The growing adoption of liquefied natural gas (LNG) as a marine fuel has brought increased attention to safety, standardization, and regulatory compliance across the bunkering process. LNG Bunkering Certification plays a crucial role in ensuring that all operations – from equipment design and installation to transfer procedures and emergency systems – meet international safety and environmental standards. This certification framework establishes uniform criteria for vessels, trucks, and shore-based facilities engaged in LNG transfer activities, helping operators minimize risks and maintain operational integrity. Understanding the definitions, certification pathways, transfer equipment, and emergency shutdown systems is essential for all stakeholders involved in the LNG supply chain. The following sections provide a comprehensive overview of the certification process, relevant equipment, and the accreditation schemes that support safe and efficient LNG bunkering operations worldwide.

Certification, in LNG bunkering, has a significantly wide scope. Taking into account the different options that we have today for LNG fuel transfer, it is also possible to determine the large possible.

Introduction

In the context of Certification and Accreditation the present section focuses strictly on ISO 20519 Specification for bunkering of gas fuelled ships, focusing in particular on the provision by this international standard for operators to consider demonstration of compliance with the standard through the adoption of an adequate management objective (ISO 201519, Section 7). The objective, inscribed into an existing Management System (ISO 9001, ISO 14001, ISM, ISO 29001 and API Spec Q1) would serve the purpose of demonstrating compliance with ISO 20519.

In addition to this important provision from ISO 20519, also under section 7, one further suggested requirement for LNG Bunkering equipment quality reassurance is included:

Equipment used in the transfer system must conform to the standards listed for that equipment in the applicable sections of this standard and the manufacturer/fabricator of such equipment shall be certified compliant to one or more of the management systems listed in 7.1 or be listed on the API Composite List (for that piece of equipment). (ISO 20619, Section 7.2)

The purpose of this article is to list significant references for LNG bunkering certification (of equipment, vessels, trucks) making reference back to article LNG Regulatory Framework International EU Compliance“LNG Regulatory Framework International and European Maritime Safety Overview” where several instruments were summarized.

Following the references on certification and in the light of the provisions inscribed in Section 7 of ISO 20519, the present Guidance suggests, as a good practice, a simplified Accreditation Scheme intended for BFOs is included.

Definitions

| Certification | Certification refers to the confirmation of certain characteristics of given equipment, in its whole or any of its parts, of a procedure, operation or personnel, often requiring a confirmation of conformity against an existing standard or regulation. In the context of LNG Bunkering, Certification refers primarily to the LNG fuel systems, equipment and personnel. Can be applicable to systems with different complexities, provided rules, standards and regulations exist for conformity evaluation. Note: Certification and Accreditation are terms often used interchangeably but they are not synonyms. See also “Accreditation”. |

| Accreditation | Accreditation is the formal declaration by a neutral third party that the certification program is administered in a way that meets the relevant norms or standards of certification program (such as ISO/IEC accreditation standards Many accreditation bodies operate according to processes developed by the International Organization for Standardization (ISO) as specified in ISO/IEC 17011. Accredited entities in specific sectors must provide evidence to the accreditation body that they conform to other standards in the same series: ISO/IEC 17020: “General criteria for the operation of various types of bodies performing inspection” (2012). ISO/IEC 17021: “Conformity assessment. Requirements for bodies providing audit and certification of management systems” (2011). ISO/IEC 17024: “Conformity Assessment. General requirements for bodies operating certification of persons” (2012). ISO/IEC 17025: “General requirements for the competence of testing and calibration laboratories” (2005).x). Many nations have established specific bodies responsible for third-party independent accreditation. In the context of LNG Bunkering, Accreditation assures users of the competence and impartiality of the body accredited, responsible for the certification of LNG bunkering systems and equipment, processes and training. Note: Certification and Accreditation are terms often used interchangeably but they are not synonyms. See also “Certification”. |

Certification

The sections below indicate the relevant references for design and certification of LNG bunkering systems and equipment.

LNG Transfer Equipment

From ISO 20519, ISO/TS 18683:

| Component | Function | Design | Qualification test | Tests |

| Coupling | Connection to ship’s manifold | EN 1474-3:2008-12, 6.9 | For hoses intended to be used in multiple LNG transfer configurations, due to the variety of the receiving ships for example, the criteria applied for their qualification according to EN 1474-2 shall be determined on the base of an agreed envelope to be defined between the manufacturer, the owner, and the qualification body. These criteria shall be defined prior to the official qualification testing campaign is started and the qualification shall be valid for the configurations covered by the agreed envelope only. | |

| Hoses | Transfer of LNG and natural gas | EN 1474-2 | ||

| EN 12434 | ||||

| BS 4089 | ||||

| Swivel joints | Product line articulation | EN 1474-3:2008-12, 6.8 | New design qualification | EN 1474-1:200 8-12, 8.4.1 |

| Bearing | Articulation of support structure | EN 1474-3:2008-12, 6.8 | ISO 28460 | EN 1474-8.4.2 |

| EN 1474-1 | ||||

| ERS | Emergency disconnect | EN 1474-3:2008-12, 6.9 and 7.5 | ISO 28460 | EN 1474- 1:2008-12, 8.4.3 |

| EN 1474-1:2008-12, 8.2.2 | ||||

| Breakaway coupling | Emergency disconnect | EN 1474-3:2008-12, 6.9 | EN 1474-1:2008-12, 8.2.2 | EN 1474- 1:2008-12, 8.4.3 |

| Loading arms | Loading system | EN 1474-3:2008-12, Clause 6 and Clause 8 | EN 1474-3:2008-12, Clause 5 | ISO 28460 |

| EN 1474- 1:2008-12, 8.4.7 | ||||

| Transfer system | LNG bunkering loading solution | EN 1474-3:2008-12, Clause 6 and Clause 8 | EN 1474-3:2008-12, Clause 5 | ISO 28460 |

| ISO 28460 | ||||

| EN 1160 | ||||

| EN 1474-1 | ||||

| OCIMF Mooring Equipment Guidelines | ||||

| IEC 60079 | ||||

| IGC/IGF Code | ||||

| NFPA 70 | ||||

| NFPA 58 | EN 1474-1 | |||

| NFPA 59A | ||||

| EN 13645 | ||||

| API 2003 | ||||

| ISO/TS 16901 | ||||

| IEC 60092-502 | ||||

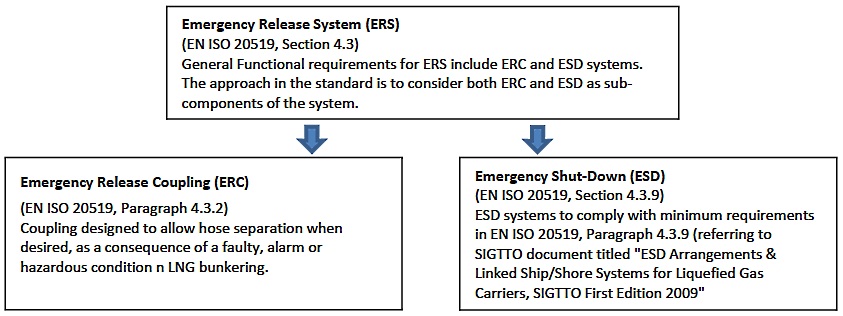

Emergency Shutdown Systems (ESD)

Certification of ERS, ERC and ESD to follow the references below:

Emergency Release System (ERS). The present Guidance refers to ERS, ERC and ESD in the terms presented in EN ISO 20519, where ERS is defined as a system comprised of two sub-systems/elements that allow the main functional requirement of quick/dry disconnect during bunkering operation, as a consequence of an emergency.

LNG Bunkering Equipment Vessels

LNG Bunker Vessels

LNG Bunker Barges

Whilst rules have been developed for LNG bunker vessels, mostly derived from IGC and IGF Codes, barges seem not to have a dedicated of rules that apply directly to the carriage LNG fuel and bunkering services. This may impose a challenge in the harmonization of these floating craft that should be taken into consideration by PAAs.

In general, however, barges intended for the carriage of liquefied gases in bulk are to comply with the International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk (IGC Code) as appropriate, or other national standard, as applicable to the non-propelled status of the vessel.

Read also: The Role of LNG Bunkering Infrastructure

A special certificate attesting to the degree of compliance with the above codes or national standard may be issued upon request.

For manned barges, consideration is to be given for full compliance with the code. In all cases, it is the Owner’s responsibility to determine the requirements of flag Administration and port Administration.

LNG Trucks

LNG trucks must be fully compliant with ADR regulations and, if applicable, with the IMDG Code.

Every LNG truck must be super vacuum-insulated (i. e. double-walled tank with insulating material and vacuum atmosphere between the walls), must have three rear axles and be designed for maximum road stability.

The outer tank wall must be made of carbon steel or stainless steel with sufficient mechanical and thermal resistance. The mechanical resistance must be demonstrated by means of a safety impact study in which the resistance to lateral impact and overturning of the truck is determined. As regards fire resistance, the tank wall must be able to withstand temperatures of at least 700 °C.

Equipment and Installations

BFO Accreditation Scheme

The present Section is outlined as a good practice advice in the context of LNG bunkering, in particular in the context of BFO recognition Based on publication no. 116/p Bunkering guidelines for LNG as marine fuel (Polish Registry of Shipping – PRS) – March 2017x.

The simplified scheme, presented in Table 1, is intended to serve as an indicative example to PAAs in order to develop their own schemes, more or less in a modular approach.

| Table 1. BFO Recognition Scheme – Accreditation of Bunker Facility Organization | |||

|---|---|---|---|

| A. General Provisions | Notes | ||

| A1 | The proposed LNG bunker supplier recognition system scheme has been developed to verify compliance and conformity of BFO with standard ISO 20519:2017 Specification for bunkering of liquefied natural gas fuelled vessels. | ||

| A2 | The objectives of the Accreditation scheme are: | To fully explore the potential of ISO 20519 in ensuring safety procedures and quality requirements for the bunker companies supplying LNG fuel for ships. | References other than ISO 20519 may be possible depending on PAA indication to certifying company, Class Society, Recognized Body, etc. |

| Ensure safe operations and periodical audit procedures in order to recognize and confirm implementation of ISO 20519 by bunker suppliers. In the bunker supply chain, LNG bunker suppliers have to comply with the port’s accreditation qualifications in order to attain a license for performing LNG bunker operations. | |||

| A3 | Recognition of LNG bunker supplier may be carried out as a result of the requirements of maritime flag administration or on request of supplier itself. The recognition does not cover equipment design or modification activities, if any. | ||

| A4 | The recognition procedure should be initiated voluntarily by Operators/BFOs wishing to be accredited/recognized for LNG bunkering operation, by a written application submitted by the Operator to the relevant certifying company. | The Certifying Company may belong to a list held by the PAA, or be part of a national/european list of recognized bodies. | |

| A5 | The following documents should be sent : | 1. Company Identification information and organizational description. | List of documents not extensive. Represents only a recommendation, with a potential final list shorter or longer. |

| 2. Possible existing Recognition from another Port. | |||

| 3. Evidence Certificate of company quality management system according to ISO 9001, ISO 14001, ISM, ISO 29001 or API Spec Q1. | |||

| 4. Existing mapping of LNG bunkering procedures. | |||

| 5. Example of one of the company’s LNGBMP. | |||

| 6. LNG bunkering experience, including reference clients and identification of significant/relevant ships bunkered. | |||

| 7. List of BFO staff involved in LNG bunkering with documented professional experience and competence. | |||

| 8. List of bunkering equipment including measuring, recording, communication and safety instruments the bunkering company is equipped with. | |||

| 9. Company LNG bunkering instructions. | |||

| 10. Check-Lists for all types of LNG bunkering (and other potential processes). | |||

| 11. Procedures and Technologies for personal and environmental protection. | |||

| 12. Record keeping and documentation of bunkering operations performed. | |||

| 13. Risk Assessment report, including HAZID, HAZOP and evidence of different LNG bunkering modes implemented on the basis of risk assessment indication. | |||

| B. Requirements | Notes | ||

| B1 | LNG bunkering operation carried out by the BFO, to the satisfaction of the recognition/accreditation scheme should be performed by qualified personnel with demonstrated competences and professional experience. | ||

| B2 | Certificates for LNG bunkering equipment, certified by manufacturers certified themselves by a relevant quality management system. | ||

| B3 | The LNG bunkering company, which has the quality management system based upon requirements of ISO 9001 (ISO 9001, ISO 14001, ISM, ISO 29001 or API Spec Q1), should, when applying for recognition, submit, together with the documents listed in p. 1.6, the respective documentation of quality system. Evaluation of the BFO will benefit from positive implementation of the subject quality system. | ||

| B4 | The BFO may be required to execute an LNG bunkering operation to demonstrate implemented procedures, check-lists, communications scheme, measures for BOG mitigation, amongst other aspects. | ||

| C. Recognition Procedure | Notes | ||

| C1 | Favourable results of appraisal of documentation submitted together with the application for recognition as well as satisfactory results of inspection for the compliance with ISO 20519:2017 Specification for bunkering of gas fuelled ships are the basis of LNG bunkering company recognition. | ||

| C2 | The purpose of the inspection is to ascertain that the requirements of Paragraph 2 are fulfilled and, in particular: | .a) personnel qualifications. | |

| .b) equipment certificates with evidence of quality managed manufacturer. | |||

| .c) equipment and machines with proper control and recording instruments. | |||

| .d) applicable manuals necessary for the safe LNG bunkering to be carried out. | |||

| .e) proper communication, recording and monitoring technologies. | |||

| .f) records and certification of the bunkering operations performed. | |||

| .g) monitoring of the work(s) carried out and its quality. | |||

| .h) work quality including safety assessment. | |||

| C3 | Criteria for recognition is: | .a) Compliance of BFO organization with ISO 20519. | |

| .b) Manufacturers of equipment used by BFO should be certified compliant to a relevant quality management system. | |||

| .c) Satisfactory results from inspection in C2. | |||

| .d) Documented procedures, as provided in B, verified and implemented. | |||

| C4 | Operation and detailed documentation of the quality assurance system when applied by LNG bunkering company, including keeping records thereon, is to be checked during the inspection as follows: | .a) Active and positively verified quality management system acc. to ISO 9001, or alternative. | |

| .b) Certified quality assurance system (QAS) in place, including, but not limited to: | |||

| i. Status with regards to key performance indicators (KPIs); i. e. operation and customer feedback report system; | |||

| ii. Environmental performance system; | |||

| iii. Near misses and incident reporting system; | |||

| iv. Maintenance system for LNG bunker equipment; | |||

| v. Training of personnel. | |||

| C5 | The LNG bunkering equipment and machines planned for operational or emergency use in bunkering operations is to be verified. The company is to provide free access surveyors/inspectors for necessary inspection and verification when required. The documents presented must include: | .a) List of the equipment and machines as well as evidence of applicable and valid certification; | |

| .b) For all LNG bunkering equipment and machines, the evidence of regular, periodically required transparent maintenance in line with implemented quality assurance system; | |||

| C6 | The company personnel competences and trainings to be verified. | ||

| The relevant certificates of competency are to be provided. The requirements with regards to professional educational topics must cover: | i. LNG in general; | ||

| ii. Knowledge of LNG safety standards; | |||

| iii. Knowledge of LNG bunkering technical standards; | |||

| iv. Knowledge of LNG bunkering guidelines or other legally required documents; | |||

| v. LNG hazard identification | |||

| vi. LNG risk & safety aspects; | |||

| vii. LNG bunker operations risk characteristics; | |||

| viii. Emergency response; | |||

| ix. Operations manual of the bunker supply company in question. | |||

| D. LNG Bunkering Management Plan (LNGBMP) | Notes | ||

| D1 | LNGBMP to be verified as described in IACS Rec.142. | ||

| Document Management within the LNGBMP to be organized according to IACS Rec.142. | |||

| The documents confirming that required risk assessments (HAZID/HAZOP/QRA) has been conducted and analysed. | |||

| D2 | The documents with description of procedures that are stated in an LNGBMP. | ||

| All procedures detailed in the LNGBMP to be result of actual verifications and recommendations resulting from Recognition process. | |||

| E. Recognition | Notes | ||

| E1 | Recognition Certificates for LNG Bunker BFO should be issued after positive completion of the submitted documentation and inspections with a validity to be agreed. | ||

| During the period of validity of the Recognition Certificate, at least once a year, inspections or audits of the BFO should be conducted. | |||

| Maintenance of the Recognition Certificate to be a function of the conditions verified at inspection/audit. | |||

The objective is the recognition of BFOs as competent organizations, complying with ISO 20519.