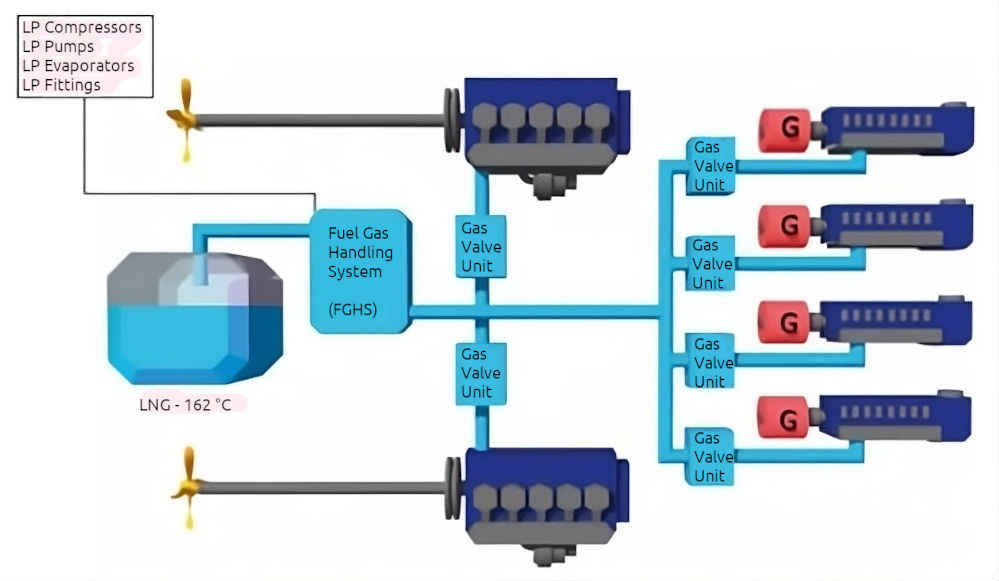

X-DF engine is a low-speed, 2-stroke, dual-fuel engine and it is an alternative to Dual-fuel diesel electric/Tri-fuel diesel electric (DFDE/TFDE)DFDE/TFDE and M-type electronically controlled gas injection (ME-GI)ME-GI propulsion systems that is estimated to offer capital expenditure reductions of 15-20 % via a simpler and lower cost LNG and gas handling system.

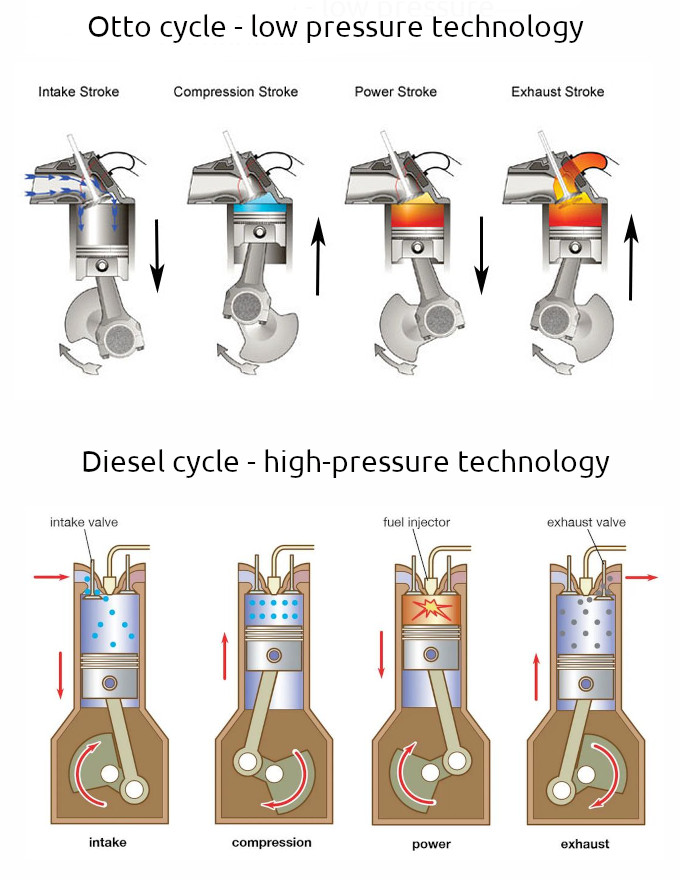

Low pressure DF technology is based on the lean burn principle (Otto cycle), in which fuel and air are premixed, and burned at a relatively high air to fuel ratio – a concept already used widely on medium-speed 4-stroke engines.

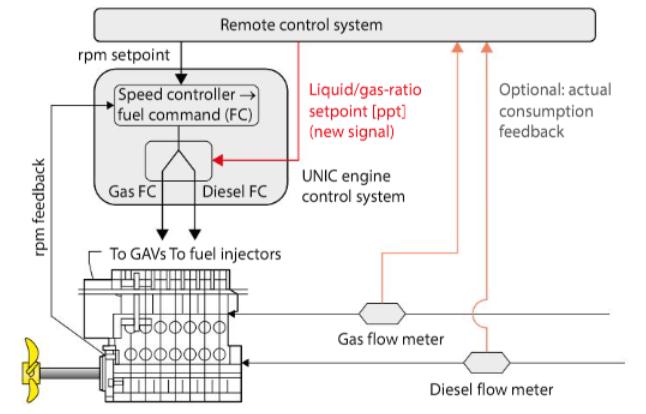

The X-DF engines may be operated in either:

- gas mode with < 1 % MDO pilot and gas;

- diesel mode, with 100 % MDO/HFO;

- adjustable ratio of gas to HFO. This can be used to balance between the available BOG and the desired ship speed.

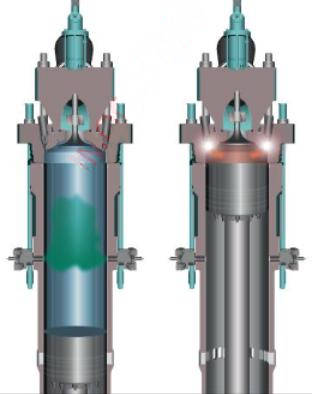

Low pressure DF technology requires a simple gas supply system, reducing complexity and auxiliary power consumption. Since the fuel gas is mixed with the scavenge air before compression, the required gas pressure is below 13 bar at any operating point and the fuel supply system is relatively simple, reliable and well proven.

Significant gains are reportedly achieved by eliminating the high pressure gas compression system.

Due to its lean burn combustion process, this technology has the potential to significantly reduce the formation of NOx. With lean burn DF engines, no additional exhaust gas treatment system is needed to meet the IMO Tier III NOx limits in coastal regions.

The low pressure DF solution also reduces the ship’s total CO2 footprint, although the backup diesel fuel mode is available at any time. Manufacturers state that it only takes one engine revolution to change from gas to diesel mode, without any interruption of power or speed, at any load. The low pressure gas supply system requires no large compression equipment and because of the low pressures involved, a wide range of Low Duty Compressor(s) on the Liquefied Natural Gas Carriersproven compressors/cryogenic pumps and manufacturers are available.

| Gas and Diesel Low-Pressure Two-Stroke Engine (X-DF) | |

|---|---|

| Advantages | Disadvantages |

| Lean burn “Otto cycle” combustion provides IMO Tier III compliance without additional equipment | Depending on engine configuration, in-port maintenance may not be allowed |

| Low fuel gas pressure < 13 bar | Machinery more complicated than steam turbine arrangement |

| Lower capital expenditure/maintenance cost due to reduced gas pressure | Limited operational experience available and development work still ongoing |

| Lower electrical power demand allows installation of less auxiliary engine power | Maintenance more intensive than steam turbine plant due to diesel engine requirements |

| Particulate matter emissions reduced to almost zero | Either GCU or reliquefaction plant required to handle excess BOG |

| Design readily lends itself to twin screw arrangements | |

I AM PROFESSOR AND MARTERS' IN MARINE DESIGNING FROM SINGAPORE I LIKE YOU PUBLICATIONS MATERIAL IT PROVIDES GREAT KNOWLEDGE AND PROVIDES GREAT SERVICES FROM YOUR ORGANIZATION

Thank you very much for your kind words!

We truly appreciate your feedback and are glad to know that our publications are useful for professionals in marine design. Your support motivates us to continue developing high-quality content for the maritime community.