Optimize laden voyage for LNG carriers with expert guidance on BOG management, gas-burning propulsion systems, steam plants, reliquefaction plants, and inner hull inspections. Ensure safe and efficient operations throughout your journey.

Reference: SIGTTO “LNG Shipping Suggested Competency Standards”, Sections:

1 Have an awareness of cargo management principles. Principles of boil-off management:

- venting;

- fuel gas burning;

- gas combustion unit;

- reliquefaction.

2 Know and understand cargo heel and cargo tank temperature management procedures:

- criteria used to determine amount of cargo heel to be retained;

- the various plans that may be adopted to maintain cargo tank temperature and boil-off required:

- spraying;

- cargo conditioning.

Laden voyage. BOG management

During a laden voyage, the movement of the LNGC and the ingress of external heat through the tank insulation generates convection currents in the cargo. These cause the relatively warm LNG to rise to the surface, producing BOG. This process can account for as much as 0,15 % of the liquid cargo per day, although a figure nearer 0,07 % is achievable.

Depending on the BOG management system type, BOG is controlled either by utilising it in the propulsion system or by reliquefaction.

Under the IGC Code, an LNGC must have two independent means of managing excess vapour (BOG). These may include:

- steam propulsion: BOG management is achieved by two separate boilers and a steam dump system may be fitted;

- Dual-fuel diesel electric/Tri-fuel diesel electric (DFDE/TFDE)DFDE/TFDE: BOG management is achieved by gas burning to engines and a GCU;

- DF/TF slow speed diesel: BOG management is achieved by gas burning to engines and a GCU;

- slow speed diesel: BOG management is achieved by a reliquefaction plant and a GCU.

In addition to the operational means of managing excess vapour, in the case of urgency or emergency, provision exists for an LNGC to vent excess vapour to the atmosphere through the No. 1 vent mast.

Laden voyage of LNG carriers with gas-burning propulsion system. Steam plant

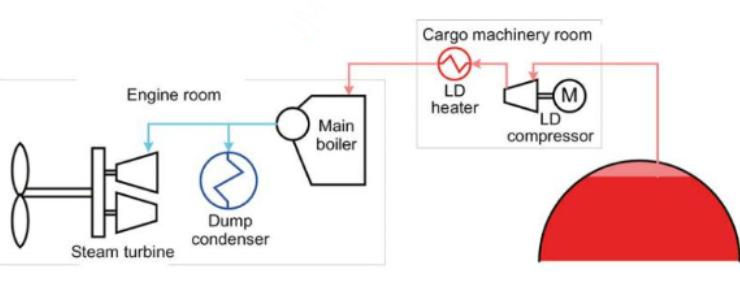

The BOG enters the common vapour header through the cargo tank vapour domes. It is then directed to the in-service LD compressor that delivers the fuel gas to the E/R through a gas heater. The heated gas is delivered to the LNGC’s power plant at approximately +30 °C by a fuel gas control valve. Compressor output is controlled by the speed of the prime mover and/or inlet guide vanes at the compressor suction.

On a steam propulsion plant, if fuel consumption is not sufficient to burn the generated amount of BOG, the tank pressure will increase. This pressure increase can be controlled either by the utilisation of a steam dump system or by increasing the speed of the LNGC. The main steam dump system is designed to dump sufficient steam to allow the boilers to continue burning BOG, even when the ship is stationary. A combination of both methods may also be used.

Conventional steam turbine propulsion systems are, generally, the least economical consumers of BOG and, in some cases where the intended voyage is at maximum speed, forced BOG operation may be required.

The decision to conduct forced BOG burning is a charterer’s decision based on the economics of gas versus fuel oil burning.

On receipt of charterer’s instructions, where additional fuel gas from the cargo tanks is required to be burned in the ship’s boilers over and above the boil-off rate, it can be generated by forced vaporisation, using a dedicated forcing vaporiser.

The normal gas burning arrangement is maintained while the forcing vaporiser is brought into operation. This uses a single stripping/spray pump in conjunction with the LNG forcing vaporiser. The excess flow from the pump is returned to the same tank through the spray return valve. The generated vapour then combines with the natural BOG from the vapour header into a mist separator (demister) before being drawn into the suction of the Low Duty Compressor(s) on the Liquefied Natural Gas CarriersLD compressor, reducing the risk of droplet carry-over.

This operation can be used to complement gas burning for up to 100 % of the boiler’s fuel requirement.

Consideration for all gas-burning system

Whichever gas burning system is used, the principles of cargo management will be similar and the only difference will be how the BOG is consumed.

The charterer will always require compliance with the voyage orders which, on laden voyages with gas burning propulsion systems, may be in “gas only” voyage mode. The receiving terminal may also have specific requirements for the temperature of cargo delivered and the maximum allowable tank pressure on arrival.

These limitations need to be taken into consideration when planning BOG utilisation for a laden passage.

The operator of the LNGC will plan the voyage to maintain BOG consumption within guaranteed daily boil-off rates (BOR). Even though BOR is expressed as a daily generated BOG, when considering consumption for gas burning it will be calculated as the difference in cargo volume from the closing CTMS in the loading port until the opening CTMS in the discharge port, divided by the length of the voyage in days. This allows flexibility for the operator to manage the BOG in the most economical way to maintain the condition of the cargo.

Usually, consumption is increased at the beginning of the voyage, as insulation is still relatively warm and this increases BOR. As the voyage progresses, consumption is reduced as BOR is reduced, depending on speed requirements and the prevailing weather conditions during the voyage.

On no account should tank pressures be allowed to fall below atmospheric pressure. Usually, the compressors used on LNG ships have N2 pressurised shaft seals, so an adequate N2 supply must be available at all times when the compressor is running. See Essential Steps for Preparing LNG Tanks for Cargo Loading on LNG Vessels“Nitrogen Purging of Containment System”.

Laden voyage of LNG carriers with reliquefaction plant

BOG is drawn from the vapour suction of each tank by compressors and reliquefied using the reliquefaction plant. The reliqueified LNG is returned to cargo tanks (maintaining tank levels within operational limits) through the condensate return line to the bottom of each tank.

A condensate management plan is implemented on LNGCs where a reliquefaction plant is used.

It is necessary to regularly check the LNG quantity in each cargo tank and manage condensate return to avoid overfilling any tank. The level in a cargo tank should not be allowed to increase above the maximum limit. This can be controlled by either the IAS or manually by the operator.

Read also: Liquefied Natural Gas Reliquefaction Plant

The reliquefaction plant will, generally, be of sufficient capacity to maintain tank pressure within safe limits.

If the BOG generation exceeds the capacity of the reliquefaction plant, the GCU will be utilised for cargo tank pressure control.

Inner hull inspections (IHI) on laden voyage

Inner hull inspections (IHI) need to be conducted throughout the service life of the LNGC and the laden passage provides the opportunity for this.

Note: at low temperatures, structural steel can suffer a brittle fracture. Such failures can be catastrophic because once brittle steel starts to fracture, only a small amount of energy is required to make it spread.

It is a Classification Society requirement, for the granting of a valid Certificate of Fitness for ships carrying liquefied gases in bulk, that routine cold spot inspections are carried out and that the results are recorded. All spaces around the cargo tanks must be inspected and any findings recorded once per year. To meet this requirement, it is a good practice to divide spaces into zones and to inspect a number of zones on each occasion, meaning that all spaces will be inspected during the designated period defined by Class.

These spaces include ballast tanks, Cofferdam – Definition and Pronunciationcofferdams, passageways, Moss hold spaces, and duct keels. On completion of loading, and to standardise the entries in associated records, the IHI should be conducted after the same period of time has elapsed on the laden voyage.

In the event of a cold spot forming, the response is controlled and graded according to severity.

The following procedures would be normal:

- note the size, location and minimum surface temperature of the affected steel;

- assess the level of stress and loading in the affected steel structure;

- take no immediate action, but continue to monitor and report to the ship’s operator;

- if the situation continues to deteriorate, seek assistance from the ship’s operator as it may be necessary to flood the space concerned. However, flooding the space is an extreme measure and should be considered carefully.