Explore the fascinating history of the gas industry, from its humble beginnings to the revolutionary introduction of LNG and LPG carriers.

Delve into the evolution of transportation and distribution, unlocking insights into how these advancements continue to shape global energy landscapes.

Liquefied petroleum gas (LPG)

Discover the milestones that paved the way for safer, more efficient gas transportation, driving innovation and sustainability forward.

Beginning of LPG

In 1911, Dr. Walter O’Snelling of the U. S. Bureau of Mines succeeded in separating and liquefying butane and propane. He patented his discoveries in 1913.

Industrial production of propane and butane by Union Carbide and Carbon Chemicals started in the 1920’s, in the USA. The gas was mainly for domestic use and was delivered to the customers in pressurised bottles. It was transported overland in larger pressurised bottles installed on trucks. The expeditions of Adm. R. Byrd to the South Pole in 1929 and 1934 used bottles of compressed gas for their cooking fuel.

Butane and propane were first transported by sea in the 1930’s on a small number of general cargo ships’ equipped with pressurised bottles on deck. The first attempt to transport LPG by sea using a purpose-built ship took place in 1931, when the Hawthorn Leslie shipyard (now Swan Hunter) designed and built the m. v. «Agnita» for the Anglo Saxon Petroleum Company in London (now Shell International Trading and Shipping). Twelve riveted tanks installed vertically in the cargo holds enabled the ship to carry pressurised butane and sulphuric acid. The normal oil cargo was carried around the butane tanks. The «Agnita» operated without problems until 1941, when she was sunk by a torpedo. A second sister-ship was built, but noticeable developments took place only after the war.

In 1947, a dry-cargo ship, the «Natalie O. Warren» was converted by the Bethlehem Steel Company of Beaumont, Texas for the Warren Petroleum Corporation, to carry propane from Houston to New York and renamed «Cape Diamond». She was fitted with 68 vertical, cylindrical tanks with a maximum working pressure of 17,6 kg/cm2 and a total cargo capacity of 6,050 m3. The tanks had diameters of 2,4 to 4,0 m and heights between 7,6 and 14,6 m and were installed in 5 holds. A second vessel, the «Rio Novo», was converted by the same shipyard a year later for the owner Oivind Lorentzen of Norway. This owner had previously equipped dry-cargo ships with deck-mounted skid tanks to carry LPG from the US Gulf to Brazil. The «Rio Novo» was fitted with 29 vertical and 2 horizontal tanks, with a total capacity of 3,000 m3 and a working pressure of 17,5 kg/cm2, in order to carry butane and propane. She was the first real sea-going LPG tanker. Two other ships were also converted for the same owner in 1952-53 in the Kieler Howaldtswerke shipyard of West Germany: the «Mundogas Sao Paulo» and the «Mundogas Norte».

All these ship conversions used the same techniques as those used for the overland transportation of LPG. The large number of small prefabricated tanks and complicated piping network made the ships cumbersome.

At the end of the war, there was a demand in Europe for the transportation of LPG between various coastal regions. A number of shipyards in Italy, Sweden, Denmark, Holland and France started to build small, specially designed, pressurised LPG tankers.

In Italy, Genoa’s C. N. Ansaldo shipyard delivered the 670 m3 «Mariotte» in 1946 and the 1 850 m3 «Agipgas Quarta», with 18 vertical tanks, in 1952. The Felszegi yard in Trieste delivered the 212 m3 «Elpigas» in 1947 to SNAM S. p. A.. The C. N. Benetti yard in Viareggio delivered the 1 730 m3 «Agipgas Terza» in 1959.

In Sweden, the Marstrands shipyard delivered the 1 042 m3, «Rasmus Tholstrup» with 12 vertical cylindrical tanks, which was the first of 23 Tholstrup LPG tankers.

In Denmark, the A/S Svendborg shipyard delivered the «Soerine Tholstrup» with a single horizontal tank of 1 750 m3, in 1954.

Also in 1954, the Muller-Foxal shipyard in Holland delivered the 816 m3 «Cap Carbon» to the French owner SAGA, to transport LPG from Berre, France to Arzew, Algeria or to Corsica.

In 1960, the France-Gironde shipyard in France delivered the 1 554 m3 «Cap Ferrat», also to SAGA.

In Japan, the beginning of the 1960’s saw a substantial requirement for coastal transport of LPG and more than 130 small pressurised ships were built by Japanese shipyards for various Japanese owners. In 1965, Mitsubishi Heavy Industries shipyard delivered two 2 080 m3 ships equipped with four spherical tanks, «Kegums» and «Kraslava», for the USSR. At the time, this was quite an unusual design.

Most ships built during this period had a total capacity below 2 000 m3 and were designed with a minimum cargo temperature of -5 °C for the transportation of butane, propane, butadiene and ammonia at ambient temperature. The maximum service pressure was between 17 and 18 bar gauge. Discharge was carried out using compressors, sometimes with the assistance of a booster pump. The quality of welding technology and the material available did not allow for tanks with a capacity larger than 600 m3, which meant the ships had to be equipped with a number of smaller tanks connected by a complicated piping network. However, fully pressurised LPG ships were the only type available through the 1950’s and they became quite popular. They were simple reliable ships and enjoyed a good safety record.

The improved availability of low temperature steel, the better knowledge of its forming and welding and the improvement of refrigeration plants suitable for on-board installation helped the development of different types of ships.

When carried at a lower temperature, the cargo pressure is reduced and its specific gravity is increased. As the pressure is reduced, cargo tanks do not require the same thickness and consequently their weight and the weight of their supports are reduced. All this allows more cargo to be carried for the same size of ship and therefore more revenue can be earned. However, to achieve this result, it is necessary to use better quality steel for the cargo tanks and to provide insulation and special equipment to maintain the cargo at a lower temperature.

Semi-pressurised ships appeared first. Early designs transported the cargo at pressures between 5 and 9 bar, but their minimum temperatures were still limited to -5 or -10 °C. This soon improved with minimum temperatures as low as -48 °C becoming available. It enabled the new ships to carry all the products described above at very nearly their atmospheric pressures. They were now capable of loading fully refrigerated cargoes which they could discharge at ambient temperature through a system of cargo heaters or to load cargoes at ambient temperature which they could cool down at sea and discharge at near atmospheric pressure. This increased greatly their flexibility and the range of cargoes available for transportation. Most of these ships were equipped to carry two and sometimes more different products, completely segregated.

Transportation of the Petroleum Gas and Amonia Cargoes on the Fully-Refrigerated LPG ShipsFully-refrigerated ships followed soon after. They could transport all the same products at near atmospheric pressure and at the same low temperatures. Because their maximum pressure was limited to 0,7 bar, the weight of their cargo containment was greatly reduced and larger ships became feasible.

The first semi-pressurised ships appeared at the end of the 1950’s. They were the 921 m3 «Descartes» in France, the 920 m3 «Lili Tholstrup» and «Birthe Tholstrup» in Denmark, seven 2 000 m3 built in Spain, the 754 m3 «Abbas» in the UK, a modified bulk carrier which become one of the largest semi-pressurised ships at the time, the 13 196 m3 «Cap Martin» in France and many others. The 6 327 m3 «Pascal», built in 1967 by Chantiers Naval de la Ciotat in France, was the first ship able to load semi-pressurised or fully refrigerated cargoes.

The first fully-refrigerated LPG ship was built in 1961 by the Mitsubishi Heavy Industries shipyard of Yokohama, Japan. The cargo containment system was designed by J. J. Henry Co. Inc. based in New York, using Conch International Methane Technology. She was «Bridgestone Maru № 1», with four prismatic independent type A tanks of 28 875 m3 total capacity, with a minimum temperature of -45 °C. The inner hull was constructed of 2 1/4 % Ni steel and the tanks of 3 1/2 % Ni steel. This was certainly above requirements, by today’s standards, for the cargoes considered. The insulation was glassfibre, attached to the inner hull surfaces and protected by aluminium foil. The design was a direct result of the experiments recently completed on LNG transportation in the United States by Conch International assisted by J. J. Henry.

This design introduced the new concept of a secondary barrier, made of steel able to maintain its mechanical properties when in contact with the low temperature of the cargo, to protect the ship’s hull from possible damage due to this low temperature in case of leaks in the primary cargo containment system.

Two years later, the first fully-refrigerated LPG tanker built in Europe was delivered by the Kockums shipyard in Sweden. This was the 25 012 m3 «Paul Endacott», designed to carry LPG, NH3, or ethylene oxide in five self-supporting prismatic tanks at a minimum temperature of -51 °C. Four different products could be carried and refrigerated simultaneously at a maximum pressure of 0,3 bar. The tank material was low carbon high tensile steel. The polyurethane foam insulation was bonded to the inner part of the hull, to allow for easy inspection of the tanks. The ballast tanks were located in way of the Ship Survivability and Cargo Tanks Placementcargo tanks within the hull’s double skin. Four pressurised tanks, with a total capacity of 1 216 m3, were installed on deck to facilitate purging and pre-cooling whilst on passage.

In the same year, the Verolme shipyard in the Netherlands delivered the 12 975 m3 «William R. Grace», specifically designed to carry fully refrigerated ammonia between Trinidad and the US Gulf or Europe. Two sister-ships would be delivered to the same owner, the Oswego Chemical Carrier Corp..

Also in that year, the MHI shipyard of Yokohama, Japan, delivered the 36 000 m3 «Bridgestone Maru № 2». This design, very similar to the standard which would be used for most of the fully-refrigerated LPG ships to come, uses the inner hull and part of the side shell itself as the secondary barrier.

Development of LPG

The 1960’s saw very fast development of all types of LPG tankers. Further developments in steel quality and welding technology allowed the size of fully pressurised cargo tanks to be increased and many ships in that category were built with a capacity of 3 to 5 000 m3 even reaching 10 000 m3. Modern fully-pressurised ships are equipped with several spherical or cylindrical tanks with a maximum service pressure of 17 or 18 bar gauge and a minimum temperature of -5 °C. Some fully-pressurised ships are now fitted with tanks able to carry cargo at temperatures as low as -25 °C, which increases their flexibility even further. Some ships can carry two different products completely separated and discharging is done using compressors and centrifugal booster pumps.

For the same reasons, cargo tanks on semi-pressurised ships were able to carry cargoes at temperatures of -50 °C and, very soon, ethylene ships able to with stand temperatures of -104 °C became available. The parallel development: of shipboard reliquefaction equipment was also instrumental in ensuring these changes. Semi-pressurised ships saw their sizes increase to 20 000 or even 25 000 m3. They became extremely flexible, able to carry many different products, often several, completely separated at the same time, and even chemical products, when the opportunity arose.

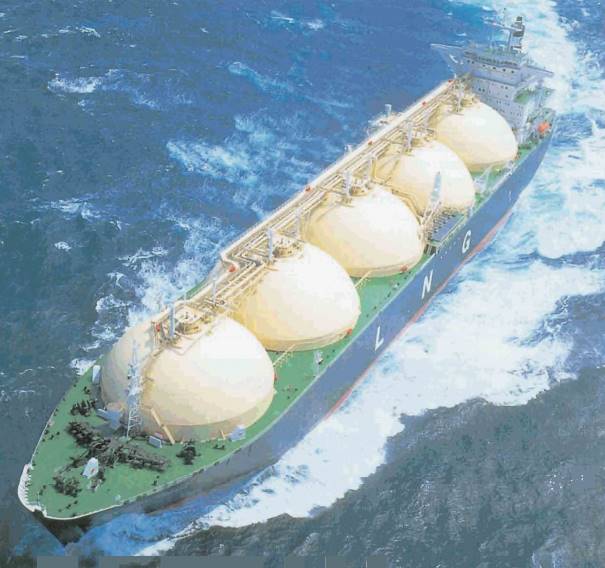

Finally, improvements in ship design, combined with those listed on the previous page, allowed the size of fully refrigerated ships to be increased to 50 000, 70 000, 80 000 and even 100 000 m3.

A limited number of owners have specialised in operating big fleets of these large fully refrigerated ships, which are usually working on long term charters.

Liquefied petrochemical gases

Most liquefied petrochemical gases have physical properties very similar to those of propane and butane and can be transported by the same types of ships. Prior to the 1960’s however, only small quantities of ammonia and even smaller quantities of butadiene were transported in fully-pressurised ships. The development of the more flexible semi-pressurised and fully-refrigerated ships saw a large increase in the liquefied petrochemical gas trade. Ammonia is transported in large quantities, mainly in fully refrigerated ships. Other products, such as butadiene, propylene and vinyl chloride monomer are transported in semi-pressurised ships. Some very dangerous products, such as chlorine, are also transported in small quantities in specially equipped semi-pressurised ships because of the increased safety provided by such vessels. Ethylene, due to its different characteristics, requires specially designed ships.

Ethylene tankers

The latest type of LPG ship to appear on the market was the ethylene tanker. Ethylene, with a temperature of -104 °C at atmospheric pressure and a critical temperature close to 10 °C (the temperature at which a gas cannot be liquefied by pressure alone), requires to be transported in refrigerated condition either fully refrigerated or at a pressure of a few bars. Special materials are required for the cargo containment system, such as 5 % nickel steel or aluminium. The reliquefaction equipment needs also some special specifications, different from diose used on normal LPG ships.

Ethylene is an important base chemical, used extensively in the plastics industry. It is, however, transported in much smaller quantities than LPG. The main trading routes are in:

- Europe;

- North and South America;

- India;

- the Far East;

- Japan and Korea.

The first ships designed specifically to carry Ethylene were built in the UK by Burntisland Shipbuilding for George Gibson & Co in 1966. They were the 826 m3 «Teviot» and «Traquair». The tanks were built of aluminium-magnesium alloy with insulation of expanded polyurethane foam covered with glass-fibre reinforced plastic to form the secondary barrier. This design was unfortunately not accepted by the IMO Gas Code implemented at the end of the 1970’s, which requires a full double hull for this type of ship.

Several of the ethylene tankers in service today are either small prototypes of various LNG tanker designs built to demonstrate the validity of the design or even small LNG ships equipped with the necessary reliquefaction equipment. However, they are a small minority in this category of ship, which now includes more than 150 vessels. The typical, modern ethylene tanker is a semi-pressurised ship of 10 000 to 15 000 m3 capacity, with IMO type C bi-lobe self supporting tanks designed to carry the cargo fully refrigerated at a temperature of -104 °C or under a moderate pressure of 5 or 6 bar.

Liquefied natural gas (LNG)

The beginning

Although the first attempts at air liquefaction were made at the end of the last century, the first liquefied methane was only obtained by the US Bureau of Mines in 1924, as a by-product of helium separation. The use of liquefied gas for distribution by the gas industry was first proposed in the United States in the 1930’s; but, it was 1940 before the first liquefaction plant for peak shaving was built. Further construction of peak shaving facilities followed until a major accident and disastrous fire at the Cleveland LNG storage plant, in 1944, set back LNG peak shaving development by several years. No further commercial plants were in fact built in the US until the early sixties, though, a large liquefaction plant was supplied by the US to the Russia and installed in Moscow in 1947.

Early in the 1950’s, the Union Stock Yards of Chicago thought of liquefying natural gas in Louisiana, where it was available in large quantities, and transporting the LNG by barge up the Mississippi River to Chicago, to be used as fuel by the meat industry. A small liquefaction plant and LNG storage tank were built at Lake Charles, Louisiana, as well as a 6 000 m3 barge called «Methane». For technical reasons, the project was abandoned and no LNG was shipped to Chicago. But, several years later, this plant was to produce the LNG for the first seven transatlantic cargoes transported by «Methane Pioneer».

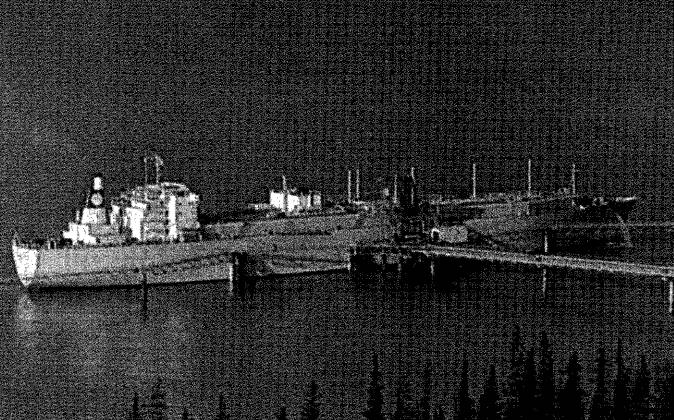

At that time, the British Gas Council was looking at ways to supplement the production of manufactured gas, which was becoming insufficient due to the reduction in coal mining. In 1957, Constock Liquid Methane Corporation, a joint venture, between Union Stock Yard and Continental Oil Co, signed an agreement with the British Gas Council to convert a World War II dry cargo vessel, «m. v. Normati», into a 5 000 m3 LNG tanker.

In February 1959, the converted vessel, renamed «Methane Pioneer», transported the first LNG cargo from Lakes Charles, Louisiana to the UK where it was discharged at the Canvey Island methane terminal in the Thames estuary. Six further cargoes were similarly transported and discharged, to complete this successful experimental project. The vessel was owned jointly by the British Gas Council and Constock and the conversion was designed by Constock Liquid Methane Co. assisted by J. J. Henry Company, naval architects, New York City. The work followed the requirements and was subject to the approval of the American Bureau of Shipping and Lloyd’s Register of Shipping and was supervised by the US Coast Guard.

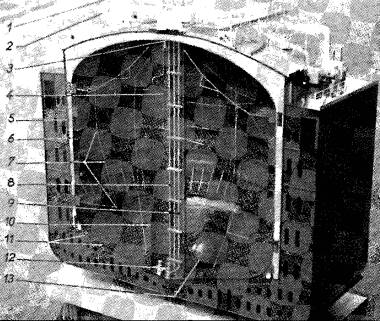

The five cargo tanks were of prismatic shape, built of aluminium alloy 5356-0 and the insulation was made of prefabricated sandwich-type panels of balsa wood faced with maple and oak plywood attached to the inner hull. These were the forerunners of the self-supporting prismatic IMO type B tank, before the concept was even invented. All deck piping was of stainless steel TP 304 L.

Following the successful results obtained by «Methane Pioneer», Shell Petroleum joined Constock in 1960 and the new group became the Conch Methane Company Limited, later known more simply as Conch.

Similar work was carried out in France to provide a way of transporting the natural gas just discovered in Algeria. The Methane Transport Company was formed in 1959, under the driving force of Gaz de France, to co-ordinate the work done by several shipyards. A wartime liberty-ship, «Beauvais», was made available for conversion and three tanks of different shapes, designed by three different shipyards and groups of shipyards, were made and installed on board. The first one, with a capacity of 400 m3, was prismatic, made of aluminium AG-4, with a secondary barrier in fibreglass; the second one, with a capacity of 120 m3, was a multi-lobe shape, made of 9 % nickel steel and enclosed in a steel casing; the third tank, with a capacity of 120 m3, was a vertical cylinder with a conical bottom and an elliptical top, the internal tank made of aluminium AG-4 and an outer tank, of the same shape, made of 9 % nickel steel.

The insulation for all three tanks consisted of PVC blocks mixed with perlite. The piping was stainless steel and three different types of cargo pump were used, two deepwell types and one Carter pump with submerged electric motor. The conversion was completed in February 1962, under the supervision of Bureau Veritas with the participation of the Lloyd’s Register of Shipping. Six months of extensive tests followed, to prove the good performance of the tanks and other equipment.

In February 1962, the British Gas Corporation placed an order for two ships, to provide transportation for the 15-year contract signed with Algeria for 100 million cubic feet/day of natural gas. They were «Methane Princess» and «Methane Progress», each of 27 400 m3 capacity, ordered from Vickers Shipbuilders, Barrow-in-Furness and Harland & Wolff, Belfast. The two ships were of the Conch design, with prismatic self-supporting cargo tanks made of 5083-0 aluminium alloy, with insulation made of combined balsa wood and glass fibre acting as a secondary barrier. The ships were jointly classed by A. B. S. and L. R. S. The boil-off was designed at 0,33 % of the total cargo capacity per day and these were the first ships to use the cargo boil-off as fuel for the boilers. Both ships were delivered to their owner in 1964. «Methane Progress» was sold for scrap after 22 years of successful service. In 1997, the decision to sell «Methane Princess» for scrap, after 32 years of service, was taken, not because of the condition of the ship, but because her size made her uneconomical in the existing market.

At the same time, in France, the 25 500 m3 capacity «Jules Verne» was ordered by Gaz Marine, a joint venture between Gaz de France, Gazocean, Bennett Corporation and a number of banks, from Ateliers et Chantiers de la Seine Maritime. The ship was delivered in 1965 and was contracted to carry LNG from Arzew, Algeria, to the Gaz de France terminal at Le Havre for 20 years. The seven cargo tanks were of vertical cylindrical shape with a conical bottom and an elliptical top and made of 9 % nickel steel. They were internally stiffened with six internal rings. The insulation was a combination of Klegecell and perlite in bulk and a secondary insulation of Klegecell covered with a liquid-tight aluminium-textile complex served as a secondary barrier. The boil-off was designed at 0,27 % of the total cargo capacity per day and was used as fuel for the boilers. «Jules Verne» is still operating regularly between Algeria and Spain, after 34 years service and almost 1 200 voyages.

«Methane Progress», «Methane Princess» and «Jules Verne» were all equipped with submerged electrical motor pumps, fitted with some apprehension as to their reliability but which proved trouble-free in service. Despite having been supplied with very carefully written operating manuals and substantial crew training, the three ships have suffered some spillage and overflow of cargo, causing cracked decks, but the resulting damage was minimal. The three ships also suffered some small amounts of inner hull leakage which eventually required some loss of time for repairs, but which did not affect the quality of the tank insulation.

Further research was being carried out during this period. In 1954, in Norway, Dr. Oivind Lorentzen designed a ship of 17 000 m3 capacity equipped with spherical tanks and the project received approval from Det Norske Veritas.

Many naval architects of the time did not think that the self-supporting tanks used for the first LNG tankers were the best solution. The hull of a ship is designed and built to transport bulk cargoes and this was well demonstrated by the success of oil and ore carriers.

This gave ship designers the idea of replacing the self-supporting tanks, which required large amounts of expensive cryogenic alloy, wich a cryogenic protection covering the internal surface of the ship’s hold. This would allow optimal use of the full volume available and the possibility to transport more cargo due to the reduction of dead weight.

In July 1962, in Oslo, a demonstration of a shore tanks using the membrane principle was organised. The concept had been invented by an engineer from Det Norske Veritas and acquired by Dr. Oivind Lorentzen, a ship-owner associated with Carol Bennett, a Texas-based oilman, both of whom were interested in the transportation of Gas Combustion Systems on Liquefied Gas Carriersliquefied gas by sea. The membrane, made of aluminium alloy, had been designed with orthogonal corrugations able to sustain extensive movements in two perpendicular directions under a light load. The insulation used a combination of rock-wool and wood. All present at the demonstration were impressed by the tests consisting of repeated filling of the 32 m3 tank with liquid nitrogen at -196 °C without any special pre-cooling.

After long and arduous negotiations, the French company Technigaz, a subsidiary of Gazocean, acquired the Norwegian licence. Following a new programme of research, a lot of changes were introduced to the basic design. The membrane was changed to low carbon stainless steel, the shape and pitch of the corrugations were altered and the insulation was PVC foam. In 1964, a small 630 m3 LNG/Ethylene tanker, «Pythagore», was built to successfully demonstrate the good operation of the system. The ship remained mainly in ethylene and LPG service until converted to a fish transporter in 1973.

Another system of membrane was developed by a French group led by Gaz de France including other French interests. The material used for the membrane was a nickel-steel alloy with 36 % nickel licensed by the IMPHY company in 1896 under the name of «Invar» for «invariable». Invar was created by Professor Guillaume, who received the Nobel Prize for physics and this material has a very small shrinkage factor. Due to this minimum shrinkage, the thermal stresses induced in the material by the very cold cargo temperature were low enough to allow its use in flat streaks to provide the required sealing function between cargo and ship’s hull. A second membrane, symmetrical to the first one, acted as the secondary barrier. The insulation was provided by two layers of plywood boxes filled with perlite. A small 30 m3 ank was installed on the «Jules Verne» for testing purposes and used for several months to carry liquid nitrogen. Then, a 2 000 m3 LNG experimental shore storage tank was built by Gaz de France. A company named Gas Transport was created in 1965 to continue this project. A 30 000 m3 LPG carrier was ordered by the Worms group from Construction Navales et Industrielles de la Mediterranee in 1967. For the minimum temperature of -45 °C specified for this ship, one layer of insulation was sufficient. Otherwise, the specifications of the cargo containment system were the same as those for LNG. The ship was delivered at the beginning of 1969 and traded successfully until 1974 when she was converted to a Ro-ro.

Development

The end of the 1960’s saw the start of two important LNG projects.

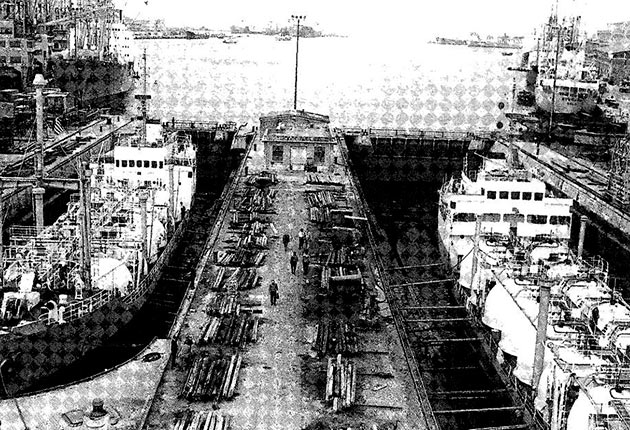

In the final weeks of 1965, Esso signed an agreement with Libya, Italy and Spain to deliver respectively 235 MMSCF and 110 MMSCF per day of natural gas. This project, due to start in 1968, required four ships of approximately 40 000 m3 capacity and 18 knot service speed. After careful review of the LNG containment systems available, their relative costs, licensing conditions and potential reliability in service, Esso decided to develop their own independent, prismatic, self-supporting tank design. They opted for a double-wall, longitudinally divided aluminium tank. The insulation, comprising an assembly of PVC blocks in two layers, with glass fibre fitted between adjacent blocks to accommodate the expansion and contraction of the tanks, was attached to the outer tank shell. Three ships were ordered from the Italcantieri shipyard in Genoa and one from the Astano yard in El Ferrol, near La Coruna in western Spain. All four ships were fitted with Carter submerged pumps, two per tank, giving a total combined discharge rate of 4 000 m3/hour. Each tank was equipped with a valve in the longitudinal bulkhead to enable each pump to discharge the whole tank in case of pump failure. The first ship, «Esso Brega», entered service in October 1969, the second, «Esso Portovenere» in March 1970 and the third and fourth «Laieta» and «Esso Liguria» later the same year. «Esso Portovenere» was sold for scrap in 1982 but the other three ships are still in service today.

The first contract to import LNG to Japan was signed in the spring of 1967 between two American companies, Phillips Petroleum and Marathon Oil, on one side and Mitsubishi Corporation and Tokyo Electric Power Corp on the other. The contract involved the delivery of 1,1 million tonnes of LNG per year from Kenai Nilziski in Alaska to Negishi in the Tokyo Bay. Two ships were ordered from the Kockums hipyard in Malmo, Sweden. The new Gas Transport Invar membrane system was selected as the tank design. The two ships, «Polar Alaska» and «Arctic Tokyo» entered service in November 1969 and March 1970 respectively. After 25 years service on that particularly demanding route, the two ships are still successfully trading world-wide and will enter new long-term commitments in the near future.

Read also: Ship/shore interface for safe loading and unloading of LNG/LPG

During the seventies and eighties, a number of other projects involving many ships of various designs were started. Some of these projects had a very short life span and some never materialised at all, leaving a number of ships without employment. Some ships were built but remained in lay-up for more than 20 years without ever carrying a commercial cargo. Other ships were very successfully employed and will probably continue to be so for many years to come. It is worth noting that, although a small number of LNG ships have been scrapped over the years, the decision has always been taken for commercial reasons and not due to the ship’s poor performance or deterioration. The exception to this is a series of three ships built in the United States at the end of the seventies, with Conch design tanks. The material selected for the secondary barrier never performed to the required standard and the ships were eventually converted into coal carriers.

The size of LNG ships has increased very quickly, from the 27 400 m3 of «Methane Princess» and «Methane Progress» to reach 125 000 m3 in the middle of the 1970’s and this capacity remained as a standard for many years. It is only recently that sizes have crept up slightly to 138 000 m3 and, for the time being, there are no serious prospects to go much higher.

Another interesting point is that LNG ships, even those ordered in 1999, are consistently specified with steam turbine propulsion. This is the least efficient ship propulsion mode available today, but it survives due to its reputation for great reliability and for providing an easy disposal of the boil-off.

Shipyards have suggested various other propulsion systems, such as slow diesel engines combined with reliquefaction plants or diesel-electric systems with medium speed gas burning diesel engines, but, so far, no owner has been bold enough to take advantage of such developments.