LNG Importer Cooperation is essential for ensuring a safe and efficient supply chain in the liquefied natural gas industry. Over the years, various stakeholders have come together to share best practices, enhance safety protocols, and improve operational standards. Organizations like SIGTTO and GIIGNL have played a pivotal role in fostering these partnerships, driving significant changes in the sector.

Their collaborative efforts focus not only on safety but also on regulatory compliance and environmental considerations. Training programs and fit-for-purpose assessments are vital components that underpin the success of LNG carrier operations. Ultimately, LNG importer cooperation leads to a more resilient and sustainable energy future.

Rich history of cooperation amongst LNG importers

As this SIGTTO/GIIGNL commemorative publication highlights, the LNG industry was launched in the 1960s when several export projects were developed, namely in Algeria, Libya and Alaska.

By the end of the decade Japan had received its first shipments and embarked down a path that would soon establish the country as the world’s № 1 LNG importer. In the Atlantic Basin the US made preparations to receive Algerian volumes while Italy and Spain pushed ahead with plans to join France and the UK as European LNG importers.

The technologies needed to create a safe and effective LNG supply chain were novel and complex for the time. The industry was opening up new realms of engineering as it introduced natural gas liquefaction, LNG storage and LNG regasification on a large scale, as well as LNG carrier containment systems and concepts such as cold recovery.

LNG importers faced formidable technical and economic challenges when purchasing, shipping and handling LNG in the volumes required to justify the commercial viability of the project and to satisfy the needs of their customers. All these activities needed to be developed and implemented in the context of their respective national energy policies and regulatory frameworks.

A few companies, including Gaz de France, took the initiative to try to bring together from across the globe the top executives of those gas companies involved in LNG imports and facing common challenges. The idea of creating an Navigating LNG Industry Insights – From Pioneers to European Shipyardsindustry association of LNG importing companies received very favourable feedback from the interests concerned.

Thus were laid the foundations of a new association consisting of 19 founding members. The International Group of Liquefied Natural Gas Importers (GIIGNL) was born just as the nascent LNG industry was taking its first tentative steps.

The association had, at least in its early stages, the character of a club without a rigid legal structure and statutory framework. The members exchanged information and developed studies covering the scientific, technical and economic aspects of issues such as:

- purchasing;

- processing;

- transportation;

- storage;

- handling;

- regasification and the various uses of natural gas.

GIIGNL’s work was undertaken with the aims of promoting the development of the industry and pursuing objectives of common interest, including the development of safety and industry best practice guidelines. Delegates from the US member companies in particular, anxious not to breach any anti-trust laws, appreciated the association’s set-up and working methods.

The first meeting of the Group was held in Paris in December 1971 under the leadership of Gaz de France. Mr. Le Guellec, honorary president of Gaz de France, accepted the presidency of GIIGNL while Hiroshi Anzai of Tokyo Gas and Howard Boyd of El Paso were appointed vice-presidents.

The association functioned well throughout the 1970s and 1980s. In tandem with the relatively slow expansion of the global LNG industry in those formative years, GIIGNL’s membership grew only slowly and did not rise above 25. The resignations of some US members whose projects had been discontinued were offset by new members joining from Asia.

On the occasion of this SIGTTO/GIIGNL commemorative publication, we had the opportunity to interview Robert Venet, GIIGNL director from April 1981 to April 1989, a key period in the association’s history.

Q: Mr. Venet, what was the state of the LNG industry in the 1980s and what were the interests of the world’s major LNG importers at that time?

Robert Venet: «The late 1970s were a very turbulent period for the LNG industry because many of the leading buyers of gas, especially in the US, had become rather disillusioned by the high prices being demanded by the Algerian LNG producers».

«In Europe some new players, like the Italian companies, wanted to enter the LNG scene by acquiring some supplies. However, eventually most opted instead for cheaper pipeline supplies, especially from Russia».

«The LNG boom happened in Asia, and specifically in Japan, when supplies from Indonesia began to flow».

Q: Can you describe the function of GIIGNL at that time? What were the organisation’s activities?

Robert Venet: «The International Group of LNG Importers was essentially an association which offered a meeting place for the top executives of our LNG importing member companies. At that time Howard Boyd, who was a leading personality in the US gas industry and had chaired El Paso, was GIIGNL president, while Pierre Alby from Gaz de France, Denis Rooke from British Gas and Hiroshi Anzai from Tokyo Gas were vice-presidents. All were distinguished captains of the gas industry in the 1980s and chief executives of leading gas companies».

«The activities of the association were mainly centred on two annual meetings. These gatherings allowed member representatives to meet, exchange views and commission joint studies on topics of specific interest. These projects were carried out by the members themselves, of which one would act as coordinator».

«I remember one particular groundbreaking study on the certification of LNG carriers. Indeed at the time, the rules governing the design and construction of such vessels were in their infancy and work to establish an appropriate regulatory regime was being coordinated by the International Maritime Organization (IMO). GIIGNL, through the experience and expertise of its members, was able to provide valuable input to the investigations that underpin the regulations which were made mandatory for new ships in 1986».

«The study topics selected covered a very wide range of technical, operational, regulatory and commercial issues. It goes without saying that those sensitive commercial issues which might have impinged on competition law were strictly off-limits».

Q: How was the association organised and managed?

Robert Venet: «GIIGNL worked on the basis of rules which had been laid down by the founding members at the First General Assembly in Paris in 1971 (these rules have since been transformed into statutes, the current version being updated in 2008). Day-to-day functioning of the association was managed by a permanent chief officer or general delegate in consultation with and under the guidance of the Group’s president».

«The statutes require that at least two meetings a year are held. These are a General Assembly of all members, in which all decisions of statutory importance are taken and plenary discussions are held, and an Executive Committee meeting attended by a selection of member companies representing the three regions in which the industry operates, namely Europe, the Americas and Asia. The Executive Committee receives an update on the activities of the association and prepares proposals to be voted on by the AGM».

Q: Who conducted these meetings? … and how did they evolve?

Robert Venet: «Many Japanese companies were represented at these meetings. When I joined the association in 1981, there were 13 Japanese companies among our 23 members. There were no other Asian members; the remainder comprised five European and five of the original eight American founding members».

«During the meetings the discussions were simultaneously translated into three languages – English, French and Japanese. Mitsubishi, with its very effective interpretation services, was in charge of the Japanese language translations».

«Gaz de France, British Gas and Tokyo Gas had assumed clear leadership roles in the meetings and the organisation in general. The first non-Japanese Asian members were Korea Gas in 1985 and CPC, headquartered in Taipei, in 1989».

Q: Do you have any particular memories of your time at GIIGNL that stand out?

Robert Venet: «Given the level of participants at our meetings, not surprisingly the events did not lack in style. I remember the 1983 Steering Committee at Artigny country house in France. Steeped in history, this is a castle that Renaissance writer Rabelais used to visit. At our meeting Hiroshi Anzai was knighted as a member of the Confrérie des Tastevins, a brotherhood whose purpose is the development of burgundy wines».

«On another occasion, at the 1985 Steering Committee at Woodstock in the UK, Denis Rooke (by then Sir Denis) proposed to the delegates that we attend a parade of the guards at Blenheim Palace …. in the pouring rain. Sir Denis spoke perfect English but with such a pure Oxford accent that our French and Japanese interpreters had difficulty in understanding him. Away from the formal meeting proceedings, however, Sir Denis spoke much more «plainly», with acid comments about, for example, the privatisation plans that UK prime minister Margaret Thatcher had for British Gas».

«While the American delegates may have been somewhat more «conventional» in their conversation, they were no less noticeable. At the Florence General Assembly in 1981, for example, several of the wealthier US companies had chartered a private Boeing 727 for their presidents to make the transatlantic flight».

«These same US delegates were somewhat amazed when, at the end of a meeting in Sapporo in 1984, our Japanese hosts proposed a lake excursion in a very American style Mississippi paddle boat steamer».

«These meetings were not always free of mishaps. During our 1989 Montreux Steering Committee in Switzerland the host company representative given responsibility for organising the closing dinner, no doubt in an effort to limit costs and impress his superiors, invited the delegates to an inn whose culinary standard could only be described as «average». The chosen meal – a greasy raclette, which is melted cheese served with boiled potatoes and cold meats – was particularly average. The raclette did not agree with everyone’s digestive system, and the president of the host company did his best to put on a bright face and salvage the evening. All the while he was gritting his teeth and casting his eyes out over the congregation, looking for his minion who had booked the inn».

Over the past 20 years GIIGNL’s membership has grown strongly. Today the Group has 74 member companies in 24 countries worldwide. The membership comprises nearly all the companies active in the Comprehensive Overview of LNG Import Projectsimport of LNG or in the operation of LNG import terminals. By region, 32 of the members are from Asia, 32 from Europe and 10 from the Americas, including North and Latin America.

It is a non-profit organisation and its resources only come from the membership fees. The association constitutes a forum for the exchange of experience among its members, with the goal of enhancing the safety, reliability and efficiency of LNG import activities.

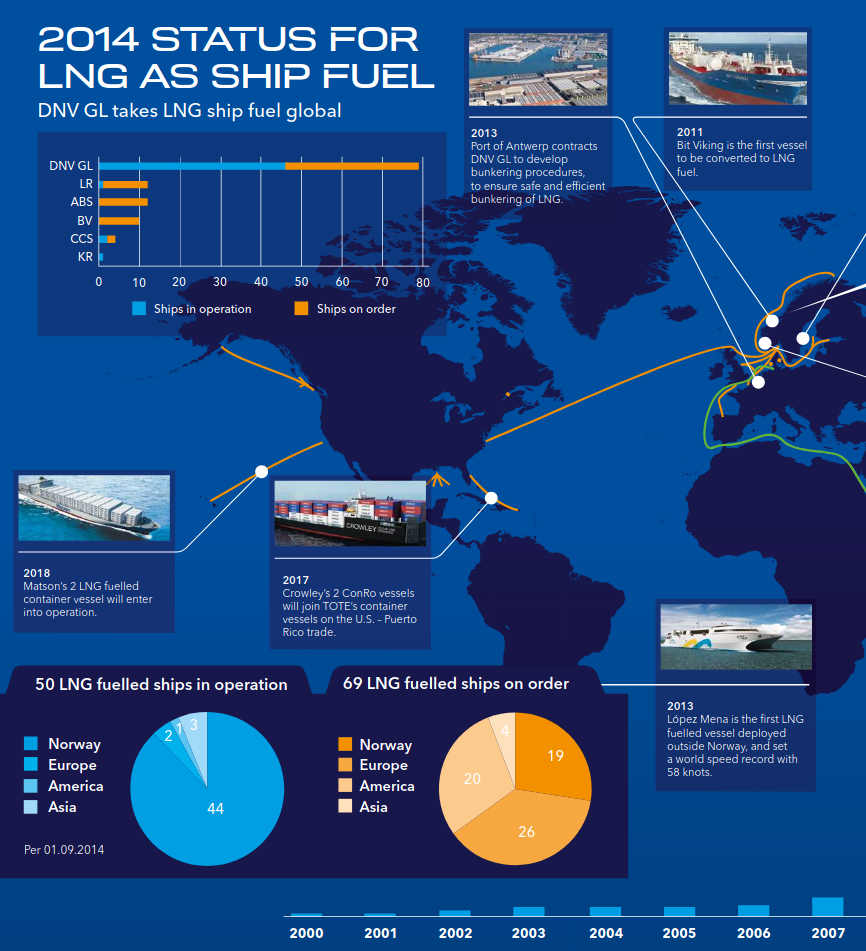

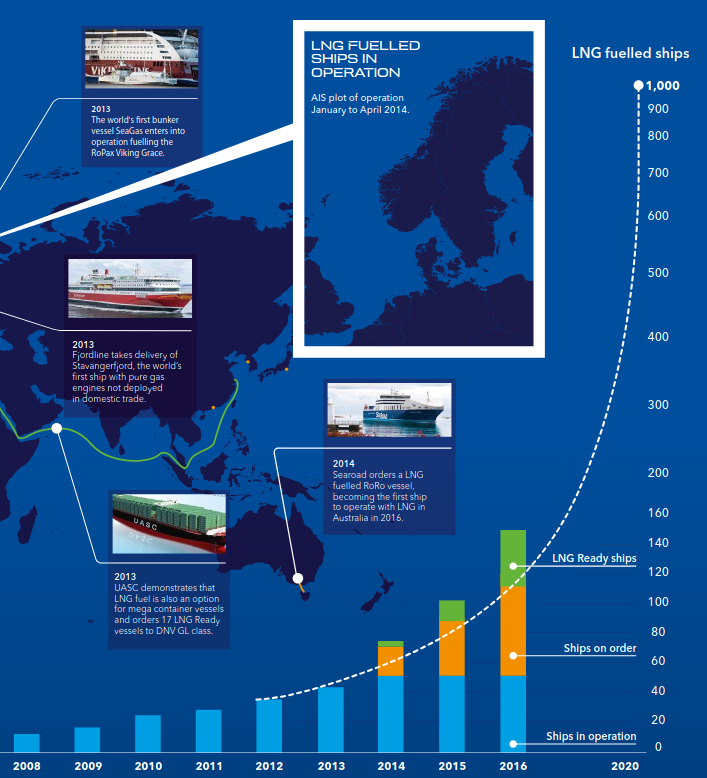

Important events:

- 2000 – The first LNG fuelled ship Glutra enters into operation.

- 2001 – DNV publishes the first rules for gas fuelled ships.

- 2010 – IMO Interim Guidelines for gas fuelled ships is developed based on DNV rules. Enabler for design and operation of LNG fuelled ships worldwide.

- 2011 – DNV recognises the need for a standard for LNG bunkering and initiates an ISO working group. ISO TC 67 – Guidelines for systems and installations for supply of LNG as fuel to ships is finalized in 2014.

- 2013 – DNV GL launches the LNG Ready concept, which is quickly pickedup by the industry. DNV GL launches Recommended Practice for LNG Bunkering, providing the industry with the first practical tool for developing bunkering procedures.

- 2014 – NYK places order for a purpose built LNG bunker vessel (5 100 m3), that will operate out of Zeebrugge from 2016. Several more orders for bunker vessels are imminent. The IGF Code is scheduled for completion and will reduce uncertainty for LNG fuel designs.

- 2015 – The 0,10 % sulphur limit for SECAs will enter into force and accelerate the uptake of LNG fuel.

- 2016 – IMO NOx Tier III will take effect in the North American ECAs, further increasing the rationale for choosing LNG for new ships that intend to have any extent of operation here.

- 2020 – The global sulphur limit of 0,50 % will enter into force, pending a fuel availability review in 2018, and will drive uptake of LNG fuel in the deep sea segments. Enforcement in EU is not subject to the availability review.

IGC Code revision reflects great changes afoot

Developing the international regime governing gas carrier design and equipment has required two monumental efforts – at its birth and during the current revision.

In the early 1970s the Inter-governmental Maritime Consultative Organization (IMCO, the earlier name for IMO) was preparing an international code covering the construction and equipment of ships carrying chemicals in bulk. The nascent gas shipping community, aware of the need for a similar set of harmonised provisions for gas carriers, began to make representations to IMCO.

Up until that point shipowners and shipbuilders had relied on classification society rules to guide their design and construction work. The US Coast Guard (USCG) was a national maritime administration that also played a key role in laying down standards for gas ships. Before a gas carrier could enter a US port, it had to undergo a rigorous inspection by USCG staff and be issued with a Letter of Compliance. Like the class societies, the technical branch of the Coast Guard was struggling to keep pace with the rich variety of ship and containment system designs being introduced into the vibrant new gas carrier market.

IMCO, too, realised there was a need for a unified approach and in September 1971 the first meeting was held of a Ship Design Sub-committee ad hoc working group tasked with defining the general format and scope of the proposed gas code, including the type of ships to be covered. The working group, under the chairmanship of the USCG’s Bob Lakey, continued its deliberations for four years, until 1975.

Progress was facilitated by the class societies agreeing to work together, under the auspices of the International Association of Classification Societies (IACS), to help prepare universally agreed code chapters on cargo containment, cargo handling and materials of construction. The societies had done the early work in developing gas carrier design and construction criteria and in helping those bold shipowners launching pioneering projects. It was essential for IMCO and its efforts to develop a harmonised code to have the societies onside and speaking with a common voice.

The Organization’s work was also supported by industry associations and technical bodies and their input was coordinated through the maritime administrations of certain IMCO member states. For example, the membership of a new USCG group that was to eventually become the Chemical Transportation Advisory Committee (CTAC) included:

- a vast range of organisations, not least the American Gas Association (AGA);

- and the Society of Naval Architects and Marine Engineers (SNAME).

The International Chamber of Shipping (ICS) and the UK Chamber of Shipping channelled their contributions to the IMCO deliberations via the UK Department of Trade.

Drafting work on the code was completed and a text agreed at an October 1974 meeting of the ad hoc working group. This set the scene for the adoption, at IMCO’s Ninth Assembly in November 1975, of the Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk, known as the GC Code. Governments were recommended to incorporate its provisions, which covered new ships built from 1976 onwards, into their national regulations as soon as possible.

periodically serving as regasification vessels (FSRUs)

To cover ships already in service another instrument, the Code for Existing Ships Carrying Liquefied Gases in Bulk, known as the Existing Ship Code, was introduced within a year of the first code. While mirroring the initial document in many respects, the new code recognised that there were areas where it would be neither easy nor cost-effective to bring existing ships into compliance with the provisions for new ships.

The international regime governing gas carrier construction and equipment has been updated over the years. The GC Code was a voluntary instrument but in 1983 the provisions for new ships were made mandatory with the adoption by IMO, the name for IMCO since 1982, of what was in effect a new code. The provisions of the International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk, popularly known as the International Gas Carrier Code, or IGC Code for short, govern vessels whose keel was laid on or after 30 June 1986.

Over the two decades following its adoption the IGC Code was amended several times. However, during the first decade of the new millennium the pace of change in gas carrier design and equipment accelerated. Shipboard reliquefaction and regasification of LNG were introduced, as were commercial ship-to-ship transfers of liquefied gases, new propulsion systems, new cargoes, sophisticated automation systems and a greater range of gas carrier sizes. It was clear that the next revision of the Code would require a much more extensive work programme than had previously been the case.

At its 83rd Session in October 2007 IMO’s Maritime Safety Committee (MSC 83) agreed to include in the work programme of the Bulk Liquids and Gases (BLG) Sub-committee a new, high priority work item entitled Revision of the IGC Code. In keeping with the strategic approach IMO is now taking with the development of regulations, the revised Code was to be «goal-based» in its approach.

At its 12th session in February 2008 BLG (BLG 12) agreed to a proposal by the UK that the industry itself conduct the revision, a departure from normal IMO procedure. In fact it was the first time that IMO had allowed industry to draft a document outside the Organization’s direct control.

To initiate the revision of the Code a broad cross-section of industry representatives was brought together to establish a steering committee to oversee the work. The UK chaired the steering committee and SIGTTO provided secretarial support. The steering committee consisted of 19 senior industry representatives and oversaw the work of 10 working groups, each of which examined and revised different sections of the Code. Progress with the revision of the IGC Code was reported back to relevant IMO committees and sub-committees on a regular basis.

The working groups consisted of experts from classification societies, liquefied gas ship operators, shipyards specialising in the construction of liquefied gas ships and designers of ship systems and equipment. This participation translated into a wide range of industry coverage, as follows:

- Owner and operators controlling 51 percent of the world’s gas carrier capacity.

- Classification societies with 98,5 percent of the gas carrier fleet on their registers.

- Shipyards responsible for 33 percent of the world’s LPGC construction capacity and 44,8 percent of the world’s LNGC capacity.

A total of 39 working group meetings were held in 14 countries during the 26-month period it took to complete the work of drafting the revised IGC Code. The steering committee met six times to review progress, offer guidance and direction, and agree on the final draft to be submitted to IMO.

The draft revised Code was received by IMO in November 2010. It then went through various IMO committee and sub-committee reviews before being adopted at MSC 93 in May 2014. It will enter into force on 1 January 2016, with an application date of 1 July 2016. This gap between entry-into-force and application dates is to minimise the effect on existing shipbuilding contracts. In practical terms the revised IGC Code applies to ships with keels laid, or at a similar point of construction, on or after 1 July 2016. It is not to be retroactively applied to the existing fleet of gas carriers.

A number of important changes are included in this new revised edition of the IGC Code. These can be summarised as follows:

- New IGC product data reporting introduced.

- Concept of tripartite agreement introduced for carriage of cargoes that fall within the scope of the revised Code but are not specified in Chapter 19 of the Code.

- Location of cargo tanks changed so that separation of cargo tanks from side shell is increased. Separation is now to be between 0,8 m and 2,0 m, as a function of the volume of the individual tanks.

- Provides guidance for gas carriers periodically serving as floating LNG production (FLNG) vessels or floating storage and regasification units (FSRUs).

- New sections addressing internal turret compartments and associated systems.

- Provides guidance for limit state design for new containment system designs.

- New, detailed emergency shutdown (ESD) system requirements.

- Provides requirements for high-pressure fuel gas systems and for gas- fired internal combustion engines.

- Requirements for thermal oxidation of vapours, which include boilers and gas combustion units (GCUs).

- Provision for sequential lifting to reduce the amount of vented cargo, as well as a requirement for emergency isolation of pressure relief valves (PRVs).

- Expands on requirements to prevent backflow in the inert gas system and adds a requirement to monitor the quantity of inert gas flowing into individual insulation spaces.

- Alignment of electrical installation requirements with IEC 60092, Electrical installations in ships.

- Alignment and reference to other applicable IMO codes and guidelines, such as the Fire Safety Systems (FSS) Code.

- New sections on automation systems and systems integration.

- Requirements for ventilation systems, vent systems and gas detection systems enhanced.

- Incorporation of applicable IACS Unified Interpretations, the most significant of which covers justification for permitting filling limits greater than 98 percent. A maximum filling limit of 99,5 percent is specified.

- Requires a Cargo Operations Manual.

- Adds requirements for new cargoes.

SIGTTO and GIIGNL in partnership

The LNG import terminal ship/shore interface is where the interests of the SIGTTO and GIIGNL memberships come together and prompt wide-ranging cooperation.

The nature of the objectives and the memberships of the Society of International Gas Tanker and Terminal Operators (SIGTTO) and the International Group of Liquefied Natural Gas Importers (GIIGNL) means that the two organisations share considerable areas of mutual interest. This alignment also means that SIGTTO and GIIGNL regularly work together on projects and initiatives of common interest to their memberships.

Both SIGTTO and GIIGNL were established in the 1970s as non-profit organisations. Both bodies have grown in tandem with the industry, and the rapid pace of change over the past decade has ensured that the areas of mutual interest and cooperation are greater than ever before.

SIGTTO was established in 1979 to promote liquefied gas shipping and terminal operations which are safe, environmentally responsible and reliable. GIIGNL, which held its first meeting in 1971, was formed to enhance the safety, reliability and efficiency of LNG import activities, and in the operation of LNG import terminals in particular. It is at the ship/shore interface, when an LNG carrier is at an import terminal delivering cargo, that the interests of the two associations overlap.

For several decades after the birth of the industry there was little variation at such ship/shore interfaces. Conventional-size LNG carriers would shuttle between dedicated terminals under long-term contracts. Ship and terminal staff involved with a particular project became very familiar with each other.

In more recent years, however, great changes have occurred in the industry and these changes have introduced new dimensions to operations at the ship/shore interface. Quite aside from the rapid rise in short-term and spot cargo movements, the LNGC fleet now contains mega gas carriers as large as 266 000 m3 and coastal tankers as small as 1 100 m3.

Import terminals are now gearing up to handle a much wider range of LNG carrier sizes as well as a new generation of LNG bunker vessels. Another type of import terminal becoming increasingly prevalent is the floating storage and regasification unit (FSRU), and such facilities often require the use of LNG Ship-to-Ship Transfer Processship-to-ship transfers of LNG from visiting delivery tankers.

The good relationship that SIGTTO and GIIGNL have enjoyed over the years has strengthened in response to the expansion and diversification of the LNG industry. The two bodies meet on regular occasions and exchange views on safety issues as well as information on their respective current projects.

Over the years topics which have been jointly covered by both SIGTTO and GIIGNL include:

- Gathering of LNG industry data.

- Ship/shore compatibility.

- LNG terminal and ship security.

- LNG quality, weathering and quality adjustment.

- Small-scale LNG.

- Specificity of the LNG industry.

- Guidance for the use of the Panama Canal.

GIIGNL sits on SIGTTO’s General Purposes Committee (GPC) and each organisation has nominated members to sit on those working groups established by its opposite number that are considering issues of mutual relevance.

Both SIGTTO and GIIGNL are part of the Protocol of International LNG bodies, which is an agreement between international gas organisations on cooperation and information sharing. This group last met in Geneva in April 2014.

This LNG Shipping at 50 magazine is the latest example of cooperation between the two organisations. SIGTTO and GIIGNL are pleased to be joint sponsors of a publication they hope will be enjoyed by not only both their memberships but also the LNG industry at large.

Class underpins LNGC safety record

Although class society rules are empirical, in the early days of LNG carrier design there was no experience on which the required standards could be based.

Back in the 1950s, when new LNG carrier design proposals were being considered, a face-to-face, roundtable discussion between designers, the shipbuilder and the classification society’s technical staff was a common occurrence. In the early years class societies were in a fortunate position in that submissions of plans for approval were being made from various sources. They were able to discern whether any patterns of consistency in LNGC design were emerging.

Early class society work on rule development was augmented by the efforts of government agencies in some of the importing countries. The Italian Ministry of Merchant Marine, the Japanese Ministry of Transport and the US Coast Guard (USCG) had each drawn up their own operational requirements.

The USCG published tentative standards in August 1959 for the transport of liquefied flammable gases at atmospheric pressure. In 1965 the Coast Guard’s exacting Letter of Compliance programme was initiated. The Japanese Ministry of Transport required fitness certificates for gas ships trading in Japanese waters.

In 1970 the Italian Ministry of Merchant Marine published provisional rules for the carriage of liquefied gases in bulk in Italian waters. Ships were required to have a fitness certificate from the Italian maritime authority. Existing ships could generally comply with the Italian rules but a requirement that did catch some out was the need for lightning conductors or suitable lightning copper nails to be fitted at the vent masts tops.

Back in 1930 some small research projects had been undertaken in the US and the UK on uninsulated pressure vessel tanks used on ships for the carriage of butane and propane. Both the American Bureau of Shipping (ABS) and Lloyd’s Register of Shipping (LRS) were involved in assessing these new ideas.

LRS followed up this work by classing the first purpose-built LPG carrier, Agnita. The vessel was delivered to Anglo-Saxon Petroleum, a Shell affiliate, in 1934 from the Hebburn yard of Tyneside shipbuilder Hawthorn Leslie.

During the 1950s ABS and LRS made significant progress in understanding the techniques required to transport LNG by sea. These advances were made possible as a result of the pioneering LNG research work in the US and an extensive study by British Gas on the feasibility of transporting LNG from Venezuela to Britain.

On 26 January 1962, as the society’s Notice No 2182 indicates, LRS added a new Section 70 to its Chapter D Steel Ships rulebook. Section 70 laid down provisional requirements for the carriage of liquefied petroleum and natural gases at or near atmospheric pressure.

In March of the same year a paper entitled The Carriage of Liquefied Petroleum and Natural Gases by principal surveyor J B Davies was presented to the Lloyd’s Register Staff Association in London. The Association had been established to advance and disseminate within LRS knowledge of current shipbuilding and marine engineering problems and issues.

Appendix II of the Davies paper contained an example of calculating methane tank scantlings, complete with formulae for acceleration, and dynamic and static loading. Despite the stated restriction of this information to LRS members and technical staff, the paper was widely circulated and used, with biblical reverence, by naval architects to determine cargo tank scantlings.

In the period 1954-56, during the early phases of the development of the Methane Pioneer project, the USCG was assisted by an industrial advisory group. Established within the framework of the American Petroleum Institute (API), the group contributed to the drafting of preliminary regulations for cryogenic tank vessels. ABS participated in this activity and contributed to the formation of some of the basic principles of LNGC design.

At the time, ABS rules had requirements for refrigerated cargo installations for ships carrying refrigerated foodstuffs. However, these rules were not applicable for ships intended to carry LNG. To fill the gap, ABS introduced a new Section 24 in the 1970 edition of its rules specifically covering the construction and classification of steel vessels intended for the carriage of liquefied gases.

The French classification society Bureau Veritas (BV) has been closely associated with the development of gas carriers since the very beginning of this new technology. The society’s early involvement began in 1953 with the classification of various pressurised LPG carriers built in Europe, mainly under the French and Danish flags.

In 1958 BV became the first class society to publish special recommendations for LPG carriers in its rules. These provisions were drawn up for vessels involved in the carriage of liquefied gases such as butane and propane at full pressure. BV followed this up with the publication of a guidance document entitled Technical general conditions governing the sea transportation of liquefied natural gas in 1962. To assist in the compilation of the guidance document, the Paris-based society had established, within its naval technical committee, a special commission made up of representatives from Gaz de France, shipowners, shipbuilders, steel manufacturers and other interested and duly qualified persons.

Det Norske Veritas (DNV, now DNVGL) has had gas carriers in its class since the late 1940s. Hydro and Herøya, a pair of 1 454 m3 anhydrous ammonia carriers, were converted on behalf of Norsk Hydro in 1949 and 1950. The early DNV work on gas carriers was formalised in July 1960 when its research department published a document entitled Preliminary recommendations for the design and construction of ships for the transport of liquefied gas.

DNV’s first comprehensive rules for gas carriers were published in 1962 in its Rules for the construction and classification of steel ships as «Chapter XIV – Recommendations for the design and construction of ships for the transport of liquefied gas».

In the early 1960s DNV’s director of research Egil Abrahamsen was to the fore in presenting the extensive guidance on the classification of gas carriers compiled by his society. His paper Special Ships for the Transport of Liquefied Gas, from the Classification Viewpoint was heard in Oslo in 1960 while Gas Transport and Ship Classification was presented to API in 1963. Another paper, The Carriage of Special Liquid Cargoes, was delivered to an audience in Sandefjord, Norway in 1964.

Nippon Kaiji Kyokai (ClassNK) developed its rules for refrigerated and pressure-type gas carriers in 1959. Goshu Maru, the first ship classed with NK to carry LPG, was delivered by Mitsui Engineering and Shipbuilding in October 1961. This ship was a combined crude oil and LPG carrier with five fully refrigerated prismatic LPG tanks providing a total capacity of 11 300 m3. The ship design, in which 90 percent of the available space for cargo was devoted to crude oil, was based on guidance plans from Esso and the ship was dual classed with ABS.

Registro Italiano Navale (RINA) published its rules for ships transporting liquefied gases in pressure vessels in 1966. The rules were based on the society’s experience during the building of six fully pressurised LPG carriers built in Italy since 1956. During the construction of these small gas carriers RINA had generally relied on its rules for oil tankers. The new 1966 rules specifically addressed Understanding Liquefied Gas Manifolds – Size Categories, Positioning, and Specific Designs for LPG & LNGgas carrier cargo tanks, piping and vent systems as well as other safety features.

Classification societies took on board the recommendations of the IMCO Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk after it was published in 1976. Most class societies had taken an active part in developing the Code’s recommendations. By the time this set of provisions became the IMO’s International Gas Carrier (IGC) Code, class societies had incorporated the essence of the Code’s recommendations into their rulebooks.

The success, progress and exemplary safety record of LNG carriers over the past 50 years owes much to class societies. The dedication, co-operation and foresight of their technicians, researchers and surveyors have been unparalleled.

Training – the bedrock of safe LNGC operations

Chris Clucas shows how the seeds of today’s sophisticated LNG carrier training regime were sown right at the start of this enterprising and challenging new industry.

However tentative it may have been in its earliest days, LNG transportation took hold quickly and went on to become a great success – both technically and commercially. LNG offered a clean and attractive alternative to gas derived from coal gasification or naphtha reforming and to other hydrocarbon fuels. The investment in liquefaction plant and shipping enabled companies to cash in on gas assets that were otherwise stranded or flared. This became increasingly important as environmental concerns developed and oil reserves became scarcer.

The pioneering exports from Algeria, Libya and Alaska were soon joined by those from Brunei, Abu Dhabi and Indonesia and within the short span of 10 years the global LNG trades had developed into the pattern we recognise today.

The subsequent expansion of these trades was more evolution than revolution. The industry favoured established commercial practices, proven liquefaction plant technology and reliable ship designs. Ship size increased only marginally over the first quarter of a century, in tandem with discreet rises in LNG production plant capacity. The conservative approach was understandable, as the industry gained familiarity with what is a challenging cargo and accommodated a relatively slow buildup in trade in the 1970s and 1980s.

LNG presents certain risks when carried as a cargo in significant volumes. Its vapours are flammable and its cryogenic carriage temperature of -162 ˚C requires special precautions. The shipping industry realised early on that if LNG was to gain and maintain a place in the global energy mix, safety would have to be given top priority. A measure of the success of the LNG shipping industry’s ongoing commitment to minimising risks is the exemplary safety record achieved over the past 50 years.

If asked what makes the LNG business unique and why a quality training regime is so important, there is no need to look beyond the ships themselves. From the birth of the industry LNG carriers have always been regarded as rather special. They are, in effect, a «floating pipeline», linking gas exporters and importers where no pipeline alternative exists.

Also, given the very nature of the trade – which is closely linked to the fuel requirements of public utilities – the reliability of LNG deliveries has always been of paramount importance. The need to provide a continuous, seamless flow and to keep the supply chain functioning according to tight contractual terms is one of the key differences between LNG ships and most other liquefied gas carriers.

The highly engineered systems and equipment needed to contain and handle large volumes of valuable, cryogenic cargo make LNGCs expensive ships. In the early days it was possible to build seven (single-hull) very large crude carriers (VLCCs) for the price of a single LNGC. The high cost of entry ensures that the LNG domain is open only to the committed shipowner.

Early LNG carriers were steam turbine-driven vessels of relatively small size, in the 25 500–75 000 m3 range. The relatively high cargo tank surface-to-volume ratio and the insulation technology at the time meant there was a comparatively high cargo boil-off gas rate to deal with. In order to avoid wasting this valuable product, it was used as propulsion system fuel in the ship’s boilers. Because ship service speeds were usually chosen to match fuel availability, this led to service speeds that were higher than the average for the time.

Of course, most of the LNG carriers ordered today are dual-fuel motor ships and managing these propulsion systems requires a completely different set of engine room skills. At the same time, steam ships still account for the largest part of the fleet, so the industry’s retention of a body of engine room staff familiar with the operation of steam turbines is essential.

Given the international nature of the shipping industry, it is perhaps surprising to note that IMO’s first set of provisions aimed at standardising maritime training worldwide was not introduced until 1978. However, for gas carrier operators this Standards of Training, Certification and Watchkeeping (STCW) Convention proved to be an excellent example of joined-up thinking.

The «Lakey Group» had just completed the International Gas Carrier (IGC) Code under the auspices of IMO and the International Chamber of Shipping (ICS) had likewise just published the ICS Tanker Safety Guide (Liquefied Gas). The establishment of SIGTTO was to follow in 1979.

The IGC Code recognised that operations onboard many liquefied gas carriers involve product flows, something not usually encountered on other cargo ships. This situation is recognised in the IGC Code in a special chapter on operational requirements, an unusual inclusion for a code dedicated to design, construction and equipment standards.

The draft syllabus for gas carrier training in the STCW Convention was reviewed and amended by the Lakey Group. This contribution ensured that the training courses would match the gas carrier equipment requirements.

While STCW may have formalised and harmonised gas ship training, the practice had begun long before work started on the STCW Convention. The Methane Pioneer crew for the historic 1959 trial shipments were selected from the sea staff of Stephenson Clarke, a venerable British shipping company dating back to 1730. While this Methane Pioneer crew may have been much more familiar with the coastal coal trades, they were highly competent seamen.

Furthermore the cargo equipment on the vessel was handled exclusively by a team of chemical and gas engineers familiar with the liquefaction of natural gas and industrial air gases, including on behalf of the NASA space programme in the US. These engineers were augmented on the transatlantic runs to Canvey Island by some naval architects from the group that designed and built the ship’s containment system.

There was so much at stake for this trial Methane Pioneer programme that training was seen as an essential and integral part of the process of transporting LNG by sea. This philosophy has been retained up to the present. Excellence in training goes hand-in-glove with excellence in operation, and smooth operations provide the LNG shipping industry with its license to operate. That commitment starts at the top, with a shipping company’s senior management, and encompasses a variety of shore staff.

The key purpose of any LNG training course is to explain how to operate the ship safely. This in turn requires a certain level of understanding of the fundamental chemistry and physics of gases. After these basic concepts are understood, it is much easier for officer trainees to comprehend how equipment functions and why cargo-handling operations are carried out in certain ways and sequences.

Familiarity with the cargo’s chemistry and physics similarly facilitates an understanding of first aid, safety equipment and gas detection. An appreciation of the cryogenic nature of LNG also leads to an appreciation of the effects of a cargo spillage on the conventional parts of the ship’s structure.

The standards laid down in IMO’s STCW Convention are deemed to be the minimum acceptable for the shipping industry. To bridge the gap perceived to exist between classroom training and practical experience, SIGTTO led an initiative to develop «competency standards» for LNG carrier crews some 10 years ago. A strong driver for this initiative was the accelerating pace of change in the LNG industry and the need to maintain operational standards during a period of rapid expansion.

The resultant SIGTTO Competency Standards set out the underpinning knowledge required and what the ship officer needs to know in order to achieve the effective performance required in carrying out a particular operation. The standards also recognise the interdependence of different departments, e. g. between the deck and engine room teams when gas vapour from the cargo tanks is supplied as fuel for the propulsion system.

Read also: Harnessing LNGC Longevity – Strategies for Sustainable Energy Transportation

This emphasis on «input and output» in the SIGTTO Competency Standards was ahead of its time in many ways and is now seen as an effective way of setting out training standards. As part of the overall initiative, SIGTTO developed Competency Standards for Steam Engineers. The Society recognised the limited availability of guidance for maritime educational faculties in setting up steam training courses. Quite simply, there are very few steam engineers available today who can serve as instructors and pass on their specialist practical experience.

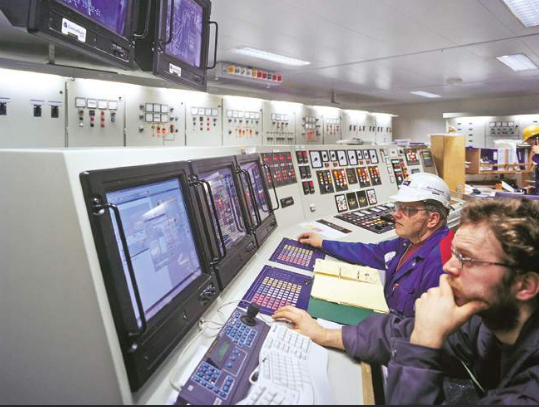

Highly sophisticated cargo-handing simulators are an important part of today’s training regime and, most recently, the applications have been made compatible with laptop computers. This development has brought highly realistic simulation training within even easier reach of LNG industry participants. Amongst other things, simulators enable students to become familiar with new technologies in a safe environment and to try out possible alternative scenarios that would be unthinkable onboard a trading LNGC.

The LNG shipping industry is poised at the start of another period of rapid expansion. While this will no doubt dilute overall experience levels, it will also open the market to further advances in technology. Innovation has already started to make itself apparent in recent years, in:

- terms of floating LNG production vessels;

- small-scale LNG carriers;

- LNG bunkering vessels and LNG-powered ships of all types.

In such circumstances the demand for training will increase markedly. A sound LNGC training regime has been established over the past 50 years and is available for participants to not only make use of in the most appropriate way but also help fine-tune and update for the benefit of the industry as a whole. Seafarer training should not just be limited to the refining of operational skills. We also need to identify and nurture the leaders of the future.

Group fleet director at Bernhard Schulte Shipmanagement Group, Chris Clucas has enjoyed a long and varied career in the LNG and LPG shipping business, including extensive experience delivering training courses around the world.

LNGC fit-for-purpose assessments

Amongst the intangible benefits of ship vetting programmes are the improvements in the quality and safety of ships and crews that can accrue.

The vetting of LNG carriers has not become an integral element of the operation of such vessels until relatively recently. In the early days LNG ships would be engaged on long-term projects shuttling cargoes between dedicated terminals, and charterers would be extremely familiar with the ships they employed and their general condition and performance.

In the late 1990s, however, spot cargoes and short-term contracts began to feature in the LNG trades, and vessels began to call at terminals they had not previously visited. In the circumstances charterers, buyers, terminal operators and sellers needed to assure themselves that the condition, operation and ownership of any third party vessel they were considering making use of was up to an acceptable standard.

For guidance the LNG industry turned to the oil tanker, chemical tanker and LPG carrier sectors, where short-term trading and spot voyage fixing was prevalent and where a sophisticated ship vetting regime was in place.

Companies involved in those sectors were acutely aware of the perils that attached to the employment of a tanker or LPG carrier subsequently found to be substandard. If such a vessel was to be involved in an accident that jeopardised lives, property and/or the marine environment, their reputations could be irretrievably damaged. They established vetting departments whose sole purpose was to assess the quality of ships and their management. This data could then be measured against their own in-house acceptance criteria to determine if a candidate ship should be selected.

In 1993 the Oil Companies International Marine Forum (OCIMF), the industry body representing users of tankers, developed the Ship Inspection Report (SIRE) system as a voluntary, industry-wide programme to assist in the vessel vetting process. SIRE is a very large database of up-to-date information about tankers, based on vessel inspections carried out by independent, third party specialists qualified and certified to undertake such work. While SIRE reports cover the external condition of a ship and the standard of operations onboard, they are not structural surveys and do not cover inspections of internal or void spaces.

The SIRE system has been taken up by the LNG shipping community as an important vetting tool. Amongst other things, the use of SIRE as a centralised system helps reduce the number of ship inspections required and eases the burden on ship crews.

But SIRE inspections are only one part of any vetting programme. The vetting team will also make use of relevant vessel information arising from classification society records, port state inspections, flag administration data, casualty records and the previous operational performance of not only the ship itself but also other vessels in the same fleet.

On a par with the condition of a vessel and the state of its operation is the standard of the vessel’s management. On the vetting department’s agenda will be a review of the management systems that the shipowner or operator has in place. Such reviews are carried out to assess the operational and technical competency of the company behind the vessel in question.

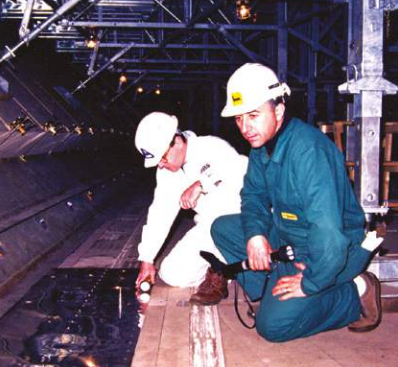

Another vetting consideration that has increased in importance in recent years, in tandem with the ageing of the fleet in general and some of the pioneering vessels in particular, is the structural condition of ships. The earliest ships have been put through life extension refurbishments at around 20 years of age to provide them with another long lease of life. As part of these rigorous life extension projects, the class society overseeing the work will provide the vessel with a Condition Assessment Programme (CAP) rating.

More and more vetting departments are requiring a CAP rating of at least a certain minimum standard before vessels of a certain age, type or size will be considered for employment. Although age is not necessarily an indicator of ship quality, its structural condition needs to be taken into account in the vetting process.

The third key element in the LNG carrier vetting process, besides the assessments of the quality of a ship and its suitability for the intended use, is the question of ship/shore compatibility. Factors that need to be considered are:

- compliance with local and national regulations;

- ship dimensions versus any terminal limitations;

- cargo-handling and mooring equipment;

- security arrangements;

- waterway restrictions;

- and weather conditions.

Furthermore terminal feedback can be utilised in ship vetting assessments and the process can be reciprocal.