LNG Rollover Causes are significant factors that can lead to hazardous situations in the handling and storage of liquefied natural gas. These causes often stem from temperature fluctuations, density differences, and improper tank management. Understanding these causes is essential for implementing effective prevention strategies to mitigate risks.

By analyzing historical incidents, operators can develop better safety protocols and damage limitation measures. Ultimately, addressing LNG rollover causes is crucial for ensuring the safety and efficiency of LNG operations.

Introduction

Within an industry devoted to the storage and maritime Assessing the safety risks of LNG bunkeringtransportation of liquefied gases the phenomenon referred to as rollover gives rise to deep concern. The effects of rollover may leave land storage facilities or ships’ tanks over-pressurised whilst simultaneously releasing considerable quantities of gaseous vapours.

Relatively few rollover incidents have led to fires, explosions, incapacitation by toxic fumes, or structural damage to storage tanks. Some serious incidents have been authenticated for shore facilities where the release of vapour clearly generates a potential hazard. On the other hand, an LNGC operating manual virtually dismisses rollover as a maritime risk. It states:

«There have been no recorded incidents of rollover occurring in an LNG ship and it is therefore not considered a hazard.»

Recorded or otherwise there has been at least one case of rollover aboard an LNGC. Nevertheless it is correct to imply rollover incidents are rare in shore storage facilities and very rare at sea.

It has long been recognised that the consequences of rollover could be serious if adequate procedures to cope with it are not taken. The causes of such a phenomenon have therefore been diligently researched and are now well understood and the prevention procedures have been established. However, it may not be said that a quantitative analysis has been fully achieved.

As a result, equipment design and application of prevention procedures have virtually eradicated incidents attributed to rollover. Notwithstanding as an industry, it is necessary to maintain an understanding of how rollover can occur and how prevention is achieved – particularly since protection is derived as much from working practice as from the introduction of equipment.

Causes

Events leading to rollover (Stratification). When liquids of different densities are stored in the same tank, there is a possibility that layers are created with a less dense liquid overlying a heavier one. This is calledstratification. Unstable stratification may occur when the liquid in the lower layer becomes less dense due to heat input, while the liquid in the upper layer becomes heavier due to the evaporation at the surface.

The rollover phenomenon. This unstable situation can relieve itself with a sudden mixing at the time when the densities of the layers become equal or are reversed. Rollover is this spontaneous rapid mixing process which occurs in tanks as a result of a density inversion. The name «rollover» aptly describesthe occurrence.

The driving force is gravity – no other action such as vibration or stirring is necessary. The process is entirely physical and must always be preceded by stratification of liquids of differing density.

Incident severity. The damage that a rollover event can inflict is dependant upon the rate of release of energy that can occur as the unstable situation relieves itself.

For cryogenic liquids, normal rates of vapour generation can be exceeded by a factor of 10 or even more. Under these circumstances concentrated vapour clouds can be released and internal tank pressures rise to levels that may cause structural damage.

Liquids liable to rollover. Liquid hydrocarbons are of concern. This is especially true of cryogenic liquids. LNG is the most likely candidate for rollover by virtue of the heavier than Methane components which it contains, the extreme conditions of temperature under which it is stored, and the fact that storage temperatures are close to the saturation temperatures relevant to storage pressure.

Rollover is not confined to LNG. Ammonia is known to have given severe problems whilst the ICS Tanker Safety Guide (Liquefied Gases) indicates LPG is not immune.

«Rollover may also occur when two part cargoes are loaded into the same tank (e. g. propane and butane). In this case there will be a large boil-off due to the temperature difference between the two, up to 3 % of the total liquid volume. For this reason, the practice is considered unsafe unless a thorough thermodynamic analysis of the process is undertaken, and the loading takes place under strictly controlled conditions.»

Rollover in LNG

LNG consists of methane, with minor amounts of other gases, liquefied at about -160 °C, and is stored in insulated tanks. At this temperature the gauge pressure in the vapour or ullage space of the tank is in the range of 0,05-0,2 bar.

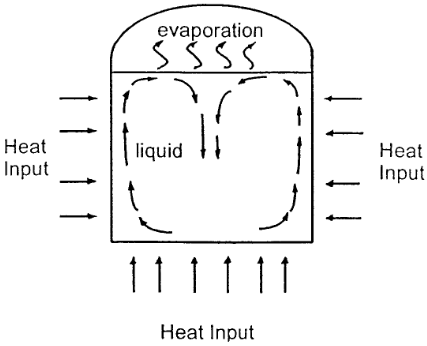

No refrigeration is applied, the leakages of heat into the tank are small and are absorbed bylatent heat of vaporisation and modest heating of the bulk liquid. For a large tank the vaporisation rate is typically 0,03-0,06 percent of the tank contents per day. The pattern of heat flow and vaporisation is shown in Figure 1 for a liquid which has not stratified.

The conditions of storage are such that the bulk liquid LNG does not boil, but evaporation takes place from the free surface, which cools due to loss of latent heat. The cooling causes an increase in density, so that the liquid sinks and is replaced by liquid of a lower density which has been warmed by heat flowing through the insulated walls and floor of the tank. A circulation pattern, driven by convection, is thus set up as shown in Figure 1. Heat also enters the system via the roof of the tank and the upper part of the walls, above liquid level. The heat transferred to the liquid surface mainly by thermal radiation augments the evaporation rate, and reinforces the convection circulation.

As LNG is a mixture, the more volatile components evaporate preferentially. As a result, the boiling point increases and, due to an ingress of heat, the temperature of the bulk liquid increases with time. This process is known as «weathering». Usually, the density of the liquid also increases with time but the presence of nitrogen complicates matters. Weathering means that when the tank is re-stocked with further LNG there are possibilities for temperature and density differentials to exist between the original stock, the «heel», and the additional liquid, the «cargo». This can lead to stratification. Rollover is prevented by avoiding stratification.

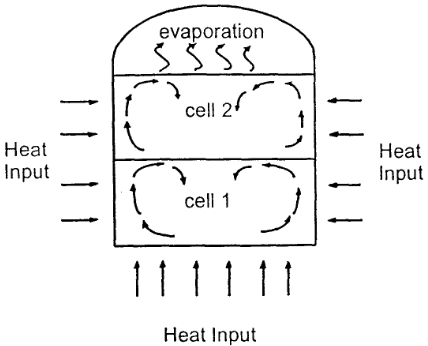

Stratification of stored LNG. The simplest version of stratification occurs when a storage tank is further filled with LNG of a different density. It is then possible for the two liquids to remain unmixed and form independent layers. Stratification occurs readily if the cargo is more dense than the heel, and filling is via the bottom of the tank, or if the cargo is less dense and filling is at the top. The stratification is initially stable, with little mass transfer between layers. A convection circulation pattern is established in each layer, see Figure 2. Stability gradually breaks down.

Reasons for the breakdown are well understood. For the upper layer heat flows in from the walls and roof of the tank, but a negligible amount comes upward by conduction from the lower layer because there is very little convection between the layers. Heat is lost from the upper layer by vaporisation, as in the case of non-stratified liquid in Figure 1. For the lower layer, heat flows in from the walls and floor of the tank. As indicated little heat is conducted to the upper layer. Since there is little mass transfer between layers, there is also little heat transfer to the upper layer in comparison with the case of free convection in the whole tank. Hence the heat accumulates and the temperature of the lower layer rises steadily, with a corresponding decrease in its mean density.

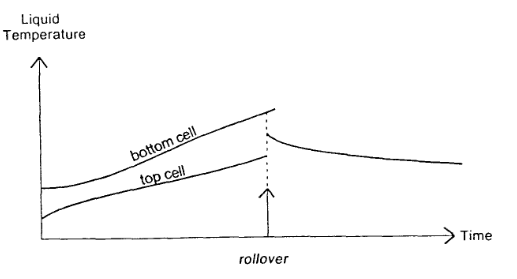

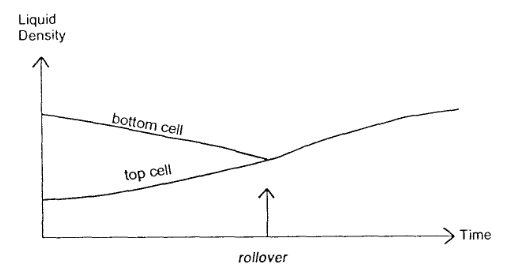

When the densities of the two layers equalise approximately, the stability of buoyancy is lost and the lower and upper layers rollover, or move and mix at least partially. When liquid from the lower part of the tank reaches the top surface of the tank it has a higher vapour pressure than the previous surface and so there is a sudden surge in the generation of vapour. This is the origin of the observed rapid increase in vapour generation associated with rollover. Figures 3 and 4 illustrate the process.

There are additional variations which complicate this simple picture.

The temperature within a layer is not exactly uniform, the liquid near the wall being slightly warmer than that in the centre. If this were not so there would be no density difference to drive convection. Rollover can probably be initiated in the lower layer by the warmer liquid rising near the wall continuing into the upper layer, rather then being deflected toward the axis of the tank for re-circulation. This provides the kinetic energy needed to start rollover.

Secondly, it is possible that the lower layer of the tank contents is exceptionally well insulated so that its temperature remains constant. The density of the upper layer will, however, increase due to «weathcring» so that rollover can still occur. The time required would be longer. Because of the unique insulation requirements this type of rollover is considered to be unusual, possibly hypothetical.

Thirdly, an experimental study of LNG rollover on a tank of 64 m diameter and 30 m height showed that an intermediate layer was formed between the upper and lower layers. This intermediate layer was about 150 mm thick and had a density gradient. This phenomenon is significant because large areas of interface between two liquids of similar density are known to be unstable and can be disrupted by small disturbances. Figure 2 does not illustrate the presence of this intervening layer. The 150 mm is small in terms of tank depth, however, mathematical modelling of rollover recognises the existence of such a layer and its destabilising influence.

The gas discharged from the tank during rollover will be mainly methane, at a temperature of about -160 °C, and so will be denser than air at ambient temperatures. As it escapes the gas will disperse at ground level before rising into the atmosphere once it has warmed and mixed with air. The possible presence of flammable clouds at ground level must always be part of the risk assessment for a storage site.

Presence of nitrogen. It has been mentioned that the presence of nitrogen affects the physical properties of LNG as it «weathers». Since liquid nitrogen boils at -195 °C it will, when present in LNG, vaporise in preference to methane. As its molecular mass is 28 compared with 16 for methane the density of the remaining LNG will diminish. Because weathering initially decreases the density of LNG containing nitrogen, new cargo liquid can be more dense than the weathered heel from the same original source. This is the converse of the situation for Prevention rollover in LNG Tanksnitrogen-free LNG.

There is also evidence that LNG containing nitrogen can stratify spontaneously from a homogenous liquid. The mechanism is as follows. The liquid in the tank gains heat and commences to circulate by convection, as shown in Figure 1. On reaching the surface the nitrogen vaporises from the circulating liquid, reducing its density sufficiently for it to the unable to sink again. A low-density fraction then floats on the bulk liquid, forming an upper and a lower layer as in Figure 2. The lower layer, prevented from losing heat by vaporisation, warms and becomes less dense and prone to rollover in the fashion already recounted.

After rollover the mixed liquid may still contain sufficient nitrogen for the auto-stratification and rollover processes to be repeated. The greater the nitrogen content in LNG the greater the likelihood of rollover becoming cyclic.

Prevention of rollover.

Most of the methods have been developed for LNG storage, but they are usually applicable to other liquids whether stored at sub-zero or at ambient temperatures. A summary is given here.

Avoidance of stratification. Possible methods are:

1 Separate storage: Liquids of different density are stored in separate tanks. Operational and economic penalties are likely to be incurred, so this is an unattractive option although it does solve the rollover problem.

2 Suitable filling arrangements: Facilities are commonly provided to add the cargo by top or bottom loading, depending on whether it is more or less dense than the heel at the time of loading. The difference in density should encourage mixing, but cases are known of incomplete mixing after correct choice of load point; three cases of rollover in LNG are known to have resulted from the bottom-loading of light liquid. Top loading may cause problems with excessive vapour generation.

3 Use of nozzles or pipes: Effective mixing can be achieved using a jet nozzle attached to a fill pipe at the bottom of the tank, provided that:

- the jet reaches the surface of the liquid, preferably at an angle but not impinging on a wall;

- mixing continues for sufficient time so that liquid in all parts of the tank is entrained.

Alternatively, loading via a vertical pipe with perforations over part of its height can prevent stratification. The perforations must avoid internal fittings within the tank and be submerged for most of the time to avoid excessive generation of vapour.

4 Handling LNG containing nitrogen: Autostratification is avoided by ensuring that the nitrogen content is low, below 1 % is recommended.

Detection of stratification. If stratification cannot be prevented with confidence, then methods to detect its presence should be installed. Possibilities are:

1 Instrumentation: Temperature and density sensors are available which, in association with a level gauge, enable the liquid to be scanned and layering detected. With LNG small temperature differences and density variations need to be detected and therefore careful and accurate measurements are essential.

2 Chemical analysis: If the cargo and heel liquids are of different composition, then stratification may be possible. Such analysis does not, of itself, provide direct evidence of stratification within a tank.

3 Vapour generation during tank loading: It is a characteristic of stratification that the rate of generation of vapour may be reduced or the total quantity evolved is low. At some LNG terminals the following guidelines have been adopted:

- A reduction of the cumulative vapour release to 90% of that expected is taken as a warning of stratification.

- A reduction to 70 %, loading to be stopped.

Removal of stratification. Existing stratification can be eliminated by various means:

1 Transfer liquid from the tank, either by use of alternative tanks or by sending into the distribution system. Predictive modelling can be used to obtain an estimate of the time available before rollover, and is likely to be hours rather than days after the liquid has stratified. However, in many cases immediate transfer is not practicable.

2 Circulate the liquid in the tank by mechanical means, such as jet nozzles. The pressure of the jet should be enough to break through the stratification, and circulation continued to enable the liquid in all parts of the tank to be entrained.

3 Recirculate the Jower layer through a top filling line. The mixing process is of only moderate efficiency.

4 Transfer the lower layer to another tank and re-introduce it into the original tank by the usual filling procedure. A new stratification may be difficult to avoid.

Damage limitation measures

If methods of preventing rollover cannot be wholly relied upon, the consequences of rollover require protective measures to be taken. The main purpose of that protection is to deal with the surge in generation of vapour that characterises rollover.

Predictive modelling of rollover effects with LNG. Earlier pages have illustrated that an in depth understanding of the causes of rollover does exist. Whilst most fundamental work has been conducted using LNG the principles resulting from the studies can equally apply to other liquefied gas mixtures.

Prediction of gas emission rates which accompany rollover is necessary for adequate design of storage vessels. The modelling of rollover basically involves heat and mass transfer calculations, contained in a computer program. An outline of the method is given here.

The inward flow of heat to the storage tank is balanced by evaporative heat loss from the multi-component LNG plus heat gained by the separate layers of liquid. The vapour evolved is assumed to be in thermodynamic equilibrium with a thin film of liquid on the surface of the top layer. Energy is transmitted to this film from the vapour space above and energy and mass are exchanged between the film and the liquid below it. The vapour-liquid equilibrium compositions and the layer densities as a function of composition and temperatures are calculated. Computer programs are available which calculate the status of the tank contents at each time increment and integrate over the rollover process. Interestingly, the rate of generation of vapour before rollover is noticeably less than under the routine storage conditions.

Applications of one program to a recorded sequence of events in La Spezia gave a predicted time to rollover accurate to within one percent of the actual time of 31 hours; the prediction of vaporisation rate during rollover was less accurate. Data is now available from controlled experiments. This information is being used to further refine the existing programs.

Rollover protection. A complete survey of operating conditions should form the input for predicting rollover effects. A risk assessment will identify the likelihood for the existence of conditions leading to rollover. In this fashion the worst credible rollover incident can be established.

For new installations this should form the design criteria and demonstrate, under the conditions identified, that:

- the pressure relief capacity is adequate, notwithstanding compliance with other relief criteria such as fire protection;

- and the methods adopted for safe dispersal of vapours released into the atmosphere are acceptable.

For existing installations these new techniques, identifying as they do the credible rollover incident, might well highlight inadequacies with the original design. If such a situation develops almost certainly strengthening of storage vessels is impractical, correction therefore will require the pressure relief system capacity to be improved.

Review of incidents

Land storage. Over the period 1970-1982 a Study Group set up by the International LNG Importers Group (GIIGNL) received reports of 41 incidents of rollover of LNG from 22 plant locations around the world. The majority of incidents involved loading cargo of one composition into a tank containing heel of a different composition. Four incidents were attributed to the preferential loss of nitrogen, causing autostratification.

The incidents varied considerably in severity, but even in the worst case there was no report of physical damage to the tanks or other facilities. In fourteen of the incidents the excess vapour was either flared or vented to the atmosphere, and in half of these a vapour cloud was reported but none ignited.

Tne sizes of the tanks involved ranged between 5 000 and 100 000 cubic metres, either above-ground or in-ground. Neither the size nor the locations appeared to be a factor influencing rollover.

In about half the incidents information was available on the peak pressures developed. Gauge cressures of more than 80 % of design were often observed, but in only two was design exceeded (by 43 % in the worst case). No damage to the tank was reported in any of the incidents, indicating that adequate capacity for pressure relief had in fact been provided.

Tre maximum rates of generation of vapour were usually recorded, and these were not more than 10 times the norm in about half the incidents. The rates were between 10 and 20 times in one-sixth and more than 20 times normal in one-eighth of the incidents.

Falling barometric pressure contributed to three incidents. Although a drop in pressure would not cause stratification, it could cause rollover to occur earlier and vapour generation to be zocelerated, provided that the tank was operated in gauge pressure. An example of a typical event occurred in La Spezia where 18 200 tonnes of cargo were added to a heel of 5 170 tonnes.

Prior to the transfer the cargo had remained aboard ship in La Spezia harbour for more than one month. During that time the cargo had weathered and warmed. The heel in the storage sarx was evolving vapour steadily before loading commenced and the rate increased sharply Zuring the loading period of about 10 hours. During this time about 30 tonnes of vapour were evolved and stratification had developed. After loading there was a quiescent period Guring which the vapour evolution was at a similar rate to that before the loading commenced; the heel was the upper layer and the cargo the lower. About 31 hours after the loading had commenced rollover occurred. The vapour release rate escalated to an estimated peak of 10 tonnes/hr., and it can be calculated that before vaporisation relapsed to its rate before loading had commenced a total of 186 tonnes of vapour would have been discharged. The computer model mentioned earlier predicted that the final temperature of the bulk liquid after rollover would be -156,1 °C, after allowing for heat losses.

Although the cargo was initially warmer and more dense than the heel (Table) evaporation of methane from the heel led to an increase in its density, and hence to the rollover, because of the relatively large proportion of higher hydrocarbons in the heel.

| Property | Heel | Cargo |

|---|---|---|

| Components | mol. % | mol. % |

| Methane | 63,62 | 62,26 |

| Ethane | 24,16 | 21,85 |

| Propane | 9,36 | 12,66 |

| Butanes | 2,35 | 3,14 |

| Pentanes | 0,16 | 0,07 |

| Nitrogen | 0,35 | 0,02 |

| Temperature (°C) | -158,9 | -154,3 |

| Liquid depth (m) | 5,029 | 17,813 |

| Density (Kg/m3) | 541,742 | 545,586 |

The tank was not damaged by overpressure, although this rose to about 140 % of the design pressure. No injuries were sustained.

Precautions taken to avoid incidents similar to the La Spezia event were recorded in a paper presented during Gastech 88. The paper is entitled: «Changes in LNG cargo composition due to long storage and prevention of rollover during the unloading operation». For a variety of reasons it had been necessary to store LNG in the LNGC «Mustafa Ben-Boulaid». Off loading the much weathered LNG in a fashion which avoided rollover is described in detail. This exercise was accompanied by the introduction of much instrumentation and careful planning. Practically all of the operational preventative measures described earlier were employed.

Ship cargoes. An LNGC operating manual makes the following statement:

«There have been no recorded incidents of rollover occurring in a LNG ship, and it is therefore not considered to be a hazard. Rollover conditions may occur however, if caution is not exercised in loading LNG into a tank containing a quantity of cargo at a significantly different temperature. By equalising the temperatures through use of the cooldown system prior to loading at a substantial rate, the potential for rollover is eliminated.»

The statement is essentially true. LNG Cargoes are homogeneous. Any ships’ heel is very small and therefore incapable of storing energy sufficient to give significant rollover.

Read also: Liquefied Natural Gas Fundamental Knowledge and Understanding

However, SIGTTO is aware of one genuine ship rollover. It occurred during the early years of LNGC operations. The vessel in question had begun to load normally. After an hour the shore plant suffered some form of failure which caused a black-out ashore. For 12 hours all loading was stopped. LNG in the ship and terminal loading lines was not circulated prior to recommencing of the loading operation. Effectively a warm slug of LNG passed into the ship. This element of the cargo was at a density which differed from that subsequently loaded. Conditions for stratification existed. Loading was completed with no further incident and the ship sailed. After 12 hours on passage a relief valve opened on two-phase flow. The uent from the vent riser appeared as an aerosol and the ship was engulfed in a fine mist which may have been water condensing from the atmosphere. No damage was reported. Since the classic conditions which precede rollover were identified as being present the incident was attributed to rollover.

Summary. Tre prevention of rollover is an activity which must be undertaken by those responsible for storage, in a single tank, of physically different forms of liquefied gas – principally LNG. Although in theory, rollover may occur with LPG storage no such reports haven been found. Since ships, both LNGCs and LPGCs, carry heels which are small or non-existent most cargoes are regarded as homogeneous. The practice of mixing propane and butane in a single ships tank has not resulted in any reports of stratification let alone rollover. Apart from the single rather unique incident mentioned earlier, rollover in ships on passage constitutes a very low order of risk.

Essentially stratification and subsequent rollover events are confined to shore LNG storage and of direct interest to limited numbers within the Membership. This situation could change if the use of LNGCs for floating storage were to be introduced. Those manning the vessels would need to be as aware and as vigilant to avoid rollover as their counterparts managing shore based storage. Although still restricted to LNG, the problem of rollover would then be encountered both sides of the ship-shore interface.

Rollover takes place with overturning of cryogenic volume, caused by stratification. Preventing it by the pump mixing is expensive and not safe .Earlier another way has been proposed , when heat , supplied to the tankage floor, is directed through the number of structures , placed at floor and used , as properly designed , of proper material, to create noticeable permanent ascending flows up to interface , instead of what We have .Funnel or something similar can be taken. In this way the tankage could become as self- mixer This relates to .patent 2027944 of Russia. 1995 .Your rollover Message is detailed. Thanks!Vladimir