Simultaneous operations, or SIMOPS, are becoming increasingly common in the maritime industry as more ships adopt liquefied natural gas (LNG) as a fuel source. While conducting LNG bunkering alongside other port activities – such as cargo loading, maintenance, or passenger embarkation – can significantly improve port turnaround times and operational efficiency, it also introduces a unique set of safety and risk management challenges. This article provides a comprehensive guide to addressing these complexities. We will explore best practices, a structured risk-based approach, and practical guidance for managing LNG bunkering SIMOPS to ensure the safety of all personnel and assets.

The present article provides guidance to PAAs considering safety and operational issues associated with SIMOPS while conducting LNG fuel transfer operations.

The subject of Simultaneous Operations has been debated extensively in the context of LNG bunkering operations, with the discussion often routed towards a purely Risk Assessment oriented evaluation. In fact the large variety of possible operations that may take place in simultaneous with LNG bunkering is very large and dependent on ship type and operational profile. A Risk Assessment on Liquefied Natural Gas TankerRisk Assessment is indeed a tool which is able to assist Operators and PAAs to best evaluate the possibility for safe SIMOPS. The culmination of the risk-based approach It has also been noted that, due to the almost purely risk assessment orientation of the SIMOPS subject, many operators and ports have adopted precautionary restrictions on SIMOPS unless Risk Assessments were conducted to support possible SIMOPS authorizations. In some cases the precautionary measures are not even flexible to that level, with ports adopting full restrictions on SIMOPS without any possibility to consider even a risk assessment-based authorization.

The lack of standards and experience with SIMOPS has probably been determinant so far in the predominantly precautionary approach to this subject.

Read also: The Role of LNG Bunkering Infrastructure

LNG fuelled ships are, from an operational perspective, just like any other ship. Restrictions for SIMOPS have a strong influence on the business profile of the ship, increasing turnaround times at port. There is therefore a strong driver to make SIMOPS viable and to ensure that other operations can be safely conducted whilst the ship is undertaking LNG bunkering.

The present sarticle proposes a good practice approach to allow SIMOPS to take place, on the basis of a structured risk and operation based decision-making process.

References

The following references were considered in particular for the present article:

- DNVGL-RP-G105 Edition October 2015 – Development and operation of liquefied natural gas bunkering facilities, Recommended Practice, DNV GL, 2015.

- USCG CG-OES Policy Letter No. 01-17 – Guidance for Evaluating Simultaneous Operations (SIMOPS) during Liquefied Natural Gas (LNG) Fuel Transfer Operations.

- LGC NCOE Field Notice 01-2017 – 14-Aug-17 – Recommended Process For Analysing Risk Of Simultaneous Operations (SIMOPS) During Liquefied Natural Gas (LNG) Bunkering.

- LNG Bunkering Guidelines IACS Recommendation n. 142, on LNG Bunkering, IACS, 2016.

- Society for Gas as a Marine Fuel (SGMF) (2017) – Gas as a marine fuel, safety guidelines, Bunkering Version 2.0, February 2015.

SIMOPS Definition

For purpose this Guidance, SIMOPS is defined as an adaptation from USCG CG-OES Policy Letter No. 01-17 as two or more operations occurring simultaneously, one of which involves LNG bunkering operations, and the combination of which may present safety, environmental and security concerns.

Other definitions are possible, such as IACS Rec. 142, where SIMOPS are defined as:

Having focused on transfers between ship and shore, IACS Rec. 142 recognizes however that special attention is to be paid to any of the above activities occurring within the Key Aspects and Recommendations for the Safety Zone for LNG Bunkeringbunkering safety zone as well as any on board testing that may impact on the bunker operation.

It is, in fact, possible to have SIMOPS occurring on the ship-shore interface, on the ship side and on the port side, nearby to the LNG bunkering location, possibly within the safety zone. For all these possibilities the definition, as adapted from the CG-OES Policy Letter No. 01-17 is the most complete and simple to adopt.

SIMOPS and Control Zones

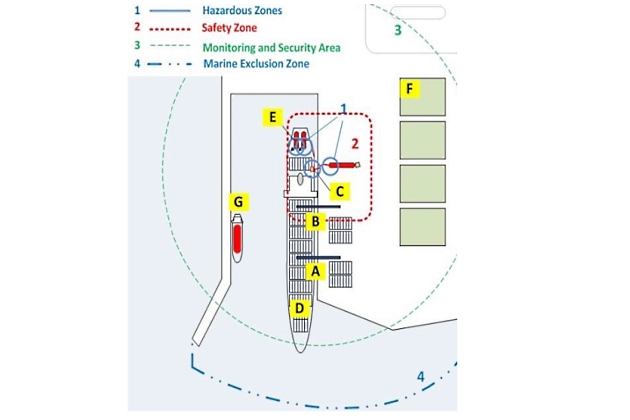

From the definitions in section “SIMOPS Definition” it can be derived that SIMOPS may occur at any point within the established Control Zones for any give LNG Bunkering. Depending on which Control Zone the SIMOPS are falling they should be address in an appropriate manner. Figures 1 to 4 present typical SIMOPS situations, here addressed from a Control Zone perspective. Considerations on possible simultaneous operations should have.

In the table above, for the generic example of a containership involved in SIMOPS, it is possible to see a suggested approach to classify simultaneous operations with due consideration for their location in the established Control Zones.

Source: Shell

A relevant note should here be made for the Security Zone, where operations may take place that are not involving either BFO or RSO. In these cases PAA should have a clear situational awareness of the multi-operation scenario that may take place within the Security Zones in LNG Bunkering: A Guide to Meaningful ProtectionSecurity Zone. Communications should be ensured amongst all those operating in the Security Area with the objective to ensure adequate alarm dissemination in the event of an accident in the vicinity of the LNG bunkering location (see in particular cases F and G in Table 1.

| Table 1. SIMOPS and Control Zones (legend for figure 1) | ||

|---|---|---|

| Operation ID (figure 1) | Short Description | SIMOPS consideration/comments |

| A | Load-on/Load-off containers with overhead gantry crane (separated from bunkering location by < 2 × SD) | Operation in the ship-shore interface, loading-on/off of containers. |

| Located outside the Safety Zone (at a distance higher than 2 times the safety distance) SIMOPS should be considered under adequate monitoring, following Security Zone provisions. | ||

| Crane can be operated respecting the Safety Zone boundary. Adequate communications to be established and operational setup for SIMOPS operations. | ||

| NOTE: An evaluation on whether the crane operation would possibly impact on the LNG bunkering operation would always be possible in the context of a Risk Assessment. Being outside the Safety Zone, should it be adequately determined, it should very likely be beyond LFL reach in the case of an accidental LNG release followed by vapour dispersion. | ||

| Other cargo operations falling outside the Safety Zone should follow the same approach. | ||

| B | Load-on/Load-off containers with overhead gantry crane (inside the Safety Zone) | Operation in the ship-shore interface, loading-on/off of containers. |

| Located inside the Safety Zone. | ||

| Special consideration to be given to crane operation and Ex-proof classification. | ||

| Simultaneous Operation can be considered, subject to special Risk Assessment and design of adequate protective measures. Risk. | ||

| C | Corrective Maintenance operation inside the Ship bunker station (Hazardous Zone) | Corrective maintenance operation inside the Safety Zone. |

| No simultaneous operation should be allowed inside the Hazardous Zones during bunkering operation. | ||

| SIMOPS inside Hazardous Zones are not recommended without a Quantitative Risk Assessment. (Note: LGC NCOE Field Notice 01-2017 also recommends a QRA to be conducted – PAAs may consider this reference. It is however important to note that QRA should result in protective measures/safeguards that should be duly implemented and certified before any SIMOPS are considered in this location. | ||

| D | Corrective Maintenance operation inside the Ship (outside Control Zone reach) | Corrective maintenance or other operation inside the ship should only be considered if an evaluation of possible impact in the LNG bunkering operation is made. |

| Other operations, even outside control zones, that have a potential to impact LNG bunkering, should be considered SIMOPS and be adequately addressed. | ||

| Operations with the potential to affect the ship’s ability to respond in emergency situations shouldn’t be allowed. (examples of such operations may be: | ||

| i. maintenance of electrical distribution systems; | ||

| ii. testing of alarms; | ||

| iii. propulsion system; | ||

| iv. ballast operation; | ||

| v. testing of stabilizers. | ||

| E | Operation on Hazardous Zone, onboard | Same consideration as in “C“. Operations onboard on any Hazardous Zones (e. g. fuel storage space) should not be without a QRA. |

| SIMOPS inside Hazardous Zones are not recommended without a Quantitative Risk Assessment. (Note: LGC NCOE Field Notice 01-2017 also recommends a QRA to be conducted – PAAs may consider this reference. It is however important to note that QRA should result in protective measures/safeguards that should be duly implemented and certified before any SIMOPS are considered in this location. | ||

| F | Operation outside the LNG bunkering scenario, occurring at a nearby warehouse/infrastructure | Operation outside the LNG bunkering scenario, occurring at a nearby warehouse/infrastructure. |

| Operation taking place within Security Area – should therefore be monitored. | ||

| It is however important to define who will be responsible for the monitoring of an operation not involving the RSO/BFO but that may have a potential effect in the LNG bunkering operation in the event of an accident. | ||

| G | Operation outside the LNG bunkering scenario, occurring at a nearby berth – handling of hazardous substances | Operation outside the LNG bunkering scenario – handling of hazardous substances. |

| Operation taking place within Security Area – should therefore be monitored. | ||

| It is however important to define who will be responsible for the monitoring of an operation not involving the RSO/BFO but that may have a potential effect in the LNG bunkering operation in the event of an accident. | ||

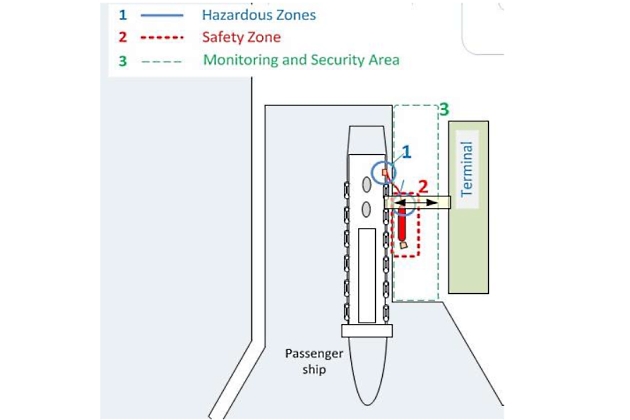

In the case of figure 1 a containership is considered. Another remarkable case for potential SIMOPS evaluation would be a passenger ship (containership or RO-PAX) with embarkation/disembarkation of passengers. Figure 3, below, includes a generic LNG fuelling scenario, where an LNG ruck feeds a DF generator inside the ship during the whole stay of the ship at berth. In the case presented the passenger embarkation/disembarkation is operated just above the LNG fuel truck/manifold Electrical Safety in LNG Carrier Hazardous Areashazardous area. In this particular case the SIMOPS situation would be present also throughout the whole stay of the ship at berth, as long as the LNG fuelling operation was ongoing and the passenger gangway accessible.

In the particular case presented in 3, the LNG fuelling location is dictated by the onboard intake manifold, which will direct the LNG to an evaporator onboard. The passenger embarkation/ disembarkation is dictated by the relevant access location in the side shell of the passenger ship. The design constraints are therefore evident.

It will be interesting: LNG (Liquefied Natural Gas) as Fuel

In the particular case the gangway is crossing the hazardous zone (a zone where explosive atmospheres will be present with a known frequency of occurrence). It is important to design an adequate safeguard to guarantee passenger safety and, ultimately, an acceptable risk level during passenger embarkation/disembarkation.

For the purpose above a QRA should be conducted that would allow to design the best safeguards to be implemented. In the case presented an enclosed gangway (as the one presented in figure 4 would be a natural barrier to design, preferably based on consequence scenario modelling.

USCG Risk-Based Approach

The recent publication of a relevant reference on SIMOPS may be considered by PAAs:

- LGC NCOE Field Notice 01-2017 – 14-Aug-17 – Recommended Process For Analysing Risk Of Simultaneous Operations (SIMOPS) During Liquefied Natural Gas (LNG) Bunkering.

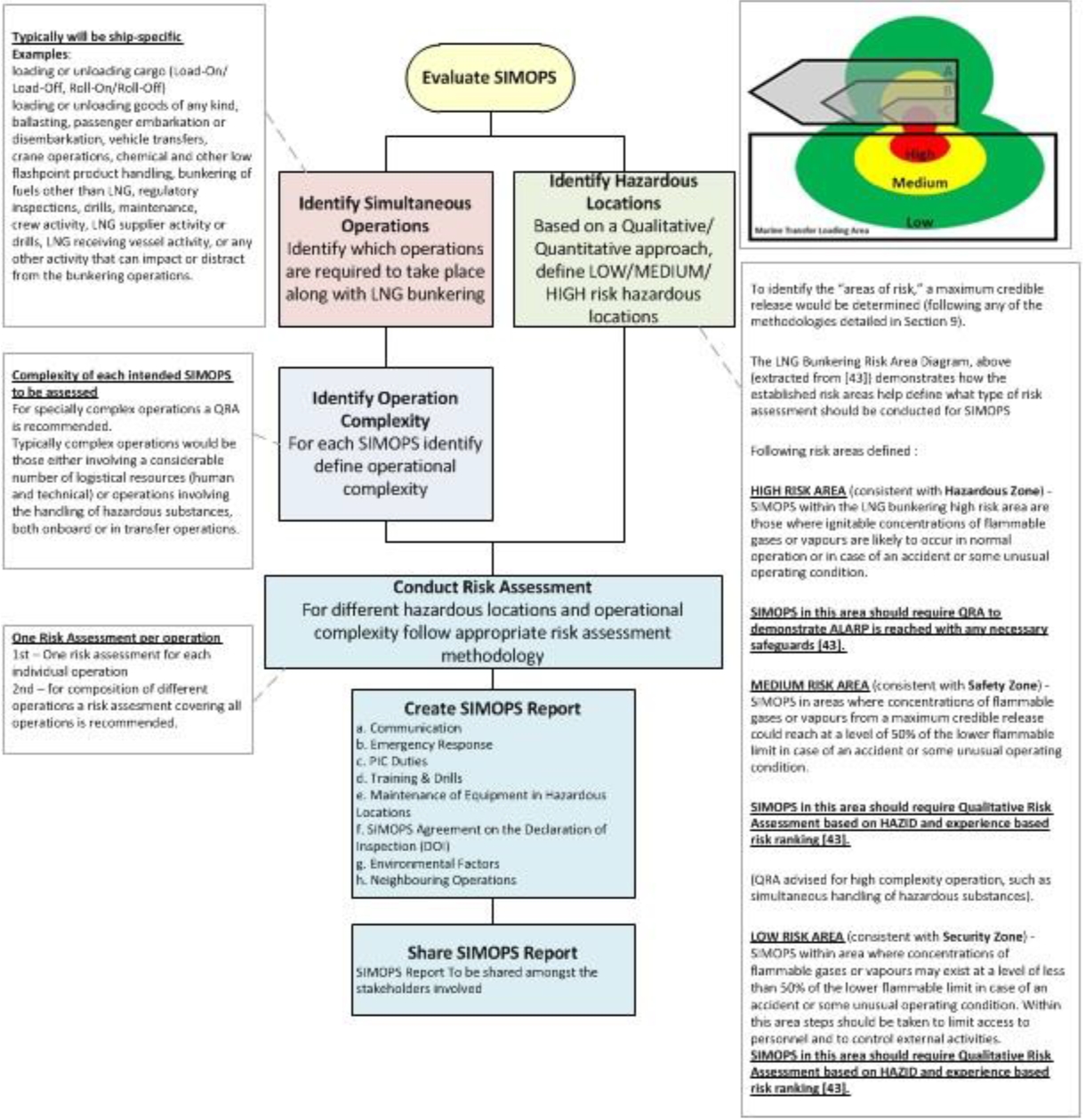

A predominantly risk-based SIMOPS evaluation process is presented below, with the significant steps defined and summarized, as taken from the reference document. Hazardous area qualitative risk classification is associated with SIMOP complexity identification.

The LGC NCOE Field Notice 01-2017 presents a key-approach which is predominantly risk-based, based on area classification (consistent with the control zones, as summarized in the diagram of figure representing the culmination of the risk assessment orientation to allow for SIMOPS to take place.

The Area Classification included in this reference document presents a good indication on a possible qualitative/quantitative preliminary evaluation of Risk through the adoption of LOW to HIGH risk classifications which can, in a way, be related in consistency with the Control Zones classification from ISO/TS 18683 and 20519 (see table 2).

| Table 2. Risk Areas – LGC NCOE Field Notice 01-2017 | ||

|---|---|---|

| RISK Areas | Recommendation on SIMOPS | |

| HIGH RISK AREA (consistent with Hazardous Zone) | SIMOPS within the LNG bunkering high risk area are those where ignitable concentrations of flammable gases or vapours are likely to occur in normal operation or in case of an accident or some unusual operating condition. | SIMOPS in this area should require QRA to demonstrate ALARP is reached with any necessary safeguards. |

| MEDIUM RISK AREA (consistent with Safety Zone) | SIMOPS in areas where concentrations of flammable gases or vapours from a maximum credible release could reach at a level of 50 % of the lower flammable limit in case of an accident or some unusual operating condition. | SIMOPS in this area should require Qualitative Risk Assessment based on HAZID and experience based risk ranking. |

| LOW RISK AREA (partly consistent with Security Zone) | SIMOPS within area where concentrations of flammable gases or vapours may exist at a level of less than 50 % of the lower flammable limit in case of an accident or some unusual operating condition. Within this area steps should be taken to limit access to personnel and to control external activities. | SIMOPS in this area should require Qualitative Risk Assessment based on HAZID and experience based risk ranking. |

Good Practice for SIMOPS

Background Elements

The previous section provides a relevant reference to allow the consideration of SIMOPS during LNG bunkering, inside the Safety Zone or onboard, for ships that have evaluated the operations through a preliminary Risk Assessment. The Risk Assessment will however only be a tool to assess SIMOPS that can be foreseen from the Planning Phase, providing a view of the attained risk levels, demonstrating ALARP for the different SIMOPS and related hazardous scenarios. The reference presents, in this sense, a recommendation which should be regarded as a reference in the development of LNG bunkering SIMOPS scenarios which can be well planned in advance, as part of the planning phase for Functional and General Requirements for LNG Bunkering OperationLNG bunkering Operations. For Pre-Bunkering stage, should SIMOPS be requested in, or very close to the Safety Zone, which haven’t been assessed with regards to risk, what option would be available to PAAs? Probably a non-authorization would have to be deemed in this case, taking into account all relevant elements provided by operators.

Operational context scenarios are however diverse and the possibility for SIMOPS to be required that haven’t been fully evaluated in advance, or even subject to a Risk Assessment, may be very likely to occur. In addition, another situation can be considered as very likely: the case where a risk base justified operation is How to derive the process for SIMOPS consideration when no Risk Assessment elements are present?

How to consider a request for SIMOPS, such as a ballast operation for trim correction, when no Risk Assessment has been developed for this? One way to answer is not to allow the SIMOPS, imposing an operational restriction. Another way is to develop an operational approach to allow for SIMOPS even when formal risk assessments (QRA or QualRA) are available. This would also accommodate for those situations where some deviations occur from the conditions established in the initial Risk Assessment.

The proposal, in the present section, drafted as good practice recommendation, follows the same inspirational line as in LGC NCOE Field Notice 01-2017, adding one further element of more operational nature, including:

- a SIMOPS meeting pre-bunkering;

- the possibility to allow SIMOPS in the Safety and Security Zones, even when deviations to the formal risk assessment occur;

- a SIMOPS Supervisor/Coordinator;

- a Staged Approach Authorization of SIMOPS;

- an Operational map proposal.

All elements are detailed in sections “Staged Approach for SIMOPS Authorization” and “SIMOPS Operational Diagram”.

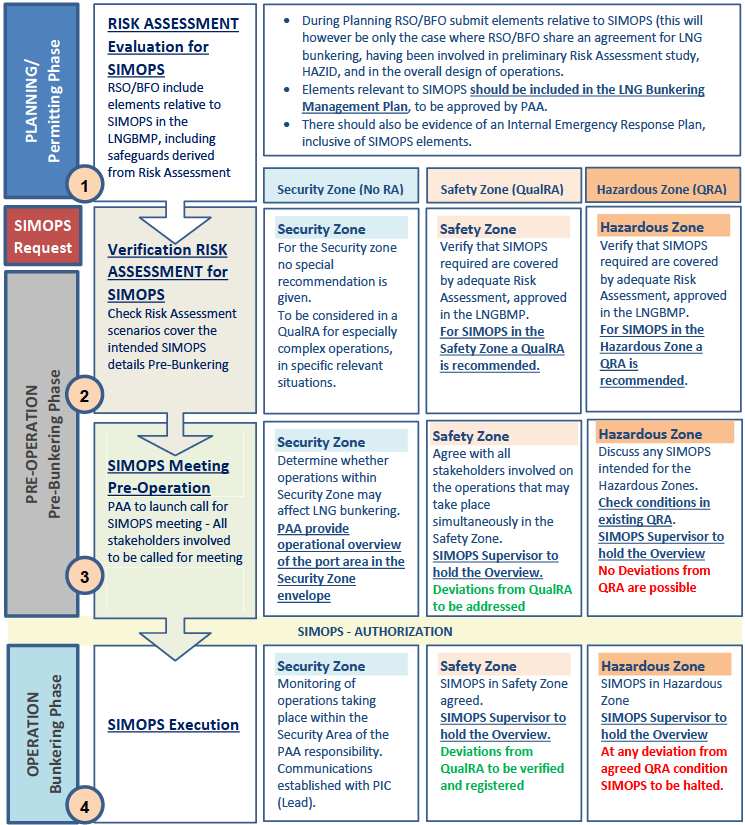

Staged Approach for SIMOPS Authorization

The diagram in figure 6 presents a staged approach for SIMOPS evaluation and authorization, considering the different Control Zones. From the Planning Phase down to the Operational stage, for LNG bunkering execution, the diagram below outlines a process structure to evaluate and authorize SIMOPS.

The diagram in Figure 6 follows the Risk Area approached recommended in LGC NCOE Field Notice 01-2017, with the clear advantage to have segregated decision-making structures, depending where SIMOPS are intended to take place. Not only the decision-making for PAA authorization is suggested to be different, also the actual organization for LNG bunkering operation is different, with the coordination done by PAA for Operations taking place in the Security Zone, whilst a designated SIMOPS Supervisor should be considered for SIMOPS directly in the The Ship/Shore Interface – Communications Necessary for Matching Ship to BerthShip-Shore interface or inside the RSO, either within the Safety Zone or in the Hazardous Zone.

As recommended by LGC NCOE document the good practice here suggested also point for a QRA anytime SIMOPS are intended inside the Hazardous Zone, and a QualRA for those intended to take place in the Safety Zone.

Read also: LNG IMO Tanks/Containment Systems

The Staged Approach leads to SIMOPS authorization and is structured from the Planning Stage (leading to Permitting) down to the Process Map & Organization of the LNG BunkeringBunkering Operation Stage. The concept behind the structured staged approach is to ensure the check for consistency between approved SIMOPS conditions and verified conditions prior to LNG Bunkering Operation.

In the context of the present Guidance it is suggested that small deviations to the approved Qualitative Risk Assessment (QualRA) may be considered, provided these are discussed in a SIMOPS Meeting, in preparation for LNG Bunkering Operation.

SIMOPS Operational Diagram

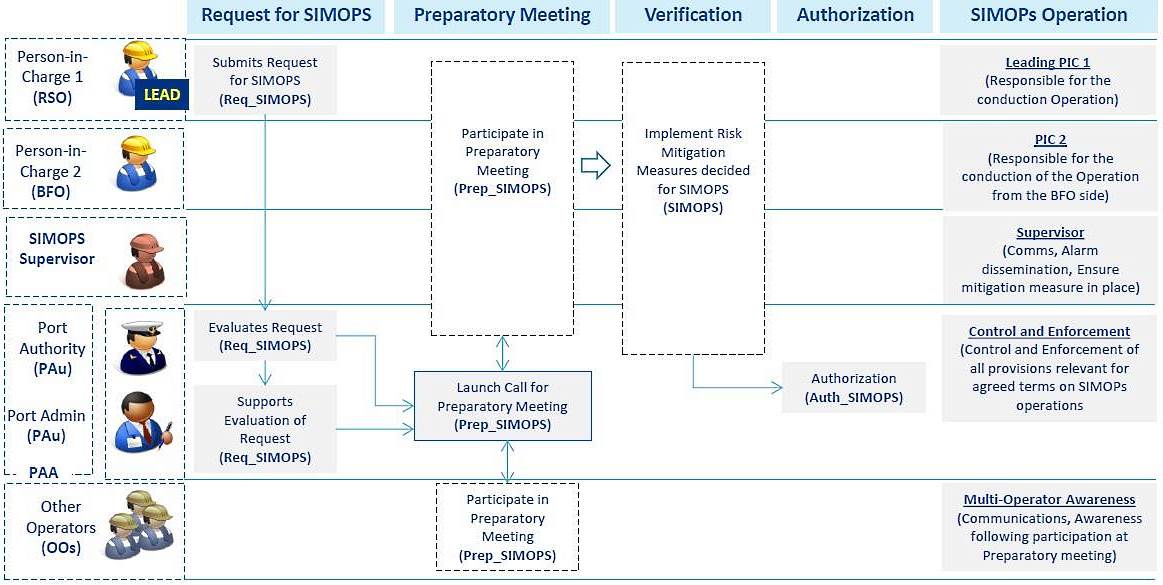

The diagram in figure 7, below, presents a flow-diagram with the operational diagram suggested for SIMOPS in LNG bunkering.

Table 3, explains each stage (each column) of the recommended operational diagram.

| Table 3. SIMOPS Operational Diagram description | ||

|---|---|---|

| Short Description | Who | Action |

| Request for SIMOPS | PIC – RSO (PIC Lead) | Person-in-Charge 1 (RSO – Lead PIC) requests SIMOPS in advance (48 hrs is recommended, but a different advance notice time may be agreed with the PAA. |

| The Lead PIC is responsible to ensure that all information sent is consistent with the existing approved Risk Assessment pertaining to SIMOPS. | ||

| Request should describe with detail what type of SIMOPS is/are intended. | ||

| Request should also identify all stakeholders involved, with relevant contacts for all operators. | ||

| Evaluate SIMOPS Request | PAA | SIMOPS request is evaluated – Consistency between request and existing information on Risk Assessment is done. |

| Evaluation of the overall operational scenario in the Port Area. | ||

| Call for SIMOPS Preparatory meeting | PAA | With the information from the SIMOPS request, the PAA launches a call for SIMOPS Preparatory Meeting. |

| RSO, BFO, PAA, Other Operators should be present at the meeting to discuss possible operational aspects that should be addressed in advance. | ||

| SIMOPS Preparatory Meeting | PAA BFO RSO Operators | For SIMOPS in the Safety Zone, should any differences be noted between assumptions in a |

| Only existing approved Risk Assessment elements should be considered. The SIMOPS Preparatory meeting is not intended to be a substitute for a HAZID or an informal risk assessment. | ||

| Verification Implementation of Risk Mitigation Measures | PAA BFO RSO | Implementation of Risk Mitigation Measures. |

| Protective Measures and Safeguards should reflect the existing Risk Assessment. | ||

| Authorization | PAA | Authorization for SIMOPS to be issued upon positive confirmation that all agreed safeguards and protective measures have been implemented. |

The diagram assumes 2 (two) PICs (as envisaged in the IGF Code) and introduces the SIMOPS Supervisory Role as an element to ensure adequate overview, communications and alarm dissemination through all the involved stakeholders in the operation. The SIMOPS Supervisor role is described in “SIMOPS Supervisor”.

The operational diagram should only be regarded as guidance to the implementation of actual control provisions for SIMOPS in LNG bunkering. Other operational arrangements are possible. The diagram below, with the SIMOPS Supervisor, reflects (according to the diagram in 6) the case where simultaneous operations are planned to take place in the Safety Zone or Hazardous Zone.

SIMOPS Supervisor

The diagram assumes 2 (two) PICs (as envisaged in the IGF Code) and introduces the SIMOPS Supervisory Role as an element to ensure adequate overview, communications and alarm dissemination through all the involved stakeholders in the operation.

It will be interesting: LNG Bunkering Guide – What It Is and How to Use It

The need for a SIMOPS Supervisor is a reflection of the need to release both PICs from the responsibility of SIMOPS overview and coordination. This should be a task with which the PICs should not be distracted. It is not only important that the PICs are not over-burdened but it should also be possible to have a dedicated person responsible for the overview of the operational context, with communications with all the operators involved in simultaneous operations.

Alarm dissemination is another important responsibility of the SIMOPS Supervisor, ensuring that in the event of an accident all involved operators receive indications that allow immediate emergency action.

The recommendation for a SIMOPS Supervisor should ensure an adequate organization for emergency, in SIMOPS context, is ensured.