LNG Imports Streamlining is revolutionizing the way we approach liquefied natural gas logistics. As regasification vessels become more advanced, they enhance efficiency and reduce turnaround times at ports. New players are entering the market, bringing innovative technologies and fresh competition that challenge traditional practices.

This shift not only improves operational effectiveness but also meets the increasing global demand for cleaner energy sources. With these developments, the LNG sector is poised for significant growth and transformation in the coming years. Ultimately, the streamlining of LNG imports paves the way for a more sustainable and responsive energy market.

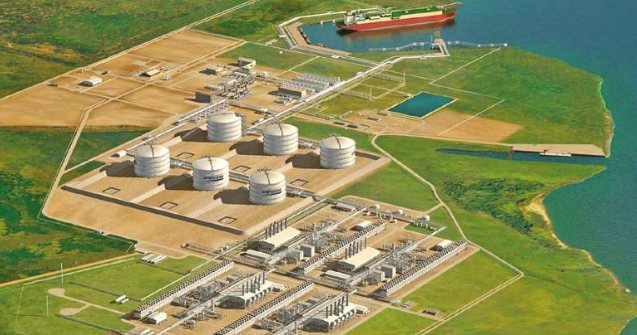

Regas vessels streamline route to LNG imports

In the space of 10 years regasification vessels have established themselves as a strong, low-cost and fast-track alternative to shore-based receiving terminals.

In 2000 El Paso Corporation began to explore the novel concept of shipboard LNG regasification. Known US gas reserves were dwindling at the same time that domestic consumption was rising and LNG imports were recognised as the best way of bridging any future gaps between supply and demand.

El Paso’s theory was that an offshore offloading system could be designed and built at far less cost than a shore-based facility and that, by delivering the product offshore in its gaseous state using a regasification vessel, expensive shore-based facilities could be eliminated from the transport equation. A regas vessel-based receiving facility would also enable LNG imports to begin more quickly than would be the case if a new shore terminal had to be built.

The company chose the Gulf of Mexico for its initial installation, selecting a site 180 km off the US Gulf Coast at the Louisiana/Texas border as the location of a deepwater port named Gulf Gateway Energy Bridge. The «port» itself would be invisible except for a small marker buoy fixed to a submerged turret loading (STL) buoy, itself linked to a subsea pipeline via umbilicals. A similar technology had been utilised for handling oil cargoes offshore in the North Sea for a decade.

On arrival at the sea marker the Liquefied Natural Gas Plant and Regasification Terminal Operationsregasification vessel would pull up the STL buoy and connect it to a moonpool arrangement in its bow. Regasification units mounted on the ship would then begin to process the LNG and pump the resultant natural gas to the shore grid via the subsea pipeline link.

The regas vessel would be supplied by LNG delivery tankers, and cargoes would be transferred in the open sea in a ship-to-ship (STS) operation using flexible cryogenic hoses. Because the regas vessel would be, to all intents and purposes, a conventional LNG carrier fitted with suitable regasification equipment, the ship could proceed to the export terminal to load cargo itself or even serve in the LNG trades until that time its regasification services were required.

In 2002 El Paso agreed to take on long-term charter three 138 000 m3 regasification vessels that Exmar of Belgium would order at Daewoo Shipbuilding & Marine Engineering (DSME) in Korea. The vessels, which were priced at approximately US $270 million each, would be owned and operated by Exmar. Advanced Production and Loading AS (APL) of Norway was contracted to provide the STL buoy required for the Gulf Gateway Energy Bridge deepwater port facility.

At about this time El Paso Corp had need to raise cash and it was decided that the Energy Bridge technology would be one of the assets put up for sale. Although one or two majors considered the offering, they decided to pass.

It was at this point that George Kaiser, an Oklahoma billionaire who had a strong belief in a bright future for natural gas in the US, stepped in to buy the technology and take over the Energy Bridge commitments made by El Paso. As part of the package Kathleen Eisbrenner and her El Paso team who had developed the concept moved over to join Kaiser’s newly established Excelerate Energy.

Excelerate Energy and Exmar went on to develop a strong relationship over the past decade and to record many regasification vessel «firsts» in the process. Excelerate now has a fleet of nine DSME-built regas ships, the latest being the 173 400 m3 Experience, delivered in April 2014. The other components of the fleet are the original three 138 000 m3 ships and five vessels of 151 000 m3. All are managed by Exmar, and both the Belgian shipowner and Excelerate hold 50 percent stakes in four of the regas ships. Excelerate fully owns the remaining five.

The Gulf Gateway facility was inaugurated in March 2005 with the delivery of a part cargo from the 138 000 m3 Excelsior, the industry’s first regas vessel. All that had been needed to bring the port onstream, besides the STL buoy, were some short lengths of pipe to a metering station installed on a nearby unused platform and to the existing gas pipeline network in the US Gulf. Gulf Gateway proved its resilience later in the year when Hurricane Katrina passed through the Gulf and the facility was the only terminal in the area that remained operational throughout.

Excelerate went on to install a similar facility, Northeast Gateway, on the US eastern seaboard, off the coast of Massachusetts. But at this point the US shale gas revolution was beginning and the country’s need for gas imports evaporated virtually overnight. Although the US Gateways were little used, Excelerate’s solution was much sought after elsewhere, proving the underlying strength of the floating regas vessel concept.

The configuration that has proved most popular is the company’s GasPort arrangement, in which the regas vessel is berthed at a dedicated jetty, either permanently or for a dedicated import season each year. GasPorts are usually provided with jetty-mounted loading arms for LNG transfers from the delivery tanker.

The next milestone for the Excelerate vessels was the first commercial STS transfer of LNG. This happened in the US Gulf in August 2006 and involved the transshipment of a partial cargo between two of the company’s regas vessels. This was followed in February 2007 by the first commercial transshipment of a full cargo, at Scapa Flow in the UK’s Orkney Islands. The receiving vessel, Excelsior, then proceeded to inaugurate the Teesside GasPort terminal by discharging the first regasified LNG directly into the UK national grid.

In June 2008 the Bahia Blanca GasPort in Argentina received South America’s first LNG cargo. Further GasPorts were commissioned in Kuwait in August 2009 and at Escobar on the Paraná River in Argentina in 2011. Because of the restricted water depth at Escobar, the operation requires STS transfers in the mouth of the nearby River Plate to enable the delivery of part cargoes to the terminal’s regas vessel in conventional size LNG carriers.

The other major players in the regasification vessel sector are Golar and Höegh LNG. Golar made its entry into the field with conversions of its existing ships. Five such conversions have been carried out to date and the company continues to own and operate four of the vessels as jetty-based floating storage and regasification units (FSRUs). Two are working in Brazil, one in Dubai and one in Indonesia. The first conversion, of the 129 000 m3, 1981-built Golar Spirit by the Keppel yard in Singapore, was completed in June 2008 and enabled Brazil’s first LNG imports.

The fifth Golar FSRU conversion, of the 138 800 m3, 2004-built, spherical tank Golar Frost, was the most ambitious. The ship was sold to the Italian company OLT Toscana and renamed FSRU Toscana. The modification work was undertaken by Drydocks World Dubai and involved the removal of the vessel’s propulsion system and the installation of not only regasification equipment but also a sophisticated turret yoke bow mooring system and deck-mounted loading arms. Designed to remain on station for 20 years, the FSRU marked a further breakthrough for offshore LNG when it went into service at a location off the Tuscany coast in autumn 2013.

Golar has extended its commitment to the regas sector through newbuildings. Three such vessels were ordered at Samsung Heavy Industries (SHI) in Korea in recent years. The first of these, the 170 000 m3 Golar Igloo, has been delivered and has gone into service in Kuwait while the 160 000 m3 Golar Eskimo is scheduled to go on station at Aqaba in spring 2015 to enable Jordan to commence LNG imports. The third FSRU newbuilding, the 170 000 m3 Golar Tundra, is scheduled for late 2015 completion. Golar is providing its newbuildings with regasification equipment capable of processing up to 5,5 million tonnes per annum (mta) of LNG.

Höegh LNG currently has two 145 000 m3 regas vessels on charter to GDF Suez. GDF Suez Cape Ann is serving as a receiving terminal at Tianjin in China while GDF Suez Neptune is earmarked for a similar, albeit temporary, role at Montevideo for Uruguay’s GNL Sayago project. The vessel will eventually be replaced by a 263 000 m3 FSRU that Mitsui OSK Lines (MOL) currently has under construction at DSME.

Höegh LNG has also been active on the newbuilding front. The shipowner has recently taken delivery of the first two of four 170 000 m3 FSRUs contracted at Hyundai Heavy Industries. The pair are being employed under long-term contracts as Indonesia’s second and Lithuania’s first LNG receiving terminal, respectively.

The MOL FSRU will be the largest such vessel when completed in 2016. Another newcomer besides MOL to the regas ship sector is BW Gas. The company has two 170 000 m3 vessels on order at SHI in Korea, the first of which is scheduled to go into service in the Dominican Republic on delivery in 2015. Exmar is building on its expertise in the sector and is promoting its non-propelled, barge-mounted regas floater design. The first such unit is under construction at the Wison yard in China.

Regasification vessels have come a long way in the space of 10 years. As of end-2013 there were 20 regasification projects in service or under construction, and global floating regasification capacity had reached 44,3 mta of LNG, 34 percent ahead of the previous year, in nine countries. By the end of 2015 a further eight The Evolution of LNG Importer Cooperation – Partnerships, Safety, and Future DirectionsLNG importing nations are expected to have regasification vessel-based terminals in place.

The blossoming of LNGC propulsion

Until a decade ago there was no serious alternative to steam turbines for LNGC propulsion. Today shipowners have four viable options available.

LNG carriers have been the last redoubt of the marine steam turbine industry. Until the early years of the new millennium every LNG carrier newbuilding was specified with a steam turbine propulsion system. While all other sectors of commercial shipping had long since been seduced by the greater propulsive efficiencies of diesel engines, LNG owners had stuck with steam turbines for several reasons, most notably their dual-fuel capabilities.

Cargo boil-off gas (BOG) generated during the course of an LNG carrier voyage can be burned in a steam vessel’s boilers as readily as fuel oil to generate steam. In addition turbines have proved to be extremely reliable throughout the history of LNG carrier operations. Their low maintenance requirements are another attribute.

Steam turbines are also able to handle any excess cargo boil-off gas by means of dumping surplus steam to the seawater-cooled condenser in the engine room. This capability means that low propulsion system loads pose no undue problems. It also obviates the need for expensive ancillary equipment such as reliquefaction plants and gas combustion units (GCUs).

However, just over a decade ago, on the verge of a major new growth phase for the LNG industry, Gaz de France (now GDF Suez) took the brave step of choosing a new LNGC propulsion system. The LNG industry was pushing to cut costs and improve efficiencies along the transport chain in order to improve the economics of gas projects. Ship propulsion had been identified as an area of potential savings, and investigative work on alternatives to steam turbines on LNG ships had been intensifying.

Through its Gazocéan shipowning subsidiary, Gaz de France ordered the first three LPGCs to be powered by dual-fuel diesel-electric propulsion (DFDE) systems. The newbuilding contract for the 74 130 m3 GDF Suez Global Energy was placed with Chantiers de l’Atlantique in February 2002 while orders for two 153 500 m3 sisters, Provalys and Gaselys, were placed with the same yard in September 2003 and July 2004, respectively. Complications with the innovative membrane containment system also specified for the three vessels delayed their delivery but they were all in service by March 2007.

Gaz de France was in a good position to pioneer DFDE propulsion because of the company’s control of the supply chains on which the vessels would operate. The three ships loaded cargoes at export plants where GDF had contracted supplies and delivered them to company-owned receiving terminals in France.

Nevertheless, despite the «in-house» nature of the employment, it was still a courageous move for an industry that was notoriously conservative. Gaz de France had been impressed by the performance of Wärtsilä’s 50 DF dual-fuel test engine and decided that, given the level of reliability and redundancy provided by the propulsion system, its improved efficiency compared to steam turbines would yield significant cost savings over the life of the vessels.

GDF Suez Global Energy was specified with four six-cylinder Wärtsilä 50 DF dual-fuel engines which provide an aggregate power of 22,8 MW and a service speed of 17,5 knots. In normal operating conditions natural BOG is complemented, when required, by forced BOG for use as fuel. The engines can run on marine diesel oil in situations where no gas is available.

The DFDE propulsion system quickly proved its ability and from the mid-2000s onwards the LNG shipowner community switched to DFDE systems for the greater part of its newbuilding requirement. Underpinning this shift was a growing awareness that DFDE systems outperform steam turbines on:

- cost;

- emission levels;

- fuel consumption;

- flexibility;

- redundancy and efficiency.

The propulsive efficiency of a steam turbine at full load, for example, is unlikely to exceed 30 percent whereas a 40 percent rating is typical for a DFDE system.

As of mid-2014, although there were 274 steam-powered LNGCs in service, the DFDE contingent had climbed to 67 ships and is growing much more rapidly. Of the 120 LNG vessels on order on 1 July 2014, 98 were specified with DFDE propulsion systems, 10 with steam, nine with low-speed dual-fuel engines and four with oil-fired diesels.

There is also a significant group of LNG vessels in service that do not utilise cargo BOG for propulsion. These are the 31 Q-flex and 14 Q-max ships delivered over the 2007-2010 period to Nakilat of Qatar. At 216 000 m3 and 266 000 m3, respectively, they are the largest LNGCs in the world.

When they were ordered the price of oil was relatively low and that of gas on the high side. Qatargas and RasGas, the vessels’ charterers, reviewed their options at the design stage and decided that a pair of oil-burning, two-stroke diesels, in combination with a powerful reliquefaction plant to process BOG and ensure the delivery of full cargoes, offered the optimum economic solution for the Q-flexes and Q-maxes.

As the ships were being delivered, however, the oil and gas pricing trends reversed, casting doubt on the wisdom of the propulsion system choice. The fuel price quandary has persisted, to the extent that Qatargas has decided to convert one of its Q-max vessels to dual-fuel running early in 2015 as a test case. Depending on the results, the propulsion systems on further Q-flex and Q-max ships could be similarly modified.

The conversion involves altering the configuration of the two MAN ME low-speed diesels on the ship to the engine manufacturer’s ME-GI gas injection type of unit. Gas is introduced into the engine at high pressure and the diesel displacement rate can be as high as 95 percent, leaving diesel’s contribution as a pilot fuel at 5 percent. MAN is seeking to reduce the amount of diesel pilot fuel required to as little as 3 percent.

MAN Diesel & Turbo reports that its ME-GI engine is not susceptible to the methane slip that other gas-burning engines have to contend with and, as such, represents an environment-friendly propulsion system choice. Furthermore the low-speed, gas-injection engine has a higher drive train efficiency than the DFDE configuration and, on the whole, is a less complex propulsion system.

The ME-GI engine has now also made a breakthrough into the LNGC newbuilding market, as the result of a December 2012 order by Teekay at Daewoo Shipbuilding & Marine Engineering (DSME) for a pair of 173 400 m3 ships. The shipowner has since exercised several options at the yard and will now have five ships in this series built with ME-GI propulsion systems. More recently two other shipowners have specified ME-GI engines for the pairs of LNGCs they have contracted.

ME-GI engines units have also been specified for eight LNG-powered container ships and car carriers currently under construction. MAN is taking the technology a stage further by developing alternative dual-fuel versions that run on LPG, methanol and ethane.

Each of the Teekay LNG carriers will have two 5G70ME-GI ultra-long-stroke, G-type engines, and MAN points out that the G-type’s longer stroke enables a reduction in engine speed and the use of larger diameter propellers. Such a configuration results in an especially high level of propulsion system efficiency. The engine manufacturer states that in recent years its conventional, heavy fuel oil-burning G-type unit has gained the fastest market acceptance of any engine in its portfolio.

That is not the end of LNGC propulsion system innovation. In November 2013 Wärtsilä unveiled its low-speed contribution to the melting pot. The 6RT-flex50DF is a new, low-pressure, two-stroke, dual-fuel gas engine. The engine manufacturer explains that in the gas-burning mode the 6RT-flex50DF is compliant with the IMO Tier III emission requirements without the need for nitrogen oxide (NOx) abatement equipment.

Furthermore it is claimed that the engine will provide capital expenditure savings of between 15 and 20 percent compared to other two-stroke gas engine technologies currently on the market. This is due, not least, to the fact that the 6RT-flex50DF can run solely on gas across the entire load range, thus obviating the need for an exhaust gas cleaning system. Also, because only low-pressure gas compression is required, the LNG and gas-handling system is substantially simpler and of lower cost than a high-pressure gas delivery system with heavy-duty compressors.

Within days of the official launch of the engine, Terntank Rederi A/S, a Danish-flag tanker operator, selected Wärtsilä RT-flex50DF engines for two 15 000 dwt, LNG-powered product tankers it ordered from the Avic Dingheng yard in China for service in the Baltic Sea. The engine was also chosen to power a 14 000 m3 coastal LNG carrier contracted in China in March 2014.

While orders for steam-driven LNGCs have become a comparatively rare occurrence over the past decade, there has been a modest resurgence of interest in this propulsion system in recent years. It is hanging on to a small segment of the newbuilding market as a result of the ultra steam turbine (UST) technology introduced by Mitsubishi Heavy Industries (MHI) in 2007.

UST, which promises a 15 percent higher propulsion system efficiency than a conventional turbine, has been chosen for eight LNG carriers ordered at MHI in recent years by Japanese owners as well as for a series of four LNGCs contracted by Petronas of Malaysia at Hyundai Heavy Industries in Korea. The first of the MHI newbuildings is set to enter service in the latter part of 2014 while the Petronas order marks the first market success for Mitsubishi’s UST system outside Japan. Petronas holds an option for four additional LNGCs of this design at Hyundai.

New players make the LNG leap

Independent owners have taken the opportunity offered by a surge in trade volumes over the past decade to establish a sizeable presence in LNG shipping.

The stakes are formidable for shipowners in the LNG sector. Newbuilding costs set the bar high for entry into the business and the lack of a long-term charter exposes the newcomer to the vagaries of the market and, potentially, if no immediate business is forthcoming, a rapid drawdown of available funds and financier goodwill. On the other side of the coin, if a lucrative term contract can be secured, the shipowner could be assured of a steady revenue stream not likely to be encountered in many other sectors of shipping.

In the early days of the LNG industry national shipping lines in the export countries became involved with the transport of their cargoes as soon as they were able, usually making use of the LNG carrier expertise of one of their international oil company project partners in the drive to get up to the necessary speed.

In the two top LNG importing countries, Japan and Korea, the leading shipping lines have long played a major role in those projects where cargoes are purchased on a free-on-board (FOB) basis. In Japan in particular, Mitsui OSK Lines, NYK and K Line have built a significant presence. Their pattern of sharing ownership stakes in individual ships and vessel management amongst the vast pool of vessels they operate on behalf of a range of Japanese utility companies is well established. The expertise of the Japanese trio is also now much sought after internationally, to the extent that they participate in a number of LNG shipping ventures outside Japan, both singly and in various combinations.

A decade ago the rather limited LNGC owner community was completed by a handful of independent owners, including Golar and Leif Höegh, with a long involvement in LNG transport. Their presence was relatively marginal, reflecting the slow pace at which the LNG industry had been expanding up to that point and the limited room to manoeuvre due to the presence of national shipping interests.

The new millennium brought with it the first sustained wave of growth in the LNG sector, both in terms of new projects and the expansion of the LNGC fleet. The surge opened up opportunities for new owners to become involved and a small group, with experience of LPG carrier and oil tanker operations, were quick to seize the opportunity. Most notable amongst the newcomers were Exmar, Maersk, Knutsen OAS and Bergesen, now BW Gas.

Exmar carved out a niche in the regasification vessel sector in tandem with Excelerate Energy. BW Gas, Knutsen OAS and Maersk built up their fleets through newbuildings backed by long-term charters. In the case of BW Gas the employment for their vessels was provided by Nigeria LNG and GDF Suez while Knutsen operated its newbuildings on behalf of Stream in Spain. RasGas of Qatar was the charterer of Maersk’s first LNG carriers.

The expansion of the LNG trades in the first decade of the new millennium was so great that there was room for yet more new players. The second wave can be summed up as the late arrival of Teekay and the emergence of the Greeks.

Teekay, a significant presence in the oil tanker and offshore sectors, announced that it was seeking to become involved in LNG shipping in late 2003. Within months it had secured an entrée through the acquisition of Tapias, Spain’s leading tanker company, with its four LNGCs and nine Suezmax tankers. This was quickly followed by an order for three 151 700 m3 newbuildings at Daewoo Shipbuilding & Marine Engineering (DSME) in tandem with Nakilat and for charter to RasGas.

Over the past decade Teekay has built is fleet through newbuildings and acquisitions, to the extent that it now owns or part owns 34 LNG carriers. Amongst the ships purchased were the four vessels from the fleet that Maersk sold as it exited the LNG sector. Teekay’s fleet is now the third largest in LNG shipping.

Teekay’s current LNGC orderbook includes five 173 400 m3 ships building at DSME that will be the first LNG ships to be powered by two-stroke, dual-fuel diesel engines with high-pressure gas injection. DSME is also constructing six 172 400 m3 icebreaking LNG carriers for a joint venture comprising Teekay and China LNG Shipping (CLNG). The latter sextet will be engaged in carrying Yamal LNG export cargoes from Sabetta in the Russian Arctic.

Although their entry into the LNG carrier field has been slow to materialise, Greek shipowners have been making up for lost time. The Greeks have always had a powerful presence in international shipping. Sixty years ago they helped lay the foundations for the modern tanker industry with the purchase of World War II-surplus T-2 tankers from the US government at knockdown prices. Larger-than-life entrepreneurs, or magnates, like Aristotle Onassis, Stavros Niarchos and George Livanos, emerged in the process. Today Greek independent owners, including some of the most famous names in shipping, control 20 percent of the world’s tonnage.

Greek involvement with LNG carriers began about 10 years ago when the Peter Livanos-controlled GasLog operation took on the technical management of a series of newbuildings for the BG Group. John Angelicoussis then upped the stakes by ordering five LNGCs, which were delivered during the 2005–07 period to his Maran Gas operation. Four of the ships are jointly owned with Nakilat and on long-term charter to the RasGas 2 project.

GasLog now has 15 LNG carriers in service and 10 on order. Fourteen of the vessels in the company’s in-service fleet are serving on multi-year charters while the remaining ship is currently engaged on a short-duration contract. The fleet also includes six ships that the company was previously managing on behalf of BG Group. They will remain on long-term charters with BG.

Maran Gas has also continued to be active in the newbuilding market. The company has 18 LNGCs on order, all of which will have TFDE propulsion systems. Fourteen of the total have been fixed on long-term charters with BG Group.

On delivery the newbuilding complement will join the 12 LNGCs that Maran Gas currently has in service. Eight ships in the existing fleet are jointly owned by Nakilat of Qatar. Maran Gas holds a 60 percent stake in the joint venture controlling these ships and Nakilat the remaining 40 percent.

Other Greek owners active in LNG transport are:

- Dynagas;

- Tsakos Energy Navigation (TEN);

- Cardiff Marine;

- Thenamaris;

- Almi Gas and Alpha Shipping.

Owned by George Procopioiu, Dynagas has seven LNG carriers in service and three on order. Of this complement, only the inaugural vessel, the 2007-built Clean Energy, does not have an ice class 1A notation. Two of the company’s ships, Ob River and Arctic Aurora, are the only LNG carriers to have completed passages of the Northern Sea Route between Europe and Asia along Russia’s Arctic coast.

Thenamaris, a leading operator of product tankers, joined the LNG sector with an order for three 160 000 m3 vessels at Samsung Heavy Industries. The trio, which will initially be technically managed and crewed by Bernard Schulte Shipmanagement, are currently delivering and all are expected to be in service by the end of 2014.

Cardiff Marine, controlled by George Economou, made its entrance into the LNG arena with a ship acquisition. The company purchased the 145 000 m3 Muscat LNG from Oman Shipping and renamed it Fuji LNG. Cardiff Marine went on to order four 159 800 m3 LNGCs at DSME and the first of these, Corcovado LNG, was delivered in spring 2014.

Tsakos Energy Navigation has one ship in service, the 150 000 m3 Neo Energy, delivered by Hyundai Heavy Industries in 2007, and a 174 000 m3 vessel on order at the same yard. The newbuilding, to be named Maria Energy, is due for completion in early 2016.

Costas Fostiropoulos has ordered a pair of 160 000 m3 LNGCs for his Almi Gas operation at DSME, a shipbuilder with which the owner has enjoyed a long association. Both newbuildings are due for delivery in 2015.

The last of the Greek newcomers to the LNGC field is Christos Kanellakis, owner of Alpha Tankers. The original play was a contract for a 160 000 m3 vessel at STX Offshore & Shipbuilding, following the conversion of an original order for a pair of capesize bulk carriers. An option was later exercised for a second LNGC but this has now been dropped. The Alpha Tankers newbuilding is due to be handed over early in 2015.

Between them the eight Greek shipowners have 38 active LNG carriers and 40 on order. When the last of the current orderbook is delivered, the Greek fleet will aggregate 78 LNG ships. That is quite a performance, considering that the first of these vessels only entered service in July 2005.

High-resolution snapshot of the global LNG trade

GIIGNL’s annual LNG industry reviews not only pinpoint all the notable trade, fleet and terminal developments but also provide some surprising insights.

The annual compilation of trade, fleet and terminal statistics published by the International Group of Liquefied Natural Gas Importers (GIIGNL) provides a succinct yet comprehensive overview of the state of the LNG industry for that particular year as well as a record of the most notable achievements and developments over the 12-month period. Because the organisation has been maintaining its log of all Managing Laden Voyages – BOG Management and Propulsion Systems for LNG CarriersLNG carrier voyages and cargo discharges completed each year for some considerable time, it is in a position to look back and trace how the global LNG trades and infrastructure have developed and, also, discern emerging trends.

The latest GIIGNL report, The LNG Industry in 2013, reports that the world trade in LNG last year was 236,9 million tonnes (mt). A review of the GIIGNL reports of 10 and 20 years ago shows that the comparable figures for 2003 were 125,2 mt while 61 mt was traded in 1993. LNG shipments have doubled over each of the last two decades and over the last 20 years international movements of LNG have grown by about 7 percent per year on average. At the end of 2013 approximately 10 percent of global demand for gas was met by LNG.

In recent years the number of countries and players involved in the LNG trades has increased dramatically. As regards importers, 29 countries received LNG in 2013, compared with 13 countries in 2003. A total of 104 LNG receiving terminals, including 15 floating storage and regasification units (FSRUs), were in operation at the end of 2013, compared with 46 in 2003 and 31 in 1993.

On the supply side, seven new countries have joined the ranks of LNG exporters since 2003. Egypt commenced exporting LNG in 2005, Equatorial Guinea and Norway in 2007, Russia and Yemen in 2009, Peru in 2010 and Angola in 2013. There were 86 liquefaction trains in operation in 17 LNG exporting countries at the end of 2013. Qatar has the greatest concentration of liquefaction capacity, with 14 trains able to produce an aggregate 77 million tonnes per annum (mta) in place at its Ras Laffan complex. Malaysia is in second place, the eight trains at Bintulu being able to produce a combined 25,7 mta.

The main feature of LNG trade in the last 10 years has been the tremendous growth in Asian demand. LNG volumes shipped to the region have more than doubled over the period, climbing from 83 mt in 2003 to 178 mt in 2013. Whereas Asia accounted for 66 percent of global LNG imports 10 years ago, the region was the destination for 75 percent of global movements of LNG in 2013.

Meanwhile Europe’s share of world LNG purchases declined from 24 percent in 2003 to 14 percent in 2013 while imports in the Americas remained stable at around 9 percent. The decrease in US imports was offset by rising volumes of LNG shipped to South America.

In terms of supply sources, the Middle East remained the biggest LNG export region in 2013, with shipments of 98,3 mt being equal to a 41,5 percent market share. The 87,9 mt exported from the Asia-Pacific region represented 37,1 percent of total shipments worldwide.

In 2013 Qatar supplied 33 percent of all LNG traded worldwide, followed by Malaysia with an 11 percent market share and Australia 10 percent. Shipments to the four North East Asia import nations of Japan, Korea, China and Taiwan accounted for 67 percent of all LNG moved by sea in 2013.

Collating this import and export data shows that the two major LNG trade flows are currently that from the Middle East to the Asia-Pacific region and intra-Asia-Pacific movements.

Switching to the LNG carrier fleet, at the end of 2013 there were 393 such ships compared with 152 in 2003 and 76 in 1993. The orderbook as of end-2013, at 113 vessels, indicates a surge in fleet growth over the next three years.

The average capacity of an LNG carrier has risen progressively over the period under review, from 102 000 m3 in 1993 to 117 000 m3 in 2003 and 143 000 m3 in 2013. Of the end-2013 fleet, 91 percent of the ships had a capacity above 90 000 m3 while 14 percent were above 170 000 m3 in size.

In comparison to the LNG carrier fleet of 10 years ago, today’s is younger. At the end of 2013 some 66 percent of the ships in the fleet were less than 10 years old. The comparative figure for the fleet of 10 years ago was 45 percent. In terms of containment systems, 68 percent of the LNG vessels in service at the end of 2013 were equipped with a membrane system, versus only 47 percent in 2003.

The emergence of new importers and exporters over the 50 years of commercial LNG shipping operations has created an elaborate matrix of shipping patterns. At the end of 2013 the world LNG trade involved 168 «flows» (country-to-country trades) over 423 sea transportation routes (port-to-port routes).

Focusing on more recent trade developments, 2013 was the third consecutive year of stagnation in global movements of LNG. In 2012 trade retreated by 1,9 percent, to 236,3 mt. Although 2013 did mark a return to growth, it was only a marginal expansion of 0,3 percent. Of the total trade in LNG last year, 65 mt, or 27 percent, was traded on a spot or short-term basis.

While the demand for LNG is robust, very little new liquefaction capacity has been commissioned in recent years. Shipowners have derived some benefit from an increase in long-distance shipments from the Atlantic Basin to Asia following the March 2011 earthquake, which forced the closure of Japan’s nuclear reactors. However, the pace of LNG carrier newbuilding deliveries has been picking up over the last 18 months and the fleet is facing a short period of oversupply, until the next wave of new LNG liquefaction capacity starts coming onstream in 2015.

Most notable amongst the new supplies of LNG poised to enter the market are seven projects in Australia. Between them the facilities will be able to produce an aggregate 65 mta of LNG when at full throttle. All seven are scheduled to be up and running by 2017.

Australia will be followed by the US. The Department of Energy has so far granted seven proposed plants approval for the export of LNG to countries with which the US does not have a free trade agreement. The total capacity of these facilities will be 62,5 mta and the first, Sabine Pass, is under construction and due to begin loading cargoes in early 2016. By the end of the decade the US is likely to be the third largest LNG exporter, behind Australia and Qatar.

Beyond the emerging Australia and US projects, a range of ambitious LNG export schemes is being developed in Canada and East Africa, with production startups targeted for the end of the decade.

As GIIGNL points out, 2013 can be considered to be a transition year for the LNG industry. Although final investment decisions were made on only three projects – Yamal LNG in the Russian Arctic and two expansions of existing facilities – they will provide another 29 mta of production capacity.

Slack demand for LNG in Europe, due to the region’s lingering economic recession and the availability of alternative pipeline supplies, was compensated for by a strengthening need for gas in Brazil and Argentina. Operators of a number of European LNG import terminals played a part by continuing with innovative transactions in the search for business, including re-loadings, two-port loadings and LNG Ship-to-Ship Transfer Processship-to-ship transfers. Of the 78 re-load cargoes despatched worldwide in 2013, Spanish terminals were responsible for 40 and the Zeebrugge facility in Belgium 20.

As part of the subtle shift in trading patterns, China and Korea, too, also recorded notable increases in LNG import volumes. China has moved up quickly through the ranks to become the world’s third largest LNG importer.

| Table 1. LNG Industry Growth Over the Past 20 Years | |||

|---|---|---|---|

| 1993 | 2003 | 2013 | |

| Liquefaction plant | 11 | 15 | 26 |

| Receiving terminals | 31 | 46 | 104 |

| Number of exporting countries | 8 | 12 | 17 |

| Number of importing countries | 9 | 13 | 29 |

| LNG carriers | 76 | 152 | 393 |

| LNG imports (million tonnes) | 61,0 | 125,2 | 236,9 |

After commissioning four new LNG import terminals over the past year China has four further receiving facilities under construction, with a combined capacity of 12 mta. Worldwide there are more than 25 import terminal projects, both newbuilds and expansions, underway. Most, if not all, should be in service by the end of 2015.

The popularity of floating storage and regasification units (FSRUs) as a means of fast-tracking LNG imports at comparatively low cost has skyrocketed in recent years. Almost one-half the new import terminals under construction will utilise FSRUs. Four FSRUs were completed in 2013 while three further such units were delivered in the first half of 2014.

| Table 2. LNG Exporters | ||

|---|---|---|

| Country | Volume (million tonnes) | Change 2012–13 (%) |

| Algeria | 10,81 | -3,5 |

| Angola | 0,33 | N/A |

| Egypt | 2,66 | -43,9 |

| Eq Guinea | 3,77 | 4,2 |

| Nigeria | 16,47 | -15,9 |

| Norway | 3,05 | -7,8 |

| Trinidad | 13,67 | 1,5 |

| Atlantic Basin (Total) | 50,76 | -9,2 |

| Abu Dhabi | 5,08 | -10,2 |

| Oman | 8,35 | 2,5 |

| Qatar | 78,02 | 2,1 |

| Yemen | 6,82 | 39,4 |

| Middle East (Total) | 98,28 | 3,4 |

| Australia | 22,41 | 7,3 |

| Brunei | 7,01 | 2,8 |

| Indonesia | 18,36 | -3,2 |

| Malaysia | 25,14 | 6,0 |

| Peru | 4,25 | 10,1 |

| Russia | 10,69 | -1,6 |

| Pacific Basin (Total) | 87,86 | 3,0 |

| World (Total) | 236,91 | 0,3 |

| Source: GIIGNL | ||

The LNG carrier fleet completed 3,998 laden voyages last year. Japan’s 26 receiving terminals accounted for 1,532 of the total, or one less cargo than in 2012. That is equivalent to just over four shiploads per day, or 30 per week.

| Table 3. LNG WORLD TRADE 2013 | ||

|---|---|---|

| LNG Importers | ||

| Country | Volume (million tonnes) | Change 2012–13 (%) |

| Belgium | 1,19 | -34,7 |

| France | 5,94 | -17,2 |

| Greece | 0,45 | -40,4 |

| Italy | 4,05 | -21,6 |

| Netherlands | 0,36 | -35,4 |

| Portugal | 1,49 | -1,6 |

| Spain | 9,13 | -36,9 |

| Turkey | 4,40 | -21,9 |

| UK | 6,91 | -33,4 |

| Europe (Total) | 33,93 | -28,5 |

| Argentina | 4,72 | 40,4 |

| Brazil | 4,15 | 53,7 |

| Chile | 2,61 | -5,5 |

| Dominican Rep | 0,84 | -9,0 |

| Mexico | 5,67 | 61,2 |

| Puerto Rico | 1,16 | 20,3 |

| Canada | 0,76 | -42,0 |

| USA | 1,90 | -38,7 |

| Americas (Total) | 21,81 | 17,1 |

| China | 18,60 | 27,0 |

| India | 13,05 | -1,7 |

| Indonesia | 1,43 | 98,6 |

| Japan | 87,98 | -0,1 |

| Korea | 40,39 | 9,8 |

| Malaysia | 1,50 | N/A |

| Singapore | 0,91 | N/A |

| Taiwan | 1272 | 0,4 |

| Thailand | 1,45 | 41,9 |

| Asia (Total) | 178,04 | 6,5 |

| Dubai | 1,15 | 10,0 |

| Israel | 0,40 | N/A |

| Kuwait | 1,59 | -20,4 |

| Middle East (Total) | 3,14 | 3,4 |

| World (Total) | 236,91 | 0,3 |

| Source: GIIGNL | ||

China received 260 cargoes in 2013, up from 206 the previous year, while deliveries to the Southern Cone of Brazil, Argentina and Chile totalled 224, a 24 percent rise on a year earlier. Interestingly there were 82 LNG cargoes delivered to the South East Asia quartet of Indonesia, Malaysia, Singapore and Thailand and 53 to the Middle East, more specifically Dubai, Kuwait and Israel. Israel and Malaysia are the two new LNG import nations of 2013.

Read also: The Role of SIGTTO LNG Safety in Advancing Industry Standards

While setting the scene for the buoyant times ahead, GIIGNL’s The LNG Industry in 2013 publication also looked back to report that since the first commercial LNG delivery in 1964, over 75 000 cargoes had been delivered without loss. That end-2013 total is currently being added to at the rate of about 340 cargoes per month.

Exporters ready to meet the greatest of expectations

The global trade in LNG is about to embark on a major new growth phase. The industry has all likely demand scenarios for the coming decade covered.

Eight countries have joined the LNG exporters league over the past decade, boosting the membership of this club to 20. Egypt began shipping:

- LNG to world markets in 2005;

- Equatorial Guinea and Norway in 2007;

- Russia and Yemen in 2009;

- Peru in 2010;

- Angola in 2013 and Papua New Guinea in 2014.

The Sakhalin 2 project in Russia, with exports of 10 million tonnes per annum (mta) of LNG, has been the most prolific of the newcomers. Egypt has two liquefaction plants, at Damietta and Idku but, after a brief initial flourish, the country’s exports have slumped dramatically due to rapidly rising domestic demand. Damietta has been idled and loadings at Idku are fitful.

The rising requirements of LNG buyers worldwide have not been helped, as yet, by the Angola project. The plant’s start-up has been dogged by technical problems and the facility is now shut until mid-2015 while major repairs are carried out.

The global financial crisis which broke in September 2008 not only temporarily dampened gas usage but also slowed investment in new LNG production capacity. The end-result is that the industry has been dealing with a sustained period of supply tightness. While the demand for gas is now greater than ever before, little new iquefaction capacity has been coming onstream. The global trade in LNG has been stalled at the 240 mta mark for the past three years.

Gas consumers and LNGC owners are anxiously awaiting the commissioning of new LNG export plants. The additional volumes will ease pressure on gas prices and boost freight rates for an LNGC fleet which is currently negotiating its way through a period of sustained overtonnaging.

The new LNG flows will originate from Australia, the US, Russia, Canada and East Africa, in that order. Each of these countries and regions holds the promise of adding substantial quantities to the global LNG supply pool.

Deliveries from new Australian schemes are imminent. Beginning in September 2009 and over a period of 30 months, final investment decisions were taken to proceed with seven LNG export projects in the country. They are Gorgon, Queensland Curtis LNG (QCLNG), Australia Pacific LNG (APLNG), Gladstone LNG (GLNG), Wheatstone, Prelude and Ichthys. Between them, these liquefaction plants will provide 65 mta of new capacity and propel Australia to the top of the Financing LNG Export Projects – Navigating Finance RisksLNG exporters league table.

Three of the new terminals – APLNG and GLNG – have been built adjacent to each other on Curtis Island in the port of Gladstone on Australia’s east coast. Bechtel is constructing all three facilities and all will process coal seam gas piped from the vast Queensland coal fields. QCLNG is on track to load its inaugural LNG cargo in December 2014 while APLNG is scheduled for a mid-2015 start-up and GLNG «sometime in 2015».

Gorgon, a three-train facility with a 15,6 mta capacity and the largest of Australia’s new projects, is also aiming for a mid-2015 commencement to operations. The other three schemes will follow a little later. Wheatstone is due onstream in 2016 while Ichthys has earmarked December 2016 as the date for loading the first cargo at its new Darwin plant.

Prelude is an offshore project being developed by Shell using a floating LNG (FLNG) production vessel. Samsung Heavy Industries in Korea is constructing the FLNG unit, and the plan is to install it in position in late 2016. That will enable the first cargo to be loaded in early 2017.

Australia has further exploitable gas reserves but the country is a high-cost place to do business, and the new onshore projects have proved to be prone to cost and time overruns. The next new Australian LNG export initiatives are likely to be based on the use of FLNG vessels.

For the moment, attention has switched to the US as the next supplier of notable volumes of LNG. Until well into the previous decade the US was identified as an LNG import market of great potential and a string of receiving terminals were built along its Gulf Coast. Almost immediately these facilities were commissioned, however, the shale gas phenomenon broke and the need for imports evaporated.

Today the emphasis is on LNG exports and monetising the sizeable reserves of shale gas that are surplus to domestic requirements. Over 25 proposed US LNG export projects have been submitted to the country’s relevant regulatory agencies for authorisation. Many of the schemes that have been put forward are based on the addition of liquefaction trains at idle import terminals where use can be made of existing storage tanks and marine jetty facilities.

The opening of the Panama Canal’s enlarged lock system in late 2015 will facilitate the delivery of US cargoes in «Pacific-max» LNG carriers of 170 000 m3 to Asia. Many of the US plans are based on tolling agreements whereby customers line up their own gas supplies, contract the appointed export terminal to process them and make their own shipping arrangements. Korea, China and particularly Japan have been lining up significant purchases of US gas under such arrangements.

In August 2014 Cameron LNG became only the second of the proposed US export initiatives, after Sabine Pass, to have its developers make a final investment decision (FID) to proceed. The timetable calls for the three 4 mta trains at the existing Louisiana terminal to be commissioned in 2018 and for full production to be reached in 2019. Having received the last of its necessary clearances in July 2014, Freeport LNG is expected to reach an FID on its project imminently.

Sabine Pass has a two-year jump on its US competitors, the decisions for the first two 5 mta trains at its Louisiana terminal having been taken in July 2012 and for the second two in May 2013. Construction work on Trains 1 and 2 is advancing well and they both could be producing LNG by late 2015.

The jury is still out on the volume of LNG that the US will ultimately be exporting. The big attractions of US LNG are the large quantities of competitively priced shale gas available, the security of supply and the storage tank capacity and marine jetty facilities already in place.

Taken in aggregate the volume offered by all the export terminals that have been proposed is nearing the current level of the global trade in LNG. That would not only be far too great for the market to absorb but also go against political will in a country sensitive to energy self-sufficiency issues. Many of the estimates for the likely quantity of US exports by 2025 instead fall within the more reasonable but still substantial 60–70 mta range.

US exports will also be in competition with the LNG cargoes that Canada, Russia and East Africa are seeking to make available to world markets by the early 2020s. Like the US, Western Canada is rich in shale gas and gas from other unconventional sources, and to date over 20 proposals have been put forward for projects that would liquefy gas from Alberta and British Columbia at terminals to be built along the coast of British Columbia.

Major international companies are involved in several of the proposed Canadian schemes and a number of preliminary sales agreements have been signed with leading gas buyers in China, Korea and Japan. Chinese buyers have expressed particular interest in Canadian LNG and its relative proximity to their growing network of import terminals. Some of the Canadian proposals involve notably large volumes of LNG.

As yet, however, no Canadian project has reached the FID stage and the spectre of competing sources of supply looms large. In Russia the developers of the 16,5 mta Yamal LNG project reached such a decision in December 2013, and an agreement to add a third 5 mta train at the Sakhalin 2 plant in the Russian Far East has also been finalised.

Beyond that, Gazprom is seeking to build a 10 mta terminal at Vladivostok and to begin shipping in early 2019. Rosneft has also tabled a plan for a liquefaction plant on Russia’s Pacific coast. The 5 mta, single-train facility would be built in conjunction with ExxonMobil and, like the Sakhalin 2 plant, located on Sakhalin Island. A 2018 start-up is targeted.

The final contender wishing to participate in the next wave of LNG supply is East Africa or, more precisely, Mozambique and Tanzania. Large deposits of gas have recently been discovered off the coastlines of both countries and LNG project development plans are well underway.

Mozambique is seeking to start exports at the rate of 10 mta and, bearing in mind the number of competitors targeting the same markets, to commence shipments by 2019/2020. That would require an FID on the project go-ahead by late 2014 or early 2015.

Tanzania also anticipates getting its LNG export train rolling with a two-train liquefaction plant but is running a year behind its southern neighbour. Project developers BG, Statoil, ExxonMobil and Ophir are looking at an FID in 2016 to enable the plant to come onstream in the early 2020s.

The future looks bright for LNG production, and a number of heavyweight projects are set to come onstream in the years ahead. There is enough capacity to meet all likely market requirements, and Canada, in particular, has the resources in hand to meet the additional volumes entailed in the most optimistic demand scenarios.