This article covers the important information about requirements for LPG tankers to navigation on Danube River.

Statement of a task

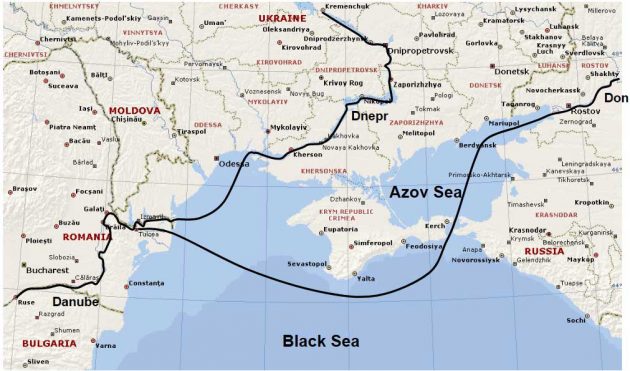

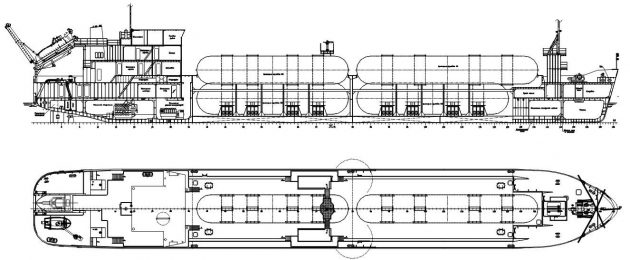

Conversion of suitable vessel in LPG (propane-butane) carrier of the mixed the river-sea navigation with carrying capacity about 1 000 t for operation from supplier (Volga and Dnepr ports) on the Danube port of Ruse.

«BULMARKET-1»

The basic requirements:

- re-equipment of an existing dry-cargo vessel due to financial limits and necessity to have required vessel in the shortest term;

- transportation of liquefied gas under pressure only (without cooling) because of available coastal infrastructure and vessel’s means;

- operation on changes of depths on the Special Requirements for LPG Carriers to Sail Cargo on Danube RiverLower and Middle Danube;

- The class of a vessel after conversion should allow normal operation in sea conditions of the Black and Azov Seas.

Requirements to overall dimensions of the vessel

Dimensional restrictions, imposed on researched vessel by expected areas of operation in river Danube:

- Draught – not greater than 3,00 – 3,10 m;

- Width – not greater than 12,0 m;

- Length – not greater than 110 m.

For operation on the Black and Azov Seas wind-wave conditions and actual distances between places of a refuge has shown that class IIISP (the permissible height of a wave of 3 % probability h3 % 3,5 m) of the Russian Maritime Register of Shipping is sufficient.

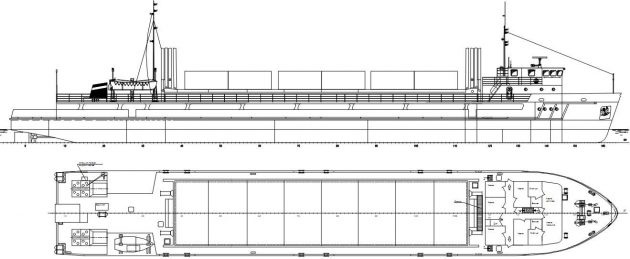

Existing dry-cargo vessel for conversion

Dry-cargo vessel of the project 191 “Dneprovets” type with Russian River Register class “O-pr” (h3 % = 2,0 m) had been chosen as most suitable under the given above restrictions.

Thus this choice besides the decision of a problem of change of purpose required to resolve a problem of increase in a class (the overall and local strength) up to RS class IISP (h3 % = 6,0 m) by reinforcements of hull structures.

In view of special purpose of the vessel, the decision on assignment of higher IISP class was accepted instead of minimum required IIISP.

conversion)

| Basic characteristics of the vessel after and before conversion under the 001RSG01 project | ||

|---|---|---|

| Name | 001RSG01 project | Initial condition |

| Length overall, m | 88,12 | 86,00 |

| Length between perpendiculars, m | 82,95 | 82,95 |

| Breadth, m | 12,00 | 12,00 |

| Depth, m | 5,80 | 3,50 |

| Cubic modulus (LxBxD), m3 | 6133 | 3612 |

| Draught at sea, m | 3,02 | 2,56 |

| Deadweight, t | 1252 | 1140 |

| Capacity of cargo holds (tanks), m3 | 2138 | 2200 |

| Gross tonnage | 2082 | 1628 |

| Net tonnage | 625 | 594 |

| RS (RRR) class for area of navigation | IISP | O-pr |

| Permissible height of wave, m | 6,0 | 2,0 |

| Section modulus of the Hull, m3 | 0,9905 | 0,5387 |

| Moment of Inertia of the Hull, m4 | 4,034 | 2,483 |

| Hull Ultimate bending moment, kNm | 230300 | 122800 |

| Purpose | Gas carrier | Dry cargo |

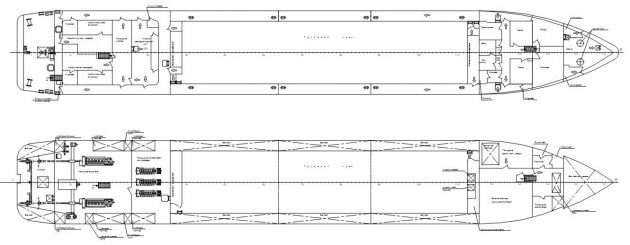

Conversion of the vessel

According the project of conversion, the following basic dismantle works were provided (all about 165 tons):

- existing inner sides in the area from the Fr. 36 to Fr. 116;

- transverse bulkheads on Fr. 39, 113, 116, 135;

- cargo hatches coamings in the area from the Fr. 39 to Fr. 113;

- insulation, bulkheads, bulwark;

- forward deckhouse.

Dismantle of cargo hatch covers and a part of other devices (all about 82 tons).

Read also: Basic Info about Liquefied Petroleum Gas Vessels and Risks while Shipping a Cargo

According the project of conversion, the following basic Installation works were provided (all about 808 tons, from them about 500 tons there are cargo tanks and their fundaments):

- side shell between the Main and the Upper decks with extension of the Upper deck to the transom;

- increasing height of forecastle;

- aft lengthening with raised transom;

- bilge keels;

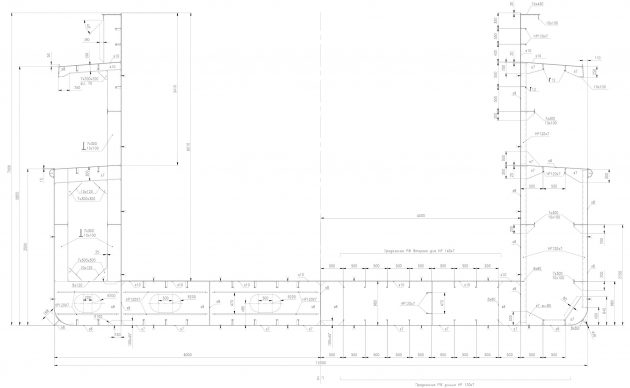

- creation of side stringer systems in cargo area;

- new watertight bulkheads on the Fr. 80 and 127, new double bottom in the area of from the Fr. 116 to Fr. 135;

- new structures of the 1-st tier aft deckhouse;

- trunk decks and casings of the deck tanks;

- six internal cargo tanks with the fundaments in holds and on the trunk deck;

- to move existing deckhouse from fore to aft (on the new 1-st tier aft deckhouse);

- installation of log and sounder trunk.

| Damage stability criterions normative for researched vessel | ||

|---|---|---|

| Criterion | Gas Code | ADN |

| Initial metacentric height at the end of flooding should not less than, m | 0,05 | 0,00 |

| Maximal lever arm of the static diagram should not less than, m | 0,10 | 0,05 |

| Extent of the positive part of the static stability diagram should not be less than, degree: | ||

| – at the symmetrical flooding | 30,00 | 27,00 |

| – at the asymmetrical flooding | 20,00 | 27,00 |

| Heeling angle at the asymmetrical flooding before cross flooding will be provided should not exceed, degree | 25,00 | 12,00 |

| Heeling angle at the asymmetrical flooding after cross flooding will be provided should not exceed, degree | 17,00 | 12,00 |

| Area of the static stability diagram when carrying cargoes should not be less than, m*radian | 0,0175 | 0,0065 |

| The distance of the dangerous openings and emergency sources of electric powers from the damage waterline should not be less than, m | 0,30 | 0,10 |

| Assumed extent of damage normative for researched vessel | ||

|---|---|---|

| Extent of damage | Gas Code | ADN |

| Side damage | ||

| – Longitudinal extent, m | 0,10 L = 8,34 | |

| – Transverse extent, m | 0,79 | |

| Vertical extent, m | From BL upward without limits | From BL upward without limits |

| Bottom | ||

| Longitudinal extent, m | ||

| – for 0,3L1 from FP | 0,10 L = 8,34 | |

| – any other part | 5,00 | 0,10 L = 8,34 |

| Transverse extent, m | 3,00 | |

| Vertical extent, m | 0,59 | |

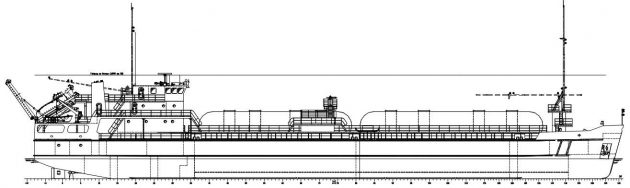

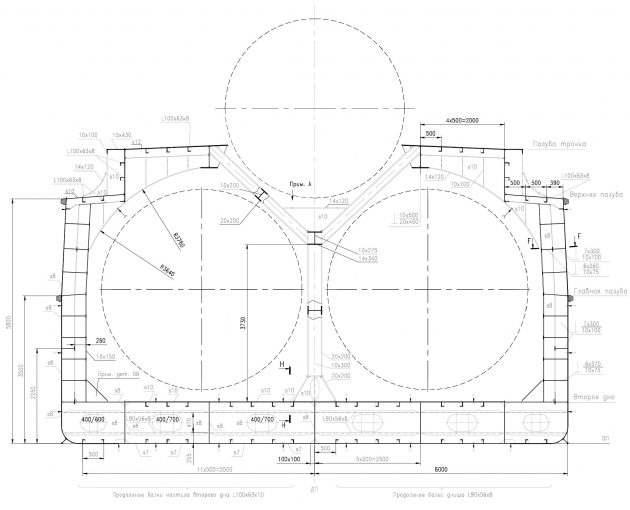

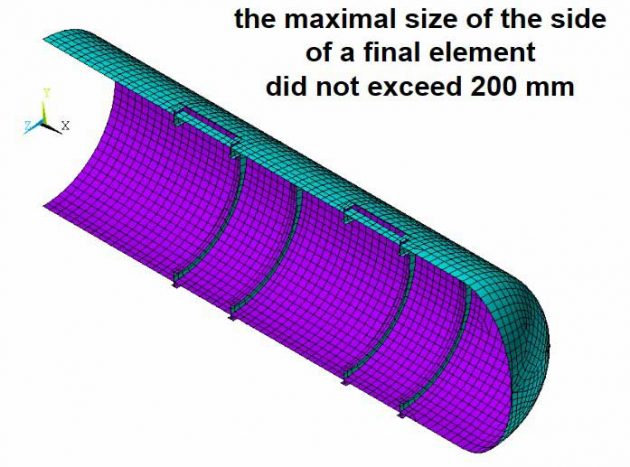

Designing of cargo tanks

Creation of optimum on weight tanks for liquefied gas transportation for since it makes up to 40-50 % from the hull weight.

Designing of tanks was made according to the Gas Code and ADN requirements.

Requirements of the Gas Code to strength of tanks at any probable loadings in operation and their real combinations:

- a test pressure;

- additional loads connected to an opportunity of increase of calculation pressure of vapour during berthing in port;

- loads at a static roll in 30°;

- absorption of energy of collision (without direct contact to a ramming vessel).

| Characteristics of cargo tanks | |||

|---|---|---|---|

| Designation in calculation | Type 1 | Type 2 | Type 3 |

| Tank capacity, m3 | 370 | 298 | 360 |

| Overall length of tank, mm | 22 956 | 22 956 | 27 400 |

| Internal diameter of tank, mm | 4 700 | 4 200 | 4 200 |

| Thickness of tank’s shell, mm | 28 | 26 | 26 |

| Design weight of tank, kg | 82 708 | 69 366 | 81 482 |

| Maximum permissible loading, kg | 217 560 | 175 224 | 211 680 |

| Design internal pressure | 1,7658 | 1,7658 | 1,7658 |

| Place of tank installation | Hold | Deck | Deck |

Modification to mixed river-sea navigation

For modification from river vessel to mixed river-sea navigation and gas carrier the following main modifications of gears and systems were provided:

- anchor gear with increase in capacity of bow chain lockers;

- installation of tanker type free-fall life boat;

- rescue boat with corresponding davit;

- modernization of doors, port lights and wheelhouse windows;

- moving of the emergency diesel – generator from the Main deck to the Upper deck;

- cargo compressors and pumps rooms;

- installation of CO2 fire extinguisher system in the Engine Room, diesel – generator compartment, emergency diesel – generator room, cargo compressors and pumps rooms;

- 2 fire pumps of 63 m3/hour capacity at pressure 0,8 МPа each;

- the emergency fire pump of 60 m3/hour at pressure 0,7 МPа;

- replacement of all external doors on steel water-gastight.

Additional equipment, special devices and systems according to the project of conversion of the vessel in gas carrier.

| Summary weights table | ||

|---|---|---|

| Weights | P, t | from total remove (install) |

| Removed weights: | ||

| Hull | 164,6 | 60,7 % |

| Gears including cargo hatch covers | 82,3 | 30,4 % |

| Systems | 12,3 | 4,5 % |

| Engine | 12,4 | 4,6 % |

| Electric, radio and navigation equipment | 0,3 | 0,1 % |

| Total Removed weights | 271,8 | 100 % |

| Installed weights: | ||

| Hull including cargo tanks and fundaments | 808,8 | 85,9 % |

| Gears | 38,4 | 4,0 % |

| Systems | 16,0 | 1,7 % |

| Engine | 2,0 | 0,2 % |

| Electric, radio and navigation equipment | 0,3 | 0,03 % |

| Reserve of displacement | 75,0 | 8,0 % |

| Total Installed weights | 940,4 | 100 % |

The basic results of Sea – Danube river navigation LPG carrier research

The basic results of research are the following conclusions:

- The most effective type of a vessel for conditions of the given transportation is LPG type gas carrier with about 1 000 t carrying capacity;

- The most effective type of tanks for the chosen type of a vessel and its carrying capacity are horizontal cylindrical tanks in hold and on a deck;

- Main dimensions of the vessel are determined by operating conditions on the river Danube: draught – not greater than 3,00-3,10 m, on width – not greater than 12,0 m, on length – not greater than 110 m;

- The class of a vessel is determined by wind-wave conditions of operation at sea (permissible IIISP, the authors recommend IISP);

- General arrangement of the vessel, arrangement of transverse and longitudinal watertight bulkheads are determined both ADN requirements, and requirements of the Gas Code to flood ability and damage stability, stated above;

- Essentially important problem at designing LPG is creation of optimum on weight tanks for LG transportation that demands application of modern settlement means, such as programs of calculation based on finite element method in plate idealization;

- For single-hull LPG carriers determining requirement is ADN requirements to local strength and survivability of side hull structures at collisions with the purpose to prevent damages of cargo tanks and cargo pipelines.