Learn how to efficiently warming up LNG cargo tank with our expert guide. Explore detailed procedures and essential considerations to ensure safe and effective tank warming operations.

Reference: SIGTTO “LNG Shipping Suggested Competency Standards”, Sections:

1 Have an awareness of warm up procedures:

- requirement for warm up;

- how remaining liquid is removed;

- how principle of heat transfer is used to warm cargo containment system.

2 Know and understand the principles of warm up:

- method used to maximise efficiency of operation;

- factors to be considered when determining the required temperature after warming up is completed;

- effect on cargo pipeline and cargo tank insulation systems.

3 Know and understand the procedures for warm up:

- use of heater to supply vapour at required temperature line-up of cargo system;

- use of HD compressors to circulate vapour:

- whether automatic control can be used;

- manual control.

- criteria to be monitored during and upon completion of the operation with specific reference to tank and insulation temperatures;

- vapour pressure:

- likely behaviour;

- pressure control via boiler;

- precautions during pressure control via vent mast.

Warming up cargo tanks

What is the warm up cargo tanks?

Tank warm-up is part of the gas freeing operation that is performed before dry-docking or when preparing tanks for inspection purposes.

Overview

A successful warm-up operation is a necessary preparation for the inerting process. As well as warming up the membrane, efficient warm-up of the insulation is essential. By continuing the warm-up process for as long as possible, cold ingress from the insulation on completion of the warm-up will be minimised (heat sink effect).

The underlying basis of the procedure is that heat is added to material (i. e. insulation) rather than extracting the cold out. A successful warm-up of the cargo vapour achieves the maximum vapour density difference between the warm LNG vapour and the inert gas (IG) for the next stage, which improves the displacement (piston effect) while inerting.

This principle also applies to Moss type tanks, where proper warming-up of the tank equator profile and tank bottom shell is a pre-requisite for efficient inerting.

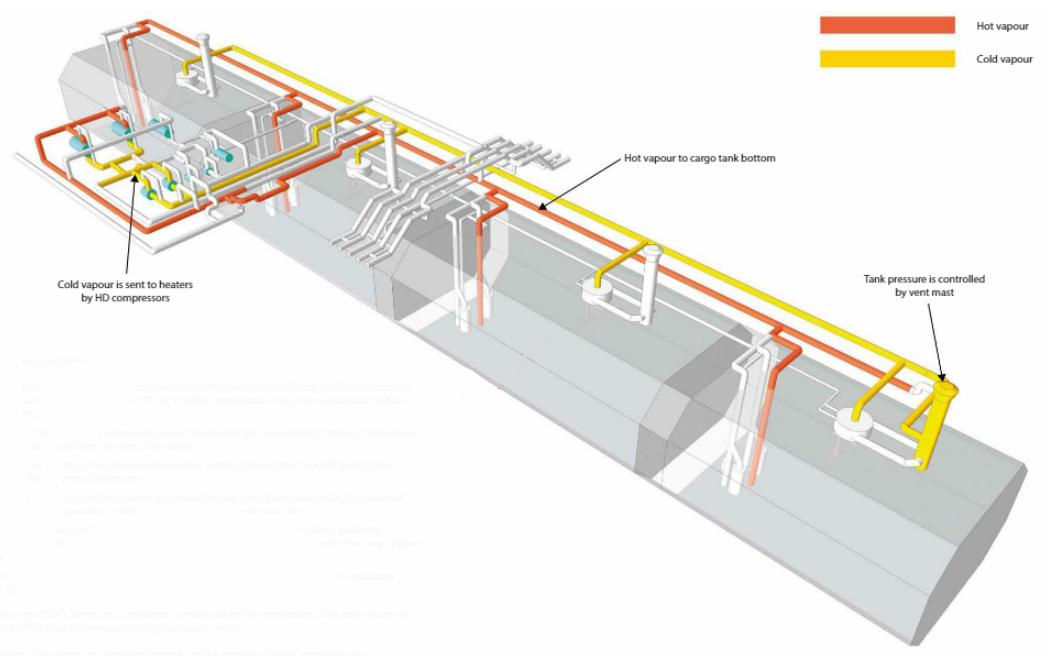

Tanks are warmed-up by recirculating heated LNG vapour. The vapour is recirculated by the High Duty Compressor(s) on the Liquefied Natural Gas CarriersHD compressor and heated by the cargo heaters to a preset value.

Preparation for warming up

The operation explained in this section will be based on a conventional membrane type LNGC where all tank(s) have been stripped. Preparations are as follows:

- a detailed plan of the operation must be prepared;

- in preparation for the warming up it will be necessary to fit relevant spool pieces;

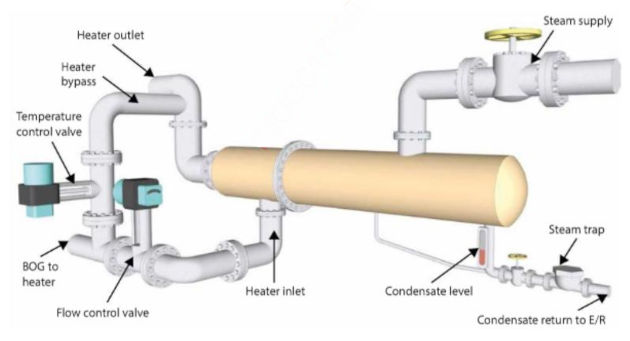

- the gas heater outlet will be lined up to the liquid header as warm vapour will be introduced to the bottom of the cargo tanks;

- line up the liquid header to forward mast riser.

Line up of the cargo piping must be as per the ship specific cargo operating manual. Typically, it will be as follows:

- open the valves to supply warm vapour to the liquid header;

- open the tank filling valves;

- open the tank vapour valves.

Operational description – cargo tanks warming up

The sequence of events is as follows:

- the first stage of the warm-up operation is to evaporate the remaining liquid. For this purpose the gas heater outlet temperature is set to 0 °C (if a higher temperature is set, the evaporation will be uncontrollable);

- warm vapour is introduced to the bottom of the cargo tanks and the suction of the HD compressor is via the vapour header from the top of the tanks;

- on Cargo containment system of gas vesselmembrane type LNGCs, the temperature sensors at the aft end of the tank will give a good indication of the progress of warm-up;

- excess vapour (this is vapour that cannot be handled by the propulsion plant or GCU) generated during the warm-up operation is vented to atmosphere via vent mast No. 1;

- once all cargo bottoms are liquid-free, the temperature of the gas heater outlet is gradually increased to approximately 70-80 °C (80 °C is generally a maximum temperature for the cargo piping insulation);

- the warm-up operation continues until the minimum temperature in the secondary insulation space is + 5 °C.

- the duration of the warm-up operation depends on the amount of liquid remaining, the composition of liquid and the initial temperature of the tanks and insulation spaces.

- initially, the tank temperatures will rise slowly as evaporation of the LNG proceeds.

- this process is accompanied by high vapour generation and venting. Expect an approximate venting rate of 8 000 m3/h at +60 °C. On completion of evaporation, tank temperatures will rise gradually and the venting rate will fall to between 1 000 and 2 000 m3/h at steadily increasing temperatures;

- temperatures within the cargo tank and insulation spaces are displayed in the CCR on the IAS;

- keep the interbarrier/insulation space pressures under close observation as the spaces warm up and the N2 atmospheres expand. This ensures that the automatic relief systems can manage the increased demand.

Note: on new Moss type LNGCs, warm-up is considered complete when the temperature of the tank equator is above minus 20 °C (-20 °C) (tank wall temperature approximately + 5 °C).

Note: in normal operation, the warm-up will take about 48 hours for membrane type LNGCs and 60 hours for Moss type LNGCs.

Further considerations

In cases where you are not required to warming up all the tanks, even if preparing for single tank entry, follow the same procedure as for all tanks. In such a situation the tank(s) to be inspected must be totally isolated from the other tanks and associated cargo systems.

The warm-up operation of a single tank will have approximately the same duration as when warming up all cargo tanks. This is because the warm-up operation is a temperature-related rather than a volume-related process.

Read also: Step-by-Step Guide for Safe and Swift Loading of Liquefied Gas

With the LNGC underway and venting, ensure the prevailing wind direction allows the vapour to disperse away from the accommodation block and machinery intakes.

“No Smoking” regulations should be clearly posted and rigorously enforced.

Before you admit the cold CH4 vapour, preheat the vapour heater(s) thoroughly with steam. This prevents the formation of ice that could damage the equipment.

When returning heated vapour to the cargo tanks, do not exceed the maximum stipulated heater outlet temperature (generally +80 °C) for the system design. This is to avoid possible damage to the cargo piping insulation, cargo valve seals, gas compressor seals, primary membranes, membrane load bearing insulation or sphere equatorial structure.

Watch the insulation space pressure as, when the space warms up, the N2 expands and will relieve to atmosphere.