LNG transportation risks are a growing concern as global reliance on liquefied natural gas increases. The process of transporting LNG involves unique challenges that can lead to serious incidents if not properly managed. LNG transportation risks include potential leaks, fires, explosions and environmental contamination, especially during loading, shipping and unloading operations. As more countries invest in LNG infrastructure, awareness of LNG transportation risks becomes essential for ensuring safety and sustainability. Engineers and safety experts work continuously to develop systems and protocols that can reduce LNG transportation risks and improve emergency response capabilities.

Despite technological progress, LNG transportation risks remain present due to factors such as equipment failure, weather conditions, human error and geopolitical instability. Understanding LNG transportation risks is critical not only for energy companies but also for governments and international regulators. Training personnel, maintaining infrastructure and conducting regular risk assessments are key strategies to manage LNG transportation risks. As the industry grows, so does the importance of transparency and cooperation in addressing LNG transportation risks. Future innovations must focus on minimizing LNG transportation risks to protect people, property and the environment from potential harm. Effective communication between stakeholders is essential to identify and respond quickly to LNG transportation risks. The development of international safety standards plays a vital role in reducing LNG transportation risks across borders. Continuous monitoring and data analysis help detect early warning signs and prevent LNG transportation risks from escalating into major incidents.

Premise

Figure 1, downloaded from an INTERNET site, refers to a fictitious and hypothetical accident.

It is a photomontage that was prepared to warn people of the awful danger that the transportation by sea of LNG could represent for our towns next to LNG terminals as well as to the environment. There exist many false claims and conjectures on the hazards of a potential disaster resulting from an LNGC “exploding” close to a metropolitan area (as show in the photomontage above). With these claims and conjectures, critics of LNG commonly refer to these vessels as “Floating Atomic Bombs“. There are many INTERNET web sites stressing this purported danger so as to persuade public opinion to avoid as far as possible any construction of new terminals and to reduce or eliminate the use of LNG.

Our objective here is to review the available data, determine if this purported damage actually exist and if so, estimate whether the consequences of an accident would come close to that stated “as Armageddon“, as shown in figure above.

Safety Aspects of LNG Carriers

Safety Records

Available records do not report any serious accident on an LNG carrier as direct result of carriage of LNG. No LNG related accidents have occurred to LNGC’s (e. g. grounding, engine room fire, etc.) none of which created particular problems for the presence of LNG in the holds. These statistics put the Key Systems for LNG Carriers Containment and Safety: Design and OperationLNG carriers at the top of all type of gas carriers, and may be of all categories of ships, with regard to safety. Table 1 shows the list of all accidents happened to LNG ships up-to-dated to the end of 2002.

| Table 1. Marine Accidents Involving LNG Carriers | ||||||

|---|---|---|---|---|---|---|

| YEAR | SHIP | ACTIVITY | CARGO SYSTEM | EVENT | CARGO SPILL | DAMAGE |

| 1965 | Cinderella | Loading | Gas de France | Overfilling | YES | Fractures in tank cover and deck |

| 1965 | Methane Princess | Disconnecting | Conch | Valve leakage | YES | Fractures in deck |

| 1971 | LNG Palmaria | Unloading | Exxon | Pressure increase | YES | Damage to top of cargo tank |

| 1974 | Methane Progress | In port | Conch | Stranded | NO | None |

| 1977 | LNG Delta | At sea | Technigaz | Valve failure | YES | None |

| 1977 | LNG Aquarius | Loading | Moss-Rosenberg | Overfilling | YES | None |

| 1979 | Mostefa Ben Boulaid | Unloading | Technigaz | Valve leakage | YES | Fractures in deck |

| 1979 | Hoegh Galleon | Unloading | Moss-Rosenberg | Valve leakage | YES | Fractures in tank cover and deck |

| 1979 | El Paso Paul Keyser | At sea | GT | Stranded | NO | Sever damage of hull and containment system |

| 1980 | LNG LIbra | At sea | Moss-Rosenberg | Shaft moved against rudder | NO | Fracture to tailshaft |

| 1980 | LNG Taurus | In port | Moss-Rosenberg | Stranded | NO | Hull damage |

| 1985 | Bebatik | In port | Technigaz | Steering gear failed | NO | None |

| 1985 | Isabella | Unloading | GT | Valve failed | YES | Fractures in deck |

| 1989 | Tellier | Loading | Technigaz | Broke mooring | YES | Hull damage |

| 1990 | Bachir Chihani | At sea | GT | Hull fatigue crack | NO | Structural cracks |

| 2002 | Norman Lady | At sea | Moss-Rosenberg | Collision with submarine | NO | Minor hull damage |

The table shows that only 16 accidents have been reported since the starting of the LNG carriers’ era in the late sixties and of these 16 accidents, only 9 led to limited spill of cargo without further serious consequence for the ships, human lives and environment.

LNGC’s safety records can be attributed to:

- The accurate verification to which the design of an LNG carrier is subjected to by the designer and the classification societies.

- The construction of the vessels (in particular the cargo containment system / cargo handling system) are built by only a few specialized shipyards (of the 15 shipyards in the world capable of building Guide for Planning Gas Trials for LNG VesselsLNG vessels, only 9 are presently active) and all with very stringent quality assurance procedures.

- The fact that these vessels are very expensive and usually sign long term charter contracts, owners and operators ensure careful maintenance to a high standard with respect to other vessels.

- In general the crew of LNGC’s is comprised of selected personnel with good performance and operation records.

- Considering that the internal spaces of the vessel are either loaded (methane is a non-corrosive substance) or inerted, the corrosion of these type of vessels is largely minimized.

For the aforementioned reasons, LNG carriers, by nature of design, construction and service, can easily reach 40 years of service, surpassing the life span of other vessels.

A potential weak point might be the ballast tanks, where corrosion could become extensive if proper coatings are not maintained. However, records show that, in general, maintenance of the protective coating in ballast tanks is assured by the owners of the LNGC’s due to the high value of the vessel, easy of access and maintenance and the high cost of lay up for repairs.

Also, reported structural damages (not due to collision or grounding) have been limited to a few fractures in way of some details, such as the connection of side longitudinals to web frames in the splash zone and connection of the lower stool to the inner bottom, which were typical of the vessels other than LNG carriers, built about 20-25 years ago. Some local brittle fractures have been detected in case of minor accidents leading to limited LNG spillage. Finally, the first ships of Gaz Transport design experienced damages to the membrane in the upper part of the tanks due to sloshing. Now these details are well known, more refined fatigue analysis techniques areused and better detail designs have proven effective at minimizing recurrences of these problems.

Additional Hazards not Strictly Related to LNGC’s

Gas carriers, including LNG carriers, have many void spaces surrounding the cargo tanks. All these spaces are dangerous due to possible inadvertent presence of gas vapor or inert gas, leaked through a crack in the cargo containment system. Serious accidents on Features of cargo delivery LNG/LPG carriersLPG carriers have occurred causing loss of life due to confined space procedures not being followed. Inert gas was found to have leaked into a space creating an atmosphere, which would not sustain life. While we have no records that this type of accident has occurred on LNG carriers, it is extremely important that all gas detection equipment are checked to be properly working and that confined spaces safety procedures for entering the spaces surrounding the tanks are well established and strictly followed. Drills are essential to make the personnel aware of the dangers and to teach them how to rescue injured persons in hazardous areas.

The Human Factor

For reasons as stated above, combined with the special requirements relative to a gas carrier, it becomes imperative that the vessels crew must be suited to the task of operating an LNGC. In that a potential dangerous situation could occur at any time, crew members must not only possess the technical knowhow, but must have the where with all to work as team through any situation, with calm, rationale strictly adherent to the safety rules.

Crew selection, retention and rotation as well as synergy should be carefully evaluated by the operating company to insure a long, safe life of vessel and crew.

The human “equation” or “factor” posses the most serious risk for an LNGC. Only by continuous, conscientious and safe operations by vessels crew, can a major accident (e. g. release of gas as explosion) be avoided and the excellent safety record of the LNGC’s fleet be maintained.

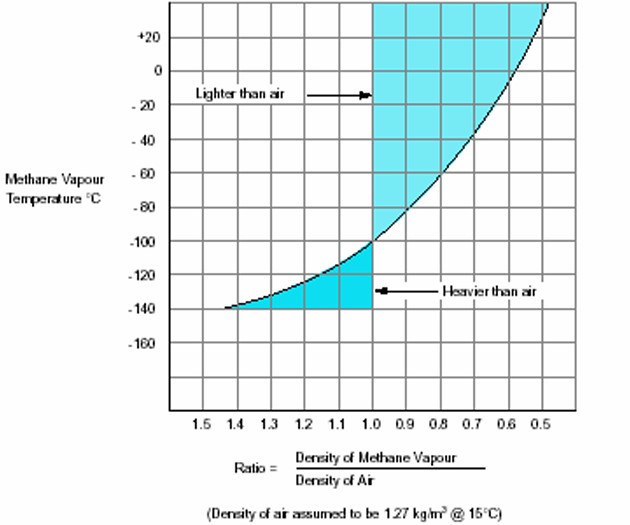

Major Spillage and Fire – Terrorism

As previously mentioned, no incident leading to a major spill of LPG has occurred to a LNGC to this date, and no records of LNG or NG fires on LNG carriers exist. However, still there is the concern that a major collision, structural collapse or an act of terrorism might cause a large quantity of spill of LNG. As a worst scenario, the spilled LNG will immediately vaporize, but the NG vapor, being heavier than air at low temperature, will not be dispersed in the atmosphere and will remain close to the site of the accident until its temperature is below about – 100 °C (See Figure 2).

A source of ignition in those areas, where the gas concentration is between the LFL and the UFL, will create a fire.

The burning gas, becoming lighter than air, might generate a fire cloud and this cloud might be transported very far from the site of the accident depending on the atmospheric conditions.

Again, this is a worst case scenario. However, according with other sources, the vapor of the spilled LNG would be heated so fast above the temperature of – 100 °C by the environment, to be dispersed in the air before a possible ignition.

There are several studies and simulations of such type of accident with no conclusive results. Unfortunately, a common understanding and agreement on the importance and consequences of a major spill has not yet been reached. Some studies foresee catastrophic consequences, others arrive to the conclusion that even in the case of a major accident, the fire would be limited to the close vicinity of the ship and a fire cloud would not have an opportunity to form. Many of these studies are heavily evidently influenced by the party who requests them and may not represent an unbiased study.

Whatever the facts are, it remains that it is not possible to predict what will occur, as luckily, there is no actual experience of this awful scenario. The only statement we can make is that, based on our experience, LNG ships are ships more robust and better protected that any other type of ships, and it would be very unlikely that this type of event would occur, unless cause purposely by man.

One of the major today’s worry today about LNGC’s is the risk they could be subject of a terrorist attack in areas close to large cities, where an explosion and the corresponding fire might extend on-shore and destroy part of the town. However, from this point of view, it is impossible to predict with any accuracy what terrorists may target. LNGC’s would not appear as a probable target. Perhaps, a pipeline is more vulnerable. Moreover, in general the terminals are quite far from the cities and therefore a major casualty in a terminal, no matter how bad it is, might not have for a terrorist the same appeal of a bomb in a public site of an important city.

Other Possible Risks

Recently some Administrations have expressed their concern that the insulating material used in the LNG ships might be flammable and/or might generate dangerous smoke in case of fire. In particular, some flammable substances are actually used for the insulation of membrane ships, such as for instance plywood, paper, etc.

This danger is to be kept present during the construction of the ship and some unfortunate accidents have been reported. However, the probability of fire in the insulation can developing in an existing ship is almost not existent. In fact, not only there are no sources of ignition in the interbarrier spaces, but this spaces are always kept inerted.

Another concern is the fact that some substances used for the construction of certain types of cargo containment systems (polyurethane foam for MARK III System: Hull and Deck Components for Marine VesselsMARK III system), might generate substance displacing the ozone in the atmosphere. However, this is problem is more related to the construction of the panels than to their installation in the LNGC, as, once these panels are fabricated and installed, they are inert and there is no further possibility of releasing substances from the cargo containment insulation that might displace ozone in the atmosphere.

Further Studies

Lloyd’s Study

The following is a summary of Lloyd’s study on the risk of LNG according to a presentation given by Chevron-Texaco.

- Historically for all types of LNG – no loss of life, land based property damage – environmental damage.

- LNG carriers inherent strength has prevented loss of containment.

- A missile hit or explosion will provide a large number of ignition sources.

- If containment loss should occur under specific conditions holing may not be visible.

- There is potential for escalating failure due to embrittlement with subsequent explosion/fire.

- Ignition and sustained burn of a vaporized LNG cloud is difficult. Multiple ignition sources would probably result in a burn back to the source.

- Unconfined LNG vapor cloud detonation has not been demonstrated and unlikely.

- External ignition (of vapor cloud) results in slow moving flame.

- Rapid Phase Transition will not cause ignition but potentially damaging for ship/equipment. The LFL for methane/air mixtures is ~5 % so the LFL boundary is well within the visible cloud.

- Modeling of dispersion cloud 3-6 km. Dispersion on that scale unlikely because of local ignition sources that scale unlikely because of local ignition sources.

- Exposure at 300 meters (1 000 ft) from a pool fire would cause pain within 60 seconds.

- Warming gas cloud will become lighter than air and rise.

- No direct environmental damage or clean up from primary spill.

- A fire fed by single (25 000 m3) cargo tank vented through a 1 m2 hole would last 1 hr with burn diameter of 25 meters.

Hazard Identification (HAZID) on LNG Vessels / Ports Hazard

The most recent study on the possible occurrence of a spill is a HAZID (Hazard Identification) study carried out by DNV together with some representatives of Industry. The results of this study have been published in the”LNG Journal” January/February 2005. The following Tables, taken from this magazine, summarize the results of this study.

Table 2 shows the events and scenarios, which has been considered in the study.

| Table 2. Events Considered by LNG Marine Consequence HAZID Team | |

|---|---|

| EVENT | COMMENT |

| Collision with another vessel | Collision potencials were considered for vessels of four sizes (VLCC 300 000 DTW, vessels > 150 000 DTW, vessels 30 000-150 000 DTW, and vessels < 5 000 DTW) |

| Grounding | Grounding events were considered in the port approaches where vessel operates below maximum oceangoing speeds (typical 12 knots) |

| Striking a fixed object | Worst credible is striking a submerged object, no worse than grounding |

| Unloading | Worst credible event is a sudden pull-away and failure of PERC connection discharging full loading rate for 10 minutes |

| Terrorism | Several scenarios were considered: missile attack, boat based explosive, hijacking. Larger scenarios are possible (e. g. deliberate airplane crash) but were not credible as better targets with more reliable consequences exist for attacks of this magnitude. Hijacking can lead to collision or cargo jettison at maximum pumping rate. Many terrorism scenario lead to immediate ignition, which reduces the impact to public |

| Natural hazards and other events | A wide range of scenarios was considered but were either not credible or resulted in lesser scale events than those already accepted |

The main problem of this kind of study is to identify a credible hole size of the cargo containment system that can be a result of one of the scenarios in table above. The approach used in the study do determine the maximum hole size is the following:

1) DESIGN EVENTS

Events expected to happen 1-2 times during the ship’s life, such as leak if flanges and/or small pipe cracks. It is envisaged that such events can be easily handled by the normal safety features of the ship.

2) MAXIMUM CREDIBLE EVENT

An event not likely to happen in the lifetime of a ship, but considered to establish emergency procedure should it actually happen.

3) WORST CASE SCENARIO

Hypothetical events, without any reference to the safety design features or operational controls. Some USA authors have envisaged a scenario leading to an inner hull breach of 3 – 4,5 m diameter. A breach of this magnitude would empty the tank in approximately 2 minutes with catastrophic implications.

DNV’s study considers this worst case scenario as unrealistic based on the presumption that current FEM analysis show that the Prevention rollover in LNG TanksLNG tanks, having a gas space of 500-800 m3 upon arrival, can deform substantially without becoming liquid full or creating a large rapid internal gas pressure not protected by the relief system.

Based on this and other considerations, such as double hull effectiveness, the DNV specialists considered the following MAXIMUM CREDIBLE holes of the inner hull from which LNG could spill.

- 250 mm: Maximum credible puncture hole from a variety of causes, but mainly related to collision or striking objects.

- 750 mm: Maximum credible hole from accidental operation events, such as collision or grounding.

- 1 500 mm: Maximum credible hole from a variety of terrorist attacks. Events leading to larger holes as major terrorist operation against a LNGC is considered not probable for the reason stated in table above.

These holes would lead to a maximum spill from 7 000 m3/h up to 10 000 m3/h in case of sabotage.

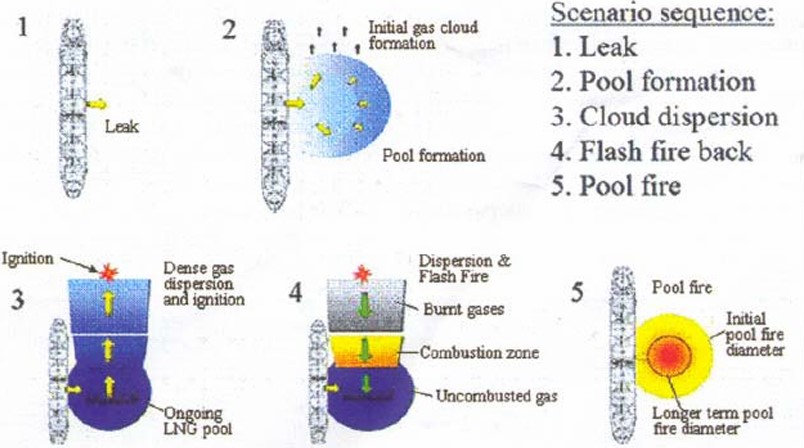

Based on the above hypothesis, Figure 3 shows the sequence of events after the spill is started.

The sequence indicated in the figure is conservative, assuming that the events following the spill do not immediate ignite a fire. If immediate fire occurs, then the interested zone will be limited to the immediate vicinity of the ship and the risk the fire extending far away from the ship is limited.

The final results of the study are given in the following Tables 3, 4, 5 and 6.

| Table 3. Discharge Results – Various Hole Sizes and Locations | ||||||

|---|---|---|---|---|---|---|

| SPILL CASE | SPILL ABOVE WATERLINE | SPILL BELOW WATERLINE | ||||

| Hole size (mm) | 250 | 750 | 1 500 | 250 | 750 | 1 500 |

| Initial spill rate (kg/s) | 226 | 2 030 | 8 130 | 200 | 1 800 | 7 220 |

| Duration (hous) | 19 | 22 | 0,54 | 30 | 3 | 0,8 |

| Total release (%) | 69 % | 100 % | ||||

| Table 4. Downwind Flammable Atmosphere Distances Estimated for Maximum Credible LNG Scenarios | |||

|---|---|---|---|

| SPILL ABOVE WATERLINE | CREDIBLE SCENARIO | HIGH UNCERTAIN SCENARIO | NON- CREDIBLE SCENARIO |

| 250 mm hole | D 3,0 m/s = 370 m D 5,0 m/s = 380 m | F 2,0 m/s = 830 m | |

| 750 mm hole | D 3,0 m/s = 910 m D 5,0 m/s = 920 m | F 2,0 m/s = 1 400 m | |

| 1 500 mm hole | D 3,0 m/s = 1 800 m D 5,0 m/s = 2 000 m F 2,0 m/s = 3 100 m | ||

| SPILL BELOW WATERLINE | CREDIBLE SCENARIO | HIGH UNCERTAIN SCENARIO | NON-CREDIBLE SCENARIO |

| 250 mm hole | D 3,0 m/s = 310 m D 5,0 m/s = 320 m | F 2,0 m/s = 430 m | |

| 750 mm hole | D 3,0 m/s = 810 m D 5,0 m/s = 840 m | F 2,0 m/s = 900 m | |

| 1 500 mm hole | D 3,0 m/s = 1 700 m D 5.0 m/s = 1 900 m F 2,0 m/s = 3 000 m | ||

| Notes: – The letter D and F in the table indicate the Code weather stability class and the following number is the wind speed. – F 2,0 m/s weather dispersion distance has greater uncertainly than other weathers due to lack of validation data, also the duration and speed of the cloud are such that contact times with the sea are longer (more than 30 minutes) and plume warm-up may be sufficient for lift off to occur, eliminating the downwind risk from that point. – The 1 500 mm is included to take into account terrorist acts. However, it is not realistic as immediate ignition is likely to happen in such case and the actual evanesce in this case would be a pool fire. | |||

| Table 5. Downwind Flammable Atmosphere Distances – Single Jetty Arm Failure (7 600 m3/h) and Terrorism Event (10 000 m3/h) | ||

|---|---|---|

| SCENARIO | CREDIBLE SCENARIOS | HIGHLY UNCERTAIN SCENARION |

| Single arm failure | D 3,0 m/s = 780 m D 5,0 m/s = 790 m | F 2,0 m/s = 1 400 m |

| Terrorism event | D 3,0 m/s = 790 m D 5,0 m/s = 790 m | F 2,0 m/s = 1 600 m |

| Table 6. Thermal Hazard Range for Maximum Credible Event Above Waterline | |||

|---|---|---|---|

| POOL SIZE | 250 mm HOLE | 750 mm HOLE | 1 500 mm HOLE |

| Sustainable pool diameter | 29 m | 86 m | 171 m |

| Thermal hazard range | 190 m | 440 m | 750 m |

| It is believed that this hazard ranges are conservative as the pool flame is likely to be smokier than the luminous assumption used | |||