Bunkering risk assessment on ships are important to ensure safe fueling operations. Key factors to consider include the storage and handling of fuel, potential fire hazards, stability issues, and environmental risks.

- LNG Bunkering operations risk assessment

- Risk assessment approach

- Qualitative Risk Assessment (QualRA)

- Quantitative Risk Assessment (QRA)

- Risk Assessment Minimum Scope for LNG bunkering

- Risk criteria

- Risk Levels in Qualitative Risk Assessment (QualRA)

- Risk Criteria in Quantitative Risk Assessment (QRA)

- Risk assessment for simultaneous operations (SIMOPS)

- Guidance on a typical Risk Assessment for LNG bunkering operations

- HAZID

- HAZOP

- Safety and security zones

- General

- Hazardous area classification

- Safety zones

- Determination of the safety zone distance

- Security zones

It is essential to identify and mitigate these risks through proper procedures, training, and equipment to prevent accidents and protect the ship and crew.

LNG Bunkering operations risk assessment

General

A bunkering operations risk assessment should be undertaken in accordance with ISO/TS 18683. This technical specification is specific to the supply of LNG as fuel to ships and refers to recognised standards that provide detailed guidance on the use and application of risk assessment. The objectives of the bunkering operations risk assessment are to:

- demonstrate that risks to people and the environment have been eliminated where possible, and if not, mitigated as necessary;

- and provide insight and information to help set the required safety zone and security zone around the bunkering operation.

In order to meet these objectives, as a minimum, the Basic Information about Liquefied Natural Gas Bunkering Operationsbunkering operations risk assessment should cover the following operations:

- preparations before and on ship’s arrival, approach and mooring;

- preparation, testing and connection of equipment;

- LNG transfer and boil-off gas (BOG) management;

- completion of bunker transfer and disconnection of equipment;

- simultaneous operations (SIMOPS) as noted below.

Risk assessment approach

Qualitative Risk Assessment (QualRA)

A Qualitative Risk Assessment (QualRA) should be undertaken prior to introduction of a new bunkering operation procedure that follows the guidance in this document and the guidance given in ISO/TS 18683 guidelines.

Provided the bunkering operation is one of the three standard bunkering scenarios below, and guidance in this document and ISO/TS 18683 is followed, i.e. there are no deviations from the functional requirements, then the qualitative approach (i. e. QualRA) is sufficient to meet the objectives of the bunkering operations risk assessment.

Standard bunkering is characterised by three bunkering scenarios, as noted in ISO/TS 18683:

- shore-to-ship (that is, LNG transfer from an onshore facility to a gas fuelled ship);

- truck-to-ship (that is, LNG transfer from a road truck to a gas fuelled ship);

- ship-to-ship (that is, LNG transfer from a ship, such as a bunker barge, to a gas fuelled ship).

Quantitative Risk Assessment (QRA)

As a supplement to the QualRA, a Quantitative Risk Assessment (QRA) may be required where:

- bunkering is not of a standard type (as described above);

- design, arrangements and operations differ from the guidance given in this document;

- and bunkering is undertaken alongside other transfer operations (SIMOPS), see below.

A QRA is also appropriate where further insight is required to:

- judge the overall level of risk (since this is not typically provided by a QualRA);

- appraise design options and mitigation alternatives;

- and/or to support a reduced safety zone and/or security zone.

The requirement for a QRA (in addition to a QualRA) is normally determined by the Administration or Port Authority based on the conclusions and outcomes of the QualRA and accepted by the concerned parties.

Risk Assessment Minimum Scope for LNG bunkering

Whether only a QualRA is required or both a QualRA and QRA are required, as a minimum the risk assessment should detail:

- a. How the bunkering operation could potentially cause harm. That is, systematic identification of potential accidents/incidents that could result in fatality or injury or damage to the environment;

- b. The potential severity of harm. That is, the worst case consequences of the accidents/incidents identified in ′a′, in terms of single and multiple fatalities and environmental damage caused;

- c. The likelihood of harm. That is, the probability or frequency with which the worst case consequences might occur;

- d. A measure of risk, where risk is a combination of (b) and (c);

- e. How the functional requirements are met.

In addition, the risk assessment should help identify the scenarios to be used to determine the safety zone; and as a minimum, consider SIMOPS within the safety zone.

A typical approach to QualRA and QRA is described in ISO/TS 18683. These approaches or similarly established approaches should be used provided they cover items (a) to (e) above.

Regardless of the approach used, the risk assessment should be carried out by a team of suitably qualified and experienced individuals with collective knowledge of, and expertise in:

- risk assessment application;

- engineering design;

- emergency response;

- and bunkering operations.

Risk criteria

Examples of qualitative and quantitative risk criteria are outlined in ISO/TS 18683. In addition, guidance on selection of appropriate criteria may be given by government organisations. Furthermore, many industry organisations, such as the international oil companies, have specific risk criteria extensively used to demonstrate safe onshore and offshore operations to governments and regulators.

Although criteria from different sources may appear similar, it is important to note that there are no universally agreed risk criteria: there are differences between governments, regulators and organisations. Therefore, prior to the commencement of the risk assessment, risk criteria should be agreed with appropriate stakeholders, in particular the port and regulatory authorities, the Administration and the ship operator.

Risk Levels in Qualitative Risk Assessment (QualRA)

Risk levels in qualitative risk assessments are commonly incorporated within a risk matrix and indicate a level of risk associated with a specific combination of consequence and likelihood. For example, the risk may be:

- sufficiently ′low′ that it need not be reduced further;

- at a level where mitigation should be considered and implemented if practicable;

- or at a ′high′ level where mitigation is required to reduce it.

An important point to note is that the risk level is indicative of one or more but not all potential accidents/incidents. That is, the assessment does not provide a collective or overall indication of the risk level from all potential accidents/incidents; rather it provides a relative ranking of the accidents/incidents considered. If the overall risk level is required then this can be determined using QRA.

Risk Criteria in Quantitative Risk Assessment (QRA)

Risk criteria in quantitative risk assessments commonly refer to individual risk and societal risk (or group risk), and these are related to fatality or some other measure of harm. Where a significant number of people are exposed to the bunkering operations then both should be assessed. This is because the risk to any individual may be ′low′ but the risk of harming many people in a single accident/incident might be sufficient to warrant risk reduction. Stakeholders should consider what constitutes a significant number of people to require assessment of societal risk. Dependent upon specifics this might be exposure of ten or more people.

It is important to note that the criteria are typically expressed on a per annum basis (i. e. per year). For hazards that are present for a relatively short time (over a year) the per annum criteria may not be appropriate. This is because the risk is not spread uniformly across the year but peaks intermittently, and for long periods of time it does not exist. As such, if this is not recognised then proposed risk mitigation may not offer the protection envisaged. As a guide, per annum criteria may not be appropriate for a hazard present less than a third of the year.

Risk assessment for simultaneous operations (SIMOPS)

Where it is proposed to carry out bunkering operations concurrently with other operations that may impact or be impacted by Risk Assessment in the Liquefied Natural Gas Bunkering Operations, Hazard Identificationthe bunkering then further risk assessment should be carried out to demonstrate that the required level of safety can be maintained.

Note: Risk assessment for simultaneous operations should be considered when the following operations are intended to be carried out simultaneously with the bunkering operations:

- cargo handling;

- ballasting operations;

- passenger embarking / disembarking;

- dangerous goods loading / unloading and any kind of other goods loading or unloading (i. e. stores and provisions);

- chemical products handling;

- other low-flash point products handling;

- bunkering of fuels other than LNG.

Simultaneous operations should be investigated for any of the above activities occurring within the safety zone calculated as described below.

Any simultaneous shipboard technical operations such as testing systems that might affect the stability of the receiving ship, for example, changes to the mooring situation, testing of power generations systems or fire-fighting systems, are not to be carried out during LNG bunkering operations.

Guidance on a typical Risk Assessment for LNG bunkering operations

The scale of risk assessment required for the bunkering process will depend on the bunkering method and equipment used with additional, more detailed, levels of risk assessment potentially required where novel procedures and/or equipment are selected.

It is generally expected that the risk assessment activities will be broken into two main parts, a higher level HAZID activity followed by a more detailed HAZOP activity. It is recommended that both of these activities are conducted with professional guidance to ensure an appropriately detailed risk assessment outcome is achieved.

Where designs or operational methods are modified after the risk assessment(s) have been conducted this may result in the risk assessments needing to be revised accordingly.

HAZID

The hazard identification process should provide sufficient detail for an operator to fully understand the nature of each hazard and to identify the controls necessary for the management of each hazard. The outcomes of the HAZID include risk rankings and recommendations for additional safeguards and analysis.

As a minimum, the HAZID should include the scope as described in the ISO/TS 18683.

Guidance for conducting a HAZID for LNG bunkering operation is detailed in the Annex of this guideline.

HAZOP

The HAZOP study is a structured and methodical examination of a planned process or operation in order to identify causes and consequences from a deviation to ensure the ability of equipment to perform in accordance with the design intent. It aims to ensure that appropriate safeguards are in place to help prevent accidents. Guidewords are used in combination with process conditions to systematically consider all credible deviations from normal conditions.

Guidance for conducting a HAZOP for LNG bunkering operation is detailed in the Annex of this guideline.

Safety and security zones

General

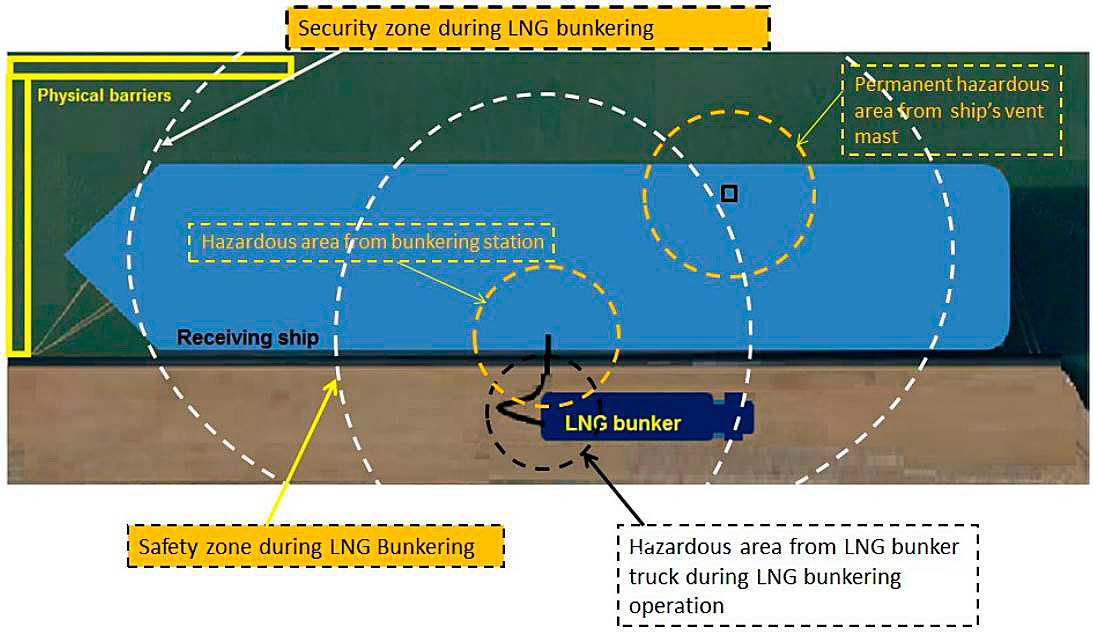

A safety zone and a security zone should be established around the bunkering operation in accordance with ISO/TS 18683. These zones are in addition to the established practice of setting hazardous area classification zones that will be required around areas with potential for explosive atmospheres such as the bunkering connections. A pictorial example of these zones is illustrated below.

Both the safety and security zones should be enforced and monitored at all times during bunkering, at all other times these zones are not enforced.

The purpose of the safety zone is to set an area within which only essential personnel are allowed and potential ignition sources are controlled. Essential personnel are those required to monitor and control the bunkering operation. Similarly, the purpose of the security zone is to set an area within which ship/port traffic is monitored and controlled.

Together, the safety and security zones help further minimise the low likelihood of a fuel release and its possible ignition, and help protect individuals and property via physical separation.

Hazardous area classification

Bunkering-related hazardous areas means any hazardous area zone 1 and zone 2 defined for:

- the receiving ship in accordance with IGF Code, regulation 12.5;

- the bunkering ship in accordance with IGC Code, regulation 1.2.24;

and example minimum hazardous zone sizes include:

- areas on open deck, or semi-enclosed spaces on deck, within 3 m of any gas tank outlet, gas or vapour outlet, bunker / supply manifold valve, other gas valve, gas pipe flange and gas tank openings for pressure release;

- areas on the open deck within spillage coamings surrounding gas bunker / supply manifold valves and 3 m beyond these, up to a height of 2,4 m above the deck;

- semi-enclosed bunkering stations;

- areas within 1,5 m surrounding spaces listed above.

The bunkering-related hazardous area also includes areas around the truck, LNG bunker vessel or shore-based bunkering facility. Depending on the outcomes of the risk assessment and the specific details of the bunkering process (equipment and transfer flow rates and pressures) the size of these areas may be increased.

In the hazardous area, only electrical equipment certified in accordance with IEC 60079 is permitted. Other electrical equipment should be de-energised prior to the bunkering operations. Attention is drawn to the following equipment, which is not intrinsically safe and should therefore be disabled, except if otherwise justified:

- the radar equipment, which may emit high power densities;

- other electrical equipment of the ship, such as radio equipment and satellite communication equipment, when they may cause arcing.

Safety zones

In the safety zone, the following restrictions normally apply during the bunkering operations, except if otherwise justified by the safety analysis or agreed by the Local Port Authorities or National Administration:

- smoking is not permitted;

- naked lights, mobile phones, cameras and other non-certified portable electrical equipment are strictly prohibited;

- cranes and other lifting appliances not essential to the bunkering operation are not to be operated;

- no vehicle (except the tank truck) should be present in the safety zone;

- no ship or craft should normally enter the safety zone, except if duly authorised by the Port Authorities;

- other possible sources of ignition should be eliminated;

- access to the safety zone is restricted to the authorised staff, provided they are fitted with personal protective equipment (PPE) with anti-static properties and portable gas detector.

Determination of the safety zone distance

There are two different approaches which are outlined in the following paragraphs.

Deterministic approach. The safety zone should be set based upon the flammable extent of a maximum credible release scenario. In ISO/TS 18683 this approach to setting the safety zone is referred to as the «deterministic approach». Specific requirements for the determination of the safety zone may be set by national and local authorities.

The flammable extent is the distance at which the lower flammable limit (LFL) is reached as the vapour / gas (from the released fuel) disperses in the atmosphere. For LNG, the LFL is approximately 5 % of natural gas in air.

As a minimum, the following information should be taken into account in the maximum credible release scenario:

- the physical properties of the released fuel;

- weather conditions at the bunkering location; wind speed, humidity, air temperature and the temperature of the surface upon which the fuel leaks. The chosen conditions should reflect the worst-case conditions that result in the greatest distance to LFL;

- roughness of the surface over which the vapour / gas disperses, (i. e. land or water);

- structures and physical features that that could significantly increase or decrease dispersion distances;

- release rate, release orientation, available inventory and rate of vapour generation.

In addition, release height is to be considered as this can significantly affect the extent of the calculated safety zone. The vertical extent of the safety zone may require special consideration, especially in cases where persons can be at elevated positions, such as located in cabins many metres above the bunker station.

Large objects, such as buildings and ships, and topography, such as cliffs and sloping ground, can constrain or direct dispersion. This should be recognised in setting the safety zone. Failure to do this can result in inappropriate safety zones that include areas that would not be affected by any release of natural gas or exclude areas that would be affected if there was a release. In certain cases, advanced modelling techniques, such as computational fluid dynamics (CFD) might be required to justify the zone’s shape and extent.

Regardless of the technique(s) used in setting the safety zone it should be applied by a suitably qualified and experienced individual.

ISO/TS 18683 provides two examples of a maximum credible release scenario, where the one resulting in the greatest LFL extent is used to set the safety zone:

- a. A release of the «trapped inventory» between emergency shutdown valves in the liquid bunkering line (i. e. bunker hose);

- and b. A «continuous release» from an instrument connection where emergency valves do not close to isolate the release and delivery pressure is maintained.

To set the safety zone either:

- The ISO/TS 18683 release cases as described above should be used (i. e. ′a′ and ′b′),

- or a maximum credible release scenario should be used that has been identified and justified using the risk assessment method described in ISO/TS 18683. This option allows for consideration of mitigation measures and other factors specific to the bunkering operation.

Probabilistic approach. An alternative approach to setting the safety zone should use quantitative risk assessment (QRA) whereby consideration is given within a predefined scenario to a representative set of potential releases and the likelihood with which they occur. This approach is often referred to as the «probabilistic» or «risk based» approach.

In theory, this approach could lead to a safety Hazards of LNG and Relevant Gaseszone of less than the hazardous area or even 0 metres. This is not acceptable. The Safety Zone should at least extend beyond the hazardous areas and/or the minimum distance defined by the authorities from any part of the bunkering installation.

Read also: LNG bunkering process – standards and rules

A key feature of QRA is that it accounts for both the consequence and likelihood of releases and can consider the location of people, the probability of ignition, and the effectiveness of mitigation measures and other emergency actions. As such, it can provide increased understanding of those releases that contribute most to the risk, and this can be useful in identifying and testing the suitability of mitigation measures, and optimizing zone extent. If this approach is selected then it is important that appropriate risk criteria are used.

Security zones

A security zone should be set based upon ship/port operations. In setting the zone consideration should be given to activities and installations that could endanger the bunkering operation or exacerbate an emergency situation. For example, consideration of the following is required when setting the security zone:

- other ship/ship movements;

- surrounding road traffic, industrial plants, factories and public facilities;

- crane and other loading/unloading operations;

- construction and maintenance works;

- utilities and telecommunication activities and infrastructure.

Many of the above are considered in the risk assessment described in this document. Therefore, to help inform setting of the zone, reference should be made to this risk assessment.