A boat is equipped equipment with various essential components that allow it to navigate and operate effectively. The main body of the sailboat, known as the hull, is designed to provide buoyancy and stability, and can be made from materials such as fiberglass, wood, or metal. The mast is a tall vertical pole that supports the sails and is typically made of aluminum or carbon fiber for strength and lightness. Attached to the mast is the boom, a horizontal pole that extends the bottom of the mainsail and allows for better control of the sail’s angle to the wind.

The sails themselves are crucial for propulsion. The mainsail, attached to the mast and the boom, captures wind and propels the boat forward, while the jib or genoa, a smaller sail at the front, helps with steering and balance. The rigging, including stays and shrouds, is a system of ropes and wires that supports the mast and controls the sails. The keel, a fixed fin-like structure at the bottom of the hull, provides stability and prevents the boat from capsizing by counteracting the force of the wind on the sails.

The rudder, located at the stern, is connected to a tiller or a wheel and is used to steer the boat. Below deck, the sailboat may have various amenities, including a cabin with sleeping quarters, a galley (kitchen), and a head (toilet). Safety equipment, such as life jackets, fire extinguishers, and first aid kits, are also essential parts of a sailboat’s gear.

Understanding Sailboat Specs

The specifications of any particular boat are important to understand because they give you some idea about how that sailboat might handle. Some specs, like boat length, are pretty simple to grasp. But to get an idea of a boat’s performance without actually taking it out on the water, you have to look at several specifications together. These are often expressed as ratios, such as the ballast to displacement ratio. Let’s look at some numbers first.

Here are the specifications for my Montgomery 17.

| Length | 17 feet 2 inches |

| L. W. L. | 15 feet 10 inches |

| Beam | 7 feet 4 inches |

| Weight | 1 600 pounds |

| Ballast | 580 pounds |

| Draft | 3 feet 6 inches/1 foot 9 inches (centerboard down/up) |

| Sail area | (100 percent foretriangle) 154 square feet |

| Disp./length ratio | 225 |

| Ballast/disp. | 37,4 |

Boat Length

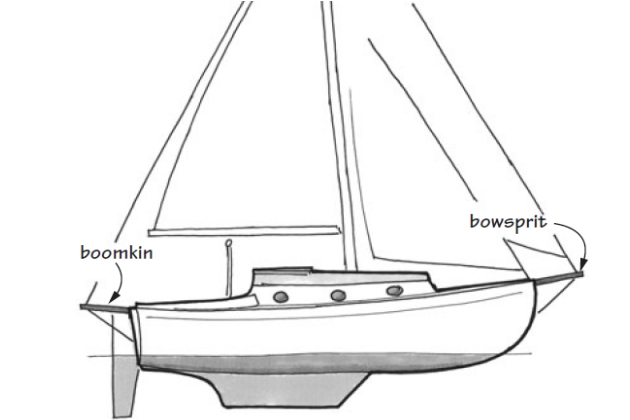

The first specification is usually the length of the boat, in this case 17 feet 2 inches. Just to confuse the goose, this specification is sometimes given as LOA (length overall) or LOD (length on deck). The difference is that LOA includes a bowsprit, if the boat has one. LOD is the length of the boat alone, not counting any rigging appendages. A bowsprit, by the way, is a short, strong pole extending forward from the boat. It gives the boat a longer effective sail plan than boats with «inboard» rigging. You’ll find bowsprits on older, traditional designs, but not often on trailerables. The only such models I can think of are the old MacGregor Venture 23 – it has a fixed bowsprit – and the Montgomery 23, which has both a bowsprit and a boomkin.

What is boomkin?

A boomkin is an extension at the stern, similar to a bowsprit, that also lengthens the sail plan.

Another expression of boat length is length at waterline, or LWL. The LWL is more important, hydrodynamically speaking, than the length on deck. In fact, older racing classes were commonly described by their waterline length rather than their overall length. The famous New York 32s by Sparkman and Stephens are actually 45 feet long on deck and 32 feet at the waterline. Waterline length is important to know for several calculations, if you like to crunch boat numbers like naval architects do.

Now, you may have heard that longer boats go faster. This is true on paper, but it’s not often a good reason to select a larger trailerable over a smaller one. Here’s why. The maximum theoretical speed for displacement hulls (that is, nearly all cruising sailboats) can be calculated using the following formula:

Plugging in the numbers for the Montgomery 17 gives the following result:

The same calculation for the MacGregor 22 gives a top theoretical speed of 5,71 knots. That’s only four-tenths of a knot difference – not much gain for 5 feet of length on deck. In actual use, my M-17 is a bit faster than my MacGregor was – it points higher and isn’t quite as tender (a tender boat heels easily in the wind). But honestly, I wouldn’t worry much about theoretical hull speed. The difference between most boats is small, and is often outweighed by other factors like sail shape, condition of the bottom, and the amount of toys you’ve loaded aboard. If you’re a racer and are comparing two all-out race boats, you might want to investigate this further, but for normal recreational sailing, I wouldn’t sweat it.

Of course, the theoretical hull speed calculation is for monohull displacement sailboats only. Multihull boats like catamarans (two hulls) and trimarans (three hulls) are different beasts altogether. And a few all-out racing Comprehensive Collection of Common Sailboat Rig Types and Designssailboats are designed with planing hulls, meaning their broad, flat hulls are designed to skim over the surface of the water rather than plow through the water.

Beam

The beam is the boat’s width measured at its widest point. The boat and trailer combined can be no wider than 8 feet without requiring a special permit to be transported on the highway (though some states have increased this limit to 8 feet 6 inches).

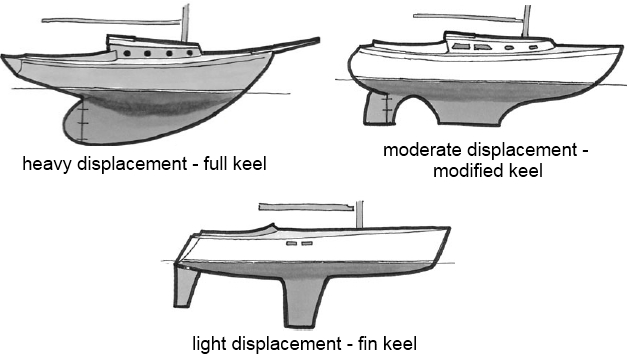

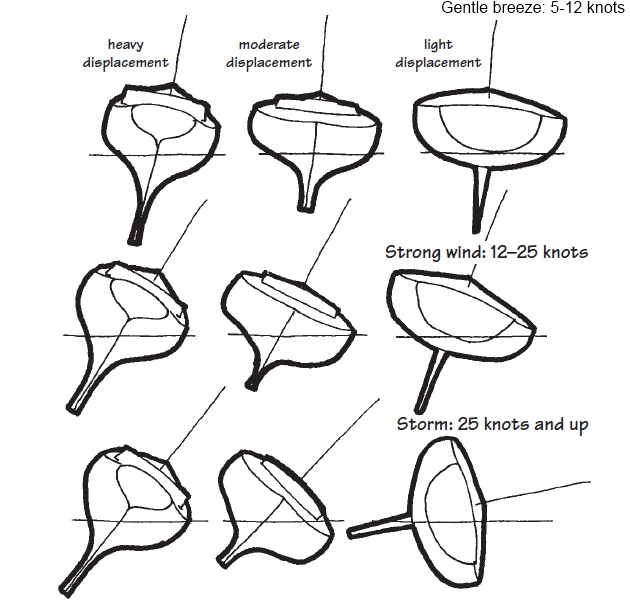

The boat’s beam is important for more reasons than just trailerability; it has a lot to do with how she sails as well. If you look at older, classic boat designs, you’ll notice that they tend to have narrower beam, deeper draft, and heavier overall displacement. The narrower beam makes the boat initially tender, but as it heels over and the ballast takes effect, the boat stiffens and (usually) sails nicely. The heeling effect of the wind is balanced primarily by the ballast in the bottom of the hull. (The term heeling means to lean as a result of the wind’s force on the sails. See the section «Getting Underway and Sailing on the SailboatSail Trim».)

With the coming of fiberglass, though, designers found a way to reduce the ballast needed for stability. On more modern boats, the flatter, beamy hull provides resistance to heeling. The whole boat, being lighter, performs better in light winds. The only downside is that in storm conditions, this type of boat is easier to capsize. And once inverted, it has more of a tendency to stay that way. So if you are out in the middle of the ocean in a really big storm, you want to be in a narrow, heavy, older type of hull rather than a new, beamy, lightweight hull.

You can visualize this somewhat with a couple of glasses and a pitcher of water. Take a wineglass and float it in the water. (Some of these classic, deep-draft hulls were called «wineglass» hull forms, in fact.) You’ll notice that it floats in a very stable manner – you can press on the sides or slosh the water around, and the wineglass won’t wiggle much – you can sink it only by sloshing water inside the glass.

Now try the same thing with a flat-bottomed tumbler of about the same volume. Pressing on the sides or sloshing the water will cause the tumbler to move quite a bit more. But the tumbler, of course, floats in a lot less water, and that’s an advantage of the more modern hulls – they often have shallower draft.

Draft and Keels

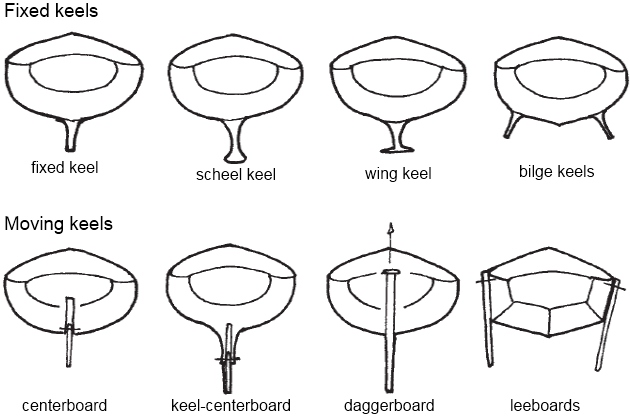

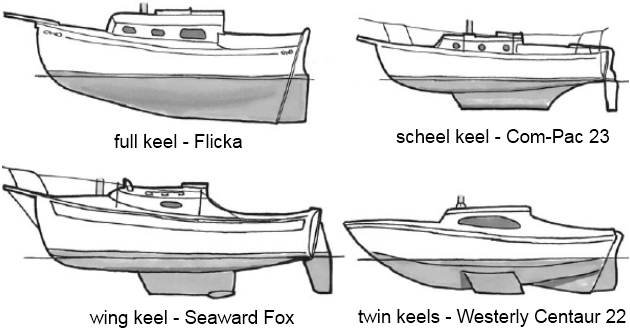

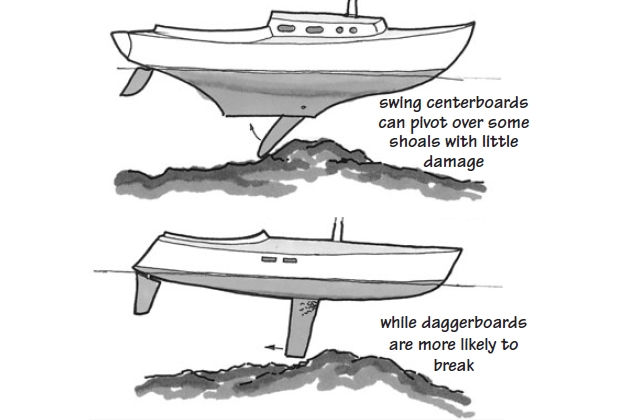

Draft is the measurement from the waterline to the bottom of the boat. Stated another way, it’s the minimum depth the boat will float without grounding. Draft includes the keel and the hull combined. A boat’s keel (or keelson) is, technically and correctly, the structural backbone of the vessel – in wooden boats, it’s the strongest timber running right down the center of the boat to which the ribs are attached. But by this definition, most Manufacturing of Fiberglass Boats and Design Featuresfiberglass boats don’t have keels, or ribs for that matter. So the term keel has come to mean the part of the boat below the waterline that primarily resists the leeward (or downwind) force of the wind.

When we talk about a fin-keel sailboat, or a full-keel sloop, we may not be technically correct, but that’s the way the term is often used.

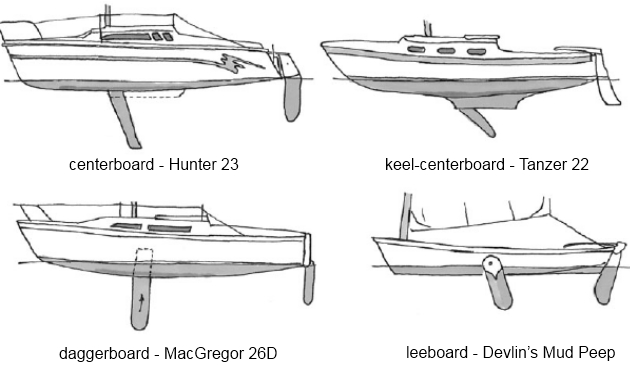

Some boats have what is called a swing keel (which technically should be called a centerboard). This is a heavy iron, lead, or fiberglass blade that’s attached at the forward end by a bolt. At the after end is a rope or wire pendant (pronounced «pennant») that is used to raise or lower the centerboard, often with the aid of a winch. So in this case, the boat’s draft is adjustable – deep when sailing, then raised for trailering or floating through shallow water. Most centerboard boats have a trunk inside the hull that houses the keel when it’s retracted. This gives the boat a very shallow draft, and it allows the boat to ride lower on the trailer, making launching and retrieving easier. My MacGregor Venture 222 was built this way. The first time I tried to haul the boat at the ramp, I floated my boat right over the trailer bunks and had a slight collision with the winch post – it required an amazingly thin layer of water to float the boat.

A few trailerable boats, such as the:

- O’Day 22,

- Cal 20,

- J/22,

have a fixed keel. A fixed keel doesn’t adjust – it’s an integral part of the hull. The advantages are:

- strength,

- simplicity,

- reduced cost.

The disadvantage is that fixedkeel boats need deeper water for launching and retrieval, and cranking up the centerboard to explore shallow waters isn’t an option. It is sometimes said that small fixed-keel sailboats don’t point as high to windward, but this isn’t universally true. If you’re a lake sailer, grounding a fixed-keel boat is a bit more of a problem than in coastal waters, since you don’t have the tide to help float you off. In the summertime or in warm waters, it’s often possible to go over the side and muscle the boat back into deeper water, since fixed-keel trailerables don’t usually draw more than 3 feet or so.

Some boats have a combination of the two systems. Called a keel-centerboarder, a shallow, ballasted keel holds a small centerboard that can be raised or lowered with a keel pendant. This system has a number of advantages, like improved upwind performance over fixedkeel trailerables, and no centerboard trunk taking up cabin space. Since the ballast is fixed in the keel and not the centerboard, the centerboard is lighter. Wear on the pivot bolt and the pendant is reduced. My Montgomery 17 has this type of keel. The disadvantages: greater depth is required to launch, the boat sits higher on the trailer, and occasionally rocks and other debris from a grounding can cause the centerboard to jam in the slot.

It will be interesting: Types of Sailboats and Their Management

Another keel system found on some boats (such as the West Wight Potter) is a daggerboard. This type of keel lifts straight up and down and is housed in a vertical trunk. Like other keels, this system has its advantages and disadvantages. A vertically oriented keel is an efficient foil for upwind work and can enhance performance. It’s a simple system requiring little maintenance – you don’t have to inspect or replace the pivot bolt, for example. But the downside is that the daggerboard and its trunk can be damaged in a hard grounding, since a lot of stress is concentrated in a small area.

Centerboards and daggerboards are the most common, but not the only, keel systems found on trailerable sailboats. A very few boats use a twin-keel system, where two large fins are fixed at the turn of the bilge.

Boats such as the:

- Pegasus Prelude,

- Signet 20,

- Westerly Warwick,

- Pageant,

- Spirit,

- Centaur,

- Hurley 22,

- Snapdragon 21,

- Pandora 21,

- Hunter Duette 23,

- and the Red Fox 200T,

were built with twin bilge keels. All of these boats are from British manufacturers – no US boatbuilders manufactured twin-keel yachts in significantnumbers. While twin keels are not as effective for upwind work, they have the advantage of shoal draft, easy trailering, and, when the tide goes out, grounding upright rather than falling over to one side. Occasionally you’ll find a leeboard or twin centerboards, but not on production sailboats.

Yet another consideration with keels is the loaded height on the trailer. Swing-keel and daggerboard boats can sit lower on the trailer, whereas fixed-keel and keel-centerboard boats must naturally rest higher on the trailer.

Some trailerable race Basic Hull, Keel, and Rudder Shapesboats have keels so deep that the boats can’t be launched from a ramp, but must use a crane. Boat manufacturers realize this is a significant liability for a generalpurpose sailboat, so nearly all designs allow for ramp launching. But some boats need better ramps than others – they may require trailer tongue extensions to get the trailer deep enough yet not flood the car.

The loaded height on the trailer can be a problem if you plan on keeping your boat in a standard garage – it might be too tall to fit.

Displacement

A boat’s displacement is a basic measurement. It can be thought of as simply the weight of the boat, but more accurately it’s the weight of the water that the boat displaces when floating at its designed waterline.

Displacement can be expressed as weight in pounds or tons, or as a volume of water in cubic feet. (Remember that salt water is slightly heavier than fresh water, so the displacement in cubic feet will be different for salt and fresh water. The difference becomes significant only with really, really big boats – like tankers.)

Knowing a boat’s displacement is useful when comparing boats of a similar or identical length. For instance, if one 17-footer displaces 1 100 pounds and another displaces 1 550 pounds, we can guess that the lighter of the two might have better light wind performance, or that the heavier might do better in a storm. Plenty of other factors play into this equation, like sail area, displacement to ballast ratio, wetted surface areas, and so forth, but displacement is an important factor in evaluating possible performance.

At the most basic level, it affects how easily the boat can be pulled with the family car – the lighter it is, the easier it is to haul, launch, and retrieve.

D/L Ratio

Displacement to length ratio (D/L or DLR) is a nondimensional expression of how heavy a boat is in relation to its waterline length. The formula looks like this:

where:

- Disp = displacement in pounds;

- LWL = length at waterline.

So, using my Montgomery 17 as an example:

This figure is for an empty boat with no one aboard and no gear. If I add 150 pounds for myself and 250 pounds for the motor, gas, water in the tanks, and swim noodles, I get a more realistic figure of about 214. The following chart shows the DLRs calculated for a range of boats.

| Light racing multihull | 40-50 |

| Ultralight ocean racer | 60-100 |

| Very light ocean racer | 100-150 |

| Light cruiser-racer | 150-200 |

| Light cruiser | 200-250 |

| Average cruiser | 250-300 |

| Heavy cruiser | 300-up |

You won’t find any heavy-displacement trailerables these days. In fact, they’re pretty rare among larger boats as well. The trend over the last forty years or so has been toward lighter boats. Fiberglass is an inherently lighter construction material, and hull shapes that originally took a lot of wood have been adapted to fiberglass using less material by weight.

Lighter displacement makes more sense for a trailer sailer, but only up to a point. If a boat is too light, the stress of regular use will cause it to wear out much more quickly. Putting a boat on a trailer often increases the point loading on the hull, where the weight of the boat is concentrated at fewer places on the hull – specifically the turn of the bilge, the keel, and the bow. You will occasionally see older lightweight boats with depressions in the hull caused by an illfitting trailer or poorly placed chocks.

This is more often a concern when looking at older racing sailboats, though some lowcost boats suffer from inadequate structural strength. It is often said that you buy sailboats by the pound, with heavier boats naturally costing more. High-tech racers are the exception, of course.

Ballast

All sailboats have some form of ballast, which is any kind of heavy, dense material placed as low as possible in the hull. It helps provide the boat’s righting moment, which is really a fancy term for gravity at work – when the wind heels the boat, the righting moment resists the wind’s force, keeping the mast as vertical as possible. Gravity is pulling at the heavy keel, trying its best to bring it to the bottom of the sea. The buoyancy of the hull prevents gravity from accomplishing its mission, provided we can keep the ocean out of the boat. This is a major tenet of any form of boating. As the boat heels, and the bottom ballast becomes more horizontal, the weight of the keel counteracts the heeling force of the wind, and the boat reaches a balance point.

Most boats have ballast that is either lead, cast iron, steel or steel punchings, concrete, or, in some newer designs, water. Lead ballast is most desirable – its high density gets the weight as low as possible in the hull, where it is most effective – but it’s also expensive. The trouble with steel ballast is that it can corrode, and rust expands with great force. Concrete is cheap and doesn’t rust, but its density is comparatively low. If two identical boats were built, one ballasted with lead and the other with concrete, the concrete boat would have a greater tendency to roll.

Cast-iron ballast is often found as a swing keel. While cast-iron keels can and do rust, cast iron is preferred – here’s why.

I’ve owned two trailer sailers with two different types of ballast. The How to Choose Your First Boat?first boat had a swing keel made of three half-inch steel plates welded together. When the boat was originally built, this very heavy assembly was laid in a mold with a few layers of fiberglass and filled with resin. This keel worked fine for a few years, but polyester resin, without much fiberglass to reinforce it, is fairly brittle. Small stress cracks appeared, and water found its way to the steel core. The resulting rust expanded, pushing the brittle resin/glass covering away from the core. This allowed more water in, which finally swelled the keel so much that it jammed tight against the centerboard trunk.

I was able to fix it, but the work took several weeks. I had to strip everything off, sandblast the core, and relaminate the whole thing with several layers of glass and epoxy resin. It wasn’t a lot of fun.

My current trailer sailer has a cast-iron centerboard that is housed in an external stub keel. (This is like a shallow keel with a slot in it for the centerboard.) While the centerboard provides some ballast (180 pounds), most of the ballast is in the keel, along the sides of the centerboard slot. This centerboard also got stuck because of corrosion, but repairing a cast-iron centerboard is a much simpler process. I removed the centerboard, had it sandblasted, and painted it with primer. I took the optional step of filling and smoothing some of the deep pits, then sanded, painted, and reinstalled the board. It was still a pain, it was a lot easier than rebuilding the keel from the core up.

Water ballast for trailerable sailboats isn’t a new idea, but it has recently been embraced by contemporary boatbuilders. When the boat is on the trailer, we want the lightest boat possible, but when it’s in the water, we need more weight. Water is pretty darned heavy, but this approach does present some design challenges. For water to be effective as ballast, it needs to be above the waterline. Otherwise it’s neutrally buoyant, and has little effect other than to lower the boat in the water. Water ballast tanks are usually filled by opening a valve when the boat is launched, allowing the tanks to fill.

The same valve drains the tanks when the boat is on the trailer. Some racing boats have more complex arrangements, using pumps to move the water to the windward tank and increase its effect. Popular water-ballasted designs include the Hunter 240, the MacGregor 26, and the Catalina 250. As the boat heels, water ballast is sometimes lifted above the waterline, where it becomes more effective, but this depends on the design of the boat. Water-ballasted boats are sometimes reported to be initially tender, and the plumbing/piping systems can be complex. But they can work well – I once sailed in side by side with a newer water-ballasted MacGregor, which performed admirably. It was quite a bit faster, and pointed almost five degrees higher than my traditionally ballasted boat.

Water ballasting does have a drawback, though. In 2002, the Burlington Free Press ran a story of a water-ballasted sailboat that capsized when the operator reportedly overloaded the boat. Seven adults were on deck, but three children were below. They were wearing PFDs, but two of them became entangled in gear and drowned. One reason the boat capsized was that the ballast tanks were never filled. The operator, who had borrowed the boat and didn’t know about the necessity of filling the ballast tanks, was charged with BWI (Boating While Intoxicated) and manslaughter. The moral of this story isn’t to condemn water ballast, but a warning to know your boat and its systems, and take your responsibility as captain seriously.

Sail Area

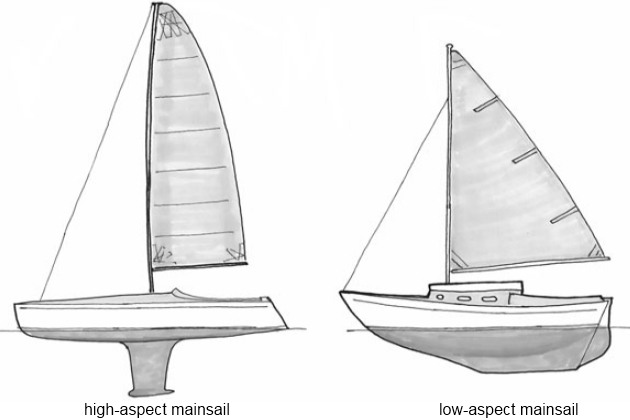

Still another predictor of sailboat performance is sail area. Published specifications usually list the sail area of a boat as a combination of mainsail and working jib, but of course the sail area can be adjusted to suit conditions. Many older designs (from the mid-1960s) often had shorter masts and long booms. These are considered low-aspect-ratio mainsails. On newer designs, the booms are shorter and the masts are taller – known as high-aspect-ratio mainsails. These are most often seen on modern racing boats.

One of the reasons modern boats have higher-aspect rigs is function – some boats that are raced and cruised need high performance upwind. Another reason is style rather than function: boats that look fast sell better. But they may also be more expensive, more complicated to rig, and trickier to sail well off the wind.

On a race boat, the high-aspect rig gets more sail higher up, and it’s a screamer upwind. But off the wind, the sail doesn’t perform as well – it’s more likely to stall, which means the wind doesn’t flow smoothly across the sail’s surface. A tall mast is also more difficult to raise at the ramp, and often requires more stays to give it strength than a shorter mast would. My point is that you shouldn’t dismiss an older design as old-fashioned, since a more moderate mainsail might be a better all-around performer. Remember too that taller masts need deeper keels to balance them.

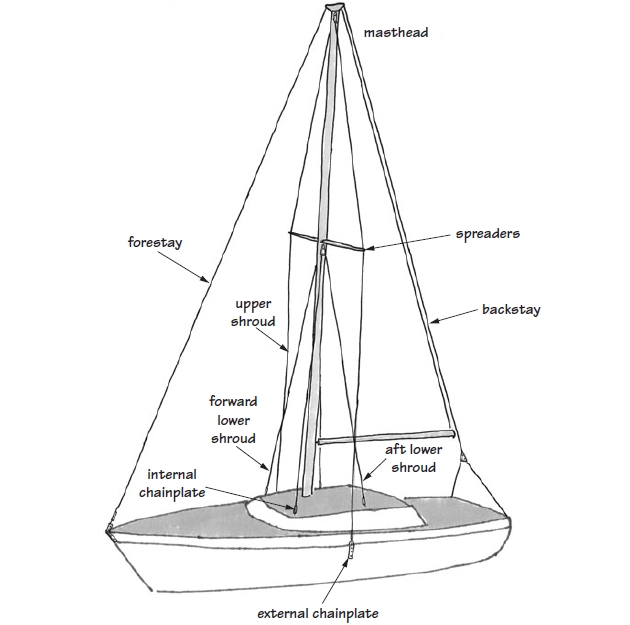

Rigging

Most trailer sailers are masthead sloops, and it can be said that smaller boats have simpler rigs. With each increase in size, rigging becomes a more complicated, longer task. One popular 16-footer, for example, has no spreaders, a small, light mast, and no backstay. Three wires are all that’s required to hold up the mast – a forestay and two shrouds. Setting up a boat like this is pretty fast, and you can often go from highway to dockside in about twenty minutes.

Go a little larger and you’ll find sloops rigged with a forestay, a backstay, two lower shrouds, and two upper shrouds. In addition, there will be spreaders, which can sometimes foul halyards and other lines when raising sail. This type of mast is taller and heavier. It’s possible to rig a boat like this by yourself, but be prepared for some heavy lifting. If you commonly rig and launch the boat alone, then some kind of mast-raising aid is a good idea. Plan on spending thirty minutes to an hour rigging this boat.

Really big trailerables sometimes have a set of:

- four lower shrouds;

- two uppers;

- a forestay;

- and a backstay.

The mast can be so heavy that you cannot raise it alone – two people or mechanical aids are necessary. It can easily take over an hour to launch a boat like this.

These launch times are approximate, of course, and you can shave them down with practice. Just watch someone who is fast and has a lot of experience – it’s like watching a strange amateur version of an Indy pit crew in action. Some folks on the sailing e-mail lists have proposed adding a «launching division» to their regular schedule of races.

Read also: Key Points for Buying and Selling a Boat

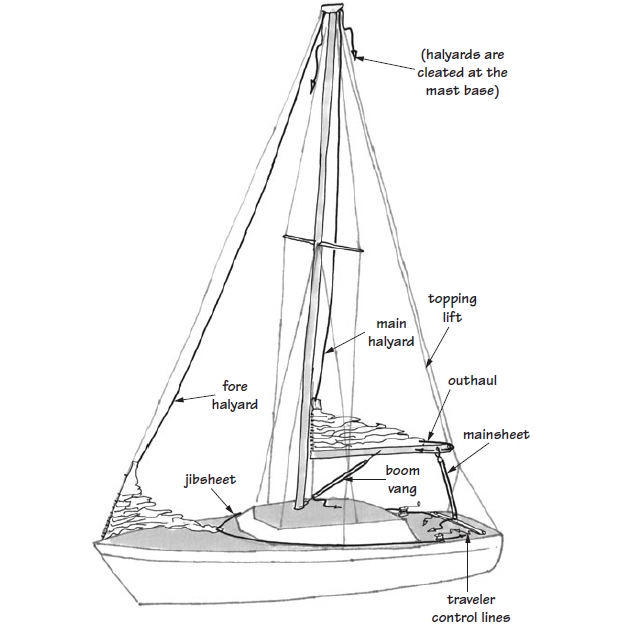

All sailboats have some form of running rigging. Where the primary job of the standing rigging is to support the mast, the running rigging is normally used to raise and control the sails. The running rigging can range from basic to bewildering, depending on the boat design, the owner, and the type of sailing that is normally done. Cruising sailboats need simplicity, strength, and ease of repair. Racers need light weight, low friction, and high performance. Being able to fine-tune the sail shape for the conditions can mean the difference between winning and losing, and racing skippers lavish their boats with some amazing «deck jewelry». Even owners of some nonracing boats upgrade their running rigging to improve performance, since in general it’s more fun to go fast on a sailboat than slow.

Some running rigging is common to all sailboats. Halyards are the lines that lift the sails. The halyards go from deck level, through a block at or near the top of the mast, and back to a cleat at the mast base. Three halyards are common:

- one for the mainsail;

- one for headsail;

- and one for either the spinnaker or a spare headsail.

Sheets are lines that pull the sail in. The mainsheet attaches to the boom at one end and the boat at the other. Mainsheets can take a the number of different forms and pass through several blocks in the process. The headsail sheet (or jibsheet) is usually two lines, one port and one starboard, which often pass through sheet lead blocks on their way back to the cockpit. Jibsheets are commonly tensioned using winches at the cockpit on trailerable sailboats.

Running rigging can go far beyond the basics, however. A sailboat may have the following:

- A traveler, which is often a rail and car arrangement that spans the cockpit. It adjusts the angle of pull on the mainsheet. Older wooden boats used an iron bar through a ring.

- A boom vang, which tensions the boom downward to give a flatter sail.

- A reefing system, such as slab or jiffy reefing, designed to make reducing sail easier.

- A barber hauler, which adjusts the jibsheet angle without using a track.

- A roller-furling jib, with corresponding control lines led aft to the cockpit.

This is just a start. There are dozens of tweaks and modifications that can be made to running rigging. Some might be considered essential to one sailer, and expensive frivolity to another. More on running rigging is covered in the article «Getting Underway and Sailing», but the finer points and multitude of possibilities could take up an entire book alone.

The Difference between Ropes and Lines. Believe it or not, you will find very few ropes on a sailboat. If you’re new to sailing, I can imagine your disbelief – «Whaddaya, crazy? There’s millions of ‘em!» But on a sailboat, they aren’t called ropes. Rope is the raw material that comes on a spool in 600-foot lengths. Once the rope is cut off the spool and given a specific job, it’s called a line. The only two exceptions that I can think of are the bellrope, used to ring the ship’s bell, and the boltrope, sewn into the edge of the sail.

Sailboats do have lots of lines, but after a few times out, they won’t seem so confusing. Most boats have the same lines for the same job, but the major ones to remember are halyards and sheets. Halyards lift the sails, and sheets control them. If you can remember those two, then you’ll be way ahead. There are a few others, such as a lift, which is intuitive – the line that holds the boom up when the mainsail is down is called the topping lift.