Ship operations refer to the various activities involved in running a ship, including navigation, maintenance, cargo handling, and safety procedures. It encompasses everything from managing the crew to ensuring the vessel’s compliance with regulations.

Cargo operations involve the loading, unloading, and handling of cargo on a ship. Port operations refer to the activities at a port, including docking, cargo handling, and customs clearance. The exchange of information between the ship, port, and terminal is crucial for efficient and safe operations, ensuring that all parties involved have the necessary information for smooth cargo handling and vessel operations. Clear communication and coordination between these entities are essential for successful maritime operations.

Ship operations

General

There is no major difference between the general operation of a liquefied gas tanker and the operation of any other type of ship. Before going to sea, a ship must be in good operating condition and seaworthy and the crew must be adequately trained in its operation and maintenance. In Other Characteristics Specific to Liquefied Gas Tankers“Main technical characteristics of LNG LPG tankers”, we have seen that there are international rules controlling this and these rules apply to all ships.

However, in view of the hazardous cargo transported by a Liquefied Natural Gas Carrier Market Insightsliquefied gas tanker, the crew must be trained to be extra vigilant and to consider at all times the potential risk under which the ship, its crew and its cargo is placed.

Liquefied gas tanker crews must be trained specifically in the following subjects:

- Characteristics of the different products carried by their ship.

- Precautions to be taken for the safety of personnel in case of cargo escape.

- Cargo handling and cargo operations.

- Fire-fighting, in particular the specific aspect of fire protection for the products carried.

- Contingency planning for the various catastrophic situations which could confront the crew.

There should be no need for extra navigation training, although emphasis must be put on maintaining a reasonable and prudent attitude at all times and avoiding any possibility of grounding or collision, which could endanger the integrity of the cargo containment of their vessel.

Frequent multinational crews make a common language, understood by all crew members, essential and it is imperative that all training is conducted in this language.

Cargo operations

The characteristics of the different cargoes transported and the specific requirements for their safe transport are what make liquefied gas tankers different from other ships.

The international regulations listed in Other Characteristics Specific to Liquefied Gas Tankers“Main technical characteristics of LNG LPG tankers” require that crews and officers manning liquefied gas tankers obtain certificates confirming their successful attendance at specific training sessions. These training sessions must cover the characteristics of the products transported and the precautions to be taken in case of release to atmosphere of these products. This should include the first-aid treatments required in case of exposure to toxic or cryogenic products. The officers must also be trained in the operation of all the specialised equipment used on board for cargo handling and monitoring.

The full sequence of cargo operations on a liquefied gas tanker, from the delivery of the ship at the end of construction or at the end of dry-docking until the next dry-docking, can be separated into a number of sections which have to be carried out once or several times during the period.

- Preparation for loading.

- Loading.

- Loaded voyage.

- Discharge.

- Ballast voyage.

- Changing cargo.

- Preparation for dry-docking.

a) Preparation for loading

The tanks of a liquefied gas tanker just delivered from the shipyard at the end of construction or at the end of a dry-dock period are usually open and under air atmosphere. When the tanks are open to the atmosphere, they should always be kept in a dry condition by circulating dry air, to avoid any possibility of corrosion.

Prior to closing the tanks, a very thorough inspection must be carried out. All parts must be perfectly clean and dry, all loose objects must be removed and all fittings secured, with stoppers in place. Pumps must be checked for free rotation and valves for free operation. The tanks can then be closed, using new gaskets.

Once the tanks are closed, all water vapour and free water must be removed from the Cooldown of Cargo System on the Liquefied Gas Carrierscargo system. Even if the tanks were kept dry whilst open, they are certainly not dry enough to receive cargo. Any moisture remaining could cause icing due to the low temperature of the cargo. Some products can react in the presence of water to produce hydrates which clog filters and freeze valves and pumps.

Drying of tank atmosphere can be achieved by various means:

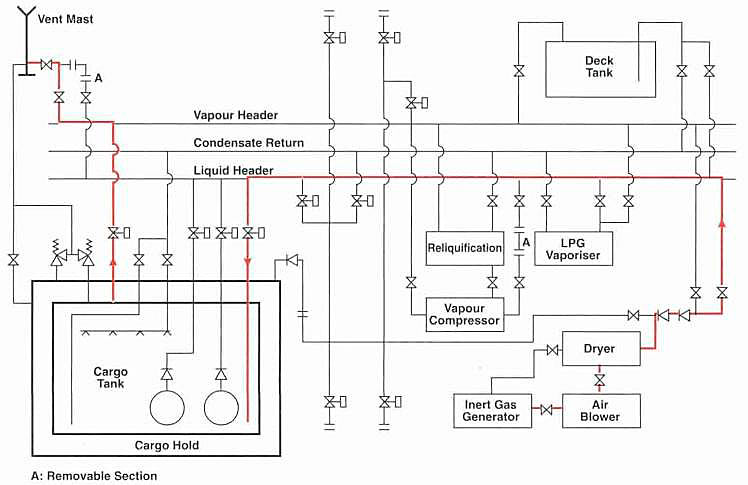

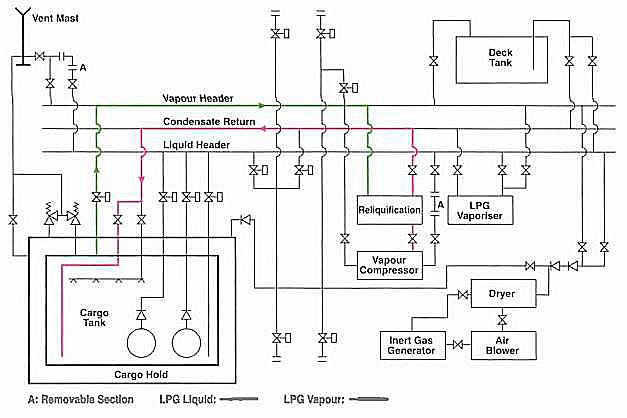

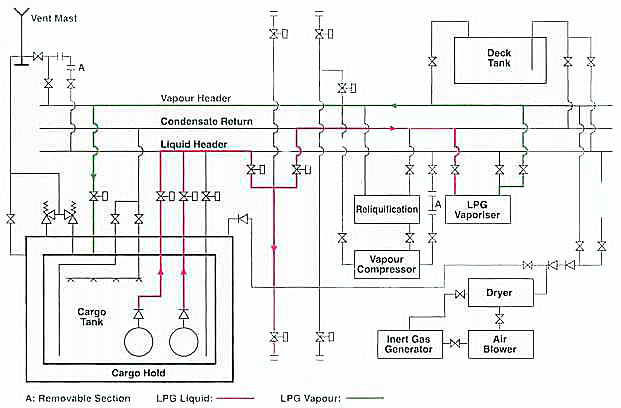

- Using dry air produced on board. This dry air can be produced using the inert gas generator blower and dryer but without firing the burner. This procedure is used if sufficient time is available. It reduces the amount of inert gas to be used later for the inerting operation but takes more time than drying at the same time as inerting.

- Using inert gas from shore as part of the inerting procedure. This method reduces the moisture content in the atmosphere down to the required dew point and at the same time reduces the oxygen content. This is done in case of LNG, ethylene or a product requiring an atmosphere with very low oxygen content such as butadiene or VCM or in the case of ammonia which reacts with the carbon dioxide of the inert gas produced on board.

- Using inert gas from the on-board generator. This follows the same principle as when the inert gas is supplied from shore. The inert gas production must be carefully monitored for good quality and a low dew point.

Whichever way the drying operation is carried out, it must be conducted until a dew-point of at least -4 °C is obtained.

The next stage of the tank preparation is the inerting operation and we have seen that, when time is short, drying and inerting can be done at the same time.

Other Characteristics Specific to Liquefied Gas Tankers“Inert gas and nitrogen” describes how inert gas is obtained on board. Inerting cargo ranks, cargo machinery and piping is carried out to ensure a non-flammable condition when first introducing cargo vapaur into the system for the gassing-up operation. To achieve this, the oxygen content must be reduced from 21 % to a maximum of 5 % by volume. The theory shows that a mixture of hydrocarbon gas and air is non-flammable when the oxygen content is less than 10 to 12 %. However the maximum value of 5 % is used on gas carriers, to allow for a degree of poor mixing in the tank. Another reason for reducing the oxygen content prior to introducing cargo into the tank is that some products react chemically with a very small quantity of oxygen. In the case of butadiene or VCM, oxygen content as low as 0,1 % is necessary to avoid such a reaction, In these cases, inert gas must be taken from shore as the on-board system can only produce inert gas with an oxygen content approaching 0,5 %.

There are several ways to conduct the inerting operation:

- For a type C tank, it is possible to use the dilution system. This type of tank can sustain a considerable vacuum, in the range of 30 to 70 per cent depending on the design and can also be pressurised to quite a high level. The operation consists in drawing the maximum possible vacuum into the tanks with the ship’s compressors and then injecting the inert gas up to a pressure of two or three bar. The pressure is then released and the operation repeated until the required oxygen level and dew point are obtained. This is a very efficient way to inert this type of tank without using too much inert gas.

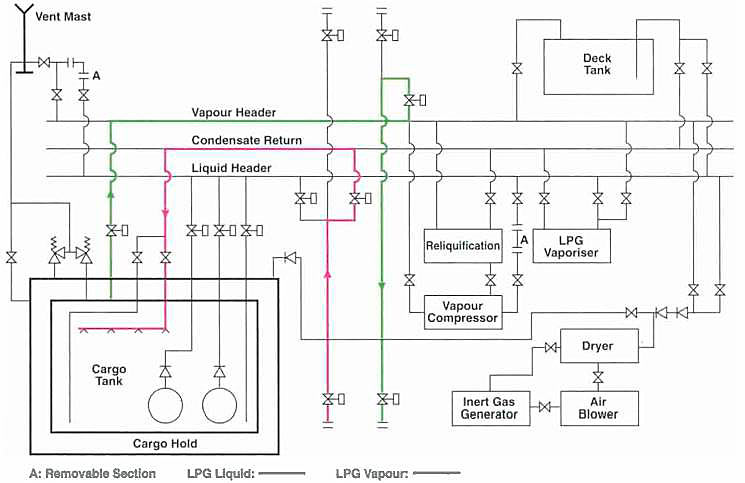

- For tanks of A, B and membrane types which are not designed to sustain any significant pressure, the only possible way would be continuous dilution. However, this would take a long time and would use far too much inert gas. Fortunately, it is possible to take advantage of the slight difference in density existing between air and inert gas and to use what is currently called the piston effect. Inert gas is slightly heavier than air and, if introduced in a regular flow at the bottom of the tank, it will stay at the bottom and push air up without too much mixing of the two. If the flow of inert gas is kept constant, without surge, the tank will gradually fill up with inert gas and the air will be removed to the venting mast through the vapour line at the top of the tank. This operation will usually take an amount of inert gas equivalent to two or two and a half times the volume of the tanks and lasts about 12 hours. If the ship’s inert gas generator can produce a sufficient amount of inert gas, the flow can be spread between all the tanks. This is called «inerting the tanks in parallel». If, however, the inert gas production is too low, providing the ship’s piping allows it, the full flow of inert gas can be sent to the bottom of one tank and the air exiting this tank can be sent to the bottom of the next tank. The discharge of the second tank will be sent to the bottom of the third and so on through all the tanks. This can save some time and some quantity of inert gas. It is called «inerting the tanks in series».

The method to be used for inerting has to be selected according to the ship type and particular design. Whichever method is used, it is important to monitor the oxygen concentration and the Dew Point – Definition and Pronunciationdew point from time to time in the different tanks, using the sampling connections provided at different heights in each tank. It is also important, before completing the inerting operation, to ensure that no oxygen-rich atmosphere remains in any of the piping or machinery equipment. When the tank atmosphere has reached the required oxygen level, it is good practice to raise the inert gas pressure in each tank to just below the relief valve setting point. This will confirm that the tank cover is not leaking and that the relief valves are set correctly. The pressure available can be used to blow through all the cargo piping and machinery equipment, pushing out any remaining air.

The hold space around the tanks must also be in the appropriate condition to be ready to load cargo. Most of the LPG ships maintain those spaces under dry air, to avoid any condensation. The hold spaces or insulation spaces on LNG ships are kept under CO2 free inert gas.

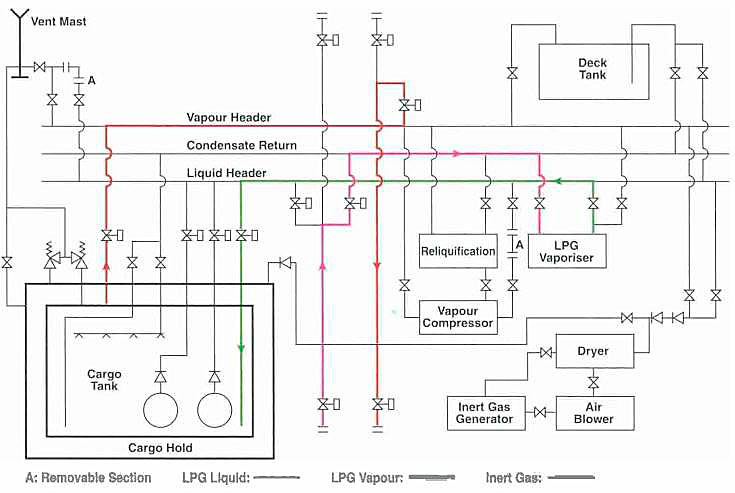

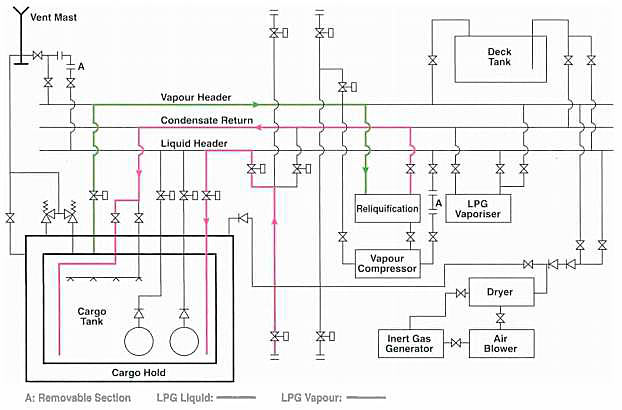

The last operation to be conducted prior to loading cargo is the gassing-up. It consists of replacing the inert gas in the tanks with vapour of the cargo to be loaded, at ambient temperature. The different procedures to be used are similar to those described above for the replacement of air by inert gas, taking advantage of the difference in density between the vapour to be used and the inert gas. Most hydrocarbon gas vapour is heavier than inert gas at ambient temperature, except for methane and ethylene. This operation is necessary on LPG ships as neither nitrogen nor carbon dioxide, the main constituents of inert gas, can be condensed by a ship’s reliquefaction plant. At cargo temperature, they both are above their critical temperatures and are therefore incondensible and it is necessary to remove them from the system prior to starting the reliquefaction plant. On LNG ships, if the inerting has been done using inert gas produced on board, the gassing-up operation is also necessary because carbon dioxide freezes at -56,6 °C which is well above -162 °C, the loading temperature of LNG. If the inerting operation has been carried out with shore supplied nitrogen containing no carbon dioxide, however, the gassing-up operation is not required and the tanks can be cooled down directly.

Some ships are equipped with pressurised deck tanks in which different products can be kept. If one tank contains a sufficient quantity of the appropriate product, the gassing-up operation can be conducted at sea and the mixture of inert gas and product vapour discharged into the atmosphere. Otherwise the operation must be carried out in the loading terminal. Either the shore can supply vapour directly to the ship or, if this is not possible, a small flow of liquid is sent to the ship’s vaporiser where it is vaporised before being directed to the ship’s tanks. As it is not possible to discharge a mixture of inert gas and hydrocarbon gas to atmosphere in port, the terminal must be equipped to receive what is discharged from the ship and dispose of it in a suitable way. Most of the time it is sent to a flare, where the inert gas is vented and any hydrocarbon vapours are burnt. Prior to connecting the ship’s manifold to the terminal system and receiving vapour from the ship, the terminal will conduct a thorough survey of the ship’s tanks to ensure that they contain only inert gas. The quantity of vapour or liquid supplied by the terminal to the ship must also be carefully measured for future invoicing. When the content of product to be loaded reaches approximately 90 per cent of the tanks’ atmosphere, the flow can be sent to the ship’s reliquefaction plant and the discharge ashore closed. The cool-down operation can then be started.

b) Loading

Prior to loading a refrigerated cargo, the ship’s tanks must be cooled down slowly. This is necessary to minimise thermal stresses and to avoid an excessive rise in tank pressure due to flash evaporation during bulk loading. The rate of cool-down depends on the design of the containment system and on the cargo carriage temperature, but a typical figure is 10 °C per hour.

A normal cool-down procedure is to introduce a small flow of cargo liquid, received from shore, into the tanks through spray lines, if specially fitted, or through the loading line. The vapour produced by the rapid evaporation may be taken ashore or handled by the ship’s reliquefaction plant. This operation is continued at a rate corresponding to the cool-down rate required. The ship’s cargo operation manual gives all indications on the rate of cool-down and the temperature required to be achieved for each different product to be loaded. In the case of LNG, for example, the cool-down operation will take approximately 12 hours, as a very low temperature must be reached. During cool-down, the reduction of the temperature in the tanks will cause them to contract and also induce a drop of temperature in the space around the tanks. The pressure in these spaces must be controlled as it, too, will drop and it should be ensured that the pressure control system operates correctly. This is especially important on membrane-type ships as a substantial make-up of nitrogen is required during the cool-down operation to maintain positive pressure in the insulation space.

Cool-down should continue until boil-off eases and liquid starts to accumulate at the bottom of the tanks. This can be confirmed from the temperature sensors located at the bottom of the tanks. The temperature at the top of the tank will still be much higher than at the bottom. Indications of acceptable temperature differences between tank top and bottom prior to the start of bulk loading are available from the cargo operating manual. In the case of LPG, some difficulty may be encountered during the cool-down operation, with icing or hydrate formation. This can be alleviated by introducing antifreeze, if this is allowed by the cargo specification. During the cool-down operation, the pump shafts must be regularly turned by hand to prevent the pumps freezing up. The cargo pipelines must also be cooled at the same time.

All pre-operational ship/shore procedures, as described in the next chapter, must have been thoroughly discussed with the terminal, prior to starting the cool-down operation. The ship’s personnel must ensure that they have all the necessary information on the cargo to be loaded, the procedures to be followed by the terminal for the loading operation, the procedures to be followed in case of emergency and on how to maintain open communications with the terminal at all times. They must have checked the following points:

- Tank safety valves, high pressure and high level alarms set at the correct values. The ship will have the required trim and stability conditions at the end of loading. Deballasting can be conducted concurrently with the loading operation.

- Maximum pressure and flow, minimum temperature, and disposal of boil-off have all been agreed with the terminal.

The Emergency Shut-Down links between ship and shore are installed and the system checked for good operation.

If the ship is arriving to load with some cargo from the previous voyage remaining in the tanks, the level of this cargo must be carefully measured and its quantity calculated.

Once all these checks are confirmed, the bulk loading operation can start. It is usual to start slowly, the speed gradually increasing up to the flow agreed with the terminal. If a vapour return line to shore is used, the flow must be confirmed as acceptable by the terminal. If the vapour displaced by the loaded liquid and the boil-off resulting from the energy injected into the cargo through friction in pumps and piping are reliquefied on board, the loading rate must be adjusted to correspond to the performance of the reliquefaction plant. At the start of the loading operation, careful checks must be made on board to ensure that the piping circuit is correctly organised and that all liquid coming from shore goes into the tanks. Throughout loading, frequent checks must be made of the tank levels, pressures and temperatures. Pressures and temperatures must also be checked in the spaces around the tank to ensure that all is normal. Ballasting and bunkering, if carried out at the same time, must be carefully supervised to maintain the ship in trim and not subject the hull to any over stress. As loading reaches completion, tanks must be brought to their maximum level one by one and the terminal given sufficient notice to be able to slow down and stop without causing an overflow.

The maximum loading level for each tank is specified by the IMO Gas Code. It depends on the maximum pressure allowed in the tank, the product loaded and the atmospheric conditions during the voyage. This is to avoid the possibility that, in case of a fire, the tanks will ever be overfilled. The reverse situation when, starring with a low level of loaded product, the quantity of liquid in the tank is further reduced by over vaporisation, leaving the tank walls vulnerable to flame impingement withour the cooling protection afforded by the liquid, is equally dangerous and must also be avoided.

After completion of loading, the terminal and the ship will proceed together with the purging of the shore loading arms or hoses prior to their disconnection, to avoid any release of cargo. Once purging is complete, disconnection can take place.

On termination of loading, tank levels must be carefully checked and the quantity of cargo loaded calculated, usually with the assistance of a surveyor representing the interests of the Charterer.

The ship can then leave the terminal and proceed to sea.

There can be variations on the loading operation described above:

- loading a pressurised ship from a pressurised storage;

- or loading a pressurised ship from a fully refrigerated storage through a cargo heater;

- or loading a cargo at ambient temperature into a fully refrigerated ship with refrigeration during loading.

All these operations will, in essence, be conducted as the one detailed above and it would be too lengthy to describe here the technical details involved.

c) Loaded Voyage

During the loaded voyage of a semi-pressurised or fully-refrigerated ship, the reliquefaction plant must be operated as necessary to maintain the cargo temperatures and pressures within the prescribed limits. On most modern ships, this is done by measuring the tank pressures and starting and stopping the plant automatically for a specified pressure window. If the reliquefaction plant is operated on several tanks in parallel, it is necessary to ensure that the condensate returns are spread equally between each tank. If the cargo temperature has to be reduced during the voyage, it is better to run the reliquefaction plant non-stop at the beginning of the voyage until the required temperature is reached, rather than wait until the last days of the voyage.

On a pressurised ship, the tanks are kept closed and the only control is, when in very warm areas, to ensure that the temperature does not rise above the estimated value for the voyage, taking the liquid level above the prescribed limits. Should this happen, the spray water system would have to be started to reduce the tank temperature.

On LNG ships, the boil-off is used in the ship’s boiler and the compressors automatically control the tank pressures. The boiler control management adjusts the amount of fuel oil and the amount of boil-off available to produce the amount of steam required.

Throughout the loaded voyage, regular checks must be made to ensure that there is no malfunction in the cargo equipment and no leaks in the nitrogen or air supply lines. On LNG ships, visual cold-spot inspections should be carried out in the cargo tank surrounds, even if the ships are fitted with temperature monitoring of the inner hull surfaces. In carrying out these inspections, all relevant safety procedures for entry into enclosed spaces must be adhered to and due regard given to hazardous atmospheres in adjacent spaces. On Membrane ships, the operation of the pressure control system for the interbarrier spaces must be checked regularly.

d) Discharging

When a ship arrives at the discharge terminal, cargo tank pressures and temperatures should be in accordance with the terminal requirements and all cargo equipment should be in good operating condition. The ESD system and the main pumps and valves must have been checked for good operation the day before arrival.

Any discrepancy must be brought to the attention of the terminal management prior to the ship’s arrival. Similarly, the terminal must advise the ship of any problem with the terminal equipment.

Before the discharging operation begins, the pre-operational Ship/Shore Interface in Gas tradingship/shore procedures should be carried out in the same way as for the loading operation. The level in the cargo tanks must be carefully measured and the quantity of cargo on arrival must be carefully calculated, if necessary with the assistance of a surveyor.

After connecting the shore piping and the ESD links, testing the connections under pressure and the ESD system for good operation, the cool-down of the piping can start.

Discharging can be carried out by different methods depending on the type of ship, cargo specification and terminal storage.

- Discharge by pressurising the vapour space: this is done on pressurised ships with type C tanks. It is sometimes helped by a booster pump.

- Discharge with deep well or submerged pumps: the number of pumps to be used will depend on the number of tanks to be discharged and on the flow which can be accepted by the terminal. In some cases, when the pressure required to reach the shore tanks is higher than the discharge pressure of the ship’s deep well or submerged pumps, a booster pump may be used. The operation of the pumps has to be monitored throughout the discharge so as to maintain a constant discharge pressure. When the liquid level goes down in the tank, the discharge valve of the pumps will need to be throttled, with a corresponding reduction of flow. This is particularly important at the end of discharge, if it is necessary to leave the tanks with a level as low as possible. When the refrigerated cargo on the ship is to be discharged into a storage at ambient temperature, it is necessary to use a booster pump and a cargo heater. The speed of discharge will have to be adjusted to the performance of the cargo heater.

Whichever method is used to discharge the cargo, the liquid level in the cargo tanks should be carefully monitored, bearing in mind ship stability and hull stress. Ballasting operations will have to be carried out to maintain a suitable trim and keep the ship’s hull within acceptable structural stress limits. Removal of liquid from the cargo tank may cause changes in inter-barrier space pressures and these should be monitored throughout the discharge operation. The boil-off due to the heat flow through the tank insulation is usually insufficient to maintain the tank pressure, which is falling because of the liquid being pumped out. This will obviously depend on the discharge rate, but for a normal discharge it is necessary to add vapour to the tanks to maintain the discharge rate. This can be done through a vapour return line from shore or by diverting some of the liquid being discharged through the ship’s vaporiser.

After completion of discharge, the sequence of operations is the same as at the end of loading:

- pipe drainag;

- disconnection;

- calculation of quantity of remaining liquid and vapour.

The quantity of cargo discharged is obtained by subtracting the quantity remaining at the end of discharge from the quantity on board on arrival.

e) Ballast byage

Refrigerated ships returning to load the same product usually retain a small quantity of the cargo on board after discharge. This is called the heel and is used to maintain the tanks at reduced temperature during the ballast voyage. The quantity retained on board will depend on the type of ship, type of cargo and the duration of the voyage. It will also depend on the commercial agreements with the charterer. On LPG ships, the amount kept on board should be sufficient to run the reliquefaction plant from time to time, returning the condensate to the tanks to ensure arrival at the loading terminal with tanks ready to load. On LNG ships with tanks of the membrane type, it is only necessary to keep enough cargo to ensure that, on arrival at the loading port, there will still be some liquid at the bottom of the tanks. In these tanks, the temperature at the top of the tank will stay around -65 °C without the need for any circulation, so long as there is liquid at the tank bottom. On ships with type B tanks, it is necessary to keep a slightly larger quantity of cargo, sufficient to ensure that the spray pumps are still able to circulate cargo at the end of the voyage. As the weight of tank material is much higher in type B tanks than in membrane-type tanks, it is necessary to maintain the temperature all around the tank by circulating liquid with small submerged cool-down or spray pumps installed at the bottom of the tanks, through spray nozzles fitted at the top.

If the ship is due to load a different cargo from the one just discharged, none of the previous cargo should be retained on board. If the ship is fitted with deck tanks, the remaining amount, which cannot be pumped out, can be stored in an available deck tank. Otherwise all cargo must be vented off and the tanks prepared for the next cargo.

f) Changing Cargo or Preparation for Drydocking

This is probably the most time-consuming part of a liquefied gas carrier operation. If the next cargo is not compatible with the previous one, a visual inspection of the tanks is often imposed by the charterer, which would require the tanks to be gas free. This is usually the case when loading chemical gases, such as:

- vinyl chloride;

- butadiene;

- or ethylene.

It is also the case when the previous cargo was ammonia. Guidance on the compatibility of different cargoes is usually given in the ship’s operation manual and this has to be checked to know what preparation is necessary prior to arriving at the loading port, if the information is not given by the charterer.

The following operations have to be carried out to obtain a gas-free condition:

- Removal of remaining liquid.

- Warm-up the tanks.

- Inert the tanks.

- Aerate the tanks.

This sequence of operations is the same in case of tank entry for visual inspection or to prepare the ship for drydock.

If the operations are carried out while the ship is at sea, the remaining liquid and vapour will be vented out to the atmosphere or, if a deck tank is available, stored in the deck tank, using the reliquefaction plant. If the operation is carried out in port, either at a gas-freeing berth or at the loading terminal, the remaining liquid and vapour must be disposed of to a flare or to a vapour recovery system, if one is available.

In case of pressurised or semi-pressurised tanks, the remaining liquid can be removed by pressurisation if the liquid can be easily disposed of. Otherwise it is necessary to vaporise the remaining liquid. Most modern LPG ships are fitted with heating coils in the cargo pump sumps. Warm vapour is circulated through the heating coil to vaporise the liquid remaining in the sumps. On ships not equipped with heating coils or on LNG ships, vaporising the remaining liquid and warming up the tanks is done at the same time by using the compressors to circulate warm vapour through the bottom of the tanks. The vapour is returned to the compressors from the top of the tanks and the circulation is maintained until the temperature at the bottom of the tanks is higher than the condensing temperature of the heaviest component of the product. When warming up an LNG tank, for example, as LNG contains, among other things, a small amount of butane (C4H10), it is necessary to have temperatures at the tank bottom well above 0 °C before stopping the warming-up operation, to be sure that all liquid is vaporised.

When the tanks are free of liquid and warmed to a temperature higher than the dew point of the gas to be used for inerting, the inerting operation can be started. The reason for continuing the warm-up to such a temperature is to avoid any possibility of condensation when the inert gas is introduced. The inerting operation is conducted as explained earlier in the Chapref a) «Prepararion Before Loading», taking advantage of the difference of densiry between the inert gas and the vapour remaining in the tanks. If inerting is carried out prior to loading the next cargo and if a visual inspection of the tanks is not required, the operation can be stopped when the content of the last cargo in the tank atmosphere is below the figure recommended for loading the next cargo. The tanks can then be gassed-up with vapour of the next cargo. If inerting is carried out prior to opening the tanks, the operation can be stopped when there remains less of the last cargo than the figure recommended by the shipyard receiving the ship or by the inspector due to carry out the inspection. A figure of 0,5 %, or sometimes even 0,2 %, is usually recommended. The tanks can then be aerated until obtaining an oxygen content of 21 %, prior to being opened and entered for inspection.

g) Changing Cargo after Ammonia

This is a very delicate and long operation. Ammonia reacts with the carbon dioxide contained in the inert gas produced on board. It is also extremely miscible in water. Finally the maximum amount of ammonia accepted in the tank atmosphere prior to loading a cargo of LPG or chemical gases is 20 ppm by volume or 0,002 %. Many charterers even refuse to load LPG on ships having just completed an ammonia voyage. They insist on a minimum of three cargoes after the last ammonia cargo. Cleaning tank after ammonia must be conducted very carefully. It is very important to maintain a dry atmosphere in the tanks throughout the operation If the slightest amount of condensation occurs in the tanks while some ammonia vapour is still present, the ammonia will be absorbed by the water and this can mix with any small amount of rust or dust inside the tanks and become very difficult to eliminate. Due to the difficulty of disposing of ammonia vapour ashore, the operation is usually carried out at sea, venting the tanks directly with air. The tanks must be liquid-free and warmed up to a temperature well above the ambient temperature. They must be vented with air as dry as possible and the venting operation must be continued until the ammonia content in all tanks, piping and cargo machinery is below 200 ppm. The tanks must then be opened and entered for sweeping out all loose material present which could trap ammonia vapour. Obviously, all necessary safety precautions must be taken when entering the tanks and breathing aids must be used if at all necessary. Ventilation must be continued throughout this operation and maintained until ammonia content in the tank’s atmosphere is below 20 ppm. The whole operation will probably take more than a week.

Port operations

General

The previous chapter has described ship operations. In this chapter, it is the turn of the port and terminal operations to be reviewed. This will be done, looking at a ship arriving at a port and berthing at a terminal to load or discharge its cargo and then depart.

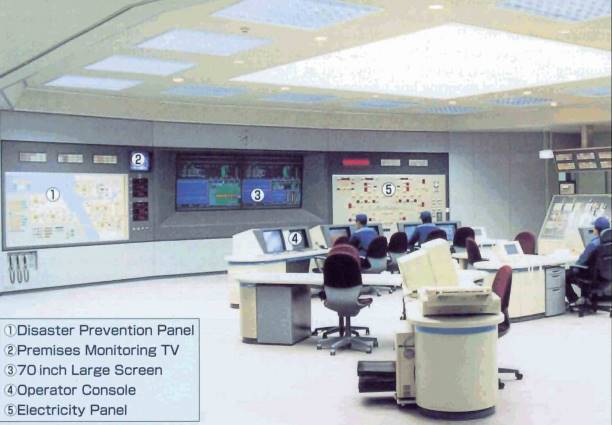

Exchange of information between ship, port and terminal

In Ports, Terminals and Jetties – Role and Significance“Operational procedures” we have seen the importance of the pre-arrival exchange of information between ship, port and terminal. The port authority and the terminal management must have received the characteristics of the arriving ship in advance to ensure that it can be accommodated by their facilities. They must ensure that the rules and regulations of the port and terminal have been communicated to the ship. They must ascertain that the ship is in good operating condition and that all equipment likely to be used while the ship is in the port or terminal is in working order. They must ensure that the crew speaks a language understood by the terminal personnel or that an interpreter will be available. They must also ensure that the ship is aware of the characteristics of the products to be transferred and that there is not, on board, any other product incompatible with these products or liable to create a dangerous situation while the ship is in the terminal.

In the case of an LNG project having several ships visiting one terminal at regular intervals over several years, meetings between the ship’s management, port authorities and the terminal management can start more than a year before the first arrival of the first ship and continue regularly throughout the life of the project. LPG ships visit many different terminals, sometimes at short notice, but it should still be possible to obtain the required information before the ship’s arrival.

Based on the Estimated Time of Arrival (ETA) given by the ship, the port and the terminal must confirm that this time is acceptable and that the facilities are available or, alternatively, advise that the ship must wait at a designated anchorage. The pilot must have received and returned, with comments if appropriate, the passage plan proposed by the ship’s master for the transit from port entrance to berth. If the port authority intends to proceed with an inspection of the ship before allowing entry, the master must be advised to proceed to a safe anchorage while the inspection is carried out.

Ship’s arrival and transit to the berth

A pilot must be waiting for the ship at the designated meeting point. If, for any reason, the ship cannot proceed, this should have been notified well in advance and not at the last minute, when turning around in the restricted port entrance waters might be difficult and risky. The pilot boarding point must be well out of the port entrance, to allow enough time for a discussion with the master and still be able to abort the ship’s entry if necessary. Once on board, and before proceeding within congested waters, the pilot must check with the master if all the propulsion and steering equipment is in working order, if the master agrees with the proposed passage plan and if there are any particular circumstance of which he should be aware. The pilot must advise the master of the position at which the tugs will join the ship, their number and capacity, the availability of an escort boat, and of all navigation aids and rules available or in force in the port. This can include restricted traffic lanes, restricted traffic time, speed limit, Vessel Traffic System (VTS), compulsory number of tugs, compulsory escort boat. The tugs supplied by the port must be able to handle the largest ship expected at the terminal in the worst weather to be expected in the port. They should meet the ship well in advance of the area where they are needed and they should remain available at short notice throughout the duration of the ship’s visit, in case an emergency makes it necessary for the ship to depart suddenly.

Transit channels from the port entrance to the berth and the turning area in front of the berth must be sized for the largest ship expected at the terminal. When the ship is berthed at the terminal, there should not be any ship traffic passing in the vicinity of the berth.

Ship alongside the berth

The berth, including fenders, mooring hooks and gangway, must be designed to accommodate all types and sizes of ship expected to visit the terminal. The ship’s mooring plan should have been reviewed by the terminal and calculations made to confirm that the ship can stay safely alongside with the worst wind speed, wave height and tidal current expected. Once the ship is safely moored alongside, the person in charge of cargo operations at the terminal must visit the ship for a pre-operation meeting. The International Ship/Shore Safety Check List for Gas Carriers must be completed by the ship and terminal personnel and signed by the persons responsible on each side. The ship Ballast Water Management must be reviewed and samples of ballast water taken if required. Procedures to be followed during the cargo operations, (including: common language, identification of the responsible persons on both sides, communications between ship and terminal, operating limits for stoppage of cargo transfer, disconnection and ship’s departure from the berth in relation to weather criteria and procedures to be followed in case of emergency) must be discussed and agreed by ship and terminal personnel. Details of preparations necessary before starting the transfer, (measurement of cargo quantity prior to the transfer, collection of cargo samples, if required, arrangement of the Emergency Shut Down Systems (ESDS) I and II, if appropriate, pressures, temperatures and flow of the product during transfer, warning to be given before stopping the transfer, piping disconnection at the end of transfer, ballasting or deballasting and maintenance of mooring line tensions throughout the transfer) must also be reviewed and agreed by ship and terminal personnel.

Read also: Terminal Operations for LNG or LPG Carrier after Arriving in Port

When all this is complete, the terminal personnel can proceed with the connection of the ship and shore piping, after careful purging to avoid any liquid spillage. The quantity of cargo on board before transfer is measured and calculated, with the assistance of a shore surveyor, if so required by the charterer. The ESD link is connected and tested. Tank and piping cool-down is started, if required, and the actual transfer can start.

Throughout the transfer, ship and shore personnel will make frequent checks to ensure that there is no cargo leakage, the mooring lines are correctly maintained, that pressures, temperatures and levels in ship and shore tanks are correct, the ballasting or deballasting operation is proceeding and the ship’s trim, heel, and hull stresses are maintained within the required limits and that the transfer is, in general, proceeding smoothly.

Once the transfer is complete, the quantity of cargo in the ship’s tanks is measured and calculated, the ship and shore piping disconnected after careful purging and the ship is ready to depart. Pilots and tugs will again assist the ship in leaving the berth and navigating through the port exit channels to the open sea.

Safety and contingency

Close co-operation between ship and shore personnel is essential for the safe handling of a ship transferring cargo in a terminal. If the operation is well prepared and if open channels of communication are maintained between ship and terminal, there is a good chance that the transfer will be carried out smoothly and that any unexpected incident will be tackled promptly before it can develop into something more serious.

However, due to the hazardous nature of the products handled, an accident is always possible. Ship and terminal personnel must be aware of their respective actions in case of emergency.

A recent joint action by the International Maritime Organization (IMO) and the Environment Office of the United Nations Environment Programme (UNEP IE) has helped to develop the «Awareness and Preparedness for Emergencies at Local Level for Port Areas» (APELL for Port Areas). This programme provides comprehensive technical information on contingency planning for maritime emergencies, including the recently updated and expanded documentation related to oil pollution, prepared in consultation with oil industry organisations and other institutions. Many of its conventions, agreements, regulations, manuals and other guidance documents have great relevance to shipping operations in port areas, including the preparation of contingency planning for emergencies.

In Europe, the «Seveso II Directive», also known as the «Control of Major Accidents Hazards Regulations (COMAH)» is applicable to all sites where a certain quantity of dangerous substances are located. It requires on and off-site emergency plans to be available.

APELL for Port Areas recommends that emergency responses manuals be developed by the terminals, setting down the procedures necessary to give effect to the emergency plan. Their primary function is to provide standing instructions and advice to all involved personnel on the actions they should take in the event of an emergency. Copy of a simplified version of the manual should be given to the ship on arrival. Similarly, the ship should have available, in a safe place near the gangway, or in an office ashore, a copy of their own emergency safety plan.

It is fundamental to safe operation and effective contingency planning that all personnel be thoroughly trained in the procedures they are to follow should there be an incident at the terminal. To this effect, it is recommended that common emergency exercises be conducted at regular intervals. These exercises should not be limited to the ship and terminal personnel but should also involve the ship’s operating management, as well as the port authority and the local fire brigade. The involvement of outside shore authorities, of outside shore services such as the fire brigade, and the structure of the chain of command in case of emergency should be clearly defined and the information distributed to all parties. The shore assistance available to the ship in case of fire on board or in the terminal should be specified. In such a case, a decision which is always difficult to make is: should the ship be kept alongside or sent out to sea. The ship should be made aware of terminal policy in this regard.

Attention must also be paid to media relations and the means used to inform the public of events. In particular, in the event of an accident, it is necessary to reassure and advise the local population. It is strongly recommended that the contingency plan identifies those persons authorised to issue public statements; these people must be fully trained in public relations and media handling.

Finally, the preparation, development and implementation of emergency plans should be considered an ongoing process, requiring frequent and regular review.