” tanks are commonly used in a variety of industries, including petroleum, chemicals, and liquefied natural gas (LNG) transportation.

One of the key advantages of Type “C” tanks is their ability to maintain the temperature and pressure of their contents, ensuring that liquids and gases remain stable and secure during transport. The insulation and structural design of these tanks play a crucial role in achieving this stability. Additionally, Type “C” tanks are built to withstand extreme conditions and are rigorously tested to ensure their safety and reliability.

Type “C” Tanks

LNG Carriers with Type “C” Tanks

There is a general consensus is the common idea that “C” type tank is not suitable for the Safety Liquefied Gas of Marine Transportationtransportation of LNG. However, a couple of LNG carriers with type “C” tanks have been built in Japan by Kawasaki for local delivery of small amount of LNG. Apparently, these ships are well suited for their intended service. Figure 1 is a view of the two photos of the 2 500 m3 capacity LNGC Shinju-Maru No. 1.

“C” Type Cargo Containment System Concept

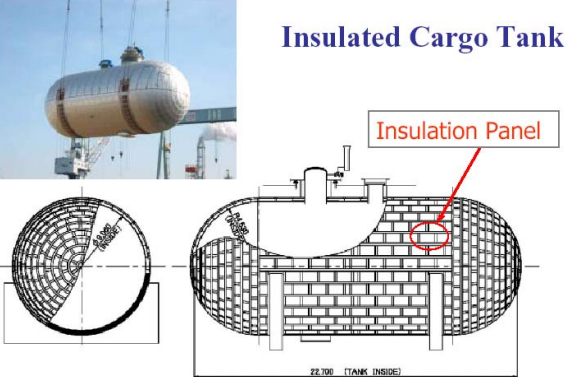

The cargo tanks consist of pressure-vessels designed in accordance with the IGC Code requirements for cargo tanks.

No secondary barrier is provided, as the IGC Gas Code does not require secondary barrier if the cargo is contained in type “C” tanks.

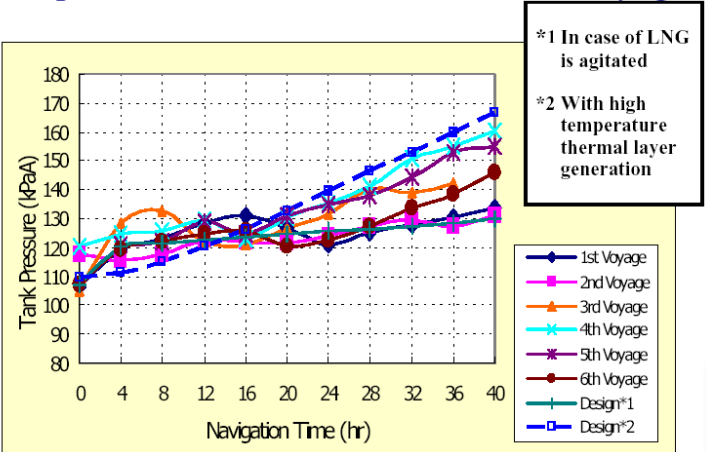

A particular feature of this type of ship is the fact that means to dispose boil-off are not addressed. BOG resulting from heat ingress is totally contained in Independent Cargo Tanksthe cargo tanks, which are designed to withstand the increased pressure during laden and ballast voyage. Heat accumulated in the tanks during the voyages is released during loading/unloading operations.

Note that this arrangement would not be acceptable under The ABS and USCG Additional Rules and GuidesUSCG regulations.

Cargo Tank Design

Cargo tanks are actually pressure vessel designed for a maximum pressure of pressure 3,0 bar. This pressure has been calculated using the maximum possible increase of pressure during a period of 7 days, i. e. 5 days (maximum length of contemplated journey) +2 days margin in fully loaded condition with thermal layer.

The tanks are two identical horizontal cylindrical tanks of 22,7 m length and 9,06 m diameter, are supported by laminated phenolic resin liner saddles. They are built with aluminum alloy and have hemispherical end. For the 330 mm thick insulation, the typical Kawasaki insulation system.

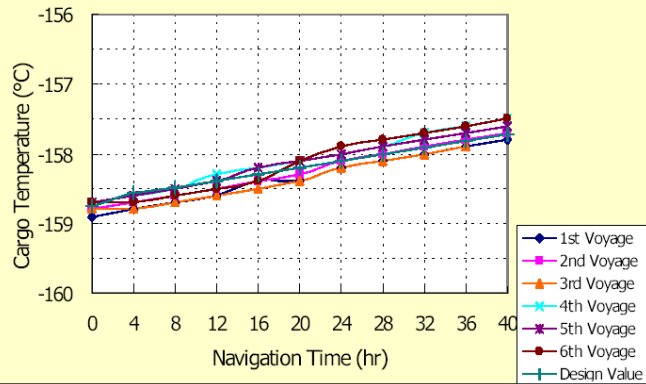

Figures 2, 3 and 4 show two diagrams showing the actual measured temperature and pressure raise in the tanks during a period of 40 hours of navigation and the construction of the tank.