The maritime industry is charting a course towards a cleaner future, and at the heart of this transformation are low sulphur fuels. With stricter environmental regulations, particularly MARPOL Annex VI, ships worldwide are adapting to new operational realities. This article will guide you through the essential aspects of low sulphur fuels, from understanding their composition and the critical ISO 8217:2017 standard to navigating the complexities of fuel management on board.

- MARPOL Annex VI Pollution by air

- Ship implementation planning guidance approved

- Marine Fuels

- Typical ranges of sulfur content and viscosity for the standard fuels used on ships

- ISO 8217 2017

- ISO 8217 2017

- Fuel Management on Board

- Operational Challenges

- Measures To Be Taken Onboard Before Fuel Switching

- Fuel Switching Considerationa

- Written procedures for fuel change-over

- Low Sulphur Fuel – SOX Emission Control Area (SECA) and other regions Imposing restriction on Exhaust Emissions

- Other Regions

- Operational Procedures

- Bunker Tank Segregation

- Low TBN ME Cylinder Oil

We’ll explore typical sulphur content and viscosity ranges, delve into operational challenges, and outline the crucial measures and written procedures for seamless fuel change-overs. Furthermore, we’ll examine the impact of low sulphur fuels on SOx Emission Control Areas (SECAs) and other restricted regions, discuss vital operational procedures like bunker tank segregation, and highlight the importance of low TBN marine engine cylinder oil in maintaining engine health. Join us as we explore how these advancements are shaping a more sustainable shipping industry.

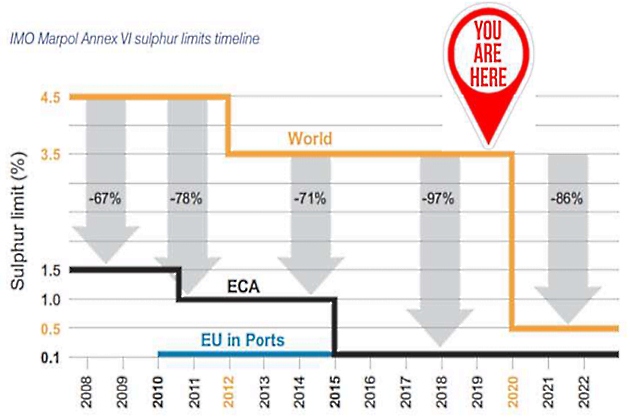

MARPOL Annex VI Pollution by air

The 2020 IMO fuel sulphur regulation:

The 2020 deadline was confirmed at the 70th session of IMO’s Marine Environment Protection Committee (MEPC) held in October 2016.

Heavy fuel oil (HFO), which is high in sulphur content , is the traditional source of energy to power ships. It is considered the bane in terms of emissions for environmentalists.

The switch to burning either the…:

- low-sulphur marine gas oil (MGO) with below 0,5 %;

- ultra low sulphur fuel oil (ULSFO) of 0,1 %;

… and two other alternatives:

- scrubbers;

- or LNG as fuel.

Compliance with ECA regulations requires:

A) Exhaust gas cleaning systems.

Also known as scrubbers, is a commercially available option for the shipping industry. Ships installed with scrubbers mean they can continue to burn high-sulphur bunker fuel from 2020 and comply with the 0,5 % sulphur limit.

B) LNG.

To burn LNG as fuel. Global The Role of LNG Bunkering InfrastructureLNG bunkering infrastructure is considered to be at an infant stage today, as most LNG-powered ships are mainly coastal vessels limited to European waters, and major bunkering ports in the world have yet to develop full-scale LNG bunkering facilities.

C) Compliant fuels.

The most straightforward way for ships is to simply switch to burning MGO or ULSFO to meet IMO’s sulphur limits. The operators will have to either absorb the cost of the higher fuels or pass it on to their customers whenever possible.

This change-over needs:

- training,

- preparation

- and – attention from all involved personnel.

Change-over from one type of fuel to another is an operation with many pitfalls and risks, as a result of this it is important that the vessel has a detailed change-over procedure.

If this is not taken seriously it may result in:

- engine failure,

- loss of power

- or – engine break down.

Ship implementation planning guidance approved

To assist ship operators and owners to plan ahead for the 0,50 % sulphur 2020 limit, the MEPC approved guidance on ship implementation planning.

Read also: Balancing Cleaner Fuel and Environmental Impact in LNG Emissions

The guidance is part of a set of guidelines being developed by IMO for consistent implementation of the MARPOL regulation coming into effect from 1 January 2020.

The ship implementation planning guidance includes sections on:

- risk assessment and mitigation plan;

- fuel oil system modifications and tank cleaning;

- fuel oil capacity and segregation capability;

- procurement of compliant fuel;

- fuel oil changeover plan;

- documentation and reporting.

Economic consequences when switching between high and low Sulphur fuels

High and low sulphur fuels often have very different properties and tend to be incompatible in certain mixed ratios it often leads to major modifications of the fuel oil system.

These modifications and incorrect operation can lead to major economic impact for these vessels. Vessels may also need expensive modifications of the cylinder oil system. Due to the high relative cost of ultra-low sulphur fuel possible reduction engine load and vessel speed, in order to consume less fuel in an ECA.

Port authorities will check bunker delivery notes, logbooks, and take fuel samples. Penalties will increase if the industry is slow to comply. Refiners can increase ULSFO production by extracting low sulphur fuel oil streams that are currently blended into LSFO or HSFO to be made available to the market as ULSFO.

The cost of low sulphur fuel is significantly higher than for high sulphur fuel.

ExxonMobil, for instance, has launched a relatively new product, Heavy Distillate Marine ECA 50 (HDME 50), that can be handled onboard like HFO and has only 0,1 % sulphur content.

Refiners can raise LNG bunker supplies in major bunkering hubs (Singapore MPA, Shell and ExxonMobil) to supply LNG as fuel. In Rotterdam, Shell launched a LNG bunker tanker to supply LNG from Rotterdam’s Gate Terminal.

The interpretation of “fuel oil used on board” includes use in main and auxiliary engines and boilers. Ships can meet the requirement by using low-sulphur compliant fuel oil.

Another exemption allows for a ship to conduct trials for the development of ship emission reduction and control technologies and engine design programmes. This would require a special permit from the Administration(s) (flag State(s)).

An increasing number of ships are also using gas as a fuel as when ignited it leads to negligible sulphur oxide emissions. This has been recognized in the development by IMO of the International Code for Ships using Gases and other Low Flashpoint Fuels (the IGF Code), which was adopted in 2015.

Another alternative fuel is methanol which is being used on some short sea services.

Ships may also meet the SOx emission requirements by using approved equivalent methods, such as exhaust gas cleaning systems or “scrubbers“, which “clean” the emissions before they are released into the atmosphere (must be approved by the ship’s Flag State Administration).

The PSC questionnaire:

- Do ships which are using separate fuel oils to comply with the maximum sulphur content of 0,1 % m/m in fuel oil while operating in SOx emission control areas;

- have a written procedure showing how fuel oil change-over is to be done for achieving compliance with the above requirements when entering SOx emission control areas?

Annex VI, regulation 14.6.

- Do ships which are using separate fuel oils to comply with the maximum sulphur content of 0,10 % m/m in fuel oil and entering or leaving SOx emission control areas;

- record detailed information showing that the ship has completed/initiated the change-over in the logbook prescribed by the Administration?

Annex VI, regulation 14.6.

Marine Fuels

What are the options for compliance? BP will continue to work with our customers to supply safe, compliant and quality fuels globally.

VLSFO

VLSFO will be a new fuel option available in 2020:

- As most VLSFO available will be blended, stability and compatibility will be key considerations.

- Economic incentives are expected to drive Increased use of VLSFO over time.

MGO

The most familiar fuel option, MGO is widely available and operationally tested.

- No fuel switching will be required. MGO can be used globally both inside and outside ports.

- As a distillate component. MGO is likely to be the most expensive option, with additional lubricant requirements.

LNG

LNG fuel systems require specialist crew and we expect their use to be limited to new build vessels due to the expense of retrofitting:

- Infrastructure for LNG bunkering will be less established than for other fuel types in 2020.

- LNG has low NOx and SOx emissions.

HSFO

Scrubber can be fitted to remove sulphur from exhaust gases and enable vessels to burn cheaper high sulphur fuels:

- Scrubber installation time and cost has resulted in limited adoption so far.

- Advances in technology are expected to make scrubbers an increasingly attractive solution.

There are two basic types of marine fuels – distillate and residual.

- Distillate fuel, also known as Marine Gas Oil (MGO), is composed of petroleum fractions that are separated from crude oil in a refinery with a “distillation” process.

- Residual fuel, or Heavy Fuel Oil (HFO), is comprised of process residues – the fractions that did not boil – and has an asphaltene content of between 3 and 10 per cent.

In order to best deal with these difficulties it is essential that vessel operators recognize the characteristics of the various ECA-category fuel grades and how to manage the fuel switch-over.

It will be interesting: Marine Safety System Integration and Compliance

Important when a ship switches fuel it needs to be done safely and effectively so as to avoid any technical issues and to also ensure that the emission limits are not breached.

The MARPOL requires:

Typical ranges of sulfur content and viscosity for the standard fuels used on ships

| Table 1. Typical Parameters of Marine Fuel | ||||

|---|---|---|---|---|

| Fuel Types | ISO Category | Viscosity (cSt) (at 50 °C for Residual and 40 °C for Disitillate Fuels) | Sulfur Content (%) | |

| Minimum | Maximum | |||

| Heavy Fuel Oil (HFO) | Residual (RMA – RMK)* | 10 | 700 | 1,1 – 3,5 |

| Marine Diesel Oil (MDO) | Distillate (DMB) | 2 | 11 | 0,10 – 1,5 |

| Marine Gas Oil (MDO, Low Sulfur Distillate Fuel) | Distillate (DMA and DMZ) | 2 | 4 | 0,10 – 1,0 |

| 0,10 % Heavy Fuel Oil (HFO, ECA Fuel) | Not standardized | 9 | 67 | 0,10 |

| 0,50 % Heavy Fuel Oil (HFO, Global Fuel) | Not standardized | No requirements defined | No requirements defined | 0,50 |

| *RMA–RMK: RMA, RMB, RMD, RME, RMG and RMK | ||||

| Table 2. 0,10 % Heavy Fuel Oil | |||||||

|---|---|---|---|---|---|---|---|

| Shell ULSFO | ExxonMobil HDME 50 | ExxonMobil AFME 200 | LUKOIL | CEP SA | BP | Phillips 66 | |

| Density (kg/m3) | 790-910 | 900-915 | 917 | 886 | 868 | 845,4 | 855,2 |

| Viscosity (cSt) | 10-600 | 30-45 | -67 | 16 | 8,8 | 8,8 | 8,6 |

| Micro Carbon (MCR) (mass %) | 2 | >0,30 | >10 | 0,1 | 0,1 | 0,1 | 0,04 |

| Sulfur (mass %) | >0,1 | >0,10 | >0,10 | 0,07 | 0,05 | 0,03 | 0,06 |

| Pour Point (deg. C) | 18 | 6-12 | 6-15 | 18 | -12 | 21 | -12 |

| Flash Point (deg. C) | <60 | >70 | >70 | 165 | 72 | <70 | 79 |

| Water (vol. %) | 0,05 | 0,05 | <0,5 | 0,05 | 0,27 | 0,04 | NA |

| Acid Number (mg KOH/g) | <0,5 | <0,1 | <0,1 | 0,5 | 0,27 | 0,04 | NA |

| Vanadium (mg/kg) | 2 | <1 | 1 | 1 | NA | <1 | <0,10 |

| Al + Si (mg/kg) | 12-20 | <5 | <10 | 2 | NA | >1 | 2 |

| Lubricity (microns) | NA | <320 | NA | 270 | 410 | 326 | NA |

| CCAI | 800 | 795-810 | 799 | 793 | NA | 765 | NA |

ISO 8217 2017

| Marine Distillate Fuels | ||||||||

|---|---|---|---|---|---|---|---|---|

| Limit | Parameter | DMX | DMA | DFA | DMZ | DFZ | DMB | DFB |

| Max. | Viscosity at 40 °C (mm2/s) | 5,500 | 6,000 | 6,000 | 11,00 | |||

| Min. | Viscosity at 40 °C (mm2/s) | 1,400 | 2,000 | 3,000 | 2,000 | |||

| Max. | Micro Carbon Residue at 10 % Residue (% m/m) | 0,30 | 0,30 | 0,30 | – | |||

| Max. | Density at 15 °C (kg/m3) | – | 890,0 | 890,0 | 900,0 | |||

| Max. | Micro Carbon Residue (% m/m) | – | – | – | 0,30 | |||

| Max. | Sulphur (% m/m) | 1,00 | 1,00 | 1,00 | 1,50 | |||

| Max. | Water (% V/V) | – | – | – | 0,30 | |||

| Max. | Total sediment by hot filtration (% m/m) | – | – | – | 0,10 | |||

| Max. | Ash (% m/m) | 0,010 | 0,010 | 0,010 | 0,010 | |||

| Min. | Flash point (°C) | 43,0 | 60,0 | 60,0 | 60,0 | |||

| Max. | Pour point in Winter (°C) | – | -6 | -6 | 0 | |||

| Max. | Pour point in Summer (°C) | – | 0 | 0 | 0 | |||

| Max. | Cloud point Winter (°C) | -16 | Report | Report | – | |||

| Max. | Cloud point Summer (°C) | -16 | – | – | – | |||

| Max. | Cold filter plugging point in Winter (°C) | – | Report | Report | – | |||

| Max. | Cold filter plugging point in Summer (°C) | – | – | – | – | |||

| Min. | Calculated Cetane Index | 45 | 40 | 40 | 35 | |||

| Max. | Acid Number (mgKOH/g) | 0,5 | 0,5 | 0,5 | 0,5 | |||

| Max. | Oxidation stability (g/m3) | 25 | 25 | 25 | 25 | |||

| Max. | Fatty acid methyl ester (FAME) | – | – | 7,0 | – | 7,0 | – | 7,0 |

| Max. | Lubricity, corrected wear scar diameter (wsd 1,4 at 60 °C) (um) | 520 | 520 | 520 | 520 | |||

| Max. | Hydrogen sulphide (mg/kg) | 2,00 | 2,00 | 2,00 | 2,00 | |||

| Appearance | Clear & Bright | – | ||||||

ISO 8217 2017

Fuel standart for marine residual fuels.

| Characteristics of Marine Residual Fuels according to ISO 8217:2017 | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Test | Unit | Test Method | Limits | Grade | ||||||||||||

| ASTM | IP | ISO | RMA 10 | RMB 30 | RMD 80 | RME 180 | RMG 180 | RMG 380 | RMG 500 | RMG 700 | RMK 380 | RMK 500 | RMK 700 | |||

| Viscosity at 50 °C | mm2/s (cSt) | D445 | 71 | 3104 | max. | 10.00 | 30.00 | 80.00 | 180.0 | 180.0 | 380.0 | 500.0 | 700.0 | 380.0 | 500.0 | 700.0 |

| Density at 15 °C | kg/m3 | D1298 | 160 | 3675 or 12185 | max. | 920.0 | 960.0 | 975.0 | 991.0 | 991.0 | 991.0 | 991.0 | 991.0 | 1010.0 | 1010.0 | 1010.0 |

| CCAI | – | Calculated | max. | 850 | 860 | 860 | 860 | 870 | 870 | 870 | 870 | 870 | 870 | 870 | ||

| Sulphur | mass % | D4294 | 336 | 8754, 14596 | max. | Statutory requirements | ||||||||||

| Flalsh point | °C | D93 | 34 | 2719 | min. | 60.0 | 60.0 | 60.0 | 60.0 | 60.0 | 60.0 | 60.0 | 60.0 | 60.0 | 60.0 | 60.0 |

| Hydrogen sulphide | mg/kg | – | 570 | – | max. | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 |

| Acid number | mg KOH/g | D664 | – | – | max. | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 |

| Total sediment aged | mass % | – | 390 | 10307-2 | max. | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 |

| Carbon residue, micro | mass % | D4530 | 398 | 10370 | max. | 2.50 | 10.00 | 14.00 | 15.00 | 18.00 | 18.00 | 18.00 | 18.00 | 20.00 | 20.00 | 20.00 |

| Pour point (Winter quality) | °C | D97 | 15 | 3016 | max. | 0 | 0 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

| Pour point (Summer quality) | °C | D97 | 15 | 3016 | max. | 6 | 6 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

| Water | volume % | D95 | 74 | 3733 | max. | 0.30 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 |

| Ash | mass % | D482 | 4 | 6245 | max. | 0.040 | 0.070 | 0.070 | 0.070 | 0.100 | 0.100 | 0.100 | 0.100 | 0.150 | 0.150 | 0.150 |

| Vanadium | mg/kg | – | 501,470 | 14597 | max. | 50 | 150 | 150 | 150 | 350 | 350 | 350 | 350 | 450 | 450 | 450 |

| Sodium | mg/kg | – | 501,470 | — | max. | 50 | 100 | 100 | 50 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Aluminium + silicat | mg/kg | D5184 | 201,407 | 10478 | max. | 25 | 40 | 40 | 50 | 60 | 60 | 60 | 60 | 60 | 60 | 60 |

| Used lubricating oil (Calcium + zinc) | mg/kg | – | 501 or 407 | – | – | The fuel shall be free of ULO. A fuel shall be considered to contain ULO when either one of the following conditions is met Calcium > 30 and zinc > 15 or calcium > 30 and phosphorus >15 | ||||||||||

| Used lubricating oil (Calcium + phosphore) | mg/kg | – | 500 | – | – | |||||||||||

ISO-8217 bunker fuel oil tests:

ISO-8217 bunker fuel testing for quality and compliance.

Crew Responsibilities for LNG BunkeringMarine bunker fuel oil is tested to ISO-8217 specifications by laboratories, helping ship bunker fuel comply with.

- MARPOL Annex VI;

- the EU Sulphur Directive;

- Sulphur Emission Control Area (ECA) requirements;

- and other commercial, legal and quality standards.

- Kinematic Viscosity;

- Density at 15 °C, ISO-3675 or ISO-12185;

- Cetane index, ISO-4264;

- Sulfur content, ISO-8754, ISO-14596;

- Flash Point Test, ISO-2719;

- Hydrogen sulfide, IP570;

- Acid number, ASTM D664;

- Total sediment by hot filtration, ISO-10307‐1;

- Oxidation stability, ISO-12205;

- Carbon residue, ISO-10370;

- Cloud point, ISO-3015;

- Pour point, ISO-3016;

- Appearance;

- Water volume, ISO-3733;

- Ash, ISO-6245;

- Lubricity, ISO-12156‐1;

- additional tests.

ISO 13739:2010

Specifies procedures and requirements for the transfer of bunkers to vessels involving bunker tankers, road tankers and shore pipelines. It applies to pre-delivery, delivery and post-delivery checks and documentation.

ISO 4259-1:2017

Petroleum and related products – Precision of measurement methods and results.

SS 600

Singapore Standard Code of Practice for Bunkering -, which covers pre-delivery, actual delivery and post-delivery checks and documentation.

The use of the incorrect fuel oil can lead to catastrophic damage to machinery and substantial claims, and can endanger the ship and personnel aboard.

Precautionary measures that can be taken:

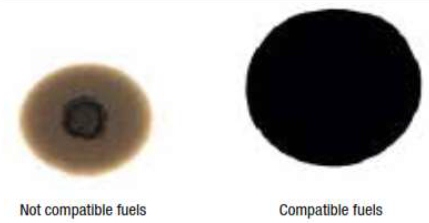

- Avoid mixing bunker fuels from different sources wherever possible.

- Store fuels separately until compatibility testing has been carried out.

- Do not mix straight-run fuel oil (the product of atmospheric or vacuum distillation) with a cracked (additionally processed) one – if not possible keep the ratio to a minimum.

- Steer clear of mixing fuels with greatly dissimilar densities.

- Where possible choose fuels with similar viscosities and densities.

- Do not mix a fuel oil with a marine diesel oil or marine gas oil.

How fuel system works in a Gas and diesel low-pressure two-stroke engine (X-DF)marine diesel engine?

The heater in the system reduces the fuel oil viscosity in the system for efficient combustion. The temperature required will depend on the fuel oil quality which will vary, however the temperature should not exceed 150 °C.

The fine filter in the system is a stainless steel mesh to filter out particles. Filters should be cleaned regularly.

Fuel Management on Board

Vessel should be equipped with sufficient Shore Natural Gas Storage Tanksstorage capacity for very-low sulphur fuel. It may require that existing fuel tank configuration is modified.

A tank which has been used for high sulphur fuels must be absolutely clean before it can hold low sulphur fuel, if not you may risk non-compliance with ECA regulations.

Read also: Guide for Planning Gas Trials for LNG Vessels

Modifications of fuel tanks may affect bunker service tanks, settling tanks and transfer pipes, ventilation and overflow systems, sounding pipes, level indicators, tank heating, etc.

According to SOLAS a service tank must have capacity of 8 hours of normal operation, this means that high and low sulphur service tanks ideally must be separated, all this to secure no contamination, and compliance with ECA regulations.

There must also be focus on the engine and boiler fuel supply lines, and return lines, to make sure that there is no contamination into the low sulphur system.

| Tank arrangement & capacity plan | ||||||

|---|---|---|---|---|---|---|

| Tank name | Intact Permeability | Demage Permeability | Fluid Type | Volume | Specific Gravity | Weight |

| % | % | [m3] | [kg/m3] | [kg] | ||

| Rig water | 98 | 95 | Rig water | 45,17 | 1,00 | 45,17 |

| Gasoil | 98 | 95 | Gasoil | 43,00 | 0,8524 | 36,65 |

| Daily oil | 98 | 95 | Gasoil | 6,42 | 0,8524 | 5,47 |

| Overflow | 98 | 95 | Gasoil | 1,34 | 0,8524 | 1,14 |

| Sludge | 98 | 95 | Sludge | 1,34 | 1,00 | 1,34 |

| Lubricating oil | 98 | 95 | Lube Oil | 0,95 | 0,92 | 0,87 |

| Bilge | 98 | 95 | Bilge | 2,97 | 1,00 | 2,97 |

| Fresh water | 98 | 95 | Fresh water | 6,71 | 1,00 | 6,71 |

| Black water | 98 | 95 | Black water | 1,69 | 1,00 | 1,69 |

| Grey water | 98 | 95 | Gray water | 1,69 | 1,00 | 1,69 |

Operational Challenges

Operating issues. 2-stoke Diesel Engine

- The change-over needs training, preparation, and attention from all involved personnel.

- Change-over from one type of fuel to another is an operation with many pitfalls and risks, as a result of this it is important that the vessel has a detailed change-over procedure.

- If this is not taken seriously it may result in engine failure, loss of power, or engine break down. You should consult your engine manufacturer for advice and best practice before switching between high and very-low sulphur fuels.

- The buyer is responsible for specifying the bunker quality ordered, and should have knowledge of the exact sulphur content for the fuels used.

- The exact sulphur level has a major impact on the time it takes to change from one fuel to another.

- The more sulphur there is in the HFO and the closer to the limit of 0,50 % sulphur there is in the MGO, the longer it will take to change-over and fulfil requirements.

- To be in compliance with MARPOL vessels using separate fuel oils to comply with ECA requirements must carry a written procedure showing how the fuel oil change-over is to be done, allowing sufficient time for the fuel oil service system to be fully flushed of all fuel oils exceeding the applicable sulphur content prior to entry into an ECA.

- The volume of low sulphur fuel oils in each tank as well as the date, time and position of the ship when any fuel oil change-over operation is completed prior to the entry into an ECA or commenced after exit from an ECA must be recorded.

Operating issues. 4-stoke Diesel Engine

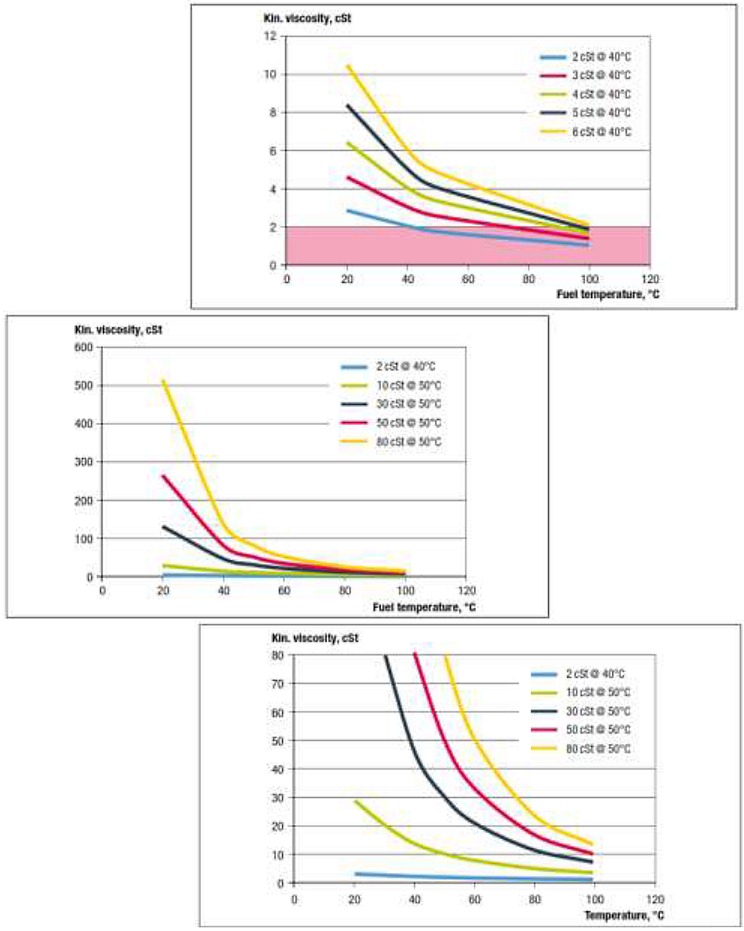

Operating 4-stroke engines on low viscosity MGO is normally not considered to be a problem. But if the viscosity drops too low it may damage the fuel injection equipment, and there may be a risk of loss in capability to produce full power or engine failure.

Operation on MGO can give less energy per pump stroke than HFO which will affect the engines output. Much will be dependent on the fuel and the condition of the fuel injection components, but it can be up to 15 % or even more.

If changing from HFO to MGO too quickly uneven temperature changes may cause uncontrolled clearances in the injection pump, which can lead to seizure, internal and external leaks.

Lubrication of fuel injection components as long as the viscosity is within the spec and the sulphur content is above 0,01 % is not considered to be a problem.

The fuel viscosity must be above 2 cSt, safety margin 3 cSt and normally below 40 °C to maintain the correct lubrication skills for the fuel pumps.

It is recommended to use lubrication oil with BN between 55 and 30 when operating on HFO, a typical BN number for an engine operating on MGO will be 12-20.

A medium speed engine is very tolerant when it comes to high BN number even when running on MGO.

It can run for several hundred hours without operational problems. But it is recommended to top up with oil with a lower BN number if the engine is operating on MGO for a longer period.

Monitoring used lubrication oil requires more attention when switching between high and ultra-low sulphur fuels, oil contamination by HFO is indicated by an increase in viscosity, but be aware that contamination of MGO can compensate this so the viscosity looks to be all right even though contamination is increasing.

Many parameters that have to be taken into consideration, the most important are:

One of the major considerations. It may require that existing fuel tank configuration is modified. A tank which has been used for high sulphur fuels must be absolutely clean before it can hold low sulphur fuel, if not you may risk non-compliance with ECA regulations.

It will be interesting: Essential Steps for Preparing LNG Tanks for Cargo Loading on LNG Vessels

Modifications of fuel tanks may affect bunker and transfer pipes, ventilation and overflow systems, sounding pipes, level indicators, tank heating, etc. Not only storage tanks are affected, service tanks, settling tanks, and fuel oil pipes with associated equipment in the engine room may also be affected.

According to SOLAS a service tank must have capacity of 8 hours of normal operation, this means that high and low sulphur service tanks ideally must be separated, all this to secure no contamination, and compliance with ECA regulations.

There must also be focus on the engine and boiler fuel supply lines, and return lines, to make sure that there is no contamination into the low sulphur system.

During a change-over period, and depending of the fuel supply system configuration there will be a mix of residual fuel (HFO) and ultra-low sulphur distillates (MGO).

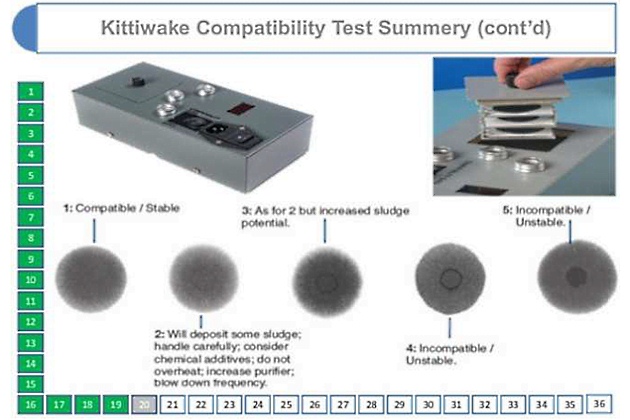

In order to prevent operational problems like clogging of filters etc. it is recommended to carry out compatibility tests, if possible before the fuel oils are bunkered.

There are also test kits available that can be used onboard, and of course it is possible to send in samples to a land based laboratory, but that will cause time lag before receiving the results.

HFO and MGO have significantly different characteristics in terms of viscosity and lubricity. Typically an engine running on HFO requires a viscosity of 10-15 centistokes (cSt).

To fulfil this, the fuel needs heating, maybe as high as 135 °C. On the opposite side, MDO can have a viscosity well under 10 cSt at 40 °C.

The injection pressure is dependent of the viscosity, low viscosity can lead to insufficient injection pressure.

The fuel index can also be influenced by low viscosity which again can lead to limitation in acceleration and rpm. In some cases it may require fuel coolers before operating on MGO.

Temperature and viscosity are very closely related, and the temperature difference between HFO and MGO into the fuel pumps can be more than 100 °C.

This difference in temperature can during a change-over period create operational problems. Mixing of hot HFO and “cold” MGO will normally not immediately turn into a homogeneous mixture, so some temperature and viscosity fluctuations must be expected.

Many engine manufacturers recommend that the viscosity must be kept between 2 cSt and 20 cSt and the temperature change must not exceed 2 °C per minute during a change-over period.

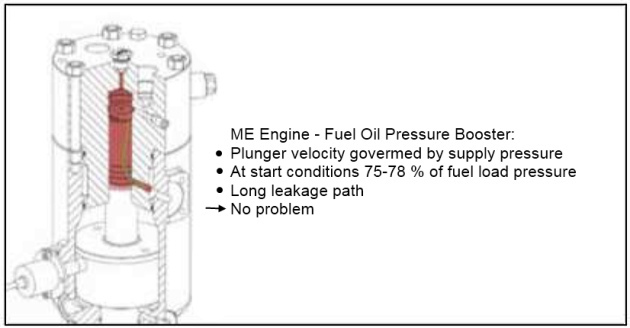

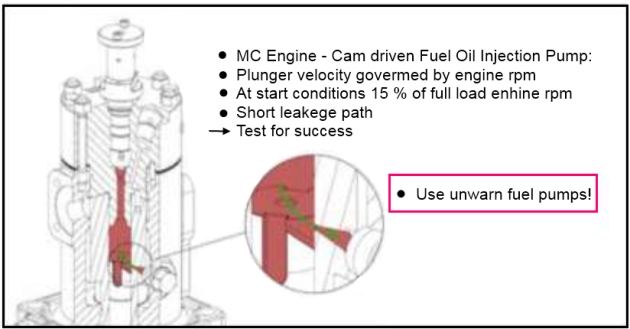

It is very important that you consult your engine manufacture regarding what are acceptable viscosity and temperature changes. The change-over from HFO to MGO or MGO to HFO may also require a certain engine load. If the change-over cause a rapid change in temperature it can result in to low or to high viscosity, thermal expansion or contraction of the injection components, insufficient clearances, causing pump plungers to scuff, stick or seize.

Highly volatile fuels with flashpoint lower than 60 °C cannot be used due to the explosion risk. However there are indications that some ultra-low sulphur fuels have flashpoint lower than 60 °C, therefore it is important to always consult the supplier of ultra-low sulphur fuels to ensure a correct flashpoint.

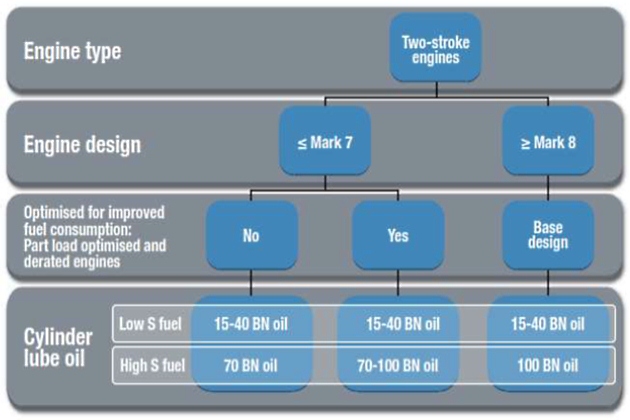

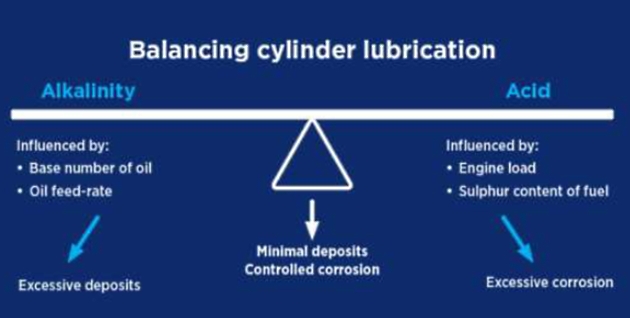

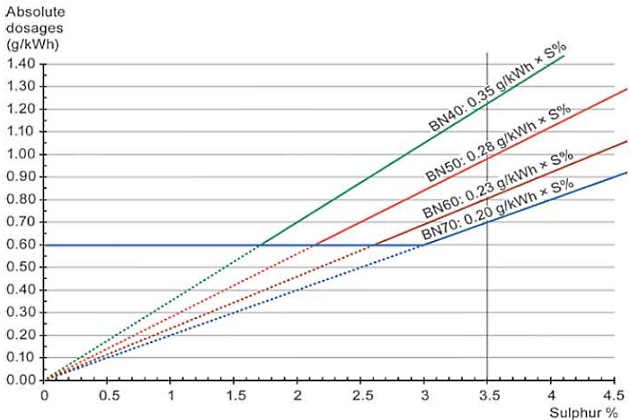

The choice of cylinder oil is dependent of the type of fuel used. The alkalinity in the cylinder oil neutralizes the corrosive acidic sulphur in the fuel oil. If the sulphur content in the fuel oil decreases, the alkalinity in the cylinder oil should be reduced.

If not there is a risk that excessive alkaline content in the cylinder forms deposit on the piston crown. These deposits become very hard and contact between deposit and cylinder wall can cause bore polishing or scuffed liner wear. If there is not enough alkalinity in the cylinder oil, the result will be corrosion in the cylinder.

Read also: The Ship/Shore Interface – Communications Necessary for Matching Ship to Berth

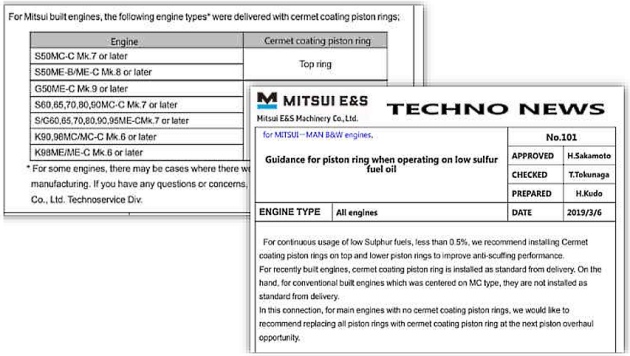

Several 2-stroke engine manufacturers recommend using cylinder oil with a Base Number (BN) of 70 for high sulphur HFO, and cylinder oil with 25-40BN for ultra-low sulphur MGO depends on Sulphur content.

Even though low sulphur fuels have been used in ships with 70BN cylinder oils, and the quantity of cylinder oil has been reduced, this poses a risk for bore polishing and excessive cylinder liner wear. Therisk is dependent on type of engine, operation and maintenance. Dependent of how often and for how long period a vessel is inside an ECA, there might be necessary with modifications to the cylinder oil system.

The modifications will not be as complex as in the fuel oil system because there are less components but it may require that two separate cylinder oil systems are built.

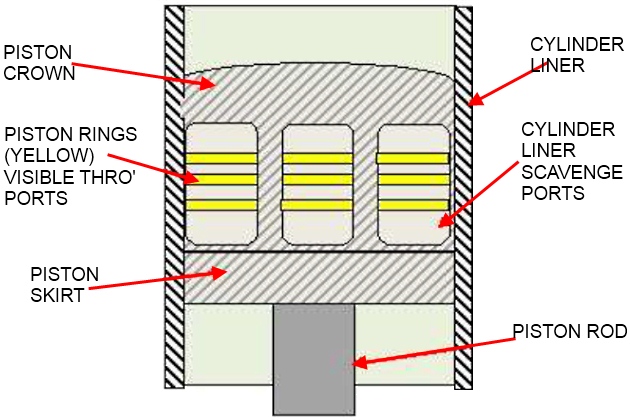

Deposits building up in the ring grooves can lead to deposits behind the piston ring, which again can lead to sticking piston rings and scuffing.

If possible scavenge drain oil analysis should be carried out. Iron content and BN in the drain oil can give strong indications of the wear and the alkalinity reserve of the cylinder oil. If these analyses are taken on a regular basis and each time there has been a change of fuel they can be used to monitor and optimize cylinder lubrication.

The system oil should also be monitored to see if there is any contamination due to stuffing box leakages.

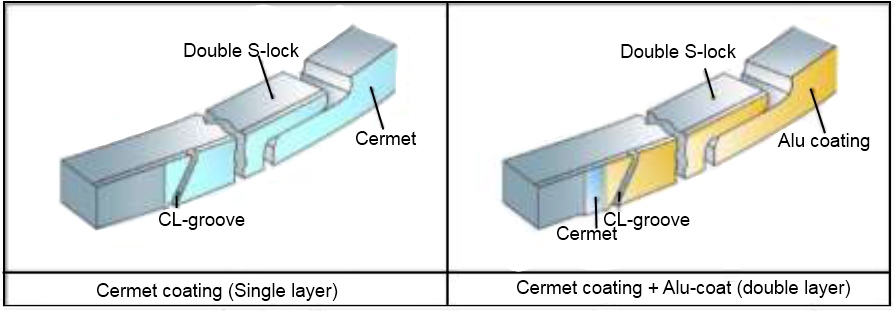

For engine types not mentioned above, we would like to recommend installing cermet coating piston rings on and furthermore we additionaly recommed to repcalct all piston rings with cermet coating piston rings.

Finally, there is also the option of installing piston rings with cermet coating piston ring and Alu-coat in slidin surface. Please refer Techno News No.083 about details.

Please contact to your local sales representative for more information for your engine type. For contact details, please refer to Mitrui Service Note No.111.

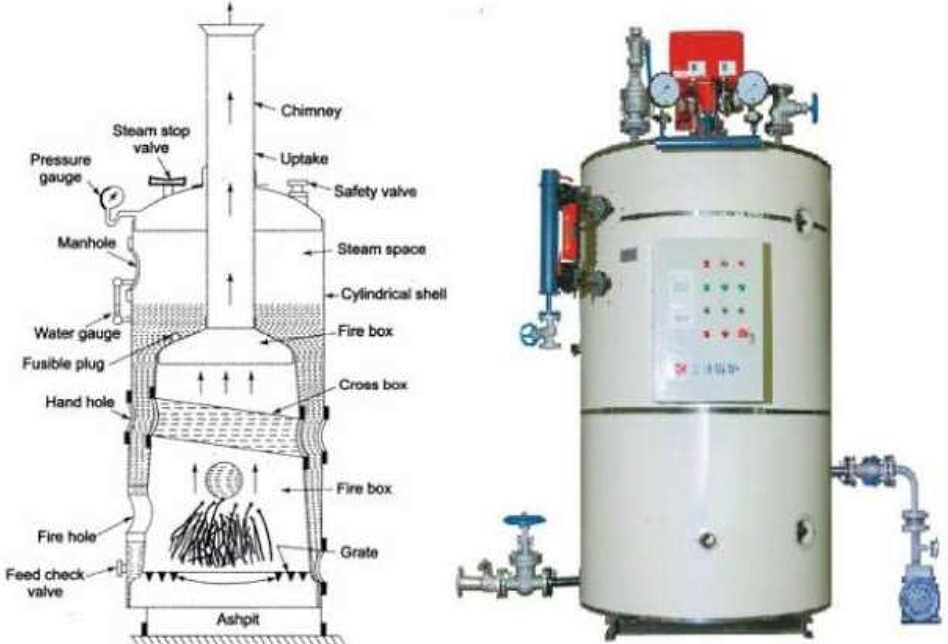

Boilers have been identified as the most at-risk component onboard when switching from HFO to MGO, and you should always consult the manufacturer of the boiler for advice and best practice.

Components like burners, fuel system, and boiler control systems need to be adjusted when switching from HFO to MGO. If the boiler is not adjusted to the fuel used the risk can be increased smoking, increased air pollution, furnace explosions and fire.

It will be interesting: Measurement and calculation of cargo on gas carriers

Most boilers are designed to operate on MGO for shorter periods, but they are not designed to operate for longer periods and full capacity on the low viscosity MGO. During ultra-low sulphur operation on volatile MGO there are many parameters that have to be taken into consideration:

Fuel supply pumps

Many existing boilers are equipped with fuel pumps for a minimum viscosity which is higher than the normal viscosity of MGO. Typical operational problems can be suction issues, lack of lubrication and overheating. Either the pumps need to be modified or a second optimized pump must be installed. Fuel pumps that circulate fuel during boiler standby should be programmed to stop when boiler is not firing. If not the circulation of fuel can heat the fuel to an unacceptable level.

Fuel heaters

When introducing volatile MGO in the boiler fuel system fuel heaters and heat tracing must be shutoff or bypassed, if not the viscosity will be too low. There is also a risk that MGO flowing through hot piping may vaporize creating vapour locks and causing irregular fuel supply, resulting in flame extinction.

Instead of fuel heaters, fuel coolers should be considered to maintain an acceptable viscosity level.

Burners

A fuel with lower viscosity will result in increased fuel through the burner and cause excessive smoke. Therefore the burner(s) should be adjusted or replaced before operation with volatile MGO. Burners with steam atomizing may not be suitable for MGO, it can lead to improper combustion and flame extinguishment.

Flame detectors

Due to the different colour spectrum and flame length when operating on HFO/MGO there may be a need for additional flame scanners. Some of the boiler safety functions are reliant of the flame detector and a failure here can lead to a fire or explosion.

Boiler control system

To prevent accidental ignition of vapours from the volatile MGO the boiler control system should be adjusted to be sure pre and post purge sequences clear the furnace of all fuel vapours in case of flame failure.

Measures To Be Taken Onboard Before Fuel Switching

Fuel Switching Considerationa

All vessels operating in areas where low sulfur is required should carry out the measure below:

- Prepare a detailed fuel switching procedure (or manual) in consultation with engine/machinery makers and place it on board. Include any required inspections or maintenance schedules. Properly train crew in the procedures. As this is a safety issue, a copy of this procedure should be retained on board, and its availability may be verified during ISM audits.

- Consult with fuel suppliers to select MGO (with viscosity at or above the minimum required for the machinery on board). Independent fuel oil testing is recommended.

- System seals, gaskets, flanges and other fittings should be carefully examined and maintained to correct any fuel seepage and leakage. Fine spray particles from such leakage may pose a severe fire safety risk.

- Maintain fuel oil purifiers, filters and strainers.

- Check and maintain control systems including alarms, transmitters, and indicators.

- Conduct crew training (initial and periodic).

- Monitor cylinder lubrication carefully to identify any increases in lube oil consumption, which may be caused by liner lacquering. Periodic testing of in-use lubricating oils can give early indications of unusual wear.

- Concerns with steam atomizing with MGO (including distortion of the tubes) should be assessed with the manufacturer and corrected. For burners having parallel tubes for steam and fuel oil, due to the lower temperature of MGO, tubes conveying MGO can distort due to temperature gradients.

- Ensure the burner management and flame supervision systems safely include MGO operation.

- Complete fuel switching prior to entering a port or restricted water to satisfy regulations and reduce risks.

Operational recommendations

Vessels that trade between areas with different sulphur limitations should test the MGO and MDO received on board as the Bunker Receipt may only give the max/min values of the viscosity.

If viscosity below 265 – 3 cst is received, problems could be expected as the viscosity will easily fall below 2 cst when passing through the fuel system on board. During the changing process from HFO to MGO, it is recommended that temperature change of the fuel inlet to the fuel pumps do not exceed 2 °C/minute.x

The first problems will be the fuel pumps, injection valves and boiler burners suffering internal leaks with malfunction and reduced capacity.

Source: en.wikipedia.org

If such low viscosity fuels are to be used, changeover on main engine, auxiliary engines and for boilers producing steam for propulsion from HFO to MDO/MGO should take place sufficient time before arrival at Californian ports to ensure that both the propulsion and manoeuvring are maintained. It is not considered necessary to test the auxiliary boilers before arrival at port.x

If difficulties are encountered, the engines must be changed back to their original HFO. Such procedures must be implemented by the Assured with reference to the ISM code and emergency procedures.

Before starting the changeover, watch out for a reduction or increase in temperature, observe the viscosity and reduce the engine load. To protect the injection equipment against rapid temperature changes, the changeover process must be carried out slowly and in accordance with the manufacturer’s instructions. The same also applies when changing from MGO to HFO.

The risks and possible consequences involved

Change from HFO to MGO or MDO on engines and boilers has occurred since HFO was initially used on board ships. However, one difference is the very low viscosity and low sulphur MGO or MDO now coming on the market as a result of the new requirements.

When changing to low sulphur fuel, several engine problems can occur, one of which is thermal shock in the fuel system due to the rapid change in temperature and poorer lubrication qualities of low sulphur fuel.

Read also: Comprehensive Overview of LNG and LPG Cargo Hoses in STS Operations

This can result in sticking/scuffing of the fuel valves, fuel suction valves and fuel pump plungers, which again lead to shut down of the main engine followed by manoeuvring problems. Waters where fuel switching is required are often environmentally sensitive and contain a number of Informed for Safe Navigation at Sea with Critical Maritime Informationhazards to navigation together with strong tides and currents.

The increased risk of furnace explosion in the event of flame failure during operation of the boiler on low sulphur fuel is another safety issue. Other significant operational implications by using low sulphur fuels might be reduced lubrication, low viscosity, flashpoint, acidity, catalytic fines or ignition and combustion quality.x

Written procedures for fuel change-over

There are no changes to the regulatory requirement concerning the need to demonstrate a written procedure showing how the fuel oil change-over is to be done and logbook recordings at each change-over (MARPOL Annex VI Regulation 14.6).

Existing fuel change-over procedures should, however, be reviewed and amended to reflect the use of new types of low sulphur fuels.

And since issues related to the change-over between HFO and low sulphur fuels are unique to each vessel and its condition, it will be important to:

- Confer with each vessel’s engine and boiler manufacturer and obtain advice on operating with low sulphur fuel and the need for any equipment or system modifications. When operating with new grades of low sulphur hybrid fuel, obtain a No Objection Letter (NOL) from the manufacturer for the fuel type and engine model in question.

- Address the difficulty of timing of a change-over prior to crossing the ECA border. Experience shows that this is one of the major operational challenges. Involve the vessel’s classification society and/or flag state if onboard modifications are required.

- Include proper procedures for checking the compatibility of the HFO and low sulphur fuels and for inspection and maintenance of the system. The difference in temperature, viscosity and lubricity when running on MGO could lead to seizure and leakages in the system. Reduced maintenance intervals may be required.

- Ensure crews receive suitable training and instruction on applying the procedures once finalised. Trial change-overs should be undertaken in safe locations.

Emphasise the importance of proper logbook recordings in order to demonstrate compliance.

Low Sulphur Fuel – SOX Emission Control Area (SECA) and other regions Imposing restriction on Exhaust Emissions

Regulation 14 of MARPOL 73/78 Annex VI, which entered into force on 19 May 2005, requires that low-sulphur fuel (LSF – Sulphur content of less than 1,0 %) be used in a SOX Emission Control Area (SECA).

The first such areas are:

- The Baltic Sea SECA – effective from 19 May 2006.

- The North Sea SECA – effective from 22 November 2007.

- The Baltic Sea Area means the Baltic Sea proper with the Gulf of Bothnia, the Gulf of Finland and the entrance to the Baltic Sea bounded by the parallel of the Skaw in the Skagerrak at 57° 44.8’N.

Other Regions

These regions will include State regulations within the United States of America. Restriction on Exhaust Emissions will be updated as SOX Emission controls are introduced into new areas.

By the end of 2019 an assessment of the measures will be carried out to determine whether further measures, such as lowering the sulphur limit to = 0,1 % m/m or extending the ECAs, will be needed. Vessels are permitted to use alternative means of compliance such as scrubbers or shore power.

Source: en.wikipedia.org

It is understood that most of the port authorities don’t have the intention to adopt higher requirement than the current standard in 2016, except Shanghai. It is likely Shanghai MSA will start to require the calling ships to use fuel with sulphur content = 0,5 % m/m during berthing excluding 1 hour after berthing and 1 hour before departure in 2016.

Operational Procedures

Bunker Tank Segregation

HSF and LSF bunkers must be kept segregated at all times. All bunker tank suction/filling valves are to be kept closed to avoid any inadvertent operation. When a vessel changes over to LSF, all valves associated with HSF bunker tanks must be locked shut. Similarly, when a vessel changes back over to HSF, all valves associated with LSF bunker tanks must be locked shut to avoid intermixing of bunkers.

Whenever vessel is maintaining two grades (LSF/HSF) of bunkers, it is to be ensured that associated pipelines/pumps are well drained to avoid any intermixing after every change of bunker grades. The designated LSF bunker tank should be used only for storing LSF. Depending on the quantity of un-pumpable ROB of HSF in this tank, the Sulphur content of the LSF bunkered in this tank may change. This must be borne in mind during operations and reported to the Management Company (Norbulk).

Note: Care must be taken when testing emergency quick-closing valves to ensure that the integrity of the segregation of high and low sulphur bunkers is not breached.

Records to be maintained

A. Regulatory Requirement

The regulation requires that the following details are officially recorded in a Marine Fuel Oil Sulphur Record Book when any fuel changeover operation is carried out between low and high-sulphur content fuels:

- The volume of low-sulphur fuel oils (less than or equal to 1,0 % m/m sulphur) in each tank;

- Date/Time;

- Position of the ship.

These details are to be taken and recorded once it has been established that only fuel oil with a sulphur content of less than 1,0 % m/m is being burned.

B. Company Requirement

- Marine Fuel Oil Sulphur Record Book;

- Vessels are required to record and report separately on consumption/ROB of both LSF and normal Fuel Oil which is being reported to office in standard Voyage Reports.

Norbulk vessels must strictly comply with these regulations and follow the guidelines given below for the implementation.

Control of Changeover Operations

Adequate monitoring and cross checking of each valve is to be carried out by Chief Engineer or authorised deputy. Soundings are to taken to confirm proper transfer of bunkers.

Changeover of Fuel and Flushing of the system (Example)

The basic changeover plan (for vessels with no separate HSF Settling tank) is to stop the purifier, empty and transfer the HSF Settling tank to HSF Bunker tank/Service tank.

Transfer LSF to settling tank and heat up as required. Wait until the HSF service tank level comes down to about 10 hrs of present consumption, then start the HSF purifier and start purifying the LSF and filling HSF service tank.

It will be interesting: Global Shipbuilding – 2024 Results and 2025 Trends

During this operation it will be required to adjust purifier throughput to maintain the service tank level at same level for next 10 hrs and thereafter can increase the feed rate to fill up the service tank slowly.

It is assumed that about 16 hrs after the start of filling HSF service tank with LSF, the HSF will have been flushed out from the system and ME/AE is on LSF. This will be the official time when the ME/AE are on LSF.

During changeover from HFO/MDO/MGO on both main propulsion and auxiliary equipment manufacturers guidelines to be closely adhered to at all times. Furthermore, this must never be carried out in enclosed waters or confined or congested shipping lanes. In this event that changeover procedure falls within the aforementioned areas, then the changeover procedure is to be carried out earlier.

Low TBN ME Cylinder Oil

As per Engine manufacturer’s specifications, running on low-sulphur fuel is considered more complex due to the relationship between liner corrosion and scuffing resistance, dry lubrication properties from the sulphur content (or lack of same), the interaction between the BN in the cylinder oil and the detergency level, possible surplus of alkaline additives, the piston ring pack and liner conditions, etc.

The TBN of Cylinder Lube Oil should be lower for LSF than for HSF.

For vessels not operating in a SECA region regularly and making a one-time entry the Cylinder Oil does not require changing but a reduction in Cylinder Oil feed rate can be done to match LSF in consultation with office.

For vessels operating continuously on LSF it is necessary to carry out frequent scavenge space inspection to monitor condition of liners/piston rings. There is no reliable data available on the effects of long-term operation with LSF. Hence the need to monitor the performance and condition very closely till more facts are known. This information can then be used to improve procedures in future.