LNG Bunkering Checklist is an essential tool for ensuring the safety and efficiency of LNG operations at ports. This checklist provides a comprehensive overview of the necessary regulations, safety measures, and operational procedures required for successful ship-to-ship transfers.

By following the guidelines outlined in the checklist, port operators and ship crews can minimize risks and enhance the overall safety of the bunkering process. Implementing this checklist not only streamlines operations but also ensures compliance with industry standards, making it a vital resource for all involved in LNG bunkering.

Introduction

General

This publication specifies the Port of Gothenburg’s regulations regarding LNG cargo handling and LNG bunkering in the Port of Gothenburg and adjacent anchorage areas. These regulations are valid in combination with Port of Gothenburg general harbour regulations.

Definitions

Hazardous area – zones 0, 1 and 2 in which an explosive gas mixture is expected to occur during normal handling in accordance with IEC 60079-10 and IEC 60092-502.

Safety zone – an area that must be established around the LNG bunkering station/facilities to control ignition sources and ensure that only essential personnel and activities are allowed in the area that could be exposed to flammable gas in case of accidental release of or other incident involving LNG or natural gas during bunkering.

Security Zone (No movement zone) – an area that must be defined and established around the LNG bunkering area to monitor and control external activities e. g. ship movements or vehicles that can lead to incidents that threaten the operation. The security zone may result in limit access for personnel and/or public. The security zone will always be larger than the safety zone.

IGF Code Code – IMO International Code of Safety for Gas-Fuelled Ships and other low-flashpoint fuels.

IGC Code – the International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk.

ISO 20519:2017 – Ships and marine technology – Specification for bunkering of liquefied natural gas fuelled vessels.

All regulations remain unaltered whether the LNG bunker vessel or LNG vessel is empty or not, if it is partially or fully loaded, or approaching or leaving the port. LNG vessel traffic in the port is subject to the Port Bye-laws, Port Regulations and National Regulations.

All bunkering operations in the Port of Gothenburg harbour area are subject to the Port Bye-laws and Port Regulations. In order to perform ship to ship bunkering the following conditions must be met:

- The bunker vessel must have accreditation from Port of Gothenburg (see below).

- The receiving vessel must comply with the IGF Code Code.

- The terminal must have a Port of Gothenburg-approved safety management system and routines for allowing bunker operations alongside terminal berths with or without simultaneous cargo operations (see below).

- All bunkering operations must be approved by Port of Gothenburg.

Bunker vessel criteria

The bunker vessel shall:

- be built according to IGC Code Code.

- be inspected according to the Green Bunkering concept.

- hold proof of adequate training and certification according to STCW and the standard ISO 20519:2017

Receiving vessel criteria

The receiving vessel must fully comply with the IGF Code Code and also have a safe bunkering procedure, which is carried out according to the approved ISM manual onboard. The receiving vessel should comply with the standard ISO 20519:2017 or similar.

Terminal criteria: The terminal must have safe bunkering procedures which are carried out according to the approved safety manual.

Applicable regulations and standards

- National Regulations.

- IMO IGF Code-Code.

- ISO 20519:2017.

- Port Bye-laws.

- General harbour regulations for Port of Gothenburg.

- Operating regulations for Energy Port Gothenburg.

LNG bunker operation regulations

Hazardous, safety and security zones

Hazardous area classification is compulsory for the bunkering station according to SRVFS 2004:7 and its standard IEC 60079-10 and for ships as per standard IEC 60092-502.

Additional to the hazardous areas a safety zone must be established around the bunkering station prior to all LNG Basic Information about Liquefied Natural Gas Bunkering Operationsbunkering operations.

The safety zone is an area around the LNG bunkering station/facilities to control ignition sources and ensure that only essential personnel and activities are allowed in the area that could be exposed to flammable gas in case of accidental release of or other incident involving LNG or natural gas during bunkering.

Prior to determination of a specific safety zone at a terminal, vapour dispersion data should be calculated for the largest credible leak, based on a risk assessment.

The safety zone should never be smaller than the hazardous area distances stated for the receiving vessel, bunker barge, terminal facility or truck.

Safety zone distances in Port of Gothenburg as stated below:

| Table 1. Safety zone distances in Port of Gothenburg | |||

|---|---|---|---|

| Type of vessel | Sea side | Bunker station | Terminal |

| LNG/LPG/Tanker | 25 metres. | 25 metres. | 25 metres. |

| Container/Bulk | 25 metres. | 25 metres. | 25 metres. |

| Ro/Ro | 25 metres. | 25 metres. | 25 metres. |

| Ferries | 25 metres. | 25 metres. | 25 metres. |

The vertical safety zone is usually 25 metres above or below the stated hazardous area.

A security zone or No movement zone must be defined and established around the LNG bunkering area to monitor and control external activities e.g. ship movements or vehicles that can lead to incidents that threaten the operation. The security zone may result in limit access for personnel and/or public. The security zone will always be larger than the safety zone. Prior the operation starts the security zone has to be communicated to all parties it may concern such as adjacent terminals, other vessels and the Port Authority.

Safety zone while moored during LNG ship to ship bunkering operation. The safety zone at the sea side is set to 25 metres. LNG bunkering must be stopped if a vessel or craft comes closer than the safety zone. Additionally for Lo/Lo vessels, if any container interferes with the safety zone, the entire container bay must be included in the safety zone.

Weather condition requirements. No ship to ship bunkering is allowed in Port of Gothenburg when wind force exceeds 20 m/s. Current wind speed can be obtained from VTS Gothenburg on VHF channel 13.

Special provisions for bunkering gas and petroleum products. LNG and FO/DO manifold on-board and ashore should be separated into independent manifolds and spillage containments for each type of purpose.

- Oil bunkering to LNG-powered vessel is allowed simultaneously with LNG bunkering.

- Oil bunkering to LNG vessel during LNG cargo transfer operation is not allowed.

LNG bunker truck. The truck to ship bunker operation is comparable to a bunker operation between a bunker vessel and receiving ship so the same regulations apply and the same checklist must be filled in. To operate an LNG bunkering vehicle at Port of Gothenburg, the operator of the vehicle must upon request show an approved ADR training certificate and knowledge of the terminal safety manual regarding the LNG bunkering procedure.

Bunkering procedures and requirements. The maximum pressure and pump rate during bunkering is based on the terminal’s and the receiving vessel’s receiving capacity. These figures should be filed in the Bunker Safety Checklist. If an emergency arises in the terminal, not affecting the vessel’s operation, the terminal will inform the vessel, bunker vessel and/or LNG truck over VHF radio or other agreed communication method. If an emergency arises in the terminal affecting the vessel, bunker vessel and LNG truck operations, any decision to abandon vessels or leave berth is the master’s or harbor master’s responsibility. Double banking of LNG bunker vessels alongside receiving vessel is not allowed. LNG bunker vessels and receiving vessels which intend to load or bunker shall be aware of the general operating regulations for the respective terminal. All terminal lighting and cables that interfere with the safety zone of the LNG vessel or LNG truck shall be switched off in a way that the lights are totally without any power supply. This is not applicable if the equipment is EX-proof. Equipment such as ro-ro ramps, gangways, hydraulic/pneumatic tools/equipment which could cause sparks/heat during movement or malfunction are not allowed to be used inside the safety zone. Passengers shall be informed when LNG Ship-to-ship LNG transfer operationstransfer operations are in progress, by means of warning signs (no smoking, no open lights etc.) and limitation of access to weather decks on the side where the LNG transfer is being carried out.

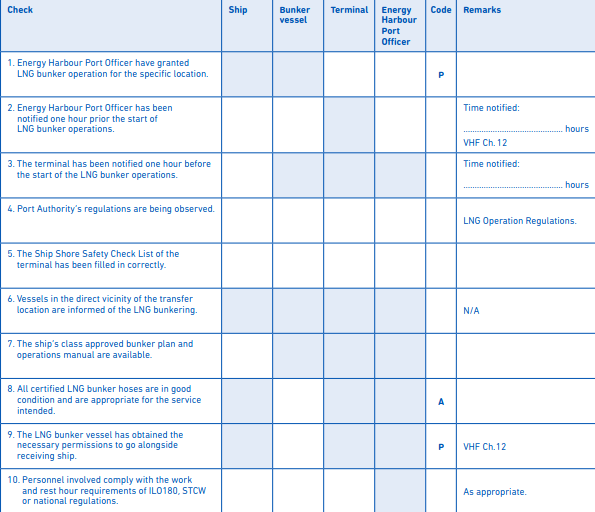

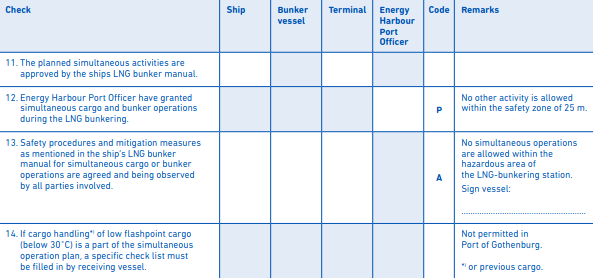

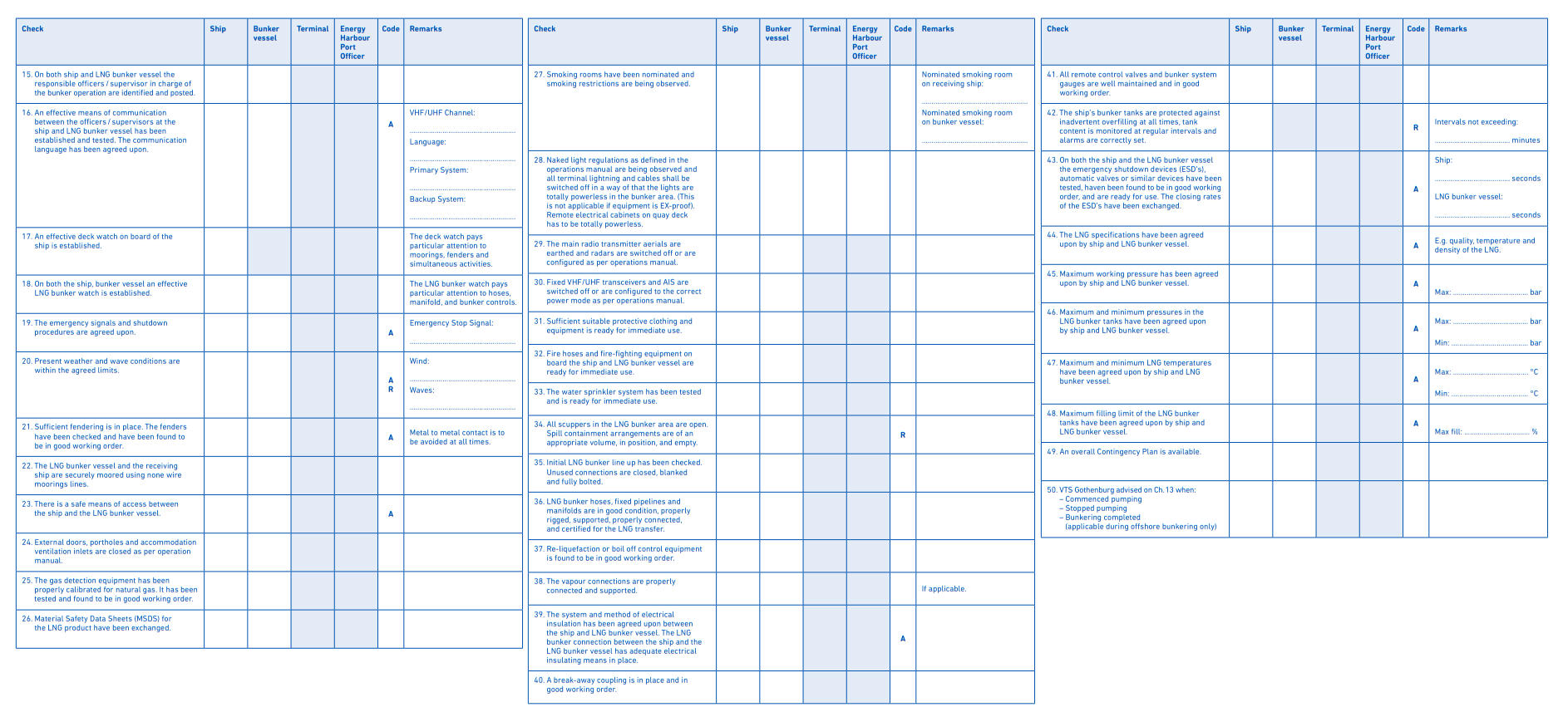

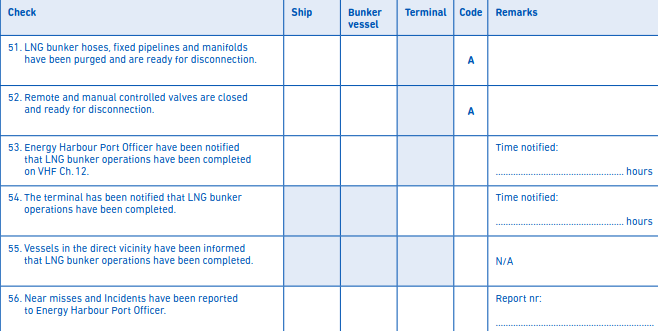

LNG bunker safety checklist. At the Port of Gothenburg, a dedicated LNG Bunker Safety Checklist is used to secure the LNG bunkering operation in a step by step process. The ship-specific LNG Bunker Safety Checklist should be filled in in such way that all risks of the receiving vessel’s cargo handling including passenger handling have been considered and determined.

Vessels. Responsibility for the safe conduct of operations while a ship is LNG Bunkering Guide – What It Is and How to Use Itreceiving bunker cargo by barge, or truck, is shared jointly between the master of the receiving vessel, the bunker vessel and the truck driver. All parties remain responsible for shutting down the operation in order to prevent incidents and accidents irrespective of the cause of any arising problem. The master of the vessel is responsible for all operations controlled and supervised from the vessel, the master of the bunker vessel is responsible for all operations controlled and supervised from the bunker vessel.

Tanker trucks. The tanker truck driver is responsible for all operations controlled from the tanker truck. The tanker truck driver shall monitor the entire bunkering process, from start to finish. Bunkering may not under any circumstances whatsoever be left unattended.

Terminal. The terminal must have a procedure regarding safe bunkering and cargo operations. The terminal representative is responsible for establishing an overall contingency plan in case of an emergency involving LNG.

Read also: Examples and Methods Liquefied Natural Gas Bunkering

The terminal representative will ensure that no one from shore violates the set and agreed safety zone at the terminal and sea side. The terminal representative should also ensure that the LNG truck (if applicable) is parked correctly and has not been blocked by any vehicle. The LNG truck shall be parked in a way that immediate departure is available, without maneuvering. The terminal representative should check that all safety precautions have been made according to terminal regulations.

LNG bunker checklist port of energy in Gothenburg – ship to ship

| Table 2. Vessel assignment and bunkering form | |

|---|---|

| Ship’s name | Bunker vessel name |

| Berth | Port |

| Date of arrival | Time of arrival |

| Terminal | |

The presence of the letters «A» , «R» or «P» in the column entitled «Code» indicates the following:

- A («Agreement»). This indicates an agreement or procedure that should be identified in the «Remarks» column of the Check-List or communicated in some other mutually acceptable form.

- R («Re-check»). This indicates items to be re-checked at appropriate intervals, as agreed between both parties, at periods stated in the declaration.

- P («Permission»). This indicates that permission is to be granted by Energy Harbour Port Officer.

| Table 5. Bunker and cargo operations plan | ||||

|---|---|---|---|---|

| Oil bunker | Cargo | Misc | ||

| Product | ||||

| Volume to be transferred | m3 | |||

| Starting rate | m3 per hour | |||

| Max transfer rate | m3 per hour | |||

| Topping of rate | m3 per hour | |||

| Max pressure at manifold | bar | |||

| Table 7. Part D: LNG transfer data. Starting temperatures and pressures | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| LNG receiving ship | LNG bunker vesse | |||||||||

| LNG tank temperature | °С | |||||||||

| LNG tank pressure | bar | |||||||||

Declaration

We, the undersigned, have checked the above items in Parts A, B, C and D in accordance with the instructions and have satisfied ourselves that the entries we have made are correct.

We have also made arrangements to carry out repetitive checks as necessary and agreed that those items coded «R» in the Checklist should be re-checked at intervals not exceeding ……. hours.

If, to our knowledge, the status of any item changes, we will immediately inform the other party.

| Table 8. Guidelines for completing the LNG Bunker Checklist | |||

|---|---|---|---|

| Ship | LNG bunker vessel | Terminal | Energy Harbour Port Officer |

| Name | Name | Name | Name |

| Position | Position | Position | Position |

| Signature | Signature | Signature | Signature |

| Date | Date | Date | Date |

| Time | Time | Time | Time |

| Table 9. Record of repetitive checks | |||||||

|---|---|---|---|---|---|---|---|

| Date | |||||||

| Time | |||||||

| Initials for ship | |||||||

| Initials for bunker vessel | |||||||

Guidelines for completing the LNG Bunker Checklis. The joint declaration should not be signed until both parties have checked and accepted their assigned responsibilities and accountabilities. When duly signed, this document is to be kept at least one year on board of the LNG receiving vessel.

| Table 11. LNG BUNKER CHECKLIST | ||

|---|---|---|

| Ship | LNG bunker vessel | Terminal |

| Name | Name | Name |

| Position | Position | Position |

| Signature | Signature | Signature |

| Date | Date | Date |

| Time | Time | Time |

Declaration We, the undersigned, have checked the above items in accordance with the instructions and have satisfied ourselves that the entries we have made are correct.