The global push for cleaner energy has positioned liquefied natural gas (LNG) as a leading alternative fuel for the maritime industry. While LNG offers significant environmental benefits, its unique properties necessitate a meticulous and highly regulated procedure for refueling ships. The bunkering process – the transfer of fuel from a supply vessel or terminal to a receiving vessel – is therefore more than a simple transaction. It is a complex operation requiring precise planning, strict adherence to safety protocols, and clear communication among all parties involved.

This article serves as a definitive guide, breaking down the entire bunkering process into its core components, from the initial planning phase to the final checks, and clarifying the key responsibilities of everyone involved.

Process Flow – LNG Bunkering

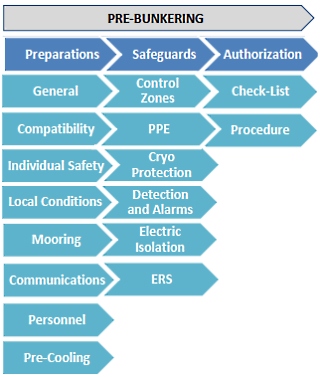

The Process Flow for LNG bunkering operation is generically described below, including the Planning and Operation phases.

Planning Stage

Operation

Responsibilities

PAA Responsibilities

PAA responsibilities in LNG Bunkering are listed in table 1, below.

| Table 1. PAA Responsibilities in LNG Bunkering | ||

|---|---|---|

| Port Role/Responsibility | Summary description | |

| Develop a regulatory framework for LNG bunkering in the ports | The development of an adequate Port Regulation that is inclusive of LNG bunkering is the fundamental instrument for the development of this activity within a port. | |

| Ensure adequate integration of different LNG bunkering regulations, standards and guidelines. | ||

| PAAs should, in this particular aspect, seek to ensure harmonization with other ports, at national, regional or global level, in the best interest of all parties involved. | ||

| Allow for adequate information on LNG bunker activities within the port by reporting procedures | Implementation of well-documented permitting procedures, including relevant provisions for management of modifications. | |

| Definition of adequate channels for communications, with the identification of the responsible Port representative(s), electronic address, or other that should be taken into account by RSO, BFO or other interested parties. | ||

| Adequate information channel for reporting of incident and near-misses in LNG bunkering. | ||

| Support to involved parties and other national competent authorities in the context of any LNG bunkering incident. | ||

| Develop restrictions on bunkering operations if necessary | Restrictions on bunkering operations can be of several types and dependent on different factors: | • Risk Assessment based Restrictions and limitations may be the practical result from risk assessment results. These may be restrictions on bunkering parameters (pressure, flow rate, hose diameter) or restriction in other operational aspects. |

| • Weather based Weather elements, such as wind, rain, temperature can determine possible operational envelopes. | ||

| • Local harbour/maritime traffic Special local maritime traffic conditions can dictate restrictions to bunkering. PAAs should be able to aim for a balance of normal operating profiles within the port, whilst ensuring the sufficient safeguards for the LNG bunkering location. | ||

| • Security restrictions Restrictions on LNG bunkering may arise from possible security related elements. Ports should avoid, to the extent possible, to favour restrictions in looking for safe LNG bunkering operations. It should be important to develop a favourable environment for this type of operations, based on a minimum restriction approach. | ||

| Approval of Safety zone in way of the bunkering area | The safety zone is an important parameter that should be calculated by the BFO and approved by the PAA. | |

| It is important, as good practice, to allow sufficient freedom to the BFO to elaborate on LNG bunkering parameters, local safeguards and to submit the proposal to the PAA for evaluation and approval. | ||

| It should be avoided, also in the terms of a good practice approach, a fixed safety distance applicable to all situations. This approach is not consistent with the mechanism that justifies the fixation of the safety distance, based on considerations on gas dispersion. Since this is fundamentally affected by environmental and local conditions, it is important to evaluate a proposed safety distance also in the light of these parameters. | ||

| Definition of Security Zone around bunkering location | The definition of the Security zone should be a responsibility of the PAA (eventually defined by the Administration and approved by the Port Authority). | |

| The fundamental objective of the Security Zone is to allow control of any possible element that may cause interference with the LNG bunkering operation. | ||

| Maintenance of the Security Zone should be a responsibility of the PAA, allowing for an alternative security maintenance scheme if so agreed between all parties, subject to approval of the Port Authority. | ||

| Confirmation of Hazardous Zone | Surrounding the LNG bunkering manifold connections a hazardous area shall be defined at the responsibility of the BFO and RSO. | |

| Port Authorities should confirm by inspection that all personnel working and equipment used inside Hazardous Zones is adequately certified for the area in consideration. | ||

| PPE and EX-proof material should be used. Even though a responsibility of the parties involved, the maintenance of the permitting should be based on periodic confirmation by PAAs that all safety procedures and measures are well kept in place and ensured by parties involved. | ||

| Approve and enforce additional control zones (in addition to Hazardous, Safety and Security Zone) | In addition to Safety Zone and Security Zone, other Control Zones may be defined to ensure the safe execution of LNG bunkering operations, These may involve navigation restricted areas or other control zones. | |

| It is important that the definition of relevant control zones is effective and adequately enforced. The definition of the relevant zones should take into account the local conditions and infrastructure that may influence the access control to these areas. | ||

| Establish passing distances for other ships during LNG bunkering | Either in context with Safety or Security zones, or even separately, the control of passing navigational traffic should be a concern of PAAs. | |

| The necessary measures should be developed, implemented and adequately enforced in order to restrict navigational traffic in the way of the LNG bunkering location. | ||

| The need for control of passing navigational traffic will also vary according to the LNG bunkering type into consideration (STS at berth, STS at anchor, PTS, TTS) with all STS modes deserving the closest attention. | ||

| Similarly to all control zones, also in the definition of passing distances for other ships the main objective is to avoid any external interference on the LNG bunkering operation. | ||

| Mooring requirements | Safe mooring during LNG bunkering operations is a fundamental element to allow a stable and secure LNG bunkering interface. | |

| It should be the role of the PAA to define the standard requirements for mooring, including under which conditions reinforced or special mooring should be considered. | ||

| Mooring of the receiving ship and bunker facility, industry standards may be referenced (e. g. OCIMF Effective Mooring 3rd Edition 2010). | ||

| Develop environmental protection requirements | As mentioned in Section 3, LNG bunkering operations should deserve careful attention with regards to potential negative environmental impact. | |

| The adequate prevention of any methane release in connection/disconnection, inerting/purging, or even in pressure relief, depends mostly on the definition of good procedures for pre-bunkering, bunkering and post-bunkering phases, including consideration for equipment compatibility. | ||

| It is important that PAAs establish as a minimum requirement that no venting is allowed. Adequate measures for control should also be developed. | ||

| LNG bunkering checklists | The implementation of LNG bunkering checklists is an important measure to ensure adequate documentation of important aspects of LNG bunkering operations. | |

| IAPH check-lists, ISO 20519 or their adaptation as include in the present Guidance, can be used for this purpose. | ||

| It is the role of the Port Administration to ensure that adequate verification and treatment of validated check-lists is adequately done. This may be either part of the port regulations or a requirement derived from the permitting process. | ||

| Develop proposals for spatial planning and bunker locations | Concurrently with other competent authorities with responsibilities for land planning, use, classification and administration, PAAs should consider the need to integrate possible LNG bunkering locations into the spatial planning of the port. | |

| A possible approach is to determine pre-destined locations for LNG bunkering, allowing for easier prospective permitting processes. | ||

| Important elements to take into account for spatial planning: | Waterways accessibility; | |

| Proximity of locations handling/storing hazardous substances; | ||

| Emergency response facilities; | ||

| Proximity of Populated areas and commercial services Commercial; | ||

| Areas of restricted security. | ||

| Approve Spatial planning elements and LNG bunkering location | Based on elements developed in the proposal for spatial planning, above, it should be the role of the Port Authority, following the administrative proposal, to assess the compliance of the proposal with respect to major accident prevention requirements and other national port authority regulations. | |

| Develop measures to allow possible simultaneous activities and operations (SIMOPs) during LNG bunkering | Simultaneous Operations (SIMOPs) are an important aspect to consider especially in LNG bunkering of larger ships with short turn-around times (such as passenger vessels and container ships). | |

| PAAs should be involved and dialogue with interested parties, from the beginning, in the development of the necessary measures to allow SIMOPS to be conducted in the safest operational environment possible. | ||

| Port Administrations, as a good practice approach, can be involved with the role of finding and developing the necessary solutions, in support to BFO and RSO, that can support SIMOPS to take place. | ||

| Approve SIMOPs | Port Authorities should be responsible for the approval of SIMOPs. | |

| This approval can however be distinguished in two levels: | 1) Permitting; | |

| and 2) Approval. In the first the BFO and RSO may be certified, within a given permit for operation, to undertake SIMOPS. On the second, Approval, the Port Authority should confirm that all necessary and agreed elements in the permit are well in place. | ||

| Develop general procedures for traffic control and restrictions in case of an LNG bunkering | Both to ensure the integrity of the Safety and Security zones (and any other control zones defined by the PAA) it is important to define relevant traffic control and restrictions. | |

| Amongst the measures for traffic control the following can be considered: | Visual signals and traffic indications; | |

| Speed limit (with possibility to vary speed limit indication depending on operational context); | ||

| Barriers to restrict traffic; | ||

| Traffic lights for temporary restriction; | ||

| Active manned traffic control; | ||

| Traffic diversion. | ||

| The adequate degree of authority should be ensured to implement and enforce the defined Traffic restrictions. | ||

| Establish clarity on the roles and responsibilities between the involved parties | The adequate definition of responsibilities between all parties involved should be a central aspect of Port Regulations. | |

| In the absence of definition in relevant port instruments the responsibilities to be defined should take EN ISO 20519, the present guidance and Industry relevant guidelines. | ||

| PAAs should also define clear internal division of responsibilities (permitting, inspections, emergency, amongst others). | ||

| Emergency Response Plan (internal) | PAAs should, in cooperation with other relevant competent authorities, approve the Emergency Response Plan developed by the BFO. | |

| Approve internal LNG bunkering facility emergency response plan. | In approving the internal ERP PAAs should develop good practice to collect elements and check for compatibility of possible existing port emergency or contingency plans. This is particularly relevant and important for major accident scenarios, where good coordination between all parties is necessary. | |

| Emergency Response Plan (external) | Based on the approved internal emergency plan developed and submitted for approval by the BFO, PAAs should develop/update their emergency plans. | |

| Develop external emergency plan, based on internal LNG bunkering facility emergency response plan. | All ERPs should be aligned and adequate management of possible modifications should be ensured. | |

| The adequate reflection of the multi-operator environment should be a challenge addressed by PAAs when developing the external emergency plan. | ||

| Emergency Response Plan (external) | In cooperation with other relevant competent authorities, Port Authority should approve the external ERP, taking into account all relevant ERPs existing in the multi- operator context of the port. | |

| Approve external emergency plan | The Port Authority should, in particular for this approval, and whenever major accident prevention aspects are relevant, liaise directly with the competent authorities responsible for that particular area. | |

| Emergency Response Plan (training) | In order to ensure adequate implementation of the Emergency Response Plan, PAAs should develop and put in practice an adequate training program to be undertaken by all relevant members of the emergency response organization. | |

| Initiate an LNG trained and LNG prepared emergency response organization | It is the responsibility of the PAA to ensure that all staff members directly or indirectly involved are aware of their roles in emergency. | |

| Training in LNG bunkering emergency & response should consider the involvement of all relevant operators involved in LNG bunkering. | ||

| Build adequate Enforcement capacity | Enforcement is an important factor to ensure that the relevant requirements are well implemented and complied with by the relevant parties involved in LNG bunkering. | |

| Initiate an enforcement system by LNG trained enforcements officers | Requirements and relevant legal/technical provisions should therefore be enforceable, clear and well understood by all parties. | |

| It is also very important that the enforcement exercise takes into account the practical aspects, both in terms of equipment and cost-benefit of possible safeguard solutions. | ||

| Approve risk acceptance criteria | In the absence of relevant directly applicable risk acceptance criteria, the BFO, RSO or Port Administration may propose relevant risk criteria to be adopted. | |

| As a good practice approach, where better procedure is not available, the risk criteria should be subject to approval by the Port Authority. | ||

| In approving the risk criteria, Port Authority should liaise in close cooperation with other relevant competent authorities involved in prevention of major accidents, or with responsibilities on civil and port protection. | ||

| Accreditation of the BFO | In pursuit of a transparent and equitable regulatory and administrative framework for the development of LNG bunkering in ports, PAAs should develop an LNG bunkering accreditation scheme. | |

| Authorize /accredit bunkering facilities, once they have demonstrated that they are compliant and prepared | The scheme should be clear and allow for equal opportunities to all those that present intention or projects for LNG bunkering within the port. | |

| The following factors should be taken into account for the accreditation scheme: | Certification of LNG bunkering Equipment; | |

| Qualification of BFO personnel; | ||

| Safety Management System implemented by the BFO; | ||

| Number of available hours per year; | ||

| Results of periodic in-service inspections. | ||

| Qualification of the Person(s)-in-Charge (PICs) | Define the main elements to consider for the qualification of the Person-in-Charge (PIC). | |

| What competencies should be derived from the already IGF-defined responsibilities for the PICs should be a responsibility of PAAs. As a minimum it should be here considered that the RSO and BFO PICs should have equivalent qualification for LNG bunkering operation. | ||

| Restrictions for repairs and maintenance on LNG installations on board of ships | (Not directly related to LNG bunkering). | |

| Repairs and maintenance of LNG fuelled ships, either planned or non-planned, in designated areas or other locations within the port should be subject to consideration of the PAA. | ||

| Subject is not related to LNG bunkering but it is of great relevance and importance in the context of operations with LNG fuelled ships. | ||

| Safety requirements for LNG propelled ships on (dock)yards | Even if the repairs of LNG fuelled ships take part in dedicated shipyards, PAAs should be reassured that relevant precautions and procedures are followed in both unloading-inerting and commissioning-cooling-loading operations. | |

| Shipyards should be required to have relevant procedures in place to allow for safe repair works in LNG fuelled ships. | ||

| Subject is not related to LNG bunkering but, for the same reason as the previous point, it is included in the present Guidance under article Guide to Certification, Accreditation, and Equipment Standards for LNG Bunkering“Certification & Accreditation”, on Certification/Permit to Work. | ||

| Safety requirements for LNG propelled ship on a lay bye berth to avoid a BOG problem | In the context of the development and implementation of relevant provisions for methane release mitigation, PAAs consider the development of all necessary measures to reduce the amount of NG release to the atmosphere. | |

| Should an LNG fuelled ship be on a lay bye berth it should be possible to ensure that adequate measures are put in place to avoid difficult BOG management situations, in particular when LNG vapour pressures are such that PRVs are actuated allowing the pressure relief at cost of environmental impact of methane release to the atmosphere. | ||

Planning Phase

Port Authority & Administration

As included in Table 1, above. PAAs should develop an active support role during the Planning Phase for prospective Comprehensive Overview of LNG: Scope, Characteristics, and Bunkering SolutionsLNG bunkering projects.

RSO and BFO

Responsibilities for RSO and BFO, during the Planning Phase are well detailed in IACS Rec.142, on which the Table 2 (Receiving ship operator (RSO) and bunkering facility organisation (BFO) responsibilities) provides a good overview of the main responsibilities for both Operators in preparation of LNG Bunkering Projects, including all relevant elements in preparation of Permitting Processes.

Read also: LNG Regulatory Framework International and European Maritime Safety Overview

PAAs, whenever receiving declared intention from operators for the proposal of as LNG bunkering Project, should assist in the elements contained in IACS Rec.142, Table 2. Providing as much elements in advance as possible will benefit all parties in the development of a well prepared proposal.

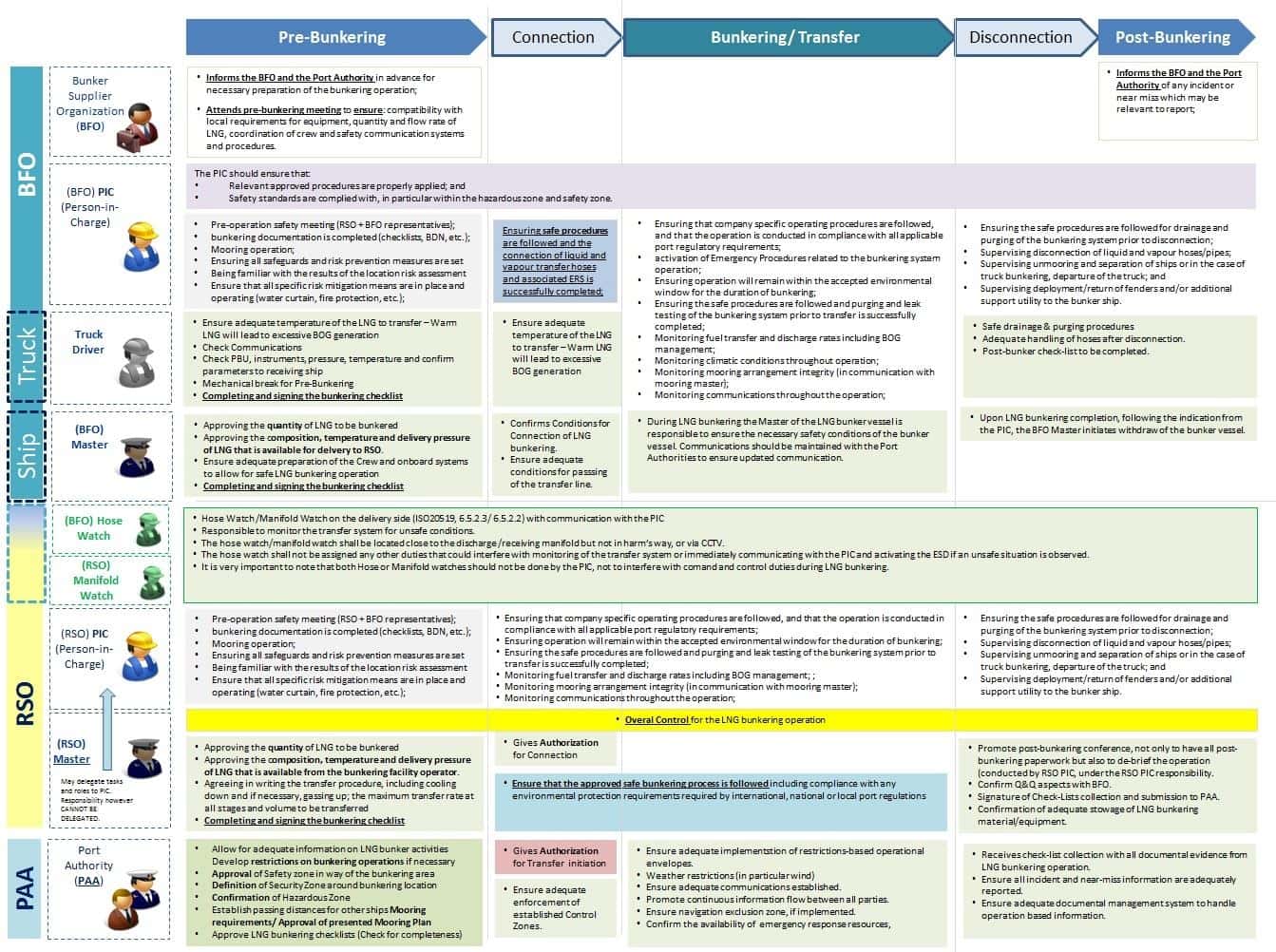

Operational Phase

ISO 20519, IACS Rec. 142, and SGMF Guidelines define, collectively, the complete set of Responsibilities of the different parties involved in LNG bunkering operations.

The Figure in the next page presents a summary of the relevant responsibilities between all parties. The two PICs are represented, giving illustration to IGF and ISO 20519 requirements/provisions. It hasn’t been represented which of the PICs take the leading position. This has however to be determined in pre-bunkering conference.

LNG Bunker Management Plan (LNGBMP)

IACS Rec.142 defines an LNG Bunker Management Plan (LNGBMP) as an important element that PAAs should consider whenever assessing LNG bunkering projects, or a bunker management plan, as defined in IACS Rec.142, should be compiled to allow for easy availability of all relevant documentation for communication between the receiving vessel and the BFO and if applicable the terminal and/or third parties.

In this context, PAAs may have relevant information in the LNGBMP and, as recommended by the present article, should give good consideration to I since the early stages of any given LNG bunkering project or activity.

The Bunker Management plan should be stored and maintained by both RSO and BFO (as transcribed from IACS Rec.142:

- Description of LNG, its handling hazards as a liquid or as a gas, including frostbite and asphyxiation, necessary safety equipment, personal protection equipment (PPE) and description of first aid measures.

- Description of the dangers of asphyxiation from inert gas on the ship.

- Bunkering safety instructions and emergency response plan.

- Description of the bunker facility LNG tank measurement and instrumentation system for level, pressure, and temperature control.

- Definition of the operating envelope for which safe LNG bunkering operations can be undertaken in reference to temperature, pressure, maximum flow, weather and mooring restrictions etc.

- A procedure for the avoidance of stratification and potential rollover, including comparison of the relative temperature and density of the remaining LNG in the receiving tank and that in the bunker provider tank and action to be taken to promote mixing during bunkering.

- The description of all risk mitigation measures to comply with during an LNG bunkering.

- The description of the hazardous areas, safety zone, and security zone and a description of the requirements in the zones to be complied with by the receiving vessel, the bunkering facilities, and if applicable the terminal and third parties.

- Descriptions and diagrams of the bunker facility LNG bunkering system, including, but not limited to, the following as applicable:

a Recirculating and vapour return line system.

b LNG fuel tank cooling down procedure.

c Procedure for collapsing the pressure of the receiving tank before and during bunkering.

d LNG fuel tank pressure relief valve.

e Ventilation and inlet/outlet location.

f Inerting system and components.

g Boil-off gas compressor or re-liquefaction system.

h Gas detection system including locations of detectors and alarms.

i List of alarms or safety indication systems linked to the gas fuel installation.

j LNG transfer line and connectors.

k Emergency Shutdown System description

l Communication systems and controls protocol.

In addition to the above list of description and schematic drawings, the LNGBMP should include:

- Documents/reports on periodic inspections of the BFO LNG installation (components), and safety equipment.

- A checklist to verify that the ship’s crew have received proper training for bunkering LNG.

- Bunkering safety instructions See IACS Rec.142, section 4.1.3.1 Bunkering safety instructions.x and safety management plan.

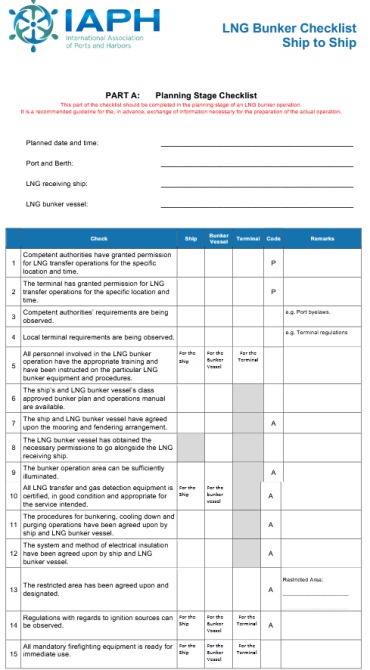

Check-Lists

Check-Lists are fundamental tools to assist all stakeholders involved in LNG bunkering planning and operations. They allow for an adequate verification of the different stepwise procedures, being also important in documenting important steps in the whole LNG bunkering operation.

IAPH Check-Lists for LNG Bunkering have become an important reference in the context of LNG bunkering:

In addition to the above, ISO 20519 includes also check-lists in Annex-A, (Part A to Part E), developed by ISO and SGMF for use with the standard. As indicated in ISO 20519, alternative check lists may be used as long as they contain at least the same information that is listed in its attached check sheets.

In addition, ISO 20519 provides for the possibility that sections 6.2.1 and 6.2.2 may be considered and checklist points that apply to those items may, in principle, only need to be conveyed once (and after any changes) need not be checked off after the first transfer if both parties involved in the transfer agree and local or national authorities allow the omission.

It will be interesting: LNG Operating Regulations Including LNG Bunkering Gothenburg Energy Port

As an option; the checklists developed by SGMF and the International Association of Ports and Harbours (IAPH) published by SGMF in their “Gas as a Marine Fuel Safety Guidelines, Bunkering” 2015 Version 1.0, February 2015 may be used in place of the ISO 20519 checklists under the following conditions (as noted in the ISO instrument)

1) Both parties involved agree to use the alternative checklists.

2) The competent authorizes permit their use:

- The checklists are used from pre-operations through completion of the transfer (no mixing of lists).

PAAs may consider the need to adapt Check-Lists to specific LNG bunkering projects proposed, where the existing references lack elements which may be considered relevant.

It is, above all things, important to note that the Check-List procedure agreed provides the necessary reassurance to all parties that all relevant procedures are being followed, that not step is left behind or forgotten. LNG bunkering, in all of its different modes and possibilities, is a complex operation. Only through a structured mapped check-list procedure it is possible to ensure that a complete coverage of all aspects is guaranteed.

PAAs should work together to ensure that the agreed Check-Lists reflect both Operators technical details and, concurrently, meet local requirements on Safety, SIMOPS, The Ship/Shore Interface – Communications Necessary for Matching Ship to Berthcommunications plan, amongst other points.

| Table 2. Possible Check-lists in LNG Bunkering | ||

|---|---|---|

| Check-List | Objective | When should be signed/confirm? |

| Planning | Check list with all relevant elements for Permitting process. Check-list for the support of Operators in ensuring completeness of the permitting submissions for a prospective LNG bunkering project. | During finalization of the Concept project, with a view to complete the permitting process. |

| Risk Assessment | Check/Verify minimum requirements for Risk Assessment from ISO/TS18683. | As a conclusion of the Risk Assessment Process. Should be done to ensure the adequate coverage of all elements listed in ISO/TS 18683. |

| Pre-Bunkering | Check-Item collection to obtain Authorization for Bunkering. Check items to perform prior to LNG transfer system connection. | Should be signed upon completion of all pre-bunkering operations. A simplified procedure could be taken into account that would consider. |

| Bunkering | Checks to perform just immediately before LNG transfer is initiated. | To be signed just before transfer is initiated. |

| SIMOPS | To check preparedness from all parties to establish safe SIMOPS. | At pre-SIMOPS meeting. Check-list should be filled in by SIMOPS Coordinator. Sent to PAA in advance for evaluation and preparation of pre-SIMOPS meeting. |

| Post-Bunkering | Checks to be performed after bunkering operation. | Upon conclusion of operations. |