In the world of maritime transport and energy, safety and environmental responsibility are paramount. With the emergence of liquefied natural gas (LNG) as a primary fuel and energy source, a complex yet vitally important system of rules and regulations has arisen. This article delves deep into the LNG Regulatory Framework – a comprehensive structure that shapes LNG operations globally and in Europe. We will examine key international conventions and European Union directives that govern every aspect of LNG use, from vessel and infrastructure design to pollution prevention and personnel training. Understanding these regulations isn’t just a matter of compliance; it’s the foundation for a safe and sustainable future in shipping and energy.

- Regulatory Structure

- High Level Instruments

- Europe

- EU Sulphur Directive

- EU Ports Regulation

- EU Alternative Fuel Infrastructure Directive

- Seveso III Directive

- EU Environmental Impact Directive

- ADR – European agreement

- ADN – European Agreement

- Rhine Vessel Inspection Regulations (RVIR)

- Regulation for Rhine navigation personnel (RPN)

- Rhine police Requirements (RPR)

- Directive (EU) 2016/1629

- International Framework

- IGF Code

- SOLAS

- MARPOL

- STCW Convention and Code

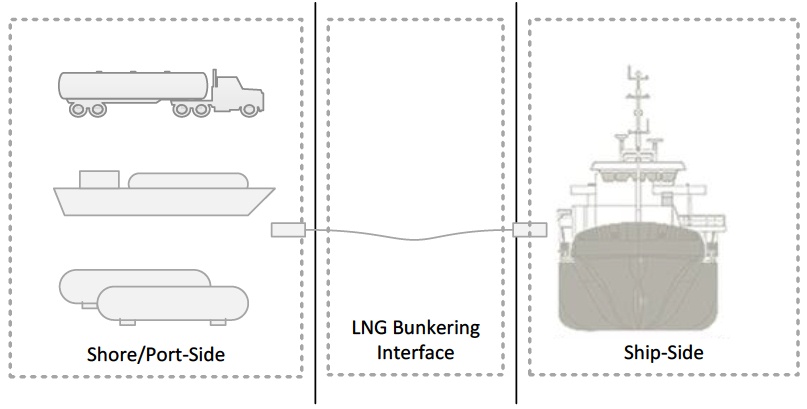

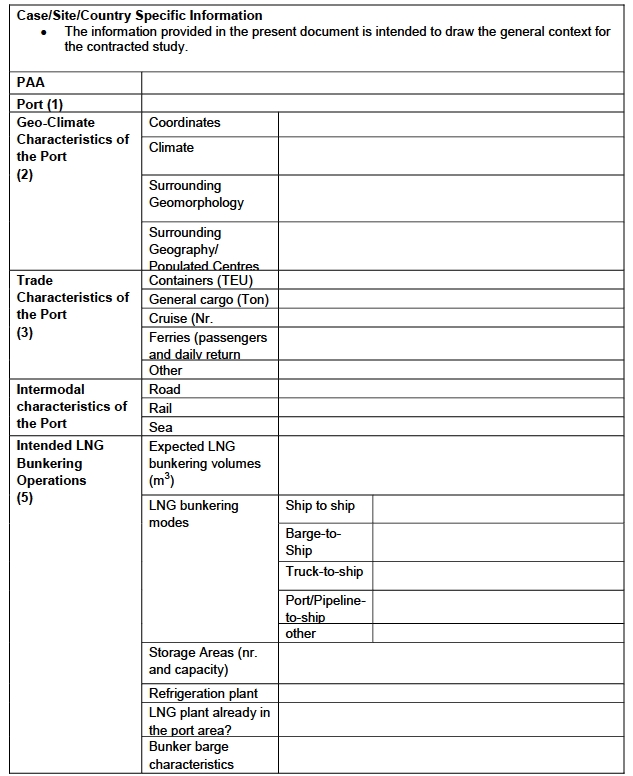

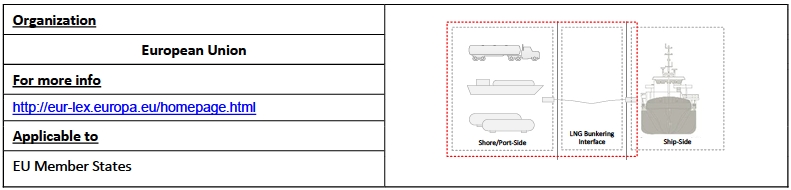

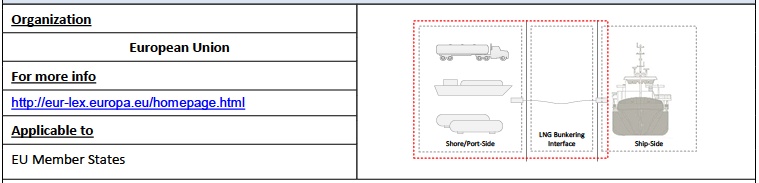

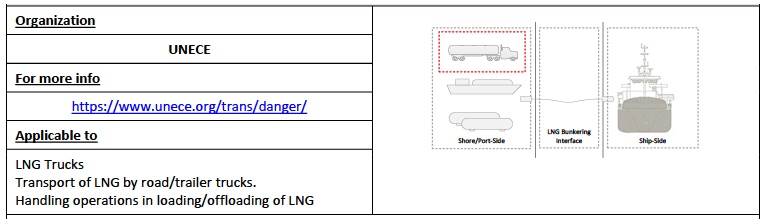

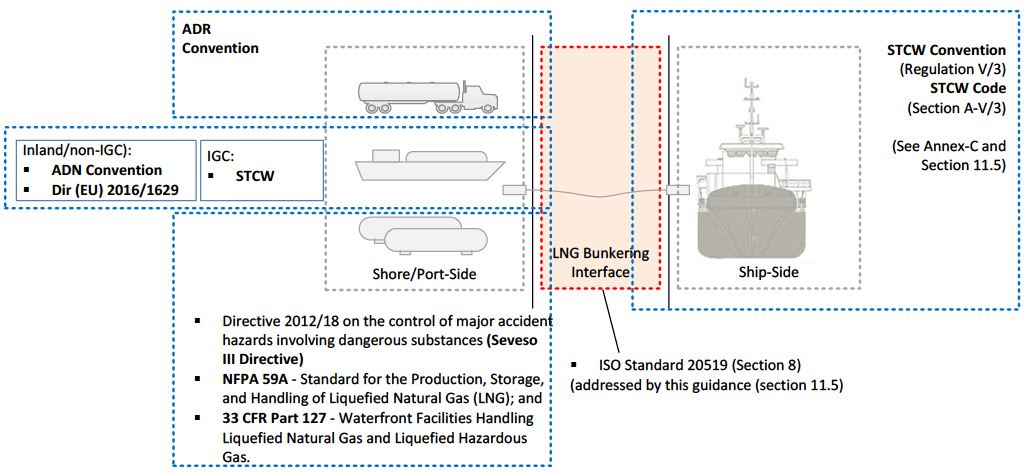

The Regulatory Framework for LNG Bunkering, on the shordesign, 2.4 LNG piping sye-ship or ship-to-ship interface, is composed of high level regulatory instruments, standards & guidelines and industry good practice references. Not only the hierarchy of the references is different but they exist in two separate regulatory frames that often result in gaps or overlaps in the bunkering interface. The receiving ship, the bunker barge, or bunker vessel, the LNG truck, the LNG terminal and possible small scale storage.

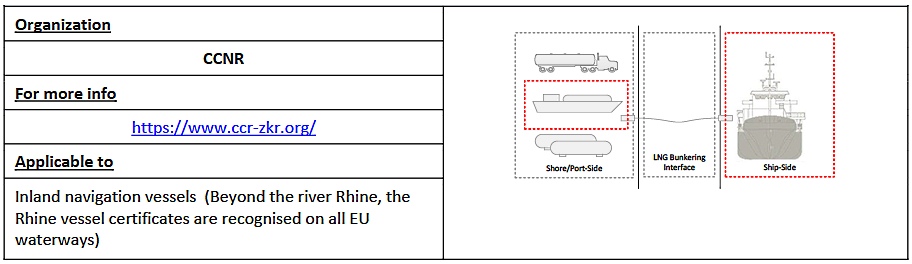

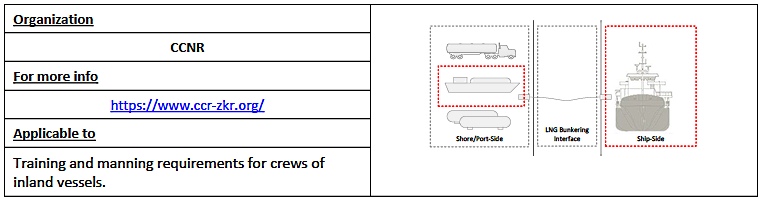

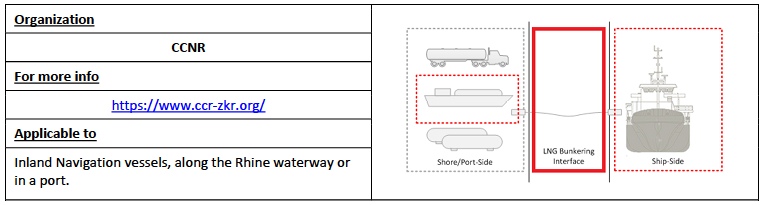

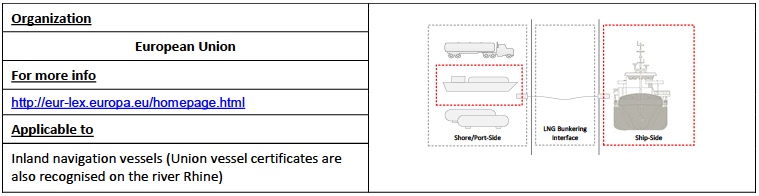

In this article, different instruments relevant to LNG Bunkering are listed. The diagram in figure 1, below, is used for each instrument presented, indicating to which part of the LNG Bunkering it is relevant to.

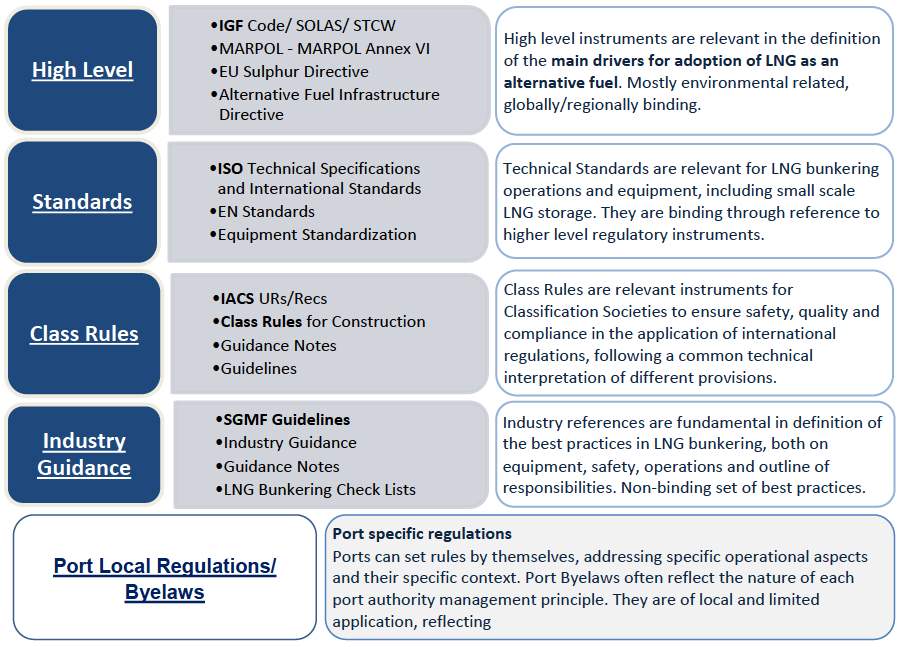

Regulatory Structure

The international (global or regional) regulatory frame is composed of 4 essential levels to which a fifth level can be added, accounting for Port regulations that are able to, locally, shape the specific regulatory environment for LNG Bunkering.

High Level Instruments

The present section lists the relevant High Level instruments with relevance to the shore-side, ship-side and Ship/shore interface for safe loading and unloading of LNG/LPGLNG bunkering interface.

Europe

In EU law it is first important to make the distinction between:

- Regulations,

- Directives.

Whereas Regulations have binding legal force throughout every Member State and enter into force on a set date in all the Member States, Directives lay down certain results that must be achieved but each Member State is free to decide how to transpose directives into national laws.

This is an important note regarding EU Framework since the present Guidance, whenever addressing Directives, does not make distinction between different implementation exercises in each EU Member States. In this way there will be particular aspects from the different national instruments that will not be captured by the present Guidance. It is important to be mindful that, for each EU Member State there should be a national instrument correspondent to the implementation of a directive. In this Guidance, whenever Directives are addressed, for a complete evaluation of each EU MS context, the corresponding national law should be consulted.x

Read also: LNG Bunkering Guide – What It Is and How to Use It

Other instruments are also of significance and these are, altogether, summarised in Table 1. For example, the Seveso Directive, in the context of major accident prevention, is one of the most important references for the permitting procedures of small scale LNG projects, with requirements on safety aspects, impact assessment and public consultation. Similarly, the ADR and ADN conventions, and Directive 2016/1629, are important instruments within the LNG supply chain.

| Table 1. EU high-level instruments | ||||

|---|---|---|---|---|

| Title | Responsible | Type | Scope | |

| EU Sulphur Directive | Directive 2016/802/EU relating to a reduction in the sulphur content of certain liquid fuels (codifying Council Directive 1999/32/EC as regards the sulphur content of marine fuels, as amended by Directive 2012/33/EU) | EC | European Directive | Limitation of sulphur content in certain fuels, with obligations on EU Member States, affecting EU flag ships and foreign flag ships visiting EU ports. |

| EU Ports Regulation | Regulation (EU) 2017/352 Of The European Parliament And Of The Council of 15 February 2017 establishing a framework for the provision of port services and common rules on the financial transparency of ports | EC | European Regulation | EU Regulation establishing a framework for the provision of port service, and common rules for transparency and on port services. LNG bunkering is within the scope and applicability of this regulation, either inside the port area or on the waterway access to the port. |

| EU Alternative Fuel Infrastructure Directive | Directive 2014/94/EU on the deployment of alternative fuels infrastructure | EC | European Directive | Development of an alternative fuel infrastructure throughout the TEN-T Core Network, including LNG for waterborne applications. |

| Seveso III – Directive | Directive 2012/18/EU of the European Parliament and of the Council of 4 July 2012 on the control of major-accident hazards involving dangerous substances, amending and subsequently repealing Council Directive 96/82/EC | EC | European Directive | Control of major-accident hazards for establishments involving dangerous substances. |

| EIA Directive | Directive 2011/92/EU of the European Parliament and of the Council of 13 December 2011 on the assessment of the effects of certain public and private projects on the environment | EC | European Directive | Environmental Impact Assessment Directive The initial Directive of 1985 and its three amendments have been codified by DIRECTIVE 2011/92/EU of 13 December 2011. Directive 2011/92/EU has been amended in 2014 by DIRECTIVE 2014/52/EU. |

| ADR | European agreement concerning the International Carriage of Dangerous Goods by Road | UNECE | Convention | Transport of hazardous goods by road. |

| ADN | European Agreement concerning the International Carriage of Dangerous Goods by Inland waterways | UNECE | Convention | Transport of dangerous goods via inland waterways – technical requirements for different type of inland navigation vessels carrying dangerous goods – certificates for vessels – requirements for crew/experts (trainings, certificates) – applicable in all UNECE MS. |

| Directive 2008/68/EC of the European Parliament and of the Council of 24 September 2008 on the inland transport of dangerous goods. | EC | European Directive | Directive 2008/68 refers to ADN, ADR and RID incorporated them into EU legal framework – ADN is obligatory in all EU. | |

| Rhine Vessel Inspection Regulations (RVIR). | CCNR | Regulation | Reference to technical requirements for Inland Navigation vessels Certificates for the Inland Navigation vessels Inspection of the Inland Navigation vessels Reference will be made to Technical Requirements within CESNI Standard ES-TRIN 2017/1. | |

| Regulation for Rhine navigation personnel (RPN). | CCNR | Regulation | Training and manning requirements for crews of inland vessels. | |

| Rhine police regulations (RPR). | CCNR | Regulation | Operational requirements for Inland Navigation vessels, including signage, mooring and bunkering procedure. The use of the standard for LNG bunker checklist (CCNR 1.0) is mandatory for all LNG bunker operations involving a ship if this bunkering takes place along the Rhine waterway or in a port. | |

| Directive/EU) 2006/87 of 12 December 2006 laying down technical requirements for inland waterway vessels (applicable until 6 October 2018). | EC | European Directive | – technical requirements for Inland Navigation vessels – certificates for the Inland Navigation vessels – inspection of the Inland Navigation vessels Directive recognizes both types of the certificates for Inland Navigation vessels on EU waterways – issued in accordance with Directive 2006/87 and with the Rhine Regulations (still the technical requirements are separately included in both legal regimes – EU and CCNR). | |

| Directive 2014/68/EU (Pressure Equipment Directive). | EC | European Directive | The Pressure Equipment Directive (PED) applies to the design, manufacture and conformity assessment of stationary pressure equipment with a maximum allowable pressure greater than 0,5 bar. The directive entered into force on 20 July 2016. | |

| Directive (EU) 2016/1629 laying down technical requirements for inland waterway vessels, amending Directive 2009/100/EC and repealing Directive 2006/87/EC (applicable from 6 October 2018). | EC | European Directive | Reference to technical requirements for Inland Navigation vessels Certificates for the Inland Navigation vessels Inspection of the Inland Navigation vessels Reference is made to Technical Requirements within CESNI Standard ES-TRIN 2015/1 (and will be updated to ES-TRIN 2017/1). | |

| Directive 99/92/EC on the minimum requirements for improving the safety and health protection of workers potentially at risk from explosive atmospheres. | EC | European Directive | Minimum requirements for improving the safety and health protection of workers potentially at risk from explosive atmospheres. | |

| Directive 2014/34/EU on the harmonisation of the laws of the Member States relating to equipment and protective systems intended for use in potentially explosive atmospheres (recast). | EC | European Directive | The ATEX Directive 2014/34/EU covers equipment and protective systems intended for use in potentially explosive atmospheres. | |

EU Sulphur Directive

Directive 2016/802/EU relating to a reduction in the sulphur content of certain liquid fuels (codifying Council Directive 1999/32/EC as regards the sulphur content of marine fuels, as amended by Directive 2012/33/EU).

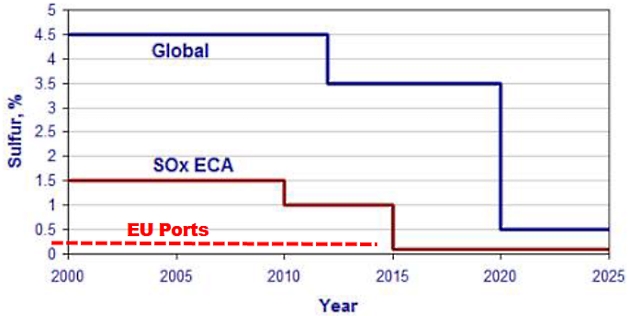

In the EU, SOx emissions from ships are regulated by Directive 2016/802/EC, known as the “Sulphur Directive“. The recent codification includes not only the limitation on the sulphur content of marine fuels but also of land-based oil fuels, establishing limits on the maximum sulphur content of gas oils and heavy fuel oil. The Directive also contains some additional fuel-specific requirements for ships calling at EU ports, obligations related to the use of fuels covered by the Directive and the placing on the market of certain fuels (e. g. marine gas oils).

The Directive had been previously amended by Directive 2012/33/EU, now repealed, in order to further adapt the European Union’s legislation to developments at international level under MARPOL Annex VI. Since 1 January 2015, stricter sulphur limits for marine fuel in SECAs apply (0,10 %) as well as in sea areas outside SECAs (3,50 %). In addition, a 0,1 % maximum sulphur requirement for fuels used by ships at berth in EU ports was introduced from 1 January 2010.

Furthermore, passenger ships operating on regular services to or from any EU port shall not use marine fuels if their sulphur content exceeds 1,50 % in sea areas outside the SECAs.

Relevance

The relevance of the Sulphur Directive in the context of LNG as fuel comes in the terms of Article 8, according to which Member States shall allow the use of emission abatement methods (EAMs) by ships of all flags in their ports, territorial seas, exclusive economic zones and pollution control zones, as an alternative to using marine fuels. Being an alternative fuel, LNG is eligible to be considered an Emission Abatement Method, and its use should be allowed in ships of all flags in ports, territorial seas and economic exclusive zones of the EU. Ships using EAMs in these areas shall continuously achieve reductions of sulphur dioxide emissions that are at least equivalent to the reductions that would be achieved by using marine fuels (figure below).

According to the Directive (Article 8) the following EAMs can be considered:

- Mixture of marine fuel and boil-off gas (BOG) for LNG carriers – criteria established in ref;

- Exhaust Gas Cleaning Systems (EGCS), commonly known as “scrubbers“;

- Biofuels (and mixtures of biofuels and marine fuels).

And, where applicable:

- On-shore power supply.

- Alternative Fuels e. g. LNG, Methanol.

At the international level, the use of EAMs is regulated by the MARPOL Annex VI (Regulation 4). According to this regulation, the Administrations of Party shall allow a fitting, material, appliance, apparatus or other procedures, alternative fuels, or compliance methods used as an alternative to that required by MARPOL Annex VI.

Figure 2, below, shows the relevant limits to consider regarding sulphur oxide emissions.

EU Ports Regulation

Regulation (EU) 2017/352 Of The European Parliament And Of The Council of 15 February 2017 establishing a framework for the provision of port services and common rules on the financial transparency of ports.

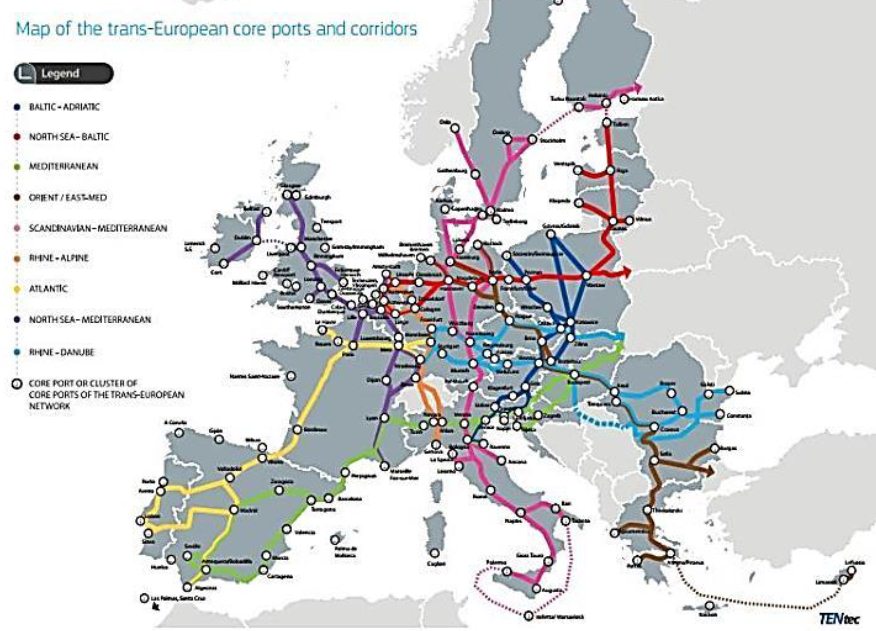

This Regulation establishes a framework for the provision of port services, and common rules on financial transparency and on port service and port infrastructure charges, being applicable to all maritime ports of the trans-European transport network, as listed in Annex II to Regulation (EU) No 1315/2013 (EU TEN-T core ports).

Regulation (EU) 2017/352 is divided into 4 main Chapters:

- Scope, Application and Definitions;

- Provision of Port Services;

- Financial Transparency and Autonomy;

- General and Final provisions.

Relevance

Regulation (EU) 2017/352 includes a large number of concepts which are relevant in the context of this Guidance. LNG bunkering is directly within the scope and applicability of this Regulation (Chapter II, Article 1).

The aim of Regulation (EU) 2017/352 is to “level the playing field” in the sector, and create a climate more conducive to efficient public and private investments. The Regulation defines the conditions under which the freedom to provide port services apply, for instance the type of minimum requirements that can be imposed for safety or environmental purposes, the circumstances in which the number of operators can be limited and the procedure to select the operators in such cases.

It introduces common rules on the transparency of public funding and of charging for the use of port infrastructure and port services, allowing the differentiation of port infrastructure charges in order to promote among others high environmental performance and energy or carbon efficiency of transport operations. It places particular emphasis on the consultation of port users and other stakeholders. It requires each Member State to have in place a clear mechanism to handle complaints and disputes between port stakeholders. Finally it requires all port service providers to ensure adequate training to employees.

It will be interesting: LNG (Liquefied Natural Gas) as Fuel

Even though the Regulation does not deal with technical aspects in itself, it contains several articles which are likely to have a significant impact on how the service providers will have to demonstrate the ability to provide a service (LNG bunkering being our case of interest):

- Art 4 (Minimum requirements for the provision of port services);

- Art 6 (Limitations on the number of providers of port services);

- Art 7 (public service obligations);

- Art 14 (training of staff);

- Art 15 (Consultation of Port Users and other stakeholders).

In Section 4.6.3 these articles are further expanded with the good practice suggested for the case of LNG bunkering.

Regulation (EU) 2017/352 was published on the 15 February 2017, having entered into force in all EU MS twenty days after that and being applicable from 24 March 2019.

EU Alternative Fuel Infrastructure Directive

Directive 2014/94/EU on the deployment of alternative fuels infrastructure.

The Directive on the deployment of alternative fuels infrastructure is an integral part of the Clean Power for Transport package. This package aims to facilitate the development of a single market for alternative fuels for transport in Europe, whilst harmonizing the efforts in the development of the relevant infrastructure for the deployment and availability of alternative fuels.

As per Directive 2014/94, “Alternative Fuels” means fuels or power sources which serve, at least partly, as a substitute for fossil oil sources in the energy supply to transport and which have the potential to contribute to its decarbonisation and enhance the environmental performance of the transport sector. The following fuels are considered in the context of this Directive:

- electricity;

- hydrogen;

- biofuels as defined in point (i) of Article 2 of Directive 2009/28/EC;

- synthetic and paraffinic fuels;

- natural gas, including biomethane, in gaseous form (compressed natural gas (CNG)) and liquefied form (liquefied natural gas (LNG));

- liquefied petroleum gas (LPG).

The final Directive, as adopted by the European Parliament and the Council on 22 October 2014:

- Requires Member States to develop national policy frameworks for the market development of alternative fuels and their infrastructure;

- Foresees the use or common technical specifications for recharging and refuelling points;

- Paves the way for setting up appropriate consumer information on alternative fuels, including a clear and sound price comparison methodology.

The required coverage and the timings by which this coverage must be put in place is as presented in follows, in table 2.

| Table 2. Directive 2014/94 – applicable deadlines | ||

|---|---|---|

| Coverage | Timings | |

| Electricity in urban/suburban and other densely populated areas | Appropriate number of publically accedssible pionts | by end 2020 |

| CNG in urban/suburban and other densely populated areas | Appropriate number of points | by end 2020 |

| CNG along the TEN-T core network | Appropriate number of points | by end 2025 |

| Electricity at shore-side | Ports of the TEN-T core network and other ports | by end 2025 |

| Hydrogen in the Member States who choose to develop it | Appropriate number of points | by end 2025 |

| LNG at maritime ports | Ports of the TEN-T core network and other ports | by end 2025 |

| LNG at inland porta | Ports of the TEN-T core network and other ports | by end 2030 |

| LNG for heavy-duty vehicles | Appropriate number of points along the TEN-T core network | by end 2025 |

Specifically for LNG as fuel, as stated in this Directive the TEN-T Core Network should be the basis for the deployment of LNG infrastructure as it covers the main traffic flows and allows for network benefits. TEN-T Core Ports are, in this sense, the main focus for the development of LNG at maritime ports, as indicated above. The deployment of the refuelling points, and LNG bunkering facilities should for LNG (and CNG) be adequately coordinated with the implementation of the TEN-T Core Network (see TEN-T network in figure 4 – 9 corridors with all EU TEN-T core ports indicated).

Concerning technical specifications for interoperability of recharging and refuelling points, this Directive establishes that these should be specified in European or international standards. In particular for LNG Bunkering standard, the Directive mentions, in point 57 of its recital, the “Guidelines for systems and installations for supply of LNG as fuel to ships” (ISO/DTS 18683). With the recent publication of the ISO Standard on LNG Bunkering (ISO 20519:2017 Specification for bunkering of liquefied natural gas fuelled vessels) this becomes the relevant Standard for LNG Bunkering, providing the necessary reference for LNG bunkering equipment, procedures, training, safety/risk assessment and quality management.

Seveso III Directive

Directive 2012/18/EU of the European Parliament and of the Council of 4 July 2012 on the control of major-accident hazards involving dangerous substances, amending and subsequently repealing Council Directive 96/82/EC.

The Seveso III Directive includes obligations on the operator, in particular measures to prevent major accidents and the requirement to communicate information on potential major-accidents with dangerous substances on its establishments. Transport outside establishments and directly related intermediate temporary storage of dangerous substances (including loading and unloading) are specifically excluded from this directive by Article 2(2) (c). LNG is listed as a named dangerous substance in entry 18 of Annex I Part 2 to the Directive. This Directive is applicable to all The Seveso III Directive does not differentiate between onshore and offshore. To this end, as an example, a ship or another floating unit could be subject to this Directive provided that is falls out of the temporary storage situation. In addition, where a barge is used as a permanent storage unit (table 3.4 case E). This can actually be a risk reduction measure to keep greater distance from the onshore part of the establishment. Such situations fall under the Seveso III Directive. Only the offshore exploration of gas and oil as such is excluded.x LNG installations, except offshore exploration, underground offshore gas storage.

All establishments which hold at least 50 tonnes Also establishments with less than 50 tonnes can be covered if other dangerous substances are present. This could be very relevant in harbours where other fuels are present. Under the Seveso III Directive different dangerous substances are summed up. This is an important point to take into account when assessing on the applicability of the Seveso Directive requirements to a given small scale/bunkering project.x of LNG (less if other dangerous substances are also present) fall under the scope of the Directive and, amongst others, need to establish a major accident prevention policy. In addition, operators of upper tier establishments holding more than 200 tonnes of LNG (equivalent to approximately 440 m3) need to establish, amongst others, a safety report. This safety report must include identification and assessment of major hazards and necessary measures to prevent major accidents. Other requirements include a safety management system and emergency plan.

Loading and unloading of dangerous goods and the related safety aspects are in principle governed by legislation on transport.

| Table 3. Seveso III Directive-applicability to LNG bunkering | |

|---|---|

| Specific aspect on the applicability of the Seveso III Directive requirements | Good practice approach |

| A. Temporary Storage | |

| Despite being clear regarding the non-applicability of Seveso III Directive to LNG transport, there are cases where temporary situations will require additional judgement. Some examples are presented below. | |

| Examples: | A disconnected transport container or a container-trailer disconnected from its means of transport may occur as part of the transport chain. These examples could meet the conditions for “intermediate temporary storage”. Although, there is no common definition of “intermediate temporary storage” the Seveso Expert Group has concluded that this refers to necessary intermediate storage in the transport chain. Whilst the unloading of trucks/containers does not define the location as a Seveso establishment there may be implications for the location where the loading takes place. A similar understanding can be found in USCG CG-OES Policy Letter 02-14, where it is considered in enclosure (1), point 1) a) that LNG tank trucks and railcars are not considered waterfront facilities handling LNG. However, when trucks or railcars are used as a means for transferring LNG to a marine vessel, the location where the transfer occurs may so be considered.x If it takes place within a site which is already classified as a Seveso establishment, the amount of dangerous substances involved would have to be considered by the operator of the establishment, e. g. whether or not the storage is temporary. The exclusion in Article 2(2) (c) only applies to temporary storage “outside the establishment”. In this case the relevant Seveso establishment would have to consider the activities within or nearby its establishment as a potential risk factor and where necessary adapt its risk management measures accordingly. On the other hand, if the loading takes place within a site which is not (yet) classified as a Seveso site (but where certain amounts of dangerous substances are present, though below the thresholds), then it will be important to assess the temporary character of the loading. In the light hereof, it would play a role how often and how long the fuelling activity l takes place at the location. If there is a frequent presence of at least 50 tonnes of LNG over a longer period of time it could be argued that there was a de-facto (semi-) permanent presence of a certain amount of a dangerous substance (i. e. LNG) at a certain location, even if the actual truck or mobile container changes. In which case the operator responsible for the location may have to check with the competent authorities whether the location might have to be considered a Seveso establishment or the de-facto (semi-)permanent presence of the LNG may have to be added to the inventory of dangerous substances at the location. However, LNG (or any other fuel) that is actually used to fuel vehicles (i. e. contained in the corresponding fuel tank of the vehicle) is not taken into account. Following the above, the applicability of Seveso III Directive requirements to intermediate storage situations, as the ones presented in 1, 2 and 3 should be subject to case-by-case assessment by the BFO and PAA, in consultation with the competent authorities, which should in the best interest of safety have the following elements into consideration: |

| 1. LNG truck trailer left temporarily in LNG Bunkering location | |

| – Quantities of LNG actually or anticipated to be present in intermediate storage. |

| 2. Bunker barge, non-propelled, left alongside a ship, or moored alongside a pier | – Whether or not the intermediate storage is directly related to transport outside Seveso establishments. |

| – Duration and frequency of the intermediate storage. |

| 3. ISO framed LNG container | – Other risk factors at the location or in its proximity such as intermediate storage of other hazardous substances. |

| The particular case of the ISO containers may be further divided in 3 (three) different situations: 1) LNG ISO container at the end of the transport chain; 2) LNG ISO unit cargo in-between the transport chain; 3) LNG fuel units for ISO bunkering of LNG fuelled ship. Whenever considered as part of an “LNG Virtual Pipeline” concept, these LNG ISO containers can be potentially waiting in the port area for embarkation on-board a container vessel to a different destination. For any of the cases presented above it is important to identify the end of the actual transport chain and, again, to address intermediate storage considering the elements listed above. |

| B. LNG fuelling | |

| The situation presented in figure “LNG fuelling” illustrates an LNG truck parked alongside a passenger ship, undertaking an operation that, in the context of this Guidance, will be addressed as “LNG fuelling”, a process-operation that cannot be considered as loading/unloading or even bunkering in exact terms.In this particular case the LNG truck parked alongside the receiving ship, feeds LNG fuel to direct use (e. g. dual fuel port generator). Article 2(2) (c) excludes from the scope of the Seveso III Directive the transport of dangerous substances and directly related intermediate temporary storage outside establishments covered by the scope of the Directive. Loading and unloading of dangerous goods and the related safety aspects are in principle governed by legislation on transport. The scenario described is not however a typical unloading situation (e. g. unloading into a storage tank) and is more suitably classified as a process-operation that is, otherwise not covered in transport instrument requirements. As outlined under “A“, the truck may affect the assessment of the location in which the truck is parked, and it may also be relevant whether or not the tractor is uncoupled from the container during the fuelling. Typically the competent authorities also apply time limits (e. g. 24 h) above which “intermediate temporary storage” can no longer be claimed. This may be subject to a case by case assessment. |

| C. LNG powered shore-side electricity | |

| LNG “power barges” are already used to provide electrical shore-side energy to ships that so wish to connect to an external electrical power source. The several advantages of having shore-side electricity to ships are obvious. The electricity is, in the case represented in the figure to the left, sourced from an LNG powered “power barge“. In essence a floating power plant that is able to produce electricity from gas or dual-fuel generators. To date only small LNG power barges have been commissioned but there is no technical limit to the size and capacity of this concept. Notwithstanding the rationale behind this particular arrangement, similarly to case “B”, above, it represents a situation where LNG is not “bunkered” to the receiving ship. In fact LNG is not being transferred at all. The use of LNG is taking place on the barge. The major concern for the location where the barge is moored to derives from the on-board LNG storage. Another consideration that may be possible is that the LNG “power barge“, either self-propelled or not, is not engaged in transport of LNG but rather on the deployment of a service (electricity production and supply). The barge is however not undertaking transport of LNG and, in comparison to “B” the transport chain has clearly ceased. This would, in principle, mean that this situation would not be covered by the exclusions in Article 2(2) (c). Applicability of Seveso III Directive requirements should be very clearly considered by PAAs, giving special consideration to the situations where such barges are alongside a fixed location within the port area. Even though these are floating units they should be assessed in light of Seveso safety requirements. As with other cases it may well be that similar measures to those prescribed by Seveso III Directive are already taken (Safety Report, Safety Management System and an Emergency Plan) as part of the project. |

| |

| D. Bunkering by Multiple trucks to one manifold | |

| LNG bunkering via a common manifold, as shown in the figure to the left, may represent an operational advantage in LNG bunkering via trucks. Optimization of LNG bunkering times, volumes and transfer rates, including reduction of operational times for truck arrival, preparation, connection/disconnection, are amongst some of the relevant drivers for the manifold multi-truck solution. The quantities of LNG in one place, and the procedures followed to connect/disconnect to the manifold, altogether, are distinctive characteristics of this type of LNG bunkering interface solution. Overall, this scenario is in principle no different from example 1 above and determination of applicable regulations may depend upon the maximum amount of LNG that may be expected in the location over a relevant amount of time, at any time. However, given the larger amount of LNG present Particular reference is made to the definition of “presence of dangerous substances” in Article 3 of Seveso III Directive. This includes the concept of anticipated presence. So in case of a manifold as depicted in the figure for situation “D” the maximum possible would be assumed to be present, i. e. 4 tanks.x and the fact that a fixed installation (i. e. the manifold) could be seen as an indication of more regular activities, this scenario is more likely than example 1 to conclude that the location is to be considered as a Seveso establishment. A case-by-case approach should be exercised, in direct consultation with PAA and Competent Authorities, with Seveso requirements applied on the basis of the maximum quantities of LNG expected for that location at any time (e. g. maximum capacity of the manifold). The presence in the area of other hazardous substances (Annex I of Seveso III Directive) should also be duly considered and added. |

| E. LNG Bunkering FSU (Floating Storage Unit) | |

| An LNG bunkering small FSU, in intermediate position, between shore and the receiving ship, as shown in figure “Small LNG FS”, may represent an additional advantage, with the receiving ship able to moor-and-bunker faster. The LNG small FSU could, in this case, fall under the Seveso III requirements. For the assessment of a particular location it does not matter whether the storage or use is land-based or water-based. If a given location happens to include an expanse of water, then this area needs to be considered as well. A vessel (e. g. a barge) that mostly remains within a certain location under the control of a single operator (e. g. a harbour) could not benefit from the exclusion described in Article 2(2)(c) of the Seveso III Directive because this refers to temporary storage during transport outside the establishment and not to transport or storage within an establishment. |

| F. LNG small scale storage | |

| Small scale LNG storage installations, such as the one illustrated in the figure to the left, are typically within the scope and applicability of the Seveso III Directive, with LNG capacities up to 10 000 m3. Fixed LNG installations, for higher capacity bunkering operations would include LNG storage tanks such as the pressure tanks illustrated. The storage installation, together with the rest of the terminal installations would be unquestionably scoped under Seveso III Directive. The LNG storage may however be done in different ways, with LNG tanks of different construction and different containment systems, amongst other aspects. Noting further that the quantities contributing to the thresholds indicated in the Seveso directive are the summation of all stored/handled hazardous substances in a given location, amongst others the following requirements apply: |

| – Major-accident prevention policy (MAPP) – Article 8 (for all tiers); | |

| – Safety Report – Article 10; | |

| – Safety Management System; | |

| – Emergency Plan. | |

| All the above situations, explored in terms of Seveso III Directive requirements applicability, may be subject to case-by-case assessments. Notwithstanding this, the following conclusions may be taken in assistance to the definition of a good practice approach in the permitting of LNG bunkering facilities: | |

| Seveso III does not apply to mobile units undertaking transport of LNG outside Seveso establishments. The bunkering operation in itself, being part of the logistic chain, is also part of the LNG distribution. Article 2(2)(c), therefore, typically applies to LNG trucks and LNG bunkering vessels or barges provided that it is directly linked to the transport in which case it would be unloading. | |

| The location where bunkering takes place, however, can be considered as a specific location where hazardous substances are handled, in this case LNG, and therefore be subject to consideration for application of Seveso. This is better addressed in Chapter 7, on Permitting. | |

| Competent Authorities for Seveso III Directive requirements, at national level, should engage periodically with PAAs to assess specific situations that may result from continuously developing LNG bunkering technology. | |

| LNG bunkering, in otherwise-Seveso installations (i. e. installations already classified as Seveso) should be carefully considered, e. g. in light of possible domino effects. Safety Distances should take pre-existing hazardous substances into account. | |

- Annex I – Dangerous substances (LNG include in entry 18, Part 2);

- Annex II – Minimum data and information to be considered in the safety report referred to in Article 10;

- Annex III – Information referred to in Article 8(5) and Article 10 on the safety management system and the organisation of the establishment with a view to the prevention of major accidents;

- Annex IV – Data and information to be included in the emergency plans referred to in Article 12;

- Annex V – Items of information to the public as provided for in Article 14(1) and in point (a) of Article 14(2);

- Annex VI – Criteria for the notification of a major accident to the Commission as provided for in Article 18(1).

EU Environmental Impact Directive

Directive 2011/92/EU of the European Parliament and of the Council of 13 December 2011 on the assessment of the effects of certain public and private projects on the environment.

EIA Directive (2011/92/EU as amended by Directive 2014/52/9EU)32 defines the Environmental Impact Assessment (EIA) process which ensures that projects likely to have significant effects on the environment are made subject to an assessment, prior to their authorization. Consultation with the public is a key feature of EIA procedure. The EIA Directive applies to a wide range of public and private projects, which are defined in Annexes I and II. Annex II lists so called “Energy Industry” projects and more specifically storage of gas. For projects listed in Annex II, the national authorities have to decide whether an EIA is needed (by a so-called “screening procedure”). Although the EIA Directive specifies no specific thresholds or criteria for “storage of gas” (LNG) installations, during the screening procedure the national authorities must take into account the criteria laid down in Annex III. The EIA Directive also specifies the requirements on participation of environmental authorities, local and regional authorities, affected Member States as well as the public in the process.

Read also: The Role of LNG Bunkering Infrastructure

Together with Seveso III, the EIA Directive can be a relevant instrument for LNG bunkering projects, especially with regards to Permitting processes. As LNG bunkering projects fall under Annex II of the EIA Directive and Member States may have introduced different thresholds or criteria for this type of projects, it is important to verify the applicable national legislation. The Directive, as such, aims to set the framework for EIA and, national legislation to provide for the technical measures.

As indicated above, it is the responsibility of each Member State to identify the thresholds and/or criteria for LNG storage capacity above which the provisions of the Directive apply, or they can apply case-by-case examination to determine of Annex II projects shall be subject to EIA.

Whether an LNG project, with local small-scale storage, would be subject to an EIA should be a result of a determination in accordance with national legislation transposing Art. 4(2)-(6) of the EIA Directive.

In section “EIA Directive” a good practice procedure is included to address the screening and assessment of LNG bunkering projects, in the wider context of permitting process. A flow diagram is included to identify the main parts that constitute the EIA process (see figure Regulatory Frame Best Practice – Applicability in the Bunkering Interface“Environmental Impact Assessment – General reference process”).

EIA Directive (85/337/EEEC) The initial Directive of 1985 and its three amendments have been codified by DIRECTIVE 2011/92/EU of 13 December 2011. Directive 2011/92/EU has been amended in 2014 by DIRECTIVE 2014/52/EU.x (and its updates) defines the Environmental Impact Assessment (EIA) and minimum requirements for the public consultation procedure. The EIA Directive (85/337/EEC) is in force since 1985 and applies to a wide range of public and private projects, which are defined in Annexes I and II. Annex II specifies requirements for so called “Energy Industry” and more specifically storage of gas. For projects listed in Annex II, the national authorities have to decide whether an EIA is needed. The EIA-directive specifies no threshold for “storage of gas” (LNG) installations. In general this Directive, and its implementation in national law by Member States, applies to larger LNG installations (some exceptions exist) rather than to small scale terminals. The EIA also specifies the requirements on public participation in the process.

Together with Seveso III, the EIA Directive can be a relevant instrument for LNG bunkering projects, especially with regards to Permitting processes. It will however depend very much on the transposition exercise of this EU Directive the very extent of its applicability to LNG bunkering projects, making it remarkably important to observe the relevant provisions for EIA in each Member State national law. The Directive, as such, aims to set the framework for EIA and, national legislation to provide for the technical measures allowing for the adequate scoping of EIAs to the relevant projects.

As indicated above, it is the responsibility of each Member State to identify the thresholds for LNG storage capacity above which the provisions of the Directive apply.

In principle, from conclusions of the EU LNG Study, there are very few Member States that would consider small scale LNG developments, such as small-scale storage associated to LNG bunkering, as subject to EIA requirements.

Whether an LNG project, with local small-scale storage, would be considered for EIA requirement is subject to local/national thresholds fixed for that purpose.

ADR – European agreement

ADR – European agreement concerning the International Carriage of Dangerous Goods by Road (Update version ADR January 2017).

The transport of hazardous goods by road is covered in the European Agreement concerning the International Carriage of Dangerous Goods by Road, commonly known as ADR (“Accord européen relatif au transport international des marchandises dangereuses”) from the Economic Commission for Europe (UNECE or ECE). The ADR is translated and included in the national legislation of the applicable countries. The Agreement itself is short and simple. The key article is the second, which describes that, excluding some excessively dangerous goods, other dangerous goods may be transferred internationally in road vehicles subject to compliance with the conditions laid down in Annexes A (packaging and labelling) and B (construction, equipment and operation of the vehicle carrying the goods in question).

Trucks that transport LNG are subjected to Annex A with respect to labelling of hazardous materials and to Annex B when it comes to construction of the cargo tank. Trucks that are using LNG as fuel are subjected to Annex B for the construction of the fuel tank.

A new version of the ADR has entered into force the 1st of January 2017. No modifications impacting LNG transport via trucks have been made.

ADN – European Agreement

ADN – European Agreement concerning the International Carriage of Dangerous Goods by Inland waterways (Update version ADN January 2017).

LNG bunker vessels and barges operating in rivers and port areas (see contracting countries in Figure 5) Construction, Operation, training of crew.

The ADN is published together with the Central Commission for the Navigation of the Rhine (CCNR). The provisions annexed to the ADN concern dangerous substances and articles, provisions concerning their carriage in packages and in bulk on board inland navigation vessels or tanks vessels, as well as provisions concerning the construction and operation of such vessels. Figure 5 shows the ADN contracting countries.

In “Table A” of the addendum, a list of substances is mentioned specifying the conditions of transportation via inland waterways for each of these substances. With an amendment coming into force of 1.1.2015, the LNG was included in the authorised cargo. ADN also prohibited the installation and utilization of engines that use a fuel with a flashpoint below 55 °C.

However, in 2017, an amendment was approved to allow derogations subject to compliance with the requirements laid down by CESNI standard ES-TRIN. It will come into force of 1.1.2019 (See ECE/TRANS/WP.15/AC.2/62, items 68 and 69).

Technical requirements for the loading and unloading procedure for liquefied natural gas (LNG) are not in scope of the update of ADN.

Fig. 6 Ship-to-ship LNG bunkering – riverine LNG bunker vessel to receiving ship

Of particular relevance, Part 8 of the ADN contais training requirements applicable for crew s of LNG bunker vessels, barges or riverine LNG carriers, (This paragraph states that an expert shall be on board the vessel, not less than 18 years of age, who has special knowledge of the ADN, taken part in a basic or specialization course as referred to in 8.2 ADN).

Proof of this knowledge shall be furnished by means of a certificate from a competent authority or from an agency recognized by the competent authority).

The ADN does not require specific training for crew of inland LNG tankers, indeed LNG falls under the provisions of gas specialisation courses.

Rhine Vessel Inspection Regulations (RVIR)

The CCNR technical rules and requirements for inland waterway vessels are captured in the RVIR. The Rhine inspection regulations, which are only legally applicable on the Rhine itself, have become Europe’s technical reference base for the construction of new vessels, irrespective of whether they are intended for use on the Rhine or somewhere else. Indeed, beyond the river Rhine, the Rhine vessel certificates are recognised on all EU waterways.

Until very recently, the RVIR prohibited the use of fuel with a flashpoint below 55 °C, as stated in Article 8.01 (3) of RVIR.

Hence, the use of LNG as a fuel for inland waterway vessels was not allowed. From 2012, CCNR allows derogations to the RVIR in order to give ship owners and builders the opportunity to develop alternative arrangements (for example LNG supply system) if comparable safety guarantees could be provided. Several vessels were built and operated, especially in the Netherlands. After an analysis of what has been learned from operating of these vessels, the CCNR adopted supplements to its regulations for Rhine navigation in order to create a legal framework which would allow the regular use of LNG as a fuel for inland navigation in Europe. In particular, from December 2015, a new chapter 8a and annex T have been included in the RVIR.

It will be interesting: Pipelines in Marine Terminals: Key Considerations for Handling Liquefied Gas

Following the update of the RVIR, the relevant technical requirements for LNG have also been included in the standard ES-TRIN published by CESNI. ES-TRIN is not binding per se. The CCNR and EU intend to enact ES-TRIN in a coordinated way, with effect from 07 October 2018, by means of a reference in their respective legislative frameworks (RVIR and Directive 2016/1629).

An evaluation of items relevant to LNG bunkering in the RVIR draft chapter 8b and Annex T is presented in Table 4, below. (Similar observations are valid for ES-TRIN, Chapter 30 and Annex 8).

| Table 4. Items relevant for LNG bunkering in draft RVIR chapter 8b and Annex T | |

|---|---|

| RVIR chapter 8b and Annex T | |

| Reference | Description |

| Article 8b.03 Safety aspects | Vessels equipped with propulsion or auxiliary systems operating on fuels with a flashpoint equal to or lower than 55 °C shall keep safety instructions on board. It shall include information on the measures to be taken in the event of accidental release of liquid or gaseous fuel, for instance during bunkering. |

| Annex T Part 1 LNG, Chapter 2 Vessel arrangements and system design, 2.1 General | A risk assessment shall be conducted on any new or altered concept or configuration or other significant changes. Hazardous areas shall be restricted and equipment installed in hazardous areas shall be minimized. Sources of ignition in hazardous areas shall be limited. Components of LNG system shall be protected against external damage. Bunkering arrangements shall be capable of taking on board and containing the fuel in the required state without leakage or environmental emissions (venting). Control, alarm, monitoring and shutdown systems along with fired detection, protection and extinction measures shall be provided. |

| Annex T Part 1 LNG, Chapter 2 Vessel arrangements and system design, 2.2 LNG containment | Requirements for LNG storage tanks are presented in this section. Under specific conditions, LNG storage tanks can be single or double walled, located below or on open deck. Design shall be according to EN 13530, EN 13458-2:2002, IGC Code (type C tank), the ADN or another appropriate standard to the satisfaction of the competent authority. |

| Annex T Part 1 LNG, Chapter 2 Vessel arrangements and system design, 2.3 Engine rooms | Engine rooms shall be gas safe or designed as ESD protected and specific requirements are given in this section. |

| Annex T Part 1 LNG, Chapter 2 Vessel arrangements and system design, 2.4 LNG piping systems | Requirements for LNG piping are given in this section. It covers items such as location, isolation; design pressure and pressure relieve valves. |

| Annex T Part 1 LNG, Chapter 2 Vessel arrangements and system design, 2.8 LNG bunkering system | The LNG bunkering system shall be so arranged that no gas is discharged to the atmosphere during filling of LNG storage tanks. |

| The LNG bunkering station shall be located on open deck. | |

| The bunkering manifold shall be so positioned and arranged that any damage to the gas piping does not cause damage to the vessel’s LNG containment system. The bunkering manifold shall be designed to withstand external mechanical loads during bunkering. The connections shall be of dry-disconnect type equipped with additional safety dry break-away coupling/ self-sealing quick release. | |

| Suitable means shall be provided to relieve the pressure and remove liquid contents from pump suctions and bunker piping. | |

| Hoses used for LNG transfer shall be suitable for LNG. Hoses shall be designed for a bursting pressure not less than five times the maximum bunkering pressure. | |

| It shall be possible to operate the master gas fuel valve for bunkering operations from a safe control station on the vessel. | |

| Bunkering piping shall be arranged for inerting and gas freeing. During operation of the vessel the bunkering piping shall be free of gas. | |

| Annex T Part 1 LNG, Chapter 2 Vessel arrangements and system design, 2.9 filling limits for LNG storage tanks | The level of LNG in the storage tank shall not exceed the filling limit of 95 % full at the reference temperature (temperature corresponding to the vapour pressure of the fuel at the opening pressure of the PRVs). A filling limit curve dependent of the actual LNG filling temperatures shall be prepared. |

| Annex T Part 1 LNG, Chapter 3 Fire safety | This section gives all the requirements related to fire safety, covering alarm system, insulation, prevention, cooling and extinguishing. Specific for bunkering are: |

| Bunker station shall be separated by class A-60 insulation from engine rooms, accommodation and high fire risk spaces. | |

| Two additional dry powder fire extinguishers of at least 12 kg capacity shall be located near the bunkering station. | |

| Annex T Part 1 LNG, Chapter 5 Control monitoring and safety systems, 5.2 LNG bunkering system and LNG containment system monitoring | This section gives all the requirements related to control, monitoring and safety systems for the LNG bunkering and containment system. It covers items such as pressure and level indicators and alarms. |

Regulation for Rhine navigation personnel (RPN)

After an analysis of what has been learned from operating inland navigation vessels already testing the use of LNG, the CCNR adopted supplements to its regulations for Rhine navigation in order to create a legal framework which would allow the regular use of LNG as a fuel for inland navigation in Europe.

In June 2015, the CCNR adopted an amendment of the Regulation for Rhine Navigation Personnel (RNP) (Resolution 2015-I-7) to come into force on 1 July 2016. The RNP includes a new Chapter 4b is on “Additional provisions concerning the expertise of crew members of inland navigation vessels fuelled by liquefied natural gas (LNG)”. This Chapter includes requirements on LNG that skippers and crew members involved in the bunkering procedure shall be subject to an obligation of expertise, and on laying down the content of training courses and examinations.

In the future, similar provisions will be included in CESNI Standards.

Rhine police Requirements (RPR)

After an analysis of what has been learned from operating inland navigation vessels already testing the use of LNG, the CCNR adopted supplements to its regulations for Rhine navigation in order to create a legal framework which would allow the regular use of LNG as a fuel for inland navigation in Europe.

In June 2015, the CCNR adopted an amendment to the Rhine Police Regulations (RPR). These regulations determine the operational requirements, including during the bunkering, applicable to ships using Liquefied Natural Gas (LNG) as a fuel which came into force on 1st December 2015.

To give effect to these requirements, the CCNR has published in October 2015 edition 1.0 of the standard for a liquefied natural gas (LNG) bunker checklist truck to ship. This standard, available in French, German, Dutch and English, is based on that published by the International Association of Ports and Harbours (IAPH) and already used by a number of river/sea ports. It comprises the checklist required by the Rhine Police Regulations (RPR) on the one hand and guidelines on the other hand, aiming to expand on the content of this list and to assist the boatmaster in completing it.

The use of this standard is mandatory for all LNG bunker operations involving a vessel if this bunkering takes place along the Rhine waterway or in a port.

Directive (EU) 2016/1629

Directive (EU) 2016/1629 laying down technical requirements for inland waterway vessels, amending Directive 2009/100/EC and repealing Directive 2006/87/EC.

In order to ensure consistency of two existing legal regimes for technical requirements for inland navigation vessels (Rhine and UE) it is necessary to provide the same standards. Both EU law and CCNR Regulation will be referring to standards delivered by CESNI – to ES-TRIN 2017/01 from 7 October 2018 (deadline of transposition of Directive EU 2016/1629 and date of applicability of ES-TRIN 2017/01).

Read also: Balancing Cleaner Fuel and Environmental Impact in LNG Emissions

Meanwhile the use of fuel with a flashpoint below 55 °C was prohibited with the previous directive 2006/87/EC, the reference to ES-TRIN (especially to Chapter 30 and Annex 8) offered the opportunity to apply the special provisions for craft using LNG as fuel.

International Framework

The international framework for LNG as fuel, similarly to the European context, starts with the main environmental instrument MARPOL, imposing restrictions on air emissions from ships, through it Annex VI regulations 13 and 14, for NOx and SOx emissions, respectively. Effectively the use of LNG is an option to allow ships meeting air pollution requirements, in particular for SOx emissions (with dramatic reductions in emissions above 95 % in even in dual fuel engine systems). Being a gaseous fuel, of flashpoint lower than 60 °C (actually -175 °C) LNG could not be considered as fuel, within SOLAS frame. The use of fuels with flashpoint lower than 60 °C is not permitted as per SOLAS 1989/1990 Amend / Chapter II-2 / Reg. 15.x Due to that reason, addressing the particular aspects concerning safe use of LNG as fuel, building from the experience of the IGC Code and from the application of Interim Guidelines MSC.285 (86) – Interim guidelines on Safety for Natural Gas-Fuelled Engine Installations in Ships.x the IGF Code was developed. Containing what is today the best collection of provisions for the design, construction and General Overview of LNG Cargo Tanks (Typical Operations)operation of LNG fuelled ships the IGF Code entered into force on 1st January 2017 and is the central focus of this section. Its functional requirements are further outlined in this section and a parallel is established with the whole LNG bunkering interface, making the relation that similar functional requirements should be applicable throughout the entire LNG bunkering scenario.

On its own the IGF Code represents a highly relevant instrument, defining the safety requirements for the construction and operation of LNG fuelled ships and, at the same time, defining the level of ambition in terms of safety, relevant safeguards, control and associated procedures. The Functional and General Requirements for LNG Bunkering OperationLNG bunkering related provisions are significant and selected, transcribed and commented below. It is, in the context of this guidance, important to follow the IGF Code requirements and establish good practice that can be expanded to the LNG Bunkering Interface and Shore-Side. Communications, Check-lists, Pre-Bunkering verification procedures, Emergency Shutdown (ESD) link compatibility, bunkering control, Persons in Charge (PICs), are amongst some of the aspects where harmonization of technical aspects and procedures must be ensured between all parties involved, including PAAs.

| Table 5. International high-level instruments | |||

|---|---|---|---|

| Title | Responsible | Type | Scope |

| IGF Code | |||

| International Code of Safety for Ships Using Gases or Other Low-Flashpoint Fuels (IMO Res.MSC.391(95)) | IMO | International Code | Ships constructed or converted to the use of gases or low flashpoint fuels, after the 1st January 2017 Requirements for design, construction and operation. |

| International convention for the Safety of Life at Sea (SOLAS)1974, as modified by the protocol of 1988 relating thereto | IMO | Convention | Ships engaged in international voyages. IGF Code is made mandatory through amendment in SOLAS, in new Regulation 57, introduced through Resolution MSC.392(95) |

| IGC Code | |||

| International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk | IMO | International Code | Construction, equipment and operation of ships carrying liquefied gases in bulk. |

| MARPOL | |||

| International Convention for the Prevention of Pollution from Ships | IMO | Convention | Relevant in particular for Annex VI, with limits on SOx and NOx Emissions, Energy Efficiency and EAMs. |

| STCW (Convention) | |||

| International convention on standards of training, certification and watch keeping for seafarers | IMO | Convention | Training, certification and qualification of seafarers serving on board sea-going ships Minimum standards of competence for seafarers |

| STCW (Code) | |||

| International convention on standards of training, certification and watch keeping for seafarers | IMO | International Code | Training, certification and qualification of seafarers serving on board sea-going ships Minimum standards of competence for seafarers |

IGF Code

International Code of Safety for Ships Using Gases or Other Low-flashpoint Fuels (IMO Res.MSC.391(95)).

This Code provides an international standard for ships using low-flashpoint fuel, other than ships covered by the The Origins of the IGC CodeIGC Code. The basic philosophy of this Code is to provide mandatory provisions for the arrangement, installation, control and monitoring of machinery, equipment and systems using low-flashpoint fuel to minimize the risk to the ship, its crew and the environment, having regard to the nature of the fuels involved.

The International Code of Safety for Ships using Gases or other Low-flashpoint Fuels (IGF Code) was adopted by the Maritime Safety Committee (MSC) at its ninety-fifth session in June 2015, by resolution MSC.391(95), in order to provide an international standard for the safety of ships using low-flashpoint fuel, other than ships covered by the IGC Code. The IGF Code is made mandatory under amendments to chapters II-1, II-2 and the appendix to the annex of the International Convention for the Safety of Life at Seas (SOLAS), 1974, that were adopted by the MSC at the same session, by resolution MSC.392(95) (entry into force: 1 January 2017).

From the IGF Code the following Chapters are of particular relevance in the context of LNG Bunkering:

- Section 3.2 – Functional Requirements.

- Chapter 8 – Bunkering (Outline of functional requirements for bunkering equipment (ship-side) with requirements to the Bunkering Station and manifold onboard the LNG fuelled ship).

- Section 18.4 – Regulations for Bunkering Operations (description of operational procedures to be followed for LNG bunkering, with the description of the particular responsibilities for the PICs and operational aspects related to communications, control and safety systems and verification of conditions for bunkering).

- Section 15.4 – Regulations for bunkering and liquefied gas fuel tank monitoring (Set of requirements specific for LNG tank filling monitoring, especially relevant during bunkering, both for overfills mitigation and for LNG vapour management.

- Section 15.5 – Regulations for bunkering control (LNG bunkering control aspects, including requirements for LNG bunkering control location.)

Section 3.2 of the IGF Code lists the Functional Requirements that are the basis of the requirements developed throughout the entire Code.

The Functional requirements are also fundamental also in the context of the LNG bunkering interface, and should be followed and used as fundamental principles.

| Table 6. IGF Functional Requirements – Applicability to Bunkering Interface | |

|---|---|

| IGF Code Functional Requirement (Section 3.2) | Applicability in LNG Bunkering |

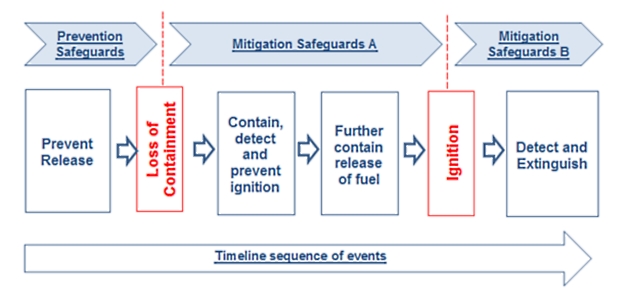

| The probability and consequences of fuel-related hazards shall be limited to a minimum through arrangement and system design, such as ventilation, detection and safety actions. In the event of gas leakage or failure of the risk reducing measures, necessary safety actions shall be initiated. | A 2 layered safeguard approach is here outlined as a safety functional requirement. Also for the LNG bunkering interface this should be followed (1st layer – avoid the hazard by design – 2nd layer – mitigate the hazard once it occurs). In this context the Safety concept as prescribed in this IGF Functional Requirement can be schematized in the diagram below. The 1st layer prevention safeguards and the 2nd layer is mitigation safeguards (further sub-divided into “A” and “B”). |

| The design philosophy shall ensure that risk reducing measures and safety actions for the gas fuel installation do not lead to an unacceptable loss of power | (functional requirement specific for the ship side). |

| Hazardous areas shall be restricted, as far as practicable, to minimize the potential risks that might affect the safety of the ship, persons on board, and equipment. | In the context of the LNG Bunkering Interface this Functional Requirement should dictate best practice such that the Hazardous Area defined for the LNG Bunkering Operation is restricted so as to minimise impact on surrounding spaces. |

| Equipment installed in hazardous areas shall be minimized to that required for operational purposes and shall be suitably and appropriately certified. | Functional requirement also applicable to the whole LNG bunkering interface. It is very important that this alignment is ensured between the RSO, BFO and all parties involved in the LNG bunkering operation. |

| Unintended accumulation of explosive, flammable or toxic gas concentrations shall be prevented. | Applicable in the context of LNG bunkering interface. The LNG bunkering space and all physical elements of the LNG bunkering interface to be protected against external damages. |

| System components shall be protected against external damages | Applicable in the context of LNG bunkering interface. LNG bunkering Hazardous Area to be protected. All physical elements of the LNG bunkering interface to be protected against external damages. |

| Sources of ignition in hazardous areas shall be minimized to reduce the probability of explosions. | Applicable in the context of the whole LNG bunkering interface. Reference standards applicable to the definition and characterization of hazardous zone: IEC60079-10-1, API 501 or NFPA 497 (See Chapter 9 – Control Zones – for the best practice advised by this Guidance on Hazardous Zone definition). |

| It shall be arranged for safe and suitable fuel supply, storage and bunkering arrangements capable of receiving and containing the fuel in the required state without leakage. Other than when necessary for safety reasons, the system shall be designed to prevent venting under all normal operating conditions including idle periods. | Functional Requirement 3.2.9 introduces a significant requirement applicable to the whole LNG bunkering operation. Venting should only be a possibility for safety reasons. This should otherwise not be possible. All equipment, systems and procedures, as described in the LNG Bunkering Plan should be designed in such a way that Venting is not considered an acceptable operational procedure. |

| Piping systems, containment and over-pressure relief arrangements that are of suitable design, construction and installation for their intended application shall be provided. | Functional requirements applicable to the whole bunkering interface and to equipment used also by BSOs. LNG Bunkering system should share similar safety levels, in particular in terms of overpressure relief, compatibility and quality standards. |

| Machinery, systems and components shall be designed, constructed, installed, operated, maintained and protected to ensure safe and reliable operation. | Applicable to all equipment and machinery used in the LNG bunkering operation. |

| Fuel containment system and machinery spaces containing source that might release gas into the space shall be arranged and located such that a fire or explosion in either will not lead to an unacceptable loss of power or render equipment in other compartments inoperable. | (functional requirement specific to the ship side). |

| Suitable control, alarm, monitoring and shutdown systems shall be provided to ensure safe and reliable operation. | Applicable to all equipment and machinery used in the LNG bunkering operation. Control, alarm, monitoring and shutdown systems should be shared by all parties in the LNG bunkering operation, in particular relevant to the BSO-RSO bunkering line where immediate action is vital in case of loss of containment or any other LNG hazard in the bunkering interface. Compatibility of equipment and procedures is fundamental. |

| Fixed gas detection suitable for all spaces and areas concerned shall be arranged. | Fixed gas detection is, indeed, a fundamental requirement to detect potential loss of containment. This functional requirement should be shared by the whole bunkering interface. Visual detection and temperature detection may however be the most effective control measures for detection of potential LNG leakage/release. Depending upon gas detector locations, under certain open-air dispersion characteristics Dispersion characteristics, following a loss of containment event, are influenced by temperature, wind and other environmental factors. Whether gas detectors will find.x visual and temperature detection may be more appropriate (i. e. faster) to detect leakage rather than gas detectors. |

| Fire detection, protection and extinction measures appropriate to the hazards concerned shall be provided. | Applicable to the whole LNG bunkering interface and parties involved. Suitable fire detection, protection and extinction should be considered. Similar safety level to be shared by all parties. |

| Commissioning, trials and maintenance of fuel systems and gas utilization machinery shall satisfy the goal in terms of safety, availability and reliability. | Should also, as best practice, be applicable to LNG bunkering equipment. Applicable to all parties. |

| The technical documentation shall permit an assessment of the compliance of the system and its components with the applicable rules, guidelines, design standards used and the principles related to safety, availability, maintainability and reliability. | The relevant technical documentation, also for the case of LNG Bunkering, should be included in an LNG Bunkering Plan, where the procedure, certificates, diagrams and maintenance records, should all be kept. As a best practice this would allow the easier verification of compliance and assessment of the RSO or BSO readiness, compatibility and preparation for a given LNG Bunkering operation. |

| A single failure in a technical system or component shall not lead to an unsafe or unreliable situation. | Should be applied to the whole LNG bunkering context. A single failure event should not lead to an unsafe or unreliable situation. |

Throughout this Guidance the Functional Requirements addressed above will also be present in the definition of the best practice considered also for PAAs in the context of LNG Bunkering.

Having visited the Functional Requirements of the IGF Code, and derived their applicability to LNG Bunkering, the transcription of both Chapter 8 and Section 18.4, below, is intended to highlight the relevance of these IGF Code provisions in the context of LNG Bunkering operations. Being applicable to the Receiving Ship, the requirements transcribed below define the level of protection intended for the receiving ship, both on equipment requirements (Chapters 8, Sections 15.4 and 15.5) or on operational procedures (Section 18.4).

Chapter 8 is fully dedicated to Bunkering, in particular to constructive aspects related to the location and details of the bunkering station. Functional requirements are outlined, followed by elements related to the bunkering station location, hoses, manifold and bunkering system.

| 8 BUNKERING | |

|---|---|

| 8.1 Goal | |

| 8.1.1 | The goal of this chapter is to provide for suitable systems on board the ship to ensure that bunkering can be conducted without causing danger to persons, the environment or the ship. |

| 8.2 Functional requirements | |

| 8.2.1 | This chapter relates to functional requirements in 3.2.1 to 3.2.11 and 3.2.13 to 3.2.17. In particular the following apply: |

| 8.2.1.1 | The piping system for transfer of fuel to the storage tank shall be designed such that any leakage from the piping system cannot cause danger to personnel, the environment or the ship. |

| 8.3 Regulations for bunkering station | |

| 8.3.1 | General |

| 8.3.1.1 | The bunkering station shall be located on open deck so that sufficient natural ventilation is provided. Closed or semi-enclosed bunkering stations shall be subject to special consideration within the risk assessment. |

| 8.3.1.2 | Connections and piping shall be so positioned and arranged that any damage to the fuel piping does not cause damage to the ship’s fuel containment system resulting in an uncontrolled gas discharge. |

| 8.3.1.3 | Arrangements shall be made for safe management of any spilled fuel. |

| 8.3.1.4 | Suitable means shall be provided to relieve the pressure and remove liquid contents from pump suctions and bunker lines. Liquid is to be discharged to the liquefied gas fuel tanks or other suitable location. |

| 8.3.1.5 | nker lines. Liquid is to be discharged to the liquefied gas fuel tanks or other suitable location. 8.3.1.5 The surrounding hull or deck structures shall not be exposed to unacceptable cooling, in case of leakage of fuel. |

| 8.3.1.6 | For CNG bunkering stations, low temperature steel shielding shall be considered to determine if the escape of cold jets impinging on surrounding hull structure is possible. |

| 8.3.2 | Ships’ fuel hoses |

| 8.3.2.1 | Liquid and vapour hoses used for fuel transfer shall be compatible with the fuel and suitable for the fuel temperature. |

| 8.3.2.2 | Hoses subject to tank pressure, or the discharge pressure of pumps or vapour compressors, shall be designed for a bursting pressure not less than five times the maximum pressure the hose can be subjected to during bunkering. |

| 8.4 Regulations for manifold | |

| 8.4.1 | The bunkering manifold shall be designed to withstand the external loads during bunkering. The connections at the bunkering station shall be of dry-disconnect type equipped with additional safety dry break-away coupling/self-sealing quick release. The couplings shall be of a standard type. |

| 8.5 Regulations for bunkering system | |

| 8.5.1 | An arrangement for purging fuel bunkering lines with inert gas shall be provided. |

| 8.5.2 | The bunkering system shall be so arranged that no gas is discharged to the atmosphere during filling of storage tanks. |

| 8.5.3 | A manually operated stop valve and a remote operated shutdown valve in series, or a combined manually operated and remote valve shall be fitted in every bunkering line close to the connecting point. It shall be possible to operate the remote valve in the control location for bunkering operations and/or from another safe location. |

| 8.5.4 | Means shall be provided for draining any fuel from the bunkering pipes upon completion of operation. |

| 8.5.5 | Bunkering lines shall be arranged for inerting and gas freeing. When not engaged in bunkering, the bunkering pipes shall be free of gas, unless the consequences of not gas freeing is evaluated and approved. |

| 8.5.6 | In case bunkering lines are arranged with a cross-over it shall be ensured by suitable isolation arrangements that no fuel is transferred inadvertently to the ship side not in use for bunkering. |

| 8.5.7 | A ship-shore link (SSL) or an equivalent means for automatic and manual ESD communication to the bunkering source shall be fitted. |

| 8.5.8 | If not demonstrated to be required at a higher value due to pressure surge considerations a default time as calculated in accordance with 16.7.3.7 from the trigger of the alarm to full closure of the remote operated valve required by 8.5.3 shall be adjusted. |

Section 18.4 is directly related to LNG Bunkering operations (i. e. procedures, planning and responsibilities. Significant concepts are brought into the regulatory frame through the IGF Code and should be respected. The terminology used in Section 18.4 should be respected in the definition of the terminology used for the entire LNG Bunkering interface. The definition of responsibilities, through the IGF code, indicates the relevance of procedural aspects as safeguards in LNG Bunkering operations.

| 18.4 Regulations for bunkering operations | |

|---|---|

| 18.4.1 Responsibilities | |

| 18.4.1.1 | Before any bunkering operation commences, the master of the receiving ship or his representative and the representative of the bunkering source (Persons In Charge, PIC) shall: |

| .1 agree in writing the transfer procedure, including cooling down and if necessary, gassing up; the maximum transfer rate at all stages and volume to be transferred; | |

| .2 agree in writing action to be taken in an emergency; and | |

| .3 complete and sign the bunker safety check-list. | |

| 18.4.1.2 | Upon completion of bunkering operations the ship PIC shall receive and sign a Bunker Delivery Note for the fuel delivered, containing at least the information specified in the annex to part C-1, completed and signed by the bunkering source PIC. |

| 18.4.2 Overview of control, automation and safety systems | |

| 18.4.2.1 | The fuel handling manual required by 18.2.3 shall include but is not limited to: |

| .1 overall operation of the ship from dry-dock to dry-dock, including procedures for system cool down and warm up, bunker loading and, where appropriate, discharging, sampling, inerting and gas freeing; | |

| .2 bunker temperature and pressure control, alarm and safety systems; | |

| .3 system limitations, cool down rates and maximum fuel storage tank temperatures prior to bunkering, including minimum fuel temperatures, maximum tank pressures, transfer rates, filling limits and sloshing limitations; | |

| .4 operation of inert gas systems; | |

| .5 firefighting and emergency procedures: operation and maintenance of firefighting systems and use of extinguishing agents; | |

| .6 specific fuel properties and special equipment needed for the safe handling of the particular fuel; | |

| .7 fixed and portable gas detection operation and maintenance of equipment; | |

| .9 a description of the procedural actions to take in an emergency situation, such as leakage, fire or potential fuel stratification resulting in rollover. | |

| 18.4.2.2 | A fuel system schematic/piping and instrumentation diagram (P&ID) shall be reproduced and permanently mounted in the ship’s bunker control station and at the bunker station. |

| 18.4.3 Pre-bunkering verification | |

| 18.4.3.1 | Prior to conducting bunkering operations, pre-bunkering verification including, but not limited to the following, shall be carried out and documented in the bunker safety checklist: |

| .1 all communications methods, including ship shore link (SSL), if fitted; | |

| .2 operation of fixed gas and fire detection equipment; | |

| .3 operation of portable gas detection equipment; | |

| .4 operation of remote controlled valves; and | |

| .5 inspections of hoses and couplings. | |

| 18.4.3.2 | Documentation of successful verification shall be indicated by the mutually agreed and executed bunkering safety checklist signed by both PICs. |

| 18.4.4 Ship bunkering source communications | |