In recent years, a transformative shift has emerged in LNG ship propulsion and power generation, challenging the longstanding dominance of steam turbine installations. The advent of low-pressure, four-stroke dual-fuel engines presents a groundbreaking alternative, particularly when integrated with electric drives.

This evolution not only promises enhanced operational efficiency but also underscores a significant step towards environmental sustainability. The imminent surge in orders for dual-fuel-electric LNG carriers reflects the industry’s growing recognition of this compelling and eco-friendly propulsion solution.

Summary

Steam turbine installations have dominated LNG carrier propulsion and electric power generation for the past forty years. The ease with which these installations can utilize boil-off gas and their apparent reliability have kept them in a position that has long been lost to diesel engines in all other segments of the shipping industry. Steam turbine installations are however not very efficient. This has a negative impact on both the ship’s operating economy and its exhaust gas emissions. Exactly these issues play an increasingly important role in LNG shipping today.

Encouraged by the latest developments in its gas engine technology, Wärtsilä started looking for a more economic and environmentally friendly way to power LNG carriers. Machinery alternatives with two- and four-stroke diesel, high- pressure gas-diesel and low-pressure dual-fuel engines, in mechanical and electric propulsion arrangements, with and without boil-off reliquefaction, were studied. Dual-fuel-electric installations were found to be the most attractive alternative to steam turbine installations.

The first dual-fuel-electric LNG carrier, Gaz de France Energy, will take to the sea later this year and two more dual- fuel-electric LNG carriers are on order.

Introduction

After having been predominantly flared off or re-injected for decades, natural gas is playing an increasingly important role in global energy consumption today. Clean combustion properties and abundant reserves are the main benefactors for this evolution from unsolicited by-product of oil production to preferred energy source.

With natural gas reserves often located far away from energy consumers and pipelines expensive or impractical to build, seaborne transportation of natural gas is on the rise as well. The most economic and common way to transport natural gas by sea is in liquefied form. Liquefied Natural Gas (LNG) is today transported by a fleet of some two-hundred dedicated LNG carriers.

With seaborne transportation of LNG expected to double within this decade, a vast expansion of the LNG carrier fleet is imminent. At the same time, increasing cargo volumes offer the possibility to apply economies of scale, and ships are about to significantly grow in size. These circumstances create the need to verify the technical solutions that have been applied in LNG carriers so far.

For the past forty years, steam turbine installations have dominated onboard LNG carriers. The ease with which steam turbine installations can burn boil-off gas and their apparent reliability have kept them in the controlling position that has been taken over by diesel engine installations a long time ago in all other segments of the shipping industry.

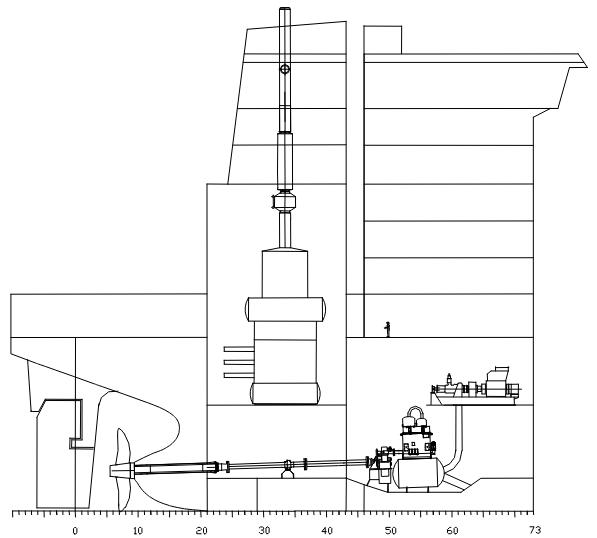

A typical steam turbine installation consists of two boilers, most commonly fired with boil-off gas and heavy fuel oil (HFO). A steam turbine is driving a fixed-pitch propeller through a high-speed gearbox. Two additional steam turbines and one or two diesel engines are driving alternators to generate electric power (Fig. 1).

Steam turbine installations are however not very efficient. This has a negative impact on the operating economy and exhaust gas emissions of the ship. Exactly these issues play an increasingly important role in LNG shipping these days.

Market Requirements

An Overview of Alternative Propulsion Systems for the LNG Vesselattractive alternative should be outperforming the steam turbine installation with respect to its apparent disadvantages, while at the same time at least matching it with respect to its advantages. It is therefore important to study these advantages and disadvantages.

The main reason to remain faithful to the steam turbine installation in LNG carriers is the ease with which they can burn boil-off gas.

Boil-off gas is an unavoidable by-product of the seaborne LNG transportation concept. A small amount of cargo, approximately 0,13 % per day in laden condition, is left to evaporate in order to control temperature and pressure in the ship’s cargo tanks. Both quantity and quality of the boil-off gas are subject to variation.

Operating Economy

Although steam turbine installations can utilize boil-off gas very easily, they do not use it very efficiently. Losses in the boilers, steam turbine, high-speed reduction gear and shafting bring the efficiency of the propulsion machinery to a level below 29 % at full load. The efficiency of the electric power generation machinery is below 25 % at full load. Part-load efficiencies of both the propulsion and electric power generation machinery are even lower.

Such low machinery efficiencies lead to a substantial amount of HFO being required for complementing the available boil-off gas. In laden conditions, some 50 % of the ship’s energy requirement is covered with HFO. In ballast condition, this share grows to 80 %.

Also for LNG carriers, like for any other kind of ship, fuel costs are one of the most important components of the ship’s operating costs.

Environmental-Friendliness

The low efficiency and the need to use large amounts of HFO have a negative impact on the ship’s CO2 and SOx emissions. CO2 emissions are already the focus of attention these days, and can be expected to get even more attention History and Future Predictions of the Liquefied Natural Gas Shippingin the near future.

Safety

Gas tankers attract lots of attention from safety regulators worldwide. The safety of crew, ship and environment is of utmost importance. Onboard LNG carriers, steam turbine installations have a very decent safety record. No major calamities have been reported.

Reliability

Except for some well-documented problems with high-speed reduction gears, steam turbine installations have proven reliable in operation.

Redundancy

In LNG shipping, it is common practice to tie up small fleets of ships on long-term charters on fixed routes with fixed sailing schedules. As the buffer capacity of such a supply chain is limited and punctual cargo operations are important, these kinds of trades require ships with amply redundant machinery.

Although steam turbine installations have proven reliable, they do not have too much redundancy incorporated.

Maintainability

Due to the nature of the LNG trade, it is also important that maintenance of the machinery installation does not interfere with the sailing schedule of the ship or influence its performance.

Steam turbine installations require a modest amount of well-schedulable maintenance. The timing can easily be made to coincide with the wet- and dry-docking intervals of the ship.

Crewability

As all other segments of the shipping industry have made the switch to diesel engine power during the last three decades, the pool of experienced and skilled steam engineers is rapidly shrinking. This poses a crewing challenge which can even reflect in manning costs.

Others

Ships with steam turbine installations have rather poor manoeuvring characteristics. When considering transits in light ice conditions and cargo operations offshore, good manoeuvring characteristics become increasingly important.

Machinery alternatives

Alternative machinery installations for LNG carriers could potentially be built around diesel engines, gas-diesel engine, dual-fuel engines and gas turbines.

Diesel engine alternatives

Since the nineteen-seventies, diesel engine installations have become dominant in all shipping segments, except LNG shipping. Experience gained from thousands of diesel engine installations in service has resulted in the development of highly-efficient, reliable and safe diesel engines. The latest developments, like the application of common rail fuel injection on both four- and two-stroke diesel engines, are taking diesel engine technology yet one step further.

As diesel engines can only burn liquid fuels like marine diesel oil (MDO) and HFO, the boil-off gas on LNG carriers has to be reliquefied in an onboard reliquefaction plant and fed back into the ship’s cargo tanks. These reliquefaction plants require a substantial amount of electric power to operate and are costly, heavy and have only been applied in the marine environment on a very limited scale.

The most simple and straightforward diesel engine installation for a ship the size of a conventional LNG carrier or larger would be a single two-stroke engine in direct-drive to a single fixed-pitch propeller. As the LNG trade sets high standards with respect to “maintainability” and redundancy, the most simple and straightforward diesel engine installation onboard an LNG carrier will likely feature twin two-stroke engines, each in direct-drive to a fixed-pitch propeller. In order to keep the complexity low and the operational flexibility high, electric power will likely be generated by a group of four-stroke diesel generating sets.

Devices for locking or disconnecting the propeller shafts will be necessary to enable maintenance activities on one engine while sailing. Having one engine out of operation for maintenance will however still have a substantial impact on the ship’s service speed. This impact can be reduced by selecting controllable-pitch propellers, or by using the tuning possibilities of electronically-controlled, common rail two-stroke engines.

The exhaust emissions of two-stroke engine installations are reasonable, but certainly not excellent. Without additional equipment like SCR units or direct water injection, NOx emissions are substantial. As an inevitable consequence of using HFO as a fuel, SOx emissions are high too.

More propulsion redundancy and operational flexibility can be offered by applying multiple four-stroke diesel engines driving controllable-pitch propellers through reduction gears. A further enhancement can be realized by applying electric propulsion. The application of electric propulsion will at the same time result in a higher part-load efficiency.

Gas-diesel engine alternatives

Gas-diesel engines act according to the Diesel principle and can virtually burn any possible mixture of gas and liquid fuel, with only a few restrictions to the quality of the gas.

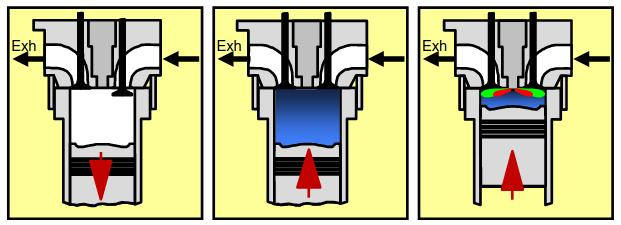

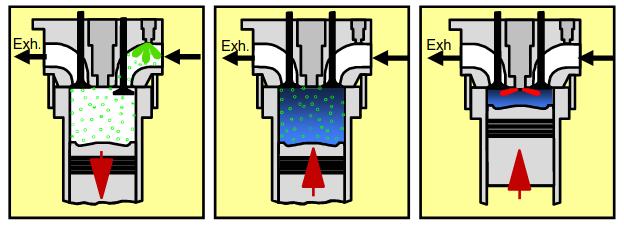

As the mixture of gas and liquid fuel is injected into the combustion chamber during air compression (Fig. 2), the required injection pressure is high. For four-stroke gas-diesel engines, a gas pressure of around 350 bar is required, while for two-stroke gas-diesel engines some 250 bar is deemed sufficient.

Wärtsilä brought its first four-stroke gas-diesel engine, the Wärtsilä 32GD, with an output of 410 kilowatt per cylinder, to the market in 1987. The larger Wärtsilä 46GD, with an output of 975 kilowatt per cylinder, was introduced in 1991.

In close cooperation with its licensee Diesel United, Wärtsilä also tested a two-stroke gas-diesel engine in the mid nineteen-eighties (Fig. 3). The project was however discontinued when commercially feasible applications could not be identified.

Except for the reliquefaction plant, LNG machinery installations based on gas-diesel engines look fairly similar to concepts based on conventional diesel engines.

As boil-off gas is generated at atmospheric pressure, large gas compressors are required to boost the gas pressure to the appropriate level. These compressors require a substantial amount of electric power to operate and are costly and heavy. Additionally, the presence of high-pressure gas in the engine room is a major safety concern, especially on LNG carriers.

Emissions of gas-diesel engine installations are generally lower than those of steam turbine and diesel engine installations as a result of higher efficiency and cleaner fuel, respectively.

Dual-fuel engine alternatives

When running on gas, dual-fuel engines act according to the Otto principle. As the gas is mixed with air before compression starts (Fig. 4), a gas pressure of about 5 bar is sufficient.

This gas pressure is in the same range as the gas pressures in steam turbine installations. Close to top-dead-centre a very small amount of MDO is injected in order to trigger ignition.

Provided that an adequate gas supply system is installed, dual-fuel engines can accept all gas qualities seen in LNG shipping. In addition to running on gas, dual-fuel engines can run on MDO. When running on MDO, the dual-fuel engine acts as a normal diesel engine.

In case the supply of gas is interrupted, the dual-fuel engine automatically transfers to diesel mode, without loss of engine power or speed. The transfer from diesel to gas mode is carried out fully-automatic on demand.

Low-pressure dual-fuel technology is only available on four-stroke engines. The first Wärtsilä dual-fuel engine, the Wärtsilä 32DF, was brought to the market in 1996. This engine, with a power of up to 350 kilowatt per cylinder, is available in six- and nine-cylinder inline and twelve- and eighteen-cylinder Vee-form configurations.

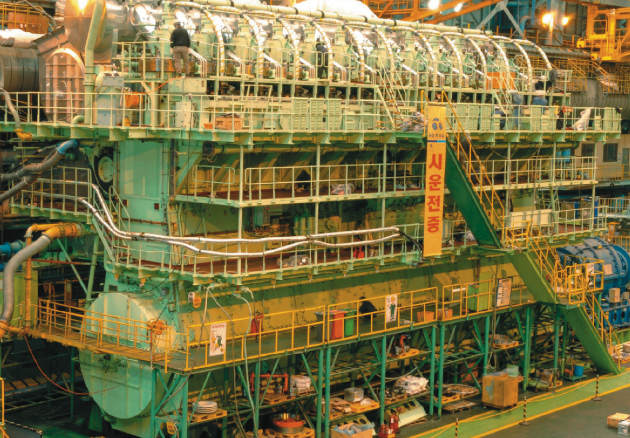

The larger Wärtsilä 50DF (Fig. 5) was launched in 1998. This engine is available in six-, eight- and nine-cylinder inline and twelve-, sixteen- and eighteen-cylinder Vee-form configurations. With an output of 950 kilowatt per cylinder, it delivers between 6 to 17 megawatt at full load.

The Wärtsilä 32DF and 50DF dual-fuel engines have been derived from the Wärtsilä Vasa 32 and Wärtsilä 46 diesel engines respectively, which have proven their reliability in various demanding marine installations. In addition to this inherited reliability, burning clean fuel has a positive impact on reliability.

As a result of higher efficiency and cleaner fuel, emissions of dual-fuel installations are lower than those of steam turbine, diesel and gas-diesel installations.

In combination with an electric propulsion system, dual-fuel installations achieve optimum performance and high efficiency at virtually any load.

Gas turbine alternatives

Gas turbine installations could also potentially be applied in LNG carriers. Their rather low efficiency at part-load, difficulty in coping with high ambient temperatures, need for high gas pressure and the required special skills and procedures for maintenance, make them less attractive.

Selection of alternatives

The feasibility of gas-diesel engines for propulsion and electric power generation onboard LNG carriers was studied by Wärtsilä and others some ten years ago. The need for gas compression turned out to be a too high burden for the operating economy of the ship.

Read also: Weather-related Economics of Natural Gas Transport for Two Propulsion Plant Configurations

The quantifiable characteristics of the other alternatives were compared using a specially developed comparison tool, whereas their non-quantifiable characteristics were discussed and compared together with major LNG carrier owners, operators, managers and shipyards over the past few years.

When comparing the operational economy of the various alternatives, it is important to take the whole machinery installation into account. Two-stroke diesel engines have a high efficiency, but the need to reliquefy the boil-off gas gives installations featuring this type of engines a higher total energy consumption.

The most attractive alternative to the traditional steam turbine installation turned out to be The New Generation of Liquefied Natural Gas Carriers – Basic Design Philosophydual-fuel-electric machinery. As a runner up but at clear distance to dual-fuel-electric machinery, an installation featuring twin two-stroke engines, each in direct-drive to a fixed-pitch propeller, a reliquefaction plant, and a group of four-stroke diesel generating sets emerged.

Dual-fuel-electric LNG Carriers

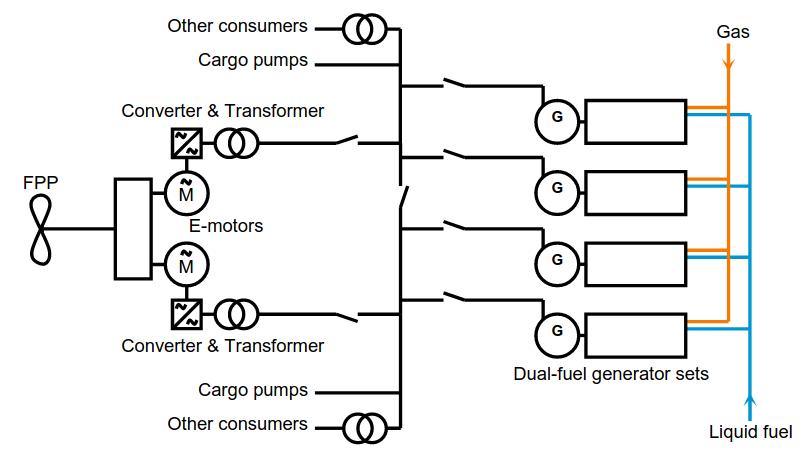

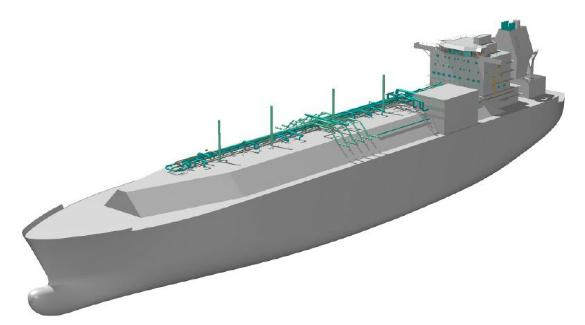

Central in the dual-fuel-electric propulsion and electric power generation solution (Fig. 6) are multiple dual-fuel generating sets. The number and size of these sets of course largely depends on the ship size and speed, but also on the envisaged operating philosophy.

An LNG carrier with a cargo capacity of some 150 000 m3 will typically require one six- and three twelve-cylinder Wärtsilä 50DF engines. An LNG carrier with a cargo capacity of 200 000 m3 will typically require two six-and four nine-cylinder engines, and a ship of 250 000 m3 cargo capacity will do with two six- and four twelve-cylinder Wärtsilä 50DF dual-fuel engines.

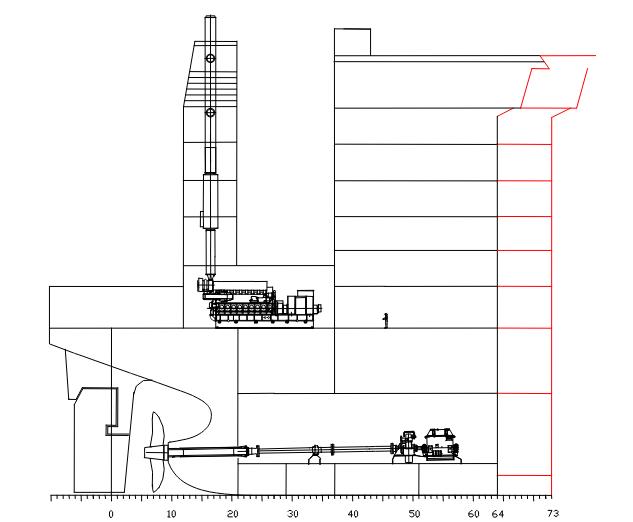

The generated electric power is fed to an electric drive fairly similar to those used on contemporary cruise ships. Two “high-speed” electric propulsion motors drive a fixed-pitch propeller through a reduction gear. Twin “low-speed” electric motors mounted on the same shaft can be selected to drive the propeller without assistance of a gearbox alternatively. For the larger ships, twin-screw arrangements can be selected without significantly increasing the complexity of the machinery installation.

Operating economy

As dual-fuel engines have the ability to run on both gas and MDO, the choice of fuel is up to operator. Several independent studies have however confirmed that forcing additional boil-off gas to complement the natural boil-off gas is the way to profit most from the potential of the dual-fuel-electric solution. Firstly, forced boil-off gas is cheaper than alternative fuels. Secondly, it is lighter than alternative fuels. Fuel “bunkers” weight is thus reduced, and at a given displacement, the ship will be able to carry more cargo weight. Carrying more cargo volume is enabled by the fact that the dual-fuel-electric solution saves engine room space (Fig. 7). Even when using a small part of the cargo as fuel, a dual-fuel-electric LNG carrier will deliver more cargo to the unloading port in this way.

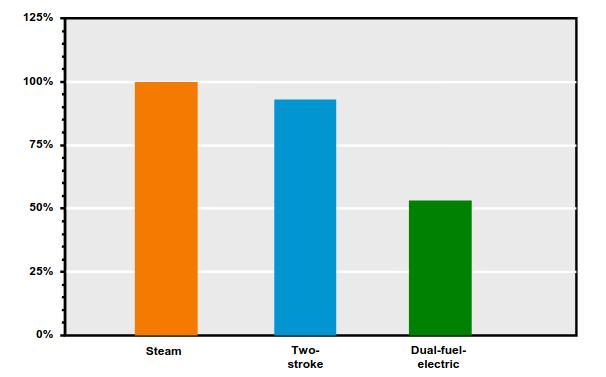

The efficiency of the propulsion machinery of a dual-fuel-electric LNG carrier is approximately 41 % and the efficiency of the electric power generation machinery is around 44 %, compared to 29 % and 25 % respectively for a steam turbine installation. A two-stroke diesel engine installation will have a propulsion machinery efficiency of about 48 % and the efficiency of the electric power generation machinery will be about 41 %, but will consume a substantially higher amount of electric power due to the presence of the liquefaction plant.

Adding the cheaper fuel of the dual-fuel-electric LNG carrier to the equation, this solution clearly excels in terms of operating costs (Fig. 8).

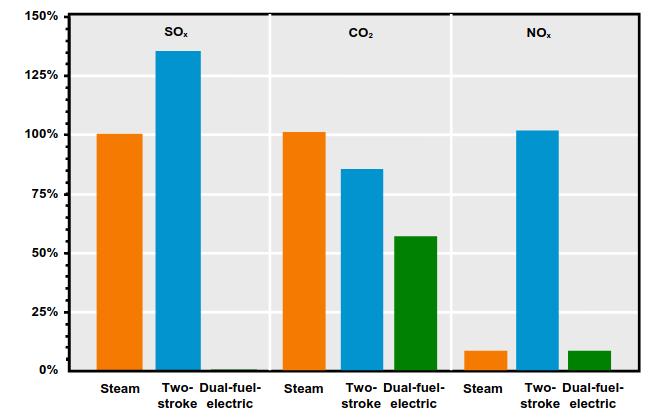

Environmental-friendliness

When exclusively using natural and forced boil-off gas as fuel, the dual-fuel electric solution shows unrivalled emission values (Fig. 9).

All other machinery alternatives suffer from the use of HFO, either used uniquely or in combination with natural boil-off gas.

Safety

A “Safety Concept” for dual-fuel-electric machinery onboard LNG carriers has been developed by Wärtsilä to make sure that the safety of the installation complies with class and at least matches the safety of steam turbine installations. The recent introduction of double-wall gas piping on the Wärtsilä 50DF will further increase the safety of the solution. With several potential customers and class, safety studies including hazard identification, FMEA and hazardous operations studies, have been conducted to further validate the safety of the solution.

Reliability

The Wärtsilä 50DF has been derived from the Wärtsilä 46, a diesel engine that has proven its reliability in various demanding marine applications, such as cruise ships. The use of gas in the Wärtsilä 50DF as compared to HFO in the Wärtsilä 46 further enhances this inherited reliability.

Redundancy

Electric propulsion systems are in their essence highly redundant, as more or less all primary functions of the system are distributed over more than one component. The dual-fuel-electric installation features multiple generating sets, potentially distributed over multiple engine rooms, has twin transformers and converters, and features twin electric propulsion motors with double windings.

Maintainability

Case studies for various customers have shown that the required maintenance on dual-fuel-electric installations can easily be carried out without affecting the ship’s operational performance. Maintenance of dual-fuel-electric installations is more costly than of steam turbine installation, but does no harm to the ship’s operating economy.

Crewability

Dual-fuel-electric installations can be operated and maintained by diesel engine crews. There is no need for crew members with exceptional skills or experience.

Others

The dual-fuel-electric installation provides excellent propulsion characteristics for navigation in ice, due to the availability of full propeller torque at zero speed and excellent manoeuvring characteristics.

Dual-fuel-electric installations can easily cope with the power requirements of dynamic positioning systems. This might become a valuable feature, as an increasing amount of offshore LNG terminals is envisaged

Market introduction

Wärtsilä dual-fuel engines have already collected a vast number of running hours in installations on land and at sea without any significant problems. In addition to this, a Wärtsilä 6L50DF dual-fuel engine is undergoing an endurance test at Wärtsilä Ibérica in Bermeo, Spain, to further validate its performance (Fig. 10).

The first dual-fuel-electric ships running on LNG, Viking Energy and Stril Pioner, are in operation since 2002 and the first dual-fuel-electric LNG carrier, Gaz de France Energy, is currently nearing completion and is scheduled to enter commercial operation in November this year.

Dual-fuel engines on land

Seventeen Wärtsilä dual-fuel engines, with a combined output of more than one-hundred megawatt, are in operation in land-based power plants in Turkey, the United Kingdom, Denmark, Russia, India, the United States of America and Spain.

Dual-fuel engines at sea

Eleven Wärtsilä dual-fuel engines are in service at sea, and twelve more engines are about to follow.

1 Petrojarl 1

Off shore Norway, two eighteen-cylinder Wärtsilä 32DF engines, with an aggregate power of 12 megawatt, are running on natural gas from the Glitne oil and gas field onboard Petroleum Geo-Services FPSO Petrojarl I (Fig. 11).

2 Sendje Ceiba

One eighteen-cylinder Wärtsilä 32DF dual-fuel engine, rated at 6 megawatt, is running on natural gas from the Ceiba oil and gas field off shore Equatorial Guinea onboard Bergesen’s FPSO Sendje Ceiba (Fig. 12).

3 Viking Energy and Stril Pioner

The platform supply vessel Viking Energy (Fig. 13), delivered to Eidesvik of Norway by Kleven Verft of Norway in 2002, is equipped with four six-cylinder Wärtsilä 32DF dual-fuel engines. These engines, with a combined output of 8 megawatt, are driving two azimuthing thrusters through an electric drive.

Added to the fact that Viking Energy is the first ship to apply dual-fuel-electric machinery, it is also the first ship running on LNG. Using hot water vaporizers, natural gas is forced to boil off from a 220 m3 insulated LNG fuel tank underneath the ship’s deck.

Viking Energy’s sister ship, Stril Pioner, was delivered to Simon Møkster of Norway by the same shipyard during the same year (Fig. 14).

Both ships are on charter to Statoil and are stationed in the port of Bergen in Norway.

Dual-fuel-electric LNG Carriers

Three dual-fuel-electric LNG carriers have been ordered

so far.

1 Gaz de France Energy

In February 2002, the French utility Gaz de France placed on order for a 74 130 m3 dual-fuel-electric LNG carrier at the French shipyard Chantiers de l’Atlantique. This ship, Gaz de France Energy (Fig. 15), is currently nearing completion and is scheduled to enter service in November 2004.

Four six-cylinder Wärtsilä 50DF dual-fuel engines, with an aggregate power of 22,8 megawatt, will power the ship to a service speed of 17,5 knots. Natural boil-off gas complemented by forced boil-off gas will serve as fuel in normal operating conditions. In case no gas is available, the engines will run on MDO.

Gaz de France Energy will primarily trade between Algeria and France.

2 Provalys

In September 2003, Gaz de France ordered a second DF-electric LNG carrier at Chantiers de l’Atlantique. This ship, Provalys (Fig. 16), will have a cargo capacity of 153 500 m3 and upon delivery at the end of 2005 be the largest LNG carrier afloat.

In this ship, three twelve- and one six-cylinder Wärtsilä 50DF dual-fuel engines, with a combined output of 39,9 megawatt, will generate the required electric power to give the ship a service speed of 19 knots. These engines are currently in production at Wärtsilä Italia in Trieste. Also in Provalys, forced boil-off gas will complement the natural boil-off gas in normal operation conditions, while MDO will serve as fuel in conditions were no gas is available.

The ship will primarily trade between Egypt and France, and Norway and France.

3 Chantiers de l’Atlantique #P32

In July 2004, a joint-venture of NYK of Japan (60 %) and Gaz de France (40 %) ordered a sister ship to Provalys at Chantiers de l’Atlantique, which is scheduled for delivery at the end of 2006.

Dual-fuel-electric machinery is presently being evaluated by ship owners and shipyards around the world for a vast number of LNG carrier newbuilding projects. The cargo capacities of the envisaged ships are ranging from the conventional 150 000 m3 to 200 000 and even 250 000 m3. Port-to-port sailing distances are ranging from several days to several weeks.

In addition, dual-fuel engines are under consideration for application in various kinds of offshore installations, including floating liquefaction units, as well as floating regasification units.

Conclusion

Steam turbine installations have dominated LNG carrier propulsion and electric power generation for decades because no suitable alternatives were available. With the market introduction of low-pressure, four-stroke dual-fuel engines came the chance to challenge the steam turbine dominance.

Dual-fuel engines in combination with an electric drive have turned out to be the most attractive alternative to the traditional steam turbine installation, especially in terms of operating economy and environmental friendliness. More orders for dual-fuel-electric LNG carriers are imminent.