Domestic Gas Infrastructure plays a crucial role in meeting the energy demands of various sectors. It encompasses the pipelines, processing facilities, and distribution networks necessary for transporting natural gas efficiently. As countries explore natural gas as a cleaner energy alternative, investment in domestic infrastructure becomes vital for fostering economic growth.

- Introduction

- LNG Value Chain

- Domestic Gas Value Chain

- Domestic Market

- Introduction

- Domestic Use of Gas

- Natural Gas – Fuel Supply and Demand Economics

- Natural Gas Power Generation

- Gas to Power Implementation

- Elements of a Gas-to-Power Value Chain

- Gas-to-Power Value Chain Planning

- Gas-to-Power Value Chain Implementation

- Power Generation Investment

- Market Structure

- Interconnected Gas Markets within Sub-Saharan Africa

- West Africa Gas Pipeline (WAGP)

- Temane – Secunda Pipeline (Mozambique to South Africa)

- Pipeline Infrastructure in Tanzania

- New Gas Discoveries in Mozambique and Tanzania

- Elements of a Gas Master Plan

- Examples of Domestic Gas Projects

- Domestic Gas Reservations – Domestic Supply Obligation

- Gas Sector Regulatory Reforms

Regulatory reforms can enhance operational efficiency and invite foreign investments into this sector. Additionally, leveraging new gas discoveries significantly boosts local energy supply, ensuring reliability and sustainability. Overall, a robust domestic gas infrastructure supports energy security and drives progress in the energy landscape.

Introduction

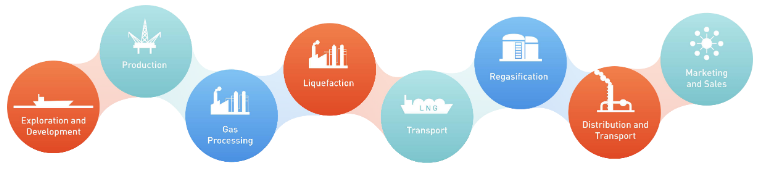

The LNG value chain starts upstream with exploration and production operations. It then proceeds through the midstream stage of processing and transportation, and then the downstream phases of liquefaction to shipping and distribution to the consumer.

Government and private sector partners need to develop trust and firm long-term commitment so that relationships between partners in each part of the chain can endure. In order to build this trust, compromise and cooperation are critical as is a cooperative rather than adversarial approach to negotiations.

The LNG value chain is only as strong as its weakest link. The development of all portions of the chain must be carefully coordinated to avoid project failures that can result from missed connections. Planning to accommodate both the LNG exports and local supply (domestic gas) within the available natural gas resource base will be important to maintaining host country support for the production, processing, and export portions of the project. If the gas and LNG value chain does not result in the development of domestic supply infrastructure, it will be difficult to sustain the rest of the value chain, ensure that all parties profit, and promote long-term harmony between the producers (international oil companies or IOCs) and the host country.

LNG Value Chain

Ensuring that LNG projects create value for all participants requires that each link in the chain fully performs its contractual obligations within a framework of trust and commitment. Failure of one link adversely affects other key links. Contracts must set forth integrated rights and responsibilities and must set up the long-term relationships which require joint planning, coordination, and flexibility. Successful value chain management should help ensure completion within budget, timeliness of start-up, safe and reliable operations within and across links, and the ability to overcome changes in the market and operating conditions.

LNG is not currently a commodity business and continues to be dominated by long-term contracts. A spot market and shorter-term contracts are emerging due to commercial and geopolitical factors. «Base load» sales of LNG are long term, typically 20-25 years with take-or-pay provisions to limit risk. LNG projects are capital intensive and it is currently harder to make the whole value chain appear profitable in the face of lower prices and projected market over-supply. Fully dedicated shipping is often required. Dedicated shipping is capital intensive and project financing depends on creditworthy partners, firm agreements and a reliable LNG value chain. Market uncertainty caused by increasing supply competition, limited demand growth, and competition from pipeline supplies, are driving shippers and suppliers to attempt to sell cargos allocated to term contracts, or new cargos, on spot markets to cover the capital costs of LNG ships and infrastructure. Pipelines have point-to-point rigidity and geographic inflexibility making it difficult to supply islands or mountainous countries or regions fragmented by geopolitical issues, trade barriers, or security conflicts. LNG may provide a competitive supply option if pipeline supply cannot profitably surmount long distances and challenging construction routes. LNG might also be considered if the buyer has security-of-supply concerns, insecure borders, or deep oceans to be crossed.

Link 1: Exploration Development and Production. The LNG and Domestic Gas Value ChainsLNG value chain begins with the drilling and production of natural gas from subsurface gas reservoirs, usually offshore. This exploration and production (E&P) activity is historically dominated by national oil company (NOC) partnerships with international oil companies (IOCs) – particularly in countries with stranded reserves far from major markets-due to large capital requirements and the need for experienced operators. Smaller international companies and national oil companies are increasingly involved in exploration and production activities but may lack experience in working with the full value chain. US markets have introduced new upstream dynamics. Large gas reserves were developed by a variety of suppliers that are able to connect to and ship gas through existing infrastructure to large markets. This has somewhat mitigated the high capital costs and risks and helps to ensure a high return on investment, though it would be difficult to replicate this in other countries. Production optimization methodologies can help to manage costs and help to understand the key value drivers and risks across upstream production processes. Thorough and detailed strategic planning is key to success at this stage. Asset plans and strategies identify the long-term requirements for physical assets and match production levels at all phases of the project with planned supply to local and export markets.

This stage provides direction and guidance to enable the creation of investment and maintenance plans – essential to putting in place the resources (including finance) to manage the assets consistent with achieving desired outcomes. Agreements must be in place so that the other links are proceeding apace to accept the gas and begin supplying consumers.

Link 2: Processing and Liquefaction. The gas supply that comes from the production field is called «feed» gas and this feed gas must be sent to a processing facility for treatment prior to liquefaction. While natural gas used by consumers is almost entirely:

- methane;

- natural gas is associated with a variety of other compounds and gases such as ethane;

- propane;

- butane;

- carbon dioxide;

- sulfur;

- mercury;

- water, and other substances.

Sometimes gas is also produced in association with oil and sometimes liquids are produced in association with gas. Most of these compounds must be removed prior to the liquefaction process.

Once the impurities and liquids are removed, the natural gas is ready to be liquefied at the liquefaction plant. At the liquefaction plant, the natural gas is chilled into a liquid at atmospheric pressure by cooling it to -162 ºC (-260 ºF). In its liquefied form, LNG takes up about 1/600th of the space of the gaseous form, which makes it more efficient to transport.

How and For What Liquefied Petroleum Gas Reliquefaction Plants WorkLiquefaction plants are typically set up as a number of parallel processing units, called trains. Each train is a complete stand-alone processing unit but typically there are multiple trains built side by side. Liquefaction is the most expensive part of the value chain.

Some African nations are considering floating liquefaction solutions due to environmental issues and the remote location of the resource offshore. In floating liquefaction, all processes occur on the vessel at sea. The same principles apply but the marine environment and limited space for equipment require slightly different technology solutions.

From a commercial standpoint, liquefaction is historically dominated by NOC/IOC partnerships and specialized contractors are required for the construction of liquefaction facilities. High capital costs are typically financed across a long development cycle of several decades. The LNG development project team must finalize bankable commercial structures for LNG projects, possibly including both onshore and floating solutions. Careful project management and assurances that the local authorities are supportive of the project are required to bring in the costly design and execution service companies. It is critical that agreements are in place to allow for shipments to credit worthy offtakers so that the government and companies can begin to recover cost and generate revenues. It is, however, equally important to assure that planned supplies to the domestic market are productively allocated and relevant processing and transportation is in place so that the local authorities and citizens will see more direct benefit from the project.

Link 3: Shipping. Once the natural gas is liquefied, it is ready to be transported via specialized LNG ships/carriers to the regasification facility. LNG carriers are double-hulled ships specially designed to contain the LNG cargo at or near -162 ºC.

Asian shipyards dominate the market for LNG ship building since this part of the industry also requires specialized expertise and Asian shipyards have he most experience. Ships are typically owned by a shipping company and chartered to seller or buyer. In some fully integrated projects, the ships are built and owned by the project consortium, Qatar being a prime example of this. High capital costs and highly leveraged financing often bring low risk to the ship-owner but also sometimes generate a low return on investment. If the ships are not owned by the company, agreements need to be in place to assure that ships arrive when the terminal begins operations. If local supplies are planned, it is also critical that infrastructure to support trucking and smaller local maritime shipping is also planned and in place; also that local consumers are prepared to accept shipments or provisions are made for allocated gas to be redirected until consumers are prepared to use the gas.

Link 4: Regasification and Storage. At the regasification stage, LNG is returned to its original gaseous form by increasing its temperature. Regasification usually occurs at an onshore import terminal that includes docking facilities for the LNG carrier, one or more cryogenic storage tanks to hold the LNG until regasification capacity is available, and a regasification plant. The LNG development project team must finalize bankable commercial structures for LNG projects possibly including both on-shore and floating solutions. Specialized cryogenic expertise is required but the capital costs are much lower relative to upstream and liquefaction. Terminals can experience challenges to site and permit requirements that must be resolved by agreements with local stakeholders. Agreements must be in place early in the development process to ensure that the regasification capacity is available to accept the LNG when the liquefaction project is completed.

Link 5: Distribution and Transport to Final Market/Sales. Key aspects of this stage include:

- the ability to factor in volume№;

- price;

- and supply/demand to best position parties to negotiate and satisfy agreements for transportation;

- distribution;

- and sales

Buyers and sellers must account for changing (and potential for change in) local and international market conditions. LNG marketing and trading require careful design so that revenues are generated to satisfy all stakeholders and allow for expansion if that is part of the project plan. Countries will need to assure the implementation of infrastructure required to derive maximum domestic benefit from the LNG value chain, including the construction of power and gas infrastructure required for delivery to consumers.

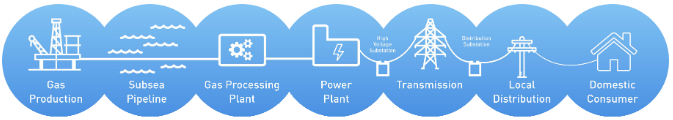

Domestic Gas Value Chain

The domestic gas value chain begins with production and proceeds to processing and treatment. Processing and treatment remove impurities and petroleum liquids that can be sold separately where available in commercial quantities (for petrochemicals, cooking gas, and so on.) The gas can then be compressed into a pipeline for transmission, distribution, and sale to consumers. In many countries, the gas aggregator, in many cases the national gas company, markets the gas to customers and operates the infrastructure.

Many national governments mandate the allocation of gas to the domestic market as this allows the development of local industries, including use as a feedstock and as fuel for power generation. Small markets will take time to develop and for some years the most likely customers for domestic gas are power plants and existing and planned large industries.

Although supplying gas to the domestic market is an aspiration of the government, developing a commercially viable and financeable project plan based on domestic markets requires careful planning and structuring. A thorough economic analysis is required to ensure that the industry consumers are profitable and the entire value chain is financially sustainable.

Hand in hand with the development of gas-fired generation, appropriate wholesale and retail market rules are a critical feature assisting in the formation of a viable gas monetization plan. Unlike an LNG take-or-pay contract, the integrity of the systems to collect bill payments from potentially thousands or millions of end-users in the domestic market can be a key challenge for credit risk management.

Domestic Market

Introduction

African countries have begun to develop local and regional gas markets, largely based in some cases on domestic pipelines, and in a few cases on regional pipelines. Markets and infrastructure remain underdeveloped and require large new investment to satisfy the needs of local populations. With properly designed market structures, local and regional gas demand could underpin more development of natural gas resources. Market participants across Africa are expressing a clear preference for leveraging indigenous natural gas resources as a primary source of fuel, feedstock for industrial chemical manufacture, a method for attracting foreign direct investment, and as a source for additional foreign exchange.

Given the substantial potential gas demand in many parts of Africa, especially for gas-fired power generation, for fueling industry and natural gas vehicles, and LNG for transportation, a well-structured, properly-regulated, local or regional market can be a deciding factor in how quickly gas can be developed to satisfy that demand. Although there are many challenges involved in using local and regional markets to support large gas development projects, with a suitable market structure, technology solutions, and contract models, there is likely to be an increasingly attractive range of options.

The chapters which follow review elements that can enable domestic market development and create beneficial spin-offs in terms of replacing competing fuels that can be more expensive. Some examples of local or regional infrastructure serving markets are also provided. A well-developed gas utilization master plan with adequate local participation and buy-in is normally a key component of enabling market development.

In today’s oversupplied global market for LNG, there are opportunities for supporting import projects, but also challenges for developing large-scale projects domestically.

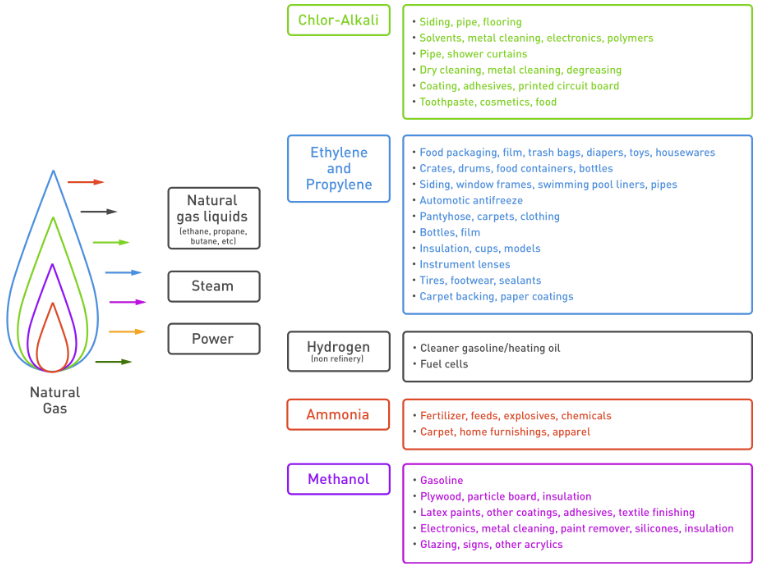

Domestic Use of Gas

This section provides an overview of the potential domestic LNG Rollover Causes and Damage Limitation Measuresuses of natural gas. A major use for domestic natural gas is power generation. Natural gas can also be used as fuel in transportation, industries, commercial buildings or residences. Natural gas can provide fuel substitution for higher cost and more environmentally damaging fuels as well as utilizing a country’s domestic gas resources. Additionally, natural gas can be used as a feedstock for various other industrial plants, such as fertilizer plants, methanol plants, petrochemical plants and gas-to-liquids plants.

Natural Gas – Fuel Supply and Demand Economics

The price of natural gas must be balanced between the cost of supply and what is affordable for consumers; otherwise, consumers will not switch to gas, assuming other alternatives are in place and/or available. The price level must be sufficient to demonstrate to the consumer adequate value that overcomes the risks and costs of converting to natural gas from the incumbent fuels (diesel, fuel oil, etc.). The fuel-switching economics must be favorable in the long term, which means, first and foremost, the price difference between the delivered cost of natural gas and the incumbent fuel must be strong over the life of investments by consumers and suppliers.

Local gas prices, particularly for imports, are influenced by global market prices and are also impacted by regulatory policy choices which impose costs through taxes and mandated technology choices. Taxes, or the lack thereof, can provide incentives or disincentives for fuel choices, while grants, subsidies, and the developing economies of scale as the adoption of new technology increases, can offset capital costs. Perhaps the greatest challenge to switching to natural gas fuels has been the recent collapse in crude oil prices and the attendant decline in refined product prices (e. g. of distillates and heavy fuel).

As mentioned above, an equipment owner (power plant, ship or vehicle) must be convinced that the benefits of switching to natural gas outweigh both the next best alternative and the risks of change. First and foremost, they must be convinced that natural gas will be reliably available at their chosen fueling location, thus the readiness of fuel supply infrastructure, both in equipment and suppliers, must be sufficient to provide the comfort of reliability. It is imperative to understand the physical infrastructure which will be required to meet demand so as to alleviate this critical concern. Owners must also be convinced that the benefits outweigh the time and effort required to understand natural gas and its impact on operations and maintenance. Some questions that could arise by the owners are:

- How safe is this fuel?

- What happens if there is a fire?

- How will my operations need to change (if possible) to accommodate this fuel?

These are all very real questions requiring honest public answers.

Natural Gas Power Generation

In the past, many large gas developments in Africa have focused on global gas export markets to underpin development, and domestic market opportunities have been secondary. Given the emergence of significant high-quality gas resources in many parts of Africa, the current weak demand in the global LNG market and the urgent need for new power generation facilities in many parts of the continent, the domestic gas and power value chain is becoming a much more critical feature of natural gas development.

There are challenges involved in connecting gas resource development with power demand, particularly with respect to the size of domestic gas demand in most African countries compared to the magnitude of natural gas resources required to justify a world-scale LNG project. Nevertheless, the ability of power projects to provide the credit necessary to support financing arrangements, and the infrastructure required to transport gas to where the power generation is needed, means that such development remains one of the most promising opportunities with which to connect African gas resources to domestic markets. The use of gas for power generation is, therefore, an important policy goal, especially as power is an enabling factor to stimulate and promote other industrial development.

The purpose of a gas-to-power strategy is to encourage the use of domestically produced natural gas and increase power supply to meet domestic needs for power. Imported gas is also an option, assuming either pipeline gas or LNG is available to the country and domestic tariffs support the cost of imports. When developing a natural gas power market, the following objectives should be considered at a national level:

Secure stable, reliable, consistent quality, and cost-effective electric power and fuel supplies to fuel electric generation or industrial operations. Global energy price volatility and geopolitical risks will likely continue. This requires an understanding of in-country risks, regional/local power grid reliability, present and future public power supply availability, local competition for power and fuel resources, public transportation systems, logistic considerations, and insourcing or outsourcing risks and opportunities to operate in an uncertain investment environment.

Achieve sustainable cost and efficiency improvements. Understand energy-related opportunity costs at a country level. Focus on cost savings, improving domestic manufacturing and trade revenue and achieving predictable operating performance for industries through stable and affordable energy supplies.

Collaborate internally and engage externally on energy policies and regulations, energy supplies, challenges, and opportunities. Communication, transparency, and collaboration amongst all stakeholders are essential to managing various aspects of the natural gas power generation, transmission, and distribution project development.

Consider renewable energy, energy-efficiency strategies and carbon offsetting to mitigate carbon footprints. African nations receive hydroelectric or coal and oil base-load power across the continent. Natural gas and other renewable sources (such as wind and solar power) may be used to supplement/offset base-load power-reducing GHG emissions. Unlike hydroelectric power, which is dramatically impacted by drought and climate change, natural gas provides consistent and reliable power.

Adapt energy generation and assist local communities to prevent future physical impacts of climate change. It is important to assess present and predicted climate change impacts to communities and projects and to apply natural gas power generation and mitigation measures during the design stage or make modifications to existing facilities and structures to reduce emissions and increase energy efficiency. Gas-to-power measures may include power generation for industrial facilities. Gas-fired plants can also be used to run facilities for:

- water storage;

- desalinization;

- diversion for mitigation of drought or flooding;

- irrigation;

- and controlling or containing environmental releases of hazardous materials;

- process solutions and/or impacted water.

Gas to Power Implementation

Natural gas-fired power generation is based on:

- existing and known technologies with low technology risk;

- repetitive and standard design;

- experienced engineering;

- procurement and construction (EPC) contractors;

- a global vendor market;

- a well-established supply chain;

- and flexible fuel consumption options.

The result, even within Africa, is a broad selection and training environment for operators, maintenance technicians, and craft workforce. When combined with natural gas-powered vehicles or industrial, commercial and retail customers, larger scale natural gas power generation could serve as an anchor client for developing large-scale capital infrastructure for pipelines, road/rail and supporting infrastructures.

Elements of a Gas-to-Power Value Chain

This diagram assumes the gas reserves and production are offshore. The gas is piped to the shore for processing/treatment, and is then supplied to an LNG export facility. Part of the gas, after any required processing/treatment, will be transported to power plants to generate electricity.

Some of the constituents of the gas, such as NGLs and condensates, may be separately sold to the market. An onshore-value chain schematic would show onshore production and onshore pipeline systems.

Gas-to-Power Value Chain Planning

To ensure the success of a domestic gas-to-power project, proper and careful planning is required. The objective of such planning is to identify the demand centers/end-users and ensure that power can be delivered to the domestic end-users at the lowest cost while meeting reliability, safety, and environmental requirements.

For countries with an integrated electricity utility company (usually owned by the government) responsible for the generation, transmission and distribution of power, the utility’s planners will conduct studies to identify the demand centers and locations for future demand growth. These are usually targeted at the main cities and other major populated areas. The electrification plan will need to address how to develop these markets in an optimized manner, and this involves the following alternatives:

- Build power plants close to the demand centers, and pipelines to deliver gas to the power plants.

- Build power plants close to where gas is available, and build transmission lines to connect to the demand centers.

The factors to be considered include:

- Cost: the difference between cost of the above alternatives is primarily the difference between the cost of pipeline vs. transmission line.

- Losses: while there are losses associated with transmitting power over long distances, transporting gas over long distances may also require intermediate compression.

- Strategic considerations: the development of the initial gas-to-power project under consideration will need to fit in the overall electrification plans for the country.

- Expansion potential: whichever option is selected, the ease of expansion for additional power generation and any associated incremental pipeline/transmission investment will need to be examined.

Gas-to-Power Value Chain Implementation

Successful implementation of a gas-to-power supply chain depends on the ability of each party to execute the elements for which it is responsible in a timely manner and in coordination with other parties.

| Typical construction and ownership arrangements | |

|---|---|

| Party | Supply Chain Ownership |

| Upstream Investor | Raw gas production / Offshore pipeline / Onshore gas treatment plant |

| Pipeline Investor | Pipeline connecting gas treatment plant to the power plant |

| IPP | Power plant |

| Utility Company | Transmission lines, substations and distribution network |

A successful Domestic market for relationships on LNG salesgas-to-power project typically has each party having the technical, financial and operational capability to undertake its respective investment. The parties must coordinate their plans, including development, construction, and financing plans, in a way to enable a timely FID (final investment decision) and start up of the entire value chain. In cases where the government-owned utility company is responsible for funding and constructing transmission and distribution networks, it must plan for and budget towards the large investments required, and provide confidence to other investors on the availability of government funds and its ability to complete the transmission and distribution networks. Likewise, other investors in the value chain will also need to demonstrate the ability to complete their respective segment of the value chain in a timely manner.

Power Generation Investment

Power plants are capital-intensive, long-term investments. Independent Power Project (IPP) investors require, among other things, steady revenue from a creditworthy power offtaker under a power purchase agreement (PPA), reliable fuel gas supply, and a stable legal, regulatory, and taxation environment. To attract IPP investment, host governments will need to provide the necessary legal and regulatory framework in the gas and electricity sector to underpin the PPA which typically has a duration of 20 or more years. Under a conducive investment environment, the IPP will be able to secure project financing as well as payment securitization provided by multilateral agencies such as the World Bank and African Development Bank.

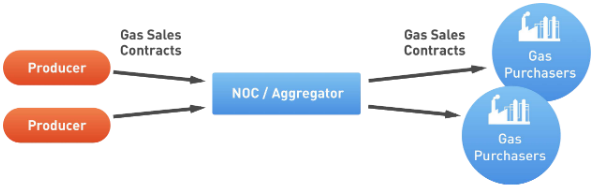

Market Structure

The ability of local or regional gas and power markets to partially or wholly underpin a major gas resource development depends largely on the way in which the wholesale and retail gas and power markets are structured.

The market segments for natural gas are supply, wholesale, and retail. Each market segment can be structured as exclusive, mixed, or competitive, with prices either regulated or market-based. In the supply segment, the producer sells to an aggregator or directly to an end-user. In the wholesale segment, an entity, such as an aggregator, purchases gas from another entity for resale to other customers. In the retail segment, an end-user purchases gas from an entity for its own use.

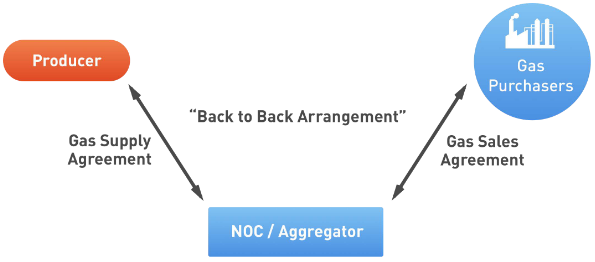

An example of an exclusive structure is shown below where a gas aggregator, e. g. the national oil or gas company, acquires natural gas, provides transportation and compression, if required, and then on-sells the natural gas to wholesale and retail customers.

Of critical importance in any energy market, is a clear and dependable path through which end-users pay for energy received. The flow of energy from the gas developer through to the end-user and the flow of funds in the opposite direction are the key feature of any market and the critical facilitating feature of any project. For domestic and regional markets to provide dependable revenues similar to that which would result from gas or LNG exports to international markets, appropriate planning and execution of market rules, and the nature and level of regulation, are critical factors.

One of the concerns with an aggregator exclusive structure is that the aggregator will stand between the supplier and the customer for contractual and payment purposes. This could lead to a situation where the aggregator is obligated to pay the supplier despite the fact that the gas customer has not paid the aggregator. This concern can be addressed through a mixed structure which includes some sort of payment security from customers or security provided on behalf of the customers.

The diagram below shows an example of a back-to-back structure where the supplier looks to the customers for payment instead of the aggregator.

In a more established market, as shown below, a direct commercial structure where a supplier sells directly to a customer may be used. This structure requires that the supplier or the customer obtains transportation for the gas supply.

In the case of an export sale, the project developers usually rely on a long- term take-or-pay LNG contract, supported by a creditworthy buyer who will sign a binding contract, thereby putting a strong balance sheet behind the purchase obligations. This means that project developers and lenders rarely need to examine what happens to the gas once the take-or-pay buyer has purchased it, so the need to examine market rules downstream of the foundation sale-and-purchase agreement is rarely considered.

For local and regional markets in Africa, establishing a creditworthy buyer presents more complex challenges, due to the lack of gas buyers with a pre-existing credit position who are able to support financing requirements. As a result, lenders and project developers typically have to examine the gas or electricity value chain down to the source of the cash flow, which terminates at the end-user of the gas or power produced. In order to provide a similar level of credit support to a traditional take-or-pay contract, the way in which monies flow through the various market participants is integral to the way the market is structured.

Interconnected Gas Markets within Sub-Saharan Africa

Within sub-Saharan Africa, there are neighboring countries without gas resources next to countries with gas production or large potential gas resources. As a result, some cross-border gas supply has begun to be established and there is much potential for future trade as additional development occurss.

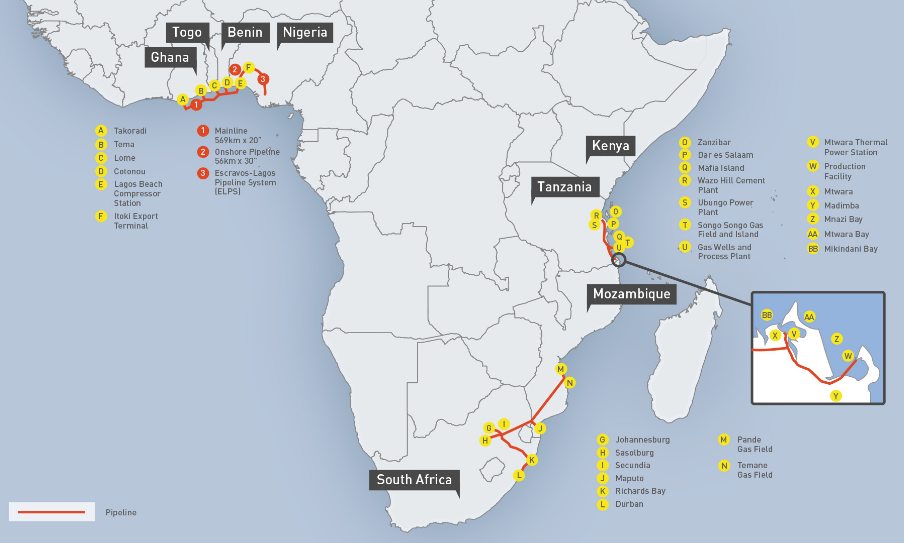

There are just a few examples of regional and trans-border pipeline projects across sub-Saharan Africa. In this section, we will discuss the following:

- West Africa Pipeline System.

- Mozambique to South Africa Pipeline.

- Tanzania Pipeline Systems.

- Mozambique and Tanzania recent gas discoveries.

These systems are depicted on the following map.

West Africa Gas Pipeline (WAGP)

West Africa produces much more natural gas than is required for domestic consumption and exports natural gas within the region and overseas. Natural gas is produced mainly in Angola, Equatorial Guinea, Cameroon, Ghana, Ivory Coast and Nigeria, The largest natural gas reserves in the region are in Nigeria.

The West Africa Gas Pipeline was built to transport natural gas from Nigeria to consumers in the Benin Republic, Togo, and Ghana. The WAGP took about 30 years to implement after being proposed by the Economic Community of West African States (ECOWAS) in 1982 with the goal of promoting regional economic growth. A series of intergovernmental agreements and treaties were negotiated and signed by the four countries.

The WAGP System consist of a 691 km 20″ (508 mm) pipeline and associated processing/receiving facilities in Lagos, Itoki, Cotonou, Lome, Tema and Takoradi. The WAGP receives gas from the Escravos-to-Lagos Pipeline System (ELPS) which gathers the gas from Shell and Chevron fields in the Niger Delta. The capacity of ELPS is being expanded from 1,1 billion cubic feet per day (bcfd) to 2,2 bcfd. The expansion work is scheduled to be completed in 2016.

The West Africa Power Company (WAPCo) owns and operates the WAGP system with headquarters in Accra, Ghana. The pipeline is owned by a consortium including:

- the Nigerian National Petroleum Corporation (NNPC);

- Shell;

- Chevron;

- the Volta River Authority (VRA) – a multi-national power company;

- the Electric Company of Ghana (ECG);

- Benin’s gas company;

- Société Beninoise de Gaz (BENGAS SA);

- and Togo’s gas company, Société Togolaise de Gaz.

The initially contracted capacity of WAGP is 170 million cubic feet per day (mm scfd) with provision to grow up to 474 mm scfd with compression. The natural gas supply comes from NNPC, Shell and Chevron fields in Nigeria. The gas buyers are VRA in Ghana and Communauté Electrique du Bénin (CEB) in the Benin and Togo as fuel for power generation.

Construction began in 2005 and the first gas was received in Ghana in April 2009. Third party access, Open Access, was declared on July 1, 2012. The gas sales from the WAGP have been limited because of disruptions to gas production from Nigeria’s oil and gas fields and periodic payment disputes.

Temane – Secunda Pipeline (Mozambique to South Africa)

In the 1960s, the US company Gulf Oil discovered natural gas in the Pande and Temane fields, located onshore in the south of Mozambique. Because the main objective at the time was oil, the gas reserves remained undeveloped until in the 1990s, while Empresa Nacional de Hidrocarbonetos (ENH) did the appraisal of the fields which culminated with the signature of the Petroleum Production Agreement (PPA) in 2000.

This agreement signed by the Government and the National Oil Company (ENH) with a consortium composed of Sasol Petroleum Temane, Lta. (SPT) with 70 %, the Companhia Mocambicana de Hidrocarbonetos, SARL (CMH), a subsidiary of ENH, with 25 %, and the International Finance Corporation (IFC) as an integral part of this agreement with acquired 5 % of CMH as part of their commitment.

With proven reserves of 3,5 trillion cubic feet (TCF), the anchor customer of the project was Sasol’s petrochemical manufacturing facilities in South Africa.

To take the gas from Temane in Mozambique to the anchor customer in Secunda, South Africa, a 26″ pipeline with 865 km length and capacity of 149 million gigajoules per annum (MGJ/a) was built, with five offtake points within Mozambique.

When the first commercial production of gas started in 2004, the gas market in Mozambique was very small. The gas distribution network consisted of 300 km of pipeline owned by ENH, which, has supplied gas to power generation and commercial and residential consumers since 1992. Mozambique used 0,2 MGJ/a, compared to 120 MGJ/a that was exported to South Africa.

As soon as the pipeline infrastructure was built, the demand for natural gas increased exponentially, and today the whole domestic supply obligation (DSO) from the project – 27 MGJ/a – is used internally and many industrial projects are demanding additional natural gas.

ENH accomplished the successful construction of the Maputo Gas Distribution Network Project in 2014, bringing natural gas from the fields to Maputo city and Marracuene district. This project was an important milestone in the history of hydrocarbons in Mozambique because, for the first time, piped natural gas was supplied to a city in Mozambique. Previously, all fuels in Mozambique were imported, so the natural gas plays an important role in the replacement of these imported fuels.

Pipeline Infrastructure in Tanzania

As any other southern Africa country, Tanzania has a huge demand for power. Focused primarily on resolving the power shortage, three pipelines were built to connect the natural gas fields to the power plants:

- Songo Songo pipeline – with 232 km of pipeline connecting Songo Songo fields to Dar es Salaam, began operating in July 2004;

- Mnazi Bay Pipeline – with 27 km of pipeline connecting Mnazi Bay to Mtwara, began operating in July 2006;

- Mtwara to Dar es Salaam Pipeline – 551 km of pipeline connecting Mtwara to Dar es Salaam, began operating in November 2015.

These pipelines help to establish the basic infrastructure to develop the domestic market for natural gas, reducing the importation of fuels and stimulating local industries.

New Gas Discoveries in Mozambique and Tanzania

In Mozambique, more than 200 TCF of natural gas has been discovered offshore in the Rovuma Basin, while in Tanzania more than 57 TCF of natural gas has been discovered offshore. These giant gas reserves can be a game-changer for the southern African region.

Because the reserves are so large, it is possible to have a good balance between the export of LNG, which will generate needed foreign exchange, and the expansion of the domestic natural gas market to meet the power needs in the country and region, as well as an opportunity to develop local industry. Many downstream projects were presented to Mozambique pursuant to the Mozambique Gas Master Plan, supporting a potential for 26 TCF consumption of natural gas in Mozambique.

The energy demand in the southern Africa countries has increased exponentially each year. In Mozambique, the demand for electricity is estimated at more than 1 000 megawatts (MW) in 2016 and may triple in the next 15 years, according to the Mozambican power company, Electricidade de Mocambique (EDM).

Besides the gas needed for power, various other downstream industries that utilize gas as feedstock in the production of value-added products are demanding natural gas for the:

- production of fertilizers;

- gas-to-liquid fuels;

- and methanol,

among other products, which may contribute significantly to the industrialization of those countries and associated job creation if they can be made profitable.

Read also: Challenges Developing Natural Gas Infrastructure

The governments and communities expect that the discoveries of natural gas, either in Mozambique or in Tanzania, can contribute significantly to solving the energy crisis in the region, and facilitating investments in downstream projects.

The experience of Mozambique in the Pande and Temane Project – which allowed interconnection of the Pande and Temane gas fields in Mozambique to Secunda, in South Africa, and enabled development of small gas markets within Mozambique – can be quite useful in the Rovuma projects in Mozambique, and Tanzania.

Elements of a Gas Master Plan

A starting point for many countries, especially countries that wish to develop gas resources and/or domestic markets for natural gas, is the creation of a Gas Master Plan (GMP). While the contents of a GMP will be unique to each country, there are some helpful general guidelines and principles. In general, a GMP is a holistic framework to identify and evaluate options for natural gas use for domestic supply and/or export. The main goal of the GMP is to provide the foundation to guide policy development for the gas sector of the country. The GMP provides a detailed road map for taking strategic, political and institutional decisions, on the basis of which, investments in the area can be designed and implemented in a coordinated manner.

The role of the government in developing the GMP is to provide a stable, transparent regulatory, fiscal, and financial policy regime to foster the development of the gas sector in a manner which benefits the country as a whole.

While the elements of the GMP vary by the country, there are some broad elements to consider. These elements include:

- Objective of the Gas Master Plan.

- Gas resource evaluation.

- Gas utilization strategy and options consistent with country’s energy policy.

- Domestic supply and demand analysis (power and non-power sector).

- Identification of other domestic «priority» projects.

- Infrastructure development plan/formulation.

- Institutional, regulatory and fiscal framework.

- Development of recommendations about the volumes and revenues from gas finds and future gas production.

- Identification of possible mega or «anchor» projects. For example, a country with a large natural gas find might consider an LNG export project, or other similar industrial-scale plant such as methanol, ammonia production, gas-to-liquids (GTL) projects and dimethyl ether (DME).

- Formulation of a roadmap for implementation of projects.

- Gas sector regulatory reforms.

- Socioeconomic and environmental issues associated with development.

- Gas pricing policy.

An «anchor» project is a large project that provides the economies of scale that may justify the investments in capital-intensive gas infrastructure, which is then available to smaller users. Launching a gas industry from scratch has traditionally required one or more large «anchor» customers to undertake to purchase enough gas to justify the significant investments required to build the requisite pipeline infrastructure. Examples of anchor projects include:

- LNG export terminals that may justify offshore gas exploration and production in the first place;

- power plants;

- gas-to-liquids plants;

- methanol or fertilizer plants, which in turn could provide the economic underpinning for pipeline expansions.

With the generally weak global demand for LNG from traditional markets such as Europe or Asia, GMP considerations may have to focus more closely on domestic or regional gas demand to underpin major gas developments, and this may require innovative approaches to gas market development, contractual mechanisms for gas sales, and financing arrangements.

Examples of Domestic Gas Projects

To replace flagging global demand for natural gas, the range of mega or anchor projects might also include a discussion of «priority» gas projects that might be undertaken while plans for any mega projects are being developed. Examples of possible projects include:

- Power projects.

- Gas-to-liquids projects.

- Fertilizer plans.

- Petrochemicals.

- Methanol projects.

- Gas transmission and distribution pipelines.

- Fuel for industry such as iron, steel and cement projects.

Domestic Gas Reservations – Domestic Supply Obligation

Assurance of gas supply is critical to delivering the policy objectives of the GMP. This includes recognition that gas-based industries, such as methanol, fertilizer, or power industries, need a certainty of gas supply before large investments are made. At the same time, many governments face the issue of ensuring that gas is available for critical domestic gas utilization projects which will advance the domestic economic growth agenda.

To balance these often competing objectives, many gas-producing nations have some form of gas reservation policy or domestic supply obligation, aimed at ensuring that local industry and local consumers are not disadvantaged by gas exports.

International examples of domestic supply obligations (DSO) include:

- Nigeria requires all oil and gas operators to set aside a pre-determined minimum amount of gas for use in the domestic market. This is a regulatory obligation with the initial obligation level determined based on a view of the base-case demand scenario for gas in the domestic market. The domestic gas obligation provides a base load of gas that must be processed through the gas-gathering and processing facilities. Since the obligation to supply the domestic market is the responsibility of the gas supplier, title to gas-processed remains with the gas suppliers.

- Israel, Indonesia, and Egypt have laws mandating that a percentage of gas extracted must stay within their domestic markets.Israel reserves 60 % of its offshore natural gas. Egypt has legislated that 30 % of gas production must be directed to domestic consumers. Indonesian reservation is applied on a case-by-case basis to new projects, but reservations of up to 40 % have been agreed to in recent years.

- In the United States, the Department of Energy’s (DOE) authority to regulate US natural gas exports arises from the Natural Gas Act (NGA) of 1938. By law, applications to export US natural gas to countries with which the United States has Free Trade Agreements (FTAs) are deemed to be consistent with the public interest and the Secretary of Energy must grant authorizations without modification or delay. The NGA directs DOE to evaluate applications to export US natural gas to non-FTA countries. Under the NGA, DOE is required to grant applications for authorizations to export US natural gas to non-FTA countries, unless the Department finds that the proposed exports will not be consistent with the public interest, or where trade is explicitly prohibited by law or policy. Canada also has similar public interest laws regarding the export of its gas.

- Norway, Qatar, Russia, Algeria, and Malaysia ensure domestic advantage from their gas reserves by having state-owned companies taking the role of dominant producer.

- Western Australia is the only state in Australia with a gas reservation policy. Under Western Australia law, 15 % of all the gas produced in that state must remain in the state. Western Australia’s gas reservation scheme has been able to guarantee domestic supply at attractive prices, while still allowing investment in the LNG industry and a healthy level of exports.

Gas Sector Regulatory Reforms

Depending on the level of development in the country, various regulatory reforms may be needed to promote the development of the gas sector. Legislation and regulations for licensing the construction, operations, and pricing of natural gas transmission and distribution pipelines might be needed. There should be standard, publicly available terms and conditions for licensing developers of infrastructure that define service obligations, operating rules, and tariffs. The licensing, operations and tariffs of gas transmission and distribution pipelines should be overseen by an independent regulator.

Many governments are considering unbundling value chains for regulatory purposes. Unbundling refers to the separation of segments in the gas value chain to reduce the potential for monopoly, and to increase transparency and the ease of regulating smaller projects. Consumers should see the gas price separately from the cost of transporting and distributing it for transparency. Unbundling can facilitate third-party access to pipelines.