The maritime industry, facing increasing pressure to reduce its environmental footprint, is actively exploring cleaner fuel alternatives. Among these, Liquefied Natural Gas (LNG) has emerged as a promising solution, offering significant reductions in sulfur oxides, nitrogen oxides, and particulate matter emissions compared to conventional heavy fuel oil. A crucial aspect of this transition is the development and implementation of efficient and safe methods for LNG bunkering a ship. This article will delve into the intricacies of this process, exploring the various techniques, infrastructure requirements, safety considerations, and the overall impact of LNG bunkering on the future of sustainable maritime transport.

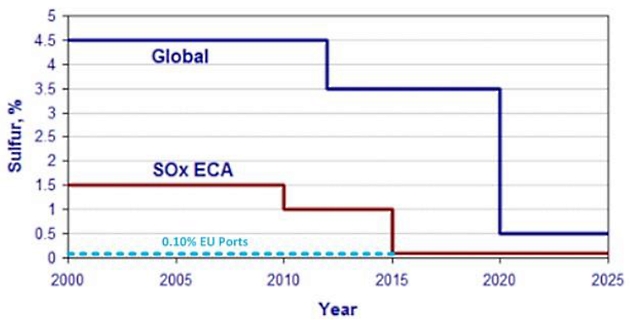

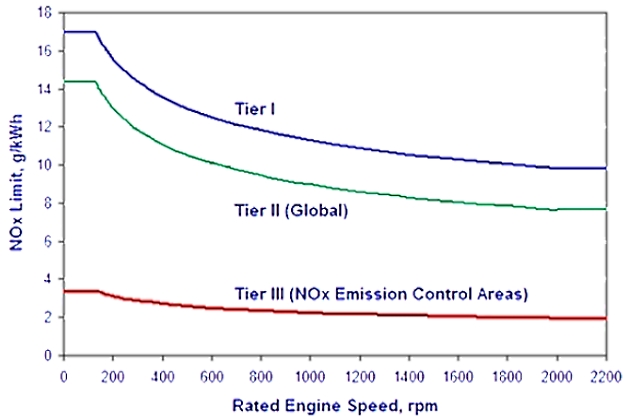

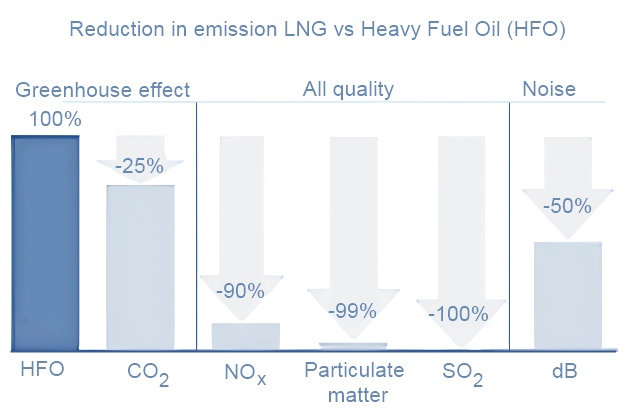

LNG as an alternative fuel for Shipping has been increasingly adopted as a strategy for environmental compliance, either sailing or at port. With an immediate significant impact on the reduction of Sulphur Oxides emissions (SOx), Particulate Matter (PM), and also of Nitrogen Oxides (NOx) the motivations for the use of LNG as fuel in maritime transport are today highly favoured by a relevant multi-layered regulatory frame. At international level MARPOL Annex VI defines gradual and tiered approaches to the reduction of both SOx and NOx, respectively through Regulations 14 and 13 (figures 1 and 2, below).

On the Safety page the International Code of Safety for Ships using Gases or other Low-flashpoint Fuels (IGF Code), entering into force on the 1st January 2017, establishes the requirements for safe design, construction, and operation, of LNG fuelled vessels. On the EU frame the Sulphur Directive (Dir. 2012/33/EU) and the Directive on the deployment of an Alternative Fuels Infrastructure (Dir. 2014/94/EU) establish the particular European framework for the development of LNG as an alternative fuel for shipping. The Sulphur Directive by including LNG as a possible Emission Abatement Method Reference is made to the provisions in the Sulphur Directive (Directive 2012/33/EU) allowing for the use of different Emission Abatement Methods, as defined by (Article 4, c), subject to the criteria listed in Annex II of the Directive. (In the letter of Article 4, c) Member States shall allow the use of emission abatement methods by ships of all flags in their ports, territorial seas, exclusive economic zones and pollution control zones, as an alternative to using marine fuels that meet the low-sulphur requirements. It remains however to be noted that the criteria specified in the Sulphur Directive relates to the use of a mixture of BOG (Boil Off Gas) with HFO, by LNG carriers, at port, in order to meet the 0,10 % EU sulphur cap in ports. Notwithstanding this LNG is used as an alternative fuel, representing a clear option for ships that, otherwise, would have to either use low-sulphur oil fuels or adopt a different Emission Abatement Method.x, and Directive 2014/94/EU by establishing the clear obligation for EU Member States to make LNG, as an Use of Cargo as Fuel on Gas Tankersalternative fuel for shipping, available at maritime ports Member States to put in place an appropriate number of refuelling points for LNG to enable LNG inland waterway vessels or seagoing ships to circulated throughout the EU TEN-T Core network by 31 December 2025.x by the end of 2025 (for inland waterways ports the target objective is set for the end of 2030).

In the above context the development of LNG as an alternative fuel for shipping has been remarkably fast, with the involvement of ship operators, shipyards, Class Societies, different national competent authorities, including the obvious and fundamental active participation of Port Authorities.

LNG fuel is often, especially in passenger vessels, a feature not perceived from the outside. (courtesy of FJORDLINE)

The technological steps given in the design of LNG fuelled vessels and LNG bunkering operations has been fast and keeping every stakeholder at the same pace in the development process is essential for a coherent, consistent and harmonized deployment of a safe LNG. The industry has been paramount in the whole process, adopting a good part of the LNG knowledge. A good part of the responsibility for the consolidation of knowledge and experience transferability from LNG cargo to LNG as a fuel for shipping is to be given to the Society for Gas as a Marine Fuel (SGMF, a new non-governmental organisation (NGO) established to promote safety and industry best practice in the use of gas as a marine fuel.x

LNG for Shipping in a Nutshell

The table below summarizes the main technology aspects of LNG as fuel for shipping, with a brief indication of the main advantages and current challenges for this alternative fuel.

| Table 1. LNG for Shipping in a Nutshell, Technology, Advantages and Challenges | |||

|---|---|---|---|

| Technology | Advantages | Challenges | |

| Liquefied Natural Gas (LNG) | Natural Gas stored as a cryogenic liquid. The temperature required to condense natural gas depends on its precise composition, but it is typically between -120 and -170 °C (-184 and -274 °F). | Environment. Environmental gains, both in GHG emissions and other relevant substances such as NOx, SOx and Particulate Matter. | GHG Impact. LNG is mostly composed of Methane (CH4) – comparative impact of CH4 on climate change is more than 25 times greater than CO2 over a 100-year period. Careful consideration needs to be given to any form of methane release throughout the Well-to-Wake chain of LNG (i. e. over the life cycle of the fuel). |

| LNG carriers have used this alternative fuel for more than 40 years now, mainly as a result of conveniently making use of cargo vapours due to impossible 100 % insulation effectiveness. | Availability. Increasing availability of Natural gas Sources. | Capital Investment. Relatively high investment costs. | |

| Onboard storage of LNG is typically a challenge for ship design | Energy Content. Energy density comparable to petrol and diesel fuels, extending range and reducing refuelling frequency | Bunkering. LNG bunkering infrastructure still in development. | |

| Engine concepts include gas-only engines, dual fuel 4-stroke and 2-stroke. | Momentum. Significant number of first-mover initiatives with an increasing number of ships adopting LNG as fuel. | Safety. Safety concerns associated to Low flashpoint and cryogenic nature of LNG. | |

| Cost Effective. LNG achieves a higher reduction in volume than compressed natural gas (CNG) so that the (volumetric) energy density of LNG is 2,4 times greater than that of CNG or 60 percent that of diesel fuel. | |||

The full potential of LNG as Fuel for Shipping is yet to be explored. Many studies have been carried out to explore the technical and economic feasibility of this fuel and the results have shown promising conclusions leading to the inevitable assumption that further development of LNG ship fuel solutions will be seen in a very near future. Context driven aspects, such as fuel oil prices, are a possible “slowdown factor” for the adoption of LNG, nevertheless it is important to develop the tools and the understanding that LNG as fuel will be a reality which will grow in maritime transport.

In the same inevitable way Ports will have to consider due facilitation of LNG, depending on specific technical (and business) feasibility, Safety, Risks and Security Aspects in Liquefied Natural Gas Industryrisk and safety, amongst other factors. The present guidance is proposed as an additional tool to assist Port Authorities to welcome LNG as fuel in a clear and safe manner.

Background

As mentioned above, LNG is today a technically feasible option as an alternative fuel for shipping. An increasing number of ships have adopted it, with an increasing number of newbuilds at the order book.

The forecasts, despite any context related oil price variations, still present an interesting uptake in all major ship types.

- Fuel engine technology;

- ship design;

- fuel tank containment systems;

- control & detection, amongst other, are some of the different areas where LNG fuelled vessels can differ from each other.

The technological diversity however does, in all cases, introduce an increase in systems’ complexity, and the low flashpoint nature of LNG highlights the Risk & safety concerns with a fuel that is not only physically so different from traditional oil fuels but that also brings additional operational challenges regarding its transport, delivery and use.

On the regulatory context, the International Code of Safety for Ships using Gases or other Low-flashpoint Fuels (IGF Code), approved in its final draft version in June 2015, is due to enter in force on the 1st January 2017. It contains mandatory provisions for the arrangement, installation, control and monitoring of machinery, equipment and systems using low-flashpoint fuels, focusing initially on LNG.

Read also: LNG System Features and Controls

The Code addresses all areas that need special consideration for the usage of low-flashpoint fuels, taking a goal-based approach, with goals and functional requirements specified for each section forming the basis for the design, construction and operation of ships using this type of fuel.

LNG bunkering operations are however characterized by the interaction of multiple stakeholders and different regulatory contexts. This poses a challenge in different levels.

Whereas the IGF Code establish technical and functional requirements for LNG bunkering equipment and operations, its focus is mainly on the receiving vessel, and on its preparation for safe LNG bunkering operations. The bunkering interface is of course required to incorporate these requirements and be in line with them, ensuring consistency with other relevant regulatory instruments such as the ADR Convention or the Seveso Directive. Some functional requirements for bunkering have been included in the draft IGF Code but are mostly related to the receiving vessel, leaving the organization for bunkering, from the port side, outside of scope. Some important concepts are however included in the IGF, particularly in Chapter 18 where the “Person in Charge” (PIC) is defined, together with requirements on Check-lists and Communications, only to mention a few.

Recent Standards & Guidance Development for LNG Bunkering

There are currently different standards and guidance on LNG bunkering, either developed or under development. ISO has issued the Guidelines for systems and installations for supply of LNG as fuel to ships (ISO/TS 18683:2015), early in 2015, and is currently working on the finalization of ISO/DIS 20519 Specification for bunkering of gas fuelled ships. The last document is expected to bring a substantial set of functional requirements for LNG bunkering equipment and operations, including aspects such as bunker connectors, hoses, risk assessment, communications, safety distances, amongst many other aspects.

SGMF, also early in 2015, has launched their SGMF LNG Bunkering Safety Guidelines, as the reflection from contribution of different industry stakeholders, with the objective to provide the LNG bunkering industry with the best practices in order to ensure that LNG fuelled ships are re-fuelled with high levels of safety, integrity and reliability. The LNG Bunkering risk on Liquefied natural gas ships assessment and safety zonesBunkering Safety Guidelines include chapters on LNG Hazards (Leaks, Cryogenic, LNG Fire and Explosion), Safety Systems (Roles, People in Charge, Communications and Emergency Systems), Bunkering Procedures and Specific Safety Guidance for the different LNG bunkering modes.

IACS, the International Association of Classification Societies, has published in June 2016 the IACS Recommendation on LNG bunkering (Rec.142), a document which would later result in an update of the SGMF LNG Bunkering Safety Guidelines, in May 2017, with this later document incorporating both earlier SGMF work and the integral reproduction of Rec. 142.

Finally, the International Association of Ports and Harbours (IAPH) have developed specific LNG bunker checklists (IAPH LNG Bunker Check-Lists) for known LNG bunkering scenarios: ship-to-ship, shore-to-ship and truck-to-ship. These check-lists include specific requirements relevant for all parties involved in the LNG bunkering operations and are already in place in some ports where LNG bunkering operations are already in place.

Collectively, the above standards and guidelines represent the most significant set of references for LNG bunkering operations, today. Together with different national requirements and local/port regulations they are instruments for safe LNG bunkering operations, including provisions on risk & safety, bunkering/transfer equipment, training, bunkering procedures, amongst other aspects. Different bunkering modes are included and all stakeholders involved are featured with proposed good practice for safe operations addressing all parties.

- The receiving LNG-fuelled vessel, the LNG bunker barge/vessel;

- LNG truck;

- Terminal Operators, Person-in-Charge (PIC);

- they all find specific requirements which are relevant either to the equipment used in LNG bunkering operations, or to the procedures established as basis for the operation.

Despite some variations in terminology, all existing guidance mentioned above is consistent with a common 3-phase approach, dividing LNG bunkering, in whichever mode, into:

- Pre-Bunkering;

- Bunkering and;

- Post-Bunkering.

An additional 4th phase can even be considered: the Planning (where feasibility, risk and other studies pertaining permitting and certification are developed).

The missing part, in the opinion of the ESSF and its subgroup of experts on LNG, is the guidance to Port Authorities/Administrations in the specific context of LNG bunkering planning, permitting and operations. Check-Lists and guidance, as mentioned above, give a good reference to the requirements for Ports to put in place; however this is only part of what is expected from competent port authorities.

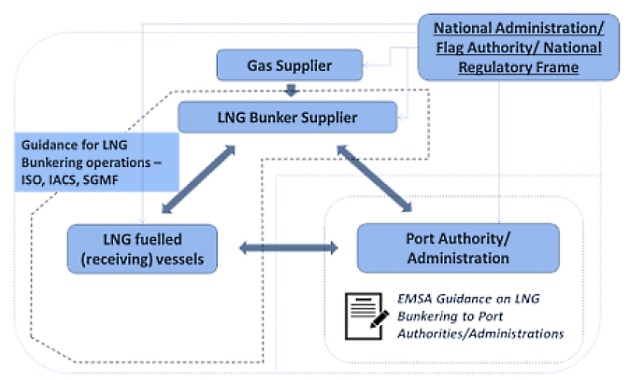

Byelaws, permitting, risk-based restrictions and tailor-made Emergency Response, amongst other aspects, are exclusive areas where Port Authorities/Administrations are given statutory powers and develop measures for good governance within the port area under their jurisdiction. Guidance to these competent authorities, on the different relevant aspects of LNG bunkering, is the objective of this document. The simple diagram presented in figure 1, below, (further developed in the definition of the Scope for the present guidance) presents the complete frame for LNG Bunkering where a triangle is completed between LNG Bunker supplier, Receiving Vessel and Port (competent) Authority.

EU Context

Directive 2014/94/EC on the deployment of alternative fuels infrastructure, part of the EU Clean Power for Transport package establishes a comprehensive set of requirement for an inter-modal development of an alternative fuel infrastructure. As defined by Directive 2014/94/EC, availability of LNG in EU core ports is scheduled for 31 December 2025 (maritime ports) and 31 December 2030 (inland ports), with the same document establishing an obligation for EU Member States to develop appropriate standards containing detailed technical specifications for refuelling points for LNG for maritime and inland waterway transport.

It will be interesting: Type “C” Tank Design Advancements: Analysis and Future Developments

In the context of the Directive, EU Member States are currently developing their National Policy Frameworks, in line with the provisions of Article 3 of the same instrument, to be notified to the European Commission by 18 November 2016. Following the notification of these, down to the operational level and towards implementation, it is important that EU harmonization can be supported, not only by reference to higher level international documents, standards or guidelines, but also by having in place guidance to the lower level requirement definition, where local and port authorities are envisaged.

Despite the provisions of the Directive, in fact, LNG bunkering is already well advanced and taking place in several ports in Northern Europe, with first movers and pilot project initiatives where LNG fuelled vessels operation represent the largest share of the worldwide LNG fuelled fleet. Co-financing programs, such as the CEF CEF – Connecting Europe Facility is a policy aiming to realise a core transport network comprising nine major corridors, to be completed by 2030. The infrastructure package stipulates a need to update the current energy infrastructure and also identifies a need to improve gas infrastructure. As part of the CEF, this package identifies priority gas corridors and projects that can be considered potential projects of public interest and likely to need funding under CEF.x, for studies, pilots and implementation works have been promoting and facilitating this development. It is now important to extract the main lessons learnt, specific experience-based advice and to address the most relevant challenges to harmonization, such as permitting procedures and training/qualification requirements for all those involved in the operation.

The Engineering solutions are already in place, demonstrated not only through the implementation of different LNG bunkering initiatives but also in several Feasibility Studies for prospective projects and ongoing implementation works. Not only it is possible to bunker LNG to a variety of different LNG fuelled vessels but also it is possible to do it safely and following a variety of different possible bunkering modes. The infrastructure is therefore expected to develop highlighting further the need to have a consistent minimum set of good practice references which, together with the existing standards and industry guidelines, can assist authorities in the different areas of LNG bunkering.

Guidance Map

| Table 2. Guidance Map | |||

|---|---|---|---|

| Part | Section | Title | Key Contents |

| A. General | 1 | Scope and Applicability | Scope and Application of the Guidelines |

| 2 | LNG as Fuel | LNG as fuel | |

| LNG Bunkering modes | |||

| Introduction to Equipment | |||

| 3 | Environment | Good Environmental practice in LNG Bunkering | |

| B. Governance | 4 | Regulatory Frame | Rules, regulations and standarts |

| Guidelines – Overview | |||

| Check-lists | |||

| 5 | Ports | Port governance principles | |

| Good governance and framework for LNG bunker operations in the port | |||

| Drivers for LNG Bunkering options | |||

| 6 | Feasibility | Feasibility studies | |

| Evaluation and support to prospective projects | |||

| 7 | Permitting | Permitting Procedure | |

| Bunkering Location Selection | |||

| Information management | |||

| C. Risk & Safety | 8 | Risk | LNG Hazards |

| Risk Criteria | |||

| Risk Assessment Evaluation | |||

| 9 | Control Zones | Safety Distances & Control Zones | |

| D. Organization | 10 | Process Map & Organization | LNG Bunkering Process |

| Responsibilities | |||

| 11 | SIMOPS | Simultaneous Operations | |

| E. Bunkering | 12 | Bunkering | LNG Bunkering Procedure |

| Pre-bunkering Check-Lists Weather & Operational Envelopes | |||

| Authorization Procedure | |||

| Communications Lighting, Mooring and Access | |||

| Control & Overview | |||

| Traffic control | |||

| Post-bunkering checks | |||

| Purging and inerting | |||

| 13 | Incident Reporting | LNG release reporting | |

| Incident reporting procedure | |||

| Near Misses | |||

| F. Emergency | 14 | Emergency Preparedness & Response | Emergency, Preparedness and Response for different stages of the LNG Bunkering Process |

| Approval of Emergency Response Plans | |||

| Shore side contingency Plans | |||

| D. Certification | 15 | Certification, Accreditation | Compatibility Assessment |

| Accreditation | |||

| Certification | |||

| 16 | Qualification and Training | Qualification for personnel involved in LNG | |

| Bunkering | |||

| Training | |||

Instructions Guidance

The EMSA Guidance on LNG Bunkering to Port Authorities/Administrations, hereafter referred to as “EMSA Guidance” offers, simultaneously, a reference to guide Port Authorities/Administrations (PAAs) through the relevant stages of LNG Bunkering Planning and Operations and, at the same time, an informative source on the different. The EMSA Guidance is divided into 4 (four) main Sections and 17 (seventeen) sub-sections as presented in the Guidance Map. The table below presents the main objectives and practical aspects that can be found in each of the fifteen sub-sections.

| Table 3. EMSA Guidance on LNG Bunkering – Sections insight | |||

|---|---|---|---|

| A. General | 1 | Scope and Applicability | Scope and Applicability of the EMSA Guidance are defined, especially in the context of other guidelines, standards and references of good practice in the context of LNG Bunkering. |

| List of Terms / Definitions with references. | |||

| 2 | LNG as Fuel | Informative section on the characteristics of LNG as fuel for shipping. | |

| LNG Bunkering options and other possible operations with LNG as fuel. | |||

| 3 | Environment | Overall benefits of LNG as fuel, remarkably on the reduction of GHG/CO2 emissions, are highly dependent on the adequate understanding of methane emission’s environmental impact. | |

| Apart from the informative aspects the present section defines best practice guidance to avoid mitigate the risk of natural gas emissions during LNG bunkering operations. | |||

| B. Governance | 4 | Regulatory Frame | List of the main relevant instruments for LNG as fuel for shipping, with a particular focus to those where references to Bunkering can be found. |

| Description of the main references and applicability of different instruments on LNG Bunkering. | |||

| Best practice for the formulation of Port Regulations in the context of LNG bunkering. | |||

| 5 | Ports | LNG Bunkering is here regarded in the context of Ports Good Governance. Different Port management principles are considered and their particular aspects are, again, used to frame the specific case of LNG Bunkering. | |

| In essence, sub-section 5 addresses the main aspects of Ports Good Governance, making the parallel with the LNG Bunkering development, from Planning to Operations. | |||

| 6 | Feasibility | A Feasibility Study incorporates a large number of aspects that are relevant for the development of LNG Fuel infrastructure. The elements which are relevant to Ports should be, on top of those directly related to the bunkering interface, also distribution links within Port Area, LNG small scale storage and others. | |

| Only technical and operational aspects are included. Economic feasibility outside the scope of this document. | |||

| 7 | Permitting | Sub-section intended to provide best practice in permitting processes for LNG Bunkering. | |

| Included flow-chart with reference permitting process. | |||

| C. Risk & Safety | 8 | Risk | Part on LNG Risk / Safety including information on LNG safety hazards, risk assessment options, HAZID, HAZOP and related concepts. Not extensive and mostly referring to existing references on LNG and Natural Gas. |

| Best practice guidance on how to assess/evaluate Risk Assessment Reports. List of relevant elements/contents for a Risk Study on LNG Bunkering. | |||

| Risk Criteria – Existing Risk Criteria applicable to LNG Bunkering. | |||

| 9 | Control Zones | Best practice in the approval and definition of Control Zones, in particular of Safety Zone and Hazardous Zone. | |

| Examples of best practice application in the definition of Control Zones. | |||

| D. Organization | 10 | Process Map & Organization | The core process of LNG Bunkering operation is defined, with consideration for different LNG Bunkering concepts. |

| Definition of Responsibilities. | |||

| 11 | SIMOPS | Proposal for a procedure to facilitate Simultaneous Operations during LNG bunkering. | |

| E. Bunkering | 12 | Bunkering | Bunkering process, with outline of the relevant events in bunkering, supported in a demonstration of an LNG transfer operation between two pressurized tanks (type-C). |

| Definition of the main technical concepts in the bunkering operation. | |||

| Outline of the necessary actions, from a Port Authority perspective, to be taken before, during and after LNG bunkering operation is authorized. | |||

| Procedures in Communications, Approval of Bunkering Operation, Implementation of Safety Controls, Verification. | |||

| 13 | Incident Reporting | Definition of best-practice procedure for LNG Bunkering incident and near-miss reporting. | |

| Check list/template provided with the essential elements suggested for LNG bunkering incident, or near-miss, reporting. | |||

| F. Emergency | 14 | Emergency Preparedness & Response | Best practice in Emergency, Preparedness and Response in the case of LNG related incidents, addressing all hazards listed in sub-section 8. |

| Emergency Plan for LNG Bunkering. | |||

| G. Certification | 15 | Certification & Accreditation | Definition and differentiation of the different concepts. |

| Certification of LNG Bunkering equipment. Identification of relevant certification processes. | |||

| 16 | Qualification Training | Qualification for the necessary competencies to operate in LNG bunkering. | |

| Training for and on LNG Bunkering. In addition to the competences and qualification requirements. Training program for the Port Authority on LNG Bunkering supervision and Emergency response. | |||

The objectives inside each section, as above described, is to provide PAAs with Information and Guidance on LNG Bunkering. Firstly, Information on the aspects already covered by other instruments (regulations, standards, industry guidelines), such as technical requirements for design, LNG bunkering concepts, modes and procedures for safe LNG transfer. Secondly, by providing Guidance to Port Authorities and Administrations in developing of the necessary control mechanisms, allowing for the safe development of LNG bunkering in EU Ports.

Read also: Key Characteristics of Membrane Tanks Systems

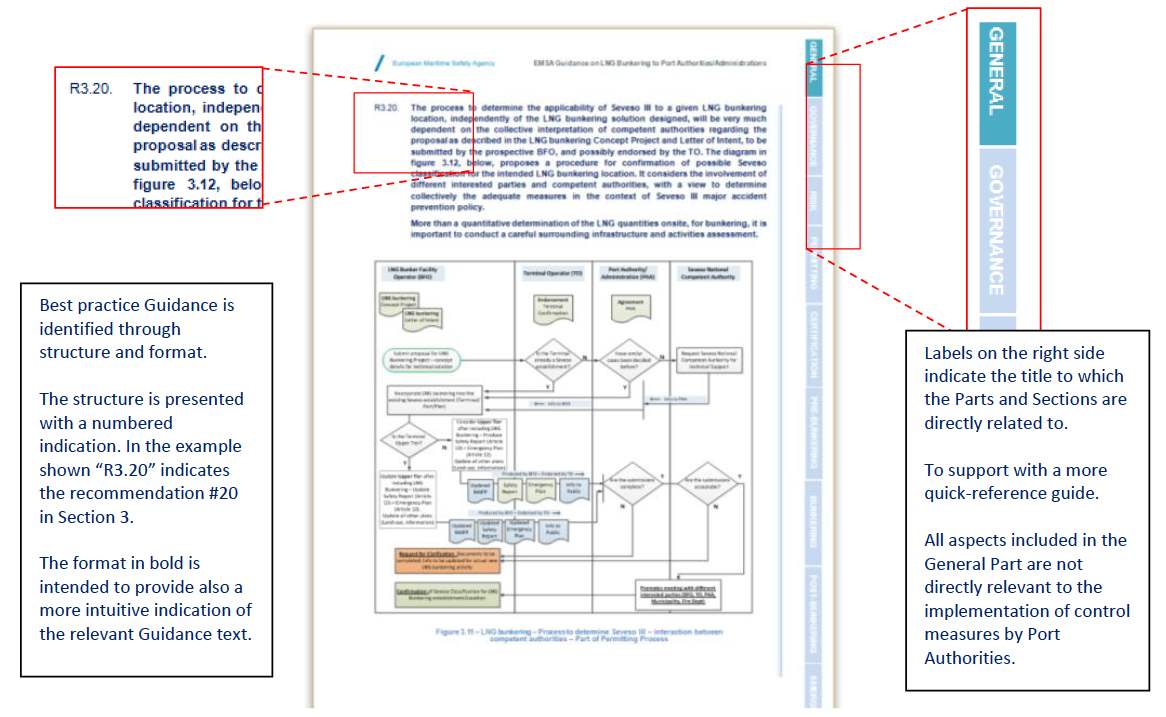

The Guidance is structured in 4 (four) parts and 15 (fifteen) sections, following the natural sequence of the LNG bunkering Process. Each section contains Information and Guidance in a distinguishable manner through the format of the text and structure given to each sub-section. Figure 6 shows the difference in text section format between more informative part and the good The word “best” is generally not used in the onshore/offshore industries. This is because the goal is to encourage good practices that meet the legal requirements. The word “best” implies exceeding the legal requirements (it also implies there is nothing better). For many reasons (often cost) “best” cannot be adopted although “good” practices can and are more likely to be adopted.x practice guidance provided to PAAs by this Guidance.

Labels are provided on the side of the document, dividing further the Guidance into the 9 (nine) labels as presented in tables 2 and 4. The labels provided for an intuitive division where the titles and sections are divided according to the sequence in LNG Bunkering.

Scope, Applicability & Definitions

This Guidance sets best practice control measures for LNG bunkering, and small scale LNG storage, relevant to Port Authorities-Administrations in their role on permitting, evaluating, approving, certifying, controlling, overviewing, documenting and providing/coordinating response in case of emergency.

Scope

The scope of this Guidance is limited to LNG bunkering Elements related to LNG as cargo, LNG terminals or other LNG wider value chain are excluded from the scope of this Guidance.x, covering the following elements Scope for the EMSA Guidance based on a gap analysis of existing references, in the context of the EU LNG Study, LOT1.x:

Regulations

- High level instrument at EU and international levels, relevant for LNG bunkering.

- Standards.

- Guidelines.

- Industry best practice.

- Port Regulations.

Operations

- Control Zones.

- Safety Distance approval.

- Simultaneous Operations (SIMOPS).

- Mooring of the receiving ship and bunker facility.

- Check-lists.

- Operational Envelopes (weather conditions, sea state, wind speed and visibility).

- General Procedures for Port Authorities.

Permitting

- Spatial planning.

- Approval of bunker locations.

- Definition of simplified.

- Overall responsibility for the good governance and framework for LNG bunker operations in the port.

Risk & Safety

- LNG Bunkering Risk Assessment.

- Definition of Risk Acceptance Criteria.

- Evaluation of Risk Assessment reports – Best practice for the evaluation of Risk Assessment report.

Emergency

- Approval of safety and emergency response plans.

- Emergency Preparedness & Response Plan.

- Shore side contingency plans, emergency response systems.

- Definition of emergency procedures for the different types of LNG Bunkering.

- Best practice in response to LNG Hazards.

Quality Management

- Several elements considered relevant to ensure the quality of the LNG bunkering process – standards and rulesLNG bunkering process, from a PAA perspective.

- Check-lists updated to include relevant indications for PAAs.

- Incident Reporting.

- Port Bye laws. Best practice in setting up port specific requirements.

Certification

- Accreditation of the Bunker Facility Operator (BFO).

- Qualification of the Person in Charge.

- Applicability of an accreditation scheme for LNG bunker operators in the ports under their authority.

- Certification of LNG bunker barges, non-IGC bunker vessels.

Training

- Training Matrix with identification of multiple training requirements in the Bunkering Interface.

- Competencies, Qualifications and Training for LNG Bunkering.

- Qualification for the PIC.

- Training Certification.

Applicability

The EMSA Guidance applies to Port Authorities/Administrations (PAAs) when involved in LNG Bunkering within their areas of port jurisdiction, either during the exploratory and planning phases or, at later stages of development, already in the context of actual LNG Bunkering operations.

The EMSA Guidance is applicable in a complimentary way to existing Standards, Guidelines and Industry Best Practice instruments, aiming to provide best practice recommendations to PAAs wherever their action is relevant, in control, evaluation, or even in guidance on the several different aspects of LNG bunkering.

It will be interesting: Basic Knowledge of Safe Working Practices and Procedures in Accordance with Legislation and Industry Guidelines Relevant to Liquefied Gas Tankers

The EMSA Guidance is applicable to the control of LNG bunkering operations by PAAs in EU Core Ports, wherever EU law is applicable. It is applicable for:

- Different LNG Bunkering methods, Fuelling with LNG at berth and Shore-side LNG electricity production.

- Different ship types.

- And different locations (in port, off shore and terminal) worldwide.

Note:

- Regulatory frame applicable to LNG bunker barges/boats/ships will depend on their area of operation. If below 500GT and not engaged in international voyages, in principle, IGC does not apply (unless enforced by national legislation). ADN agreement applies, to all LNG barges/boats/ships of contracting parties, engaged in the inland waterway transport of LNG.

- Port Administration is, in the context of the EMSA Guidance, a holder of administrative responsibility; possibly with partial delegated authority (this can typically be the case of a private Port or of a landlord Port (mostly responsible for leasing the land). Different local, regional or national context should here be taken into account.

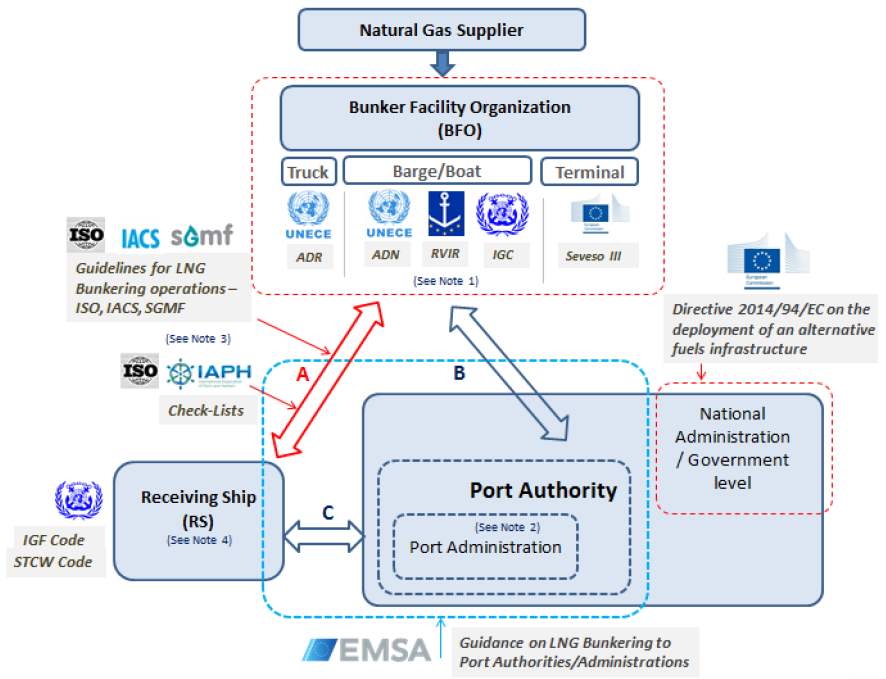

- The Guidelines from ISO, IACS and SGMF offer guidance and establish requirements that cover Functional Requirements for LNG bunkering equipment, responsibilities of RS and BFO, Risk Assessment principles, amongst other aspects relevant for interaction (A) above.

- Receiving Ship is assumed to be either an IGF Code vessel (if constructed, or converted to LNG fuel, after 1st January 2017). Before that date the IMO Interim Guidelines apply (Res. IMO MSC.285(86) Interim guidelines on safety for natural gas-fuelled engine installations in ships (2009)).

Objectives

The objectives defined for the EMSA Guidance on LNG Bunkering are to assist Port Authorities/Administrations with:

- The necessary elements to develop a harmonized procedure for the evaluation, control and through-life assessment of LNG bunkering projects.

- Definition of a unified set of first principles for permitting and approval, including a common risk assessment evaluation approach and common suggested risk acceptance criteria for the bunkering of gas as fuel in the respective.

- Implement harmonized bunkering procedures in EU ports to reduce the potential confusion caused by having to comply with different rules and regulations in different ports.

- Clear suggested definition for the responsibilities of the different involved parties including landside and waterside authorities regarding the bunkering of LNG, both in in case of normal operation and in case of malfunction or emergency.

- Definition of a procedure to allow evaluation, control and authorization of SIMOPS with LNG bunkering.

- Proposal for a harmonized approach to the approval of Control Zones in different bunkering scenarios, through the implementation of a concept of “meaningful protection”. In addition to a deterministic or probabilistic approach, it is suggested to include a context-based approach where the determination of Control Zones is driven mostly by the presence of elements meriting protection in the vicinity of the LNG bunkering location.