The maritime industry is undergoing a significant transformation, driven by increasingly stringent environmental regulations and a global push towards decarbonization. As shipping companies seek cleaner fuel alternatives, LNG bunkering operations have emerged as a critical component in this transition. Liquefied Natural Gas (LNG) offers a viable solution to reduce greenhouse gas emissions and air pollutants, making it an attractive option for vessel propulsion.

This article explores the evolving landscape of LNG bunkering, detailing the complexities, advancements, and future outlook of these essential operations that are shaping the future of sustainable shipping.

Port Regulations

Port Regulations are the best vehicle to integrate all the hierarchy for regulatory instruments presented in the introduction to this article. On one hand including the higher level instruments and, on the other, bringing the reference to Technical and International Standards, Port Regulations are important in the adequate definition of the complete legal and administrative framework for Functional and General Requirements for LNG Bunkering OperationLNG bunkering.

Ports should set rules to control LNG Bunkering, and small scale LNG installations, by themselves, in the context and frame of their jurisdiction and meeting closely the relevant national and international applicable legislation. Ports should, in this respect, note that the alignment of port regulations/byelaws with the full hierarchy of legal/reference instruments is fundamental to the harmonized and safe development of LNG Bunkering.

When developing Port Regulations specifically for LNG bunkering PAAs should align these with all the relevant regulatory references affecting the use of LNG as an alternative fuel in shipping, handling of hazardous substances within the port area, transport of hazardous substances by road and waterways.

The applicable regulatory frame, for each individual Port, will be the sum of the different instrument types listed in Sections “LNG Regulatory Framework International and European Maritime Safety OverviewHigh Level Instruments” to “Maritime Standards ExplainedOther References“. Ports should develop their regulations in strict observation of the available instruments, allowing in addition for additional justifiable provisions in order to improve safety in LNG bunkering operations (e. g. in the case of lessons learnt from casualties, incidents or near misses).

Whenever Port Regulations include requirements of higher stringency than those within national regulations, or technical measures understood to be different of those prescribed in International Standards, a substantiated justification should be included, preferably with the inclusion of possible alternative means of compliance. Whenever these alternative means are not expressed, a case-by-case analysis may be a possibility to be considered, allowing for the demonstration of equivalency.

The following points may be considered as core elements for the structure in Port Regulations for LNG bunkering.

- Regulatory Framework.

- Port Organization structure.

- Management System requirements (Safety, Quality, Environmental).

- Risk & Safety (Risk Assessment methodology, Risk Criteria).

- Technical Requirements:

- BOG management.

- Interface.

- Emergency equipment.

- Communications.

- Operational Envelopes (Weather, Traffic, Visibility, Night/day operations).

- Safety Distances.

- Simultaneous Operations (SIMOPS).

- Authorization process.

- Check-Lists.

Port Regulations should define clearly the Scope in terms of the different LNG bunkering modes. Different modes for LNG transfer will inherently represent different operational considerations and instrumental/technical/legal references. Existing industry guidelines, or best practice documents, usually privilege one, or some, of the possible LNG bunkering modes.

It is, in this context advisable that a specific Port Regulations for LNG Bunkering are adopted by each PAA. With the objective of informing and adequately preparing prospective LNG Bunker Operators. Port Regulations should, as far as practicable, make reference to the standards mentioned in Section Maritime Standards Explained“Standards”, giving special consideration for those adopted as European Standards. Standard code “EN” or “EN ISO“.x

Read also: LNG Bunkering Guide – What It Is and How to Use It

Port Local Regulations/Byelaws, as instruments of local and limited application, should, to the extent possible make reference to existing international standards. Whilst addressing specific aspects related to the safety of navigation, handling and Safety, Risks and Security Aspects in Liquefied Natural Gas Industrytransport of dangerous substances, amongst others, port local rules should, to the extent possible, be aligned with existing published best practice on LNG Bunkering.

Liaison with the relevant competent authorities for different aspects in LNG bunkering is an important point that PAAs should take into account. Notwithstanding the obligations on the Operators/BFOs, to notify and submit the relevant permit request elements, PAAs can, in the best interest of an efficient an optimized process, act as facilitators for the administrative aspects. Port Regulations can include aspects relative to the process flow and steps to be taken into consideration for permitting.

PAAs should promote regular updates of Port Regulations, maintaining an adequate tracking of revisions. They should be free and available for free access through any type of web portal that allows easy download for later reference.

National Policy Frameworks

Port Regulations should be aligned with the National Policy Framework defined at National Level National Policy Frameworks defined as per Article 3 of Directive 2014/94.x in all aspects related to LNG as Fuel. As part of the wider value chain for this Alternative Fuel, Ports represent important elements in the transfer of both LNG as fuel and LNG as cargo. They should therefore be aligned with the main national policy vectors.

Notwithstanding the importance of aligning LNG bunkering developments and infrastructure with the National Policy Frameworks, PAAs should also consider that LNG (Liquefied Natural Gas) as FuelLNG as fuel is a cross-border development. Apart from aligning with national wide policy it is also recommended that PAAs adopt dialogue and cooperation channels to allow shared development of LNG bunkering regulations aiming towards a harmonized approach to control measures.

Whenever evaluating or facilitating in favour of prospective LNG bunkering projects, PAAs are advised to consult closely with the national competent authority for the implementation of Directive 2014/94 on the deployment of an alternative fuel infrastructure. National Policy Frameworks should be able to provide the necessary environment for the consideration of LNG bunkering facilities, in the context of availability of LNG as fuel in maritime core-ports.

In the case of a National Policy Framework containing specific measures of any nature that may determine or influence the permitting process for a give prospective LNG bunkering facility project, PAAs should exercise a facilitating role and assist, wherever possible and relevant, with information to operators.

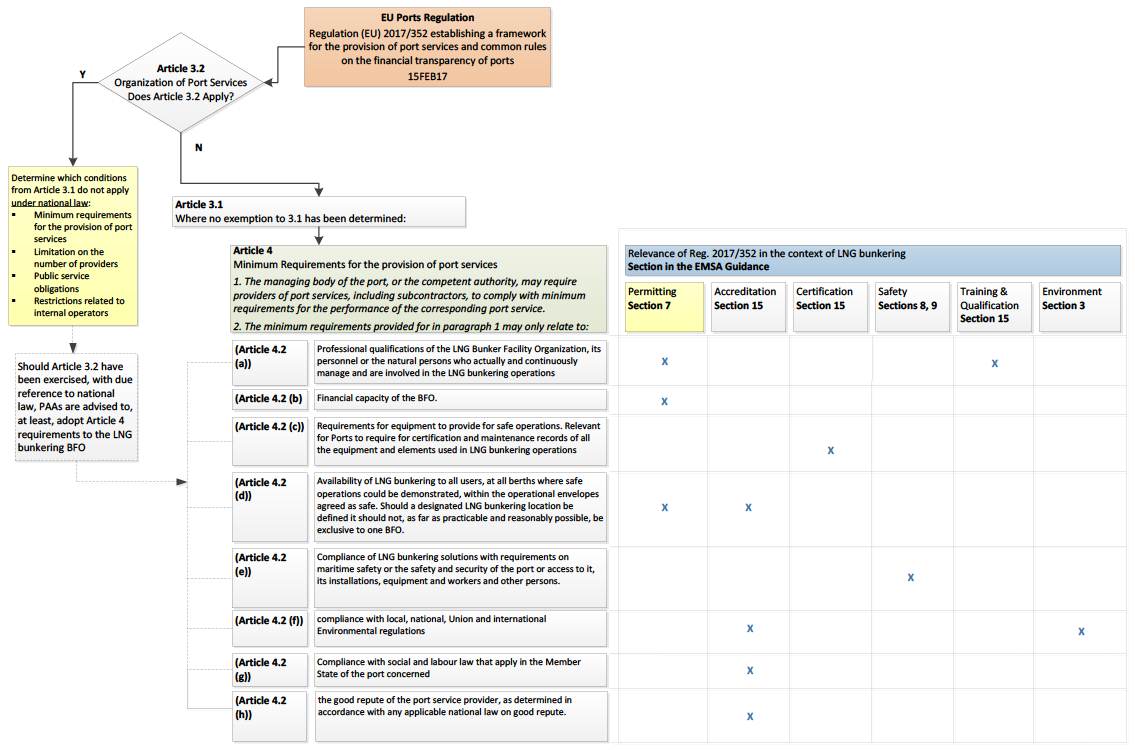

EU Ports Regulation

In the interest of efficient, safe and environmentally sound port management, PAAs Port Authority or Administrations (PAAs) are mentioned in Regulation 2017/352 as Competent Authority or Managing Body of a Port.x should be able to require that providers of LNG bunkering are able to demonstrate that they meet minimum requirements for the performance of the service in an appropriate way. Those minimum requirements should be limited to a clearly defined set of conditions in so far as those requirements are transparent, objective, non-discriminatory, proportionate and relevant for the provision of the port service. In accordance with the general objectives of Regulation 2017/352, incorporating references to the relevant standards and, where applicable to this Guidance, the minimum requirements should contribute to a high quality of port services and should not introduce market barriers.

PAAs should refer to Regulation (EU) 2017/352 for the establishment of minimum requirements for the provision of LNG bunkering as a port service. Notwithstanding the non-technical nature of this Regulation, it allows the legal vehicle for the relevant technical standards, for equipment and procedures, training requirements and best practice provisions contained in this Guidance.

Port Regulations should comply with Regulation (EU) 2017/352 and, where possible and deemed adequate, to incorporate the relevant references to LNG bunkering technical standards (Section “Maritime Standards ExplainedStandards“), guidelines and other references, as applicable (Sections “Maritime Standards ExplainedGuidelines” and “Maritime Standards ExplainedOther References” respectively). In addition, best practice elements of this Guidance may be considered when developing the LNG bunkering requirements for Port Services. The diagram in figure 1, on the next page, indicates the relevant minimum requirements to LNG bunkering as a port service, suggesting also the relevant section within this Guidance.

Fig. 1 EU Ports Regulation – Minimum requirements to the provision of port services, with reference to the applicable EMSA Guidance section for each element of Article 4.2 of the Regulation

In the context of LNG bunkering permitting, PAAs should develop information and adequate communication channels to allow for prospective service providers to be sufficiently prepared to meet the specific requirements for safety, security, staff qualification, equipment certification and any other that are found to be relevant to the adequate completion and submission of a permitting process. In addition, in accordance with art 15 of the Regulation (EU) 2017/352 shall, consult port users on its charging policy, including environmental matters, matters having impact on spatial planning and measures to ensure safety in the port area.

When PAAs are themselves the providers of the LNG bunkering service, careful observation should be given to Articles 6(6) and 8 of Regulation (EU) 2017/352. Minimum requirements for the provision of LNG bunkering service should apply in a context of transparency in the best interest of Safety.

In particular for Risk Assessment on Liquefied Natural Gas TankerRisk Assessment, whenever setting up an LNG bunkering facility, the same requirements for demonstration of safety levels, meeting the relevant risk criteria, should be imposed on either Internal Operators Internal Operators as defined in Reg. 2017/352, Article 8.x or External LNG bunkering providers.

Seveso III Directive – Major Accident Prevention Directive

The decision on the applicability of Seveso III Directive framework Seveso only provides a framework. It will be the risk assessment under the Major Accident Prevention Policy and/or the Safety Report that will determine what technical and organisational risk management measures will actually be necessary.x provisions, to any particular LNG bunkering project plan or solution, should be made at the earliest stage, during the permitting phase, immediately after receipt of a Concept Project and Letter of Intent. In addition to the obligation of notification The obligation is with the Operator/BFO to notify the CA(S). It is not the competent authority that determines. The BFO may however seek confirmation of its assessment. Actual process may be subject to national variations, accounting for each Member State implementation of Seveso Directive.x by Operators/BFO, also PAAs should liaise directly with national competent authorities for Seveso III Directive implementation (CA(S)), with a view to determine the applicability of the Seveso-III directive and the implications.

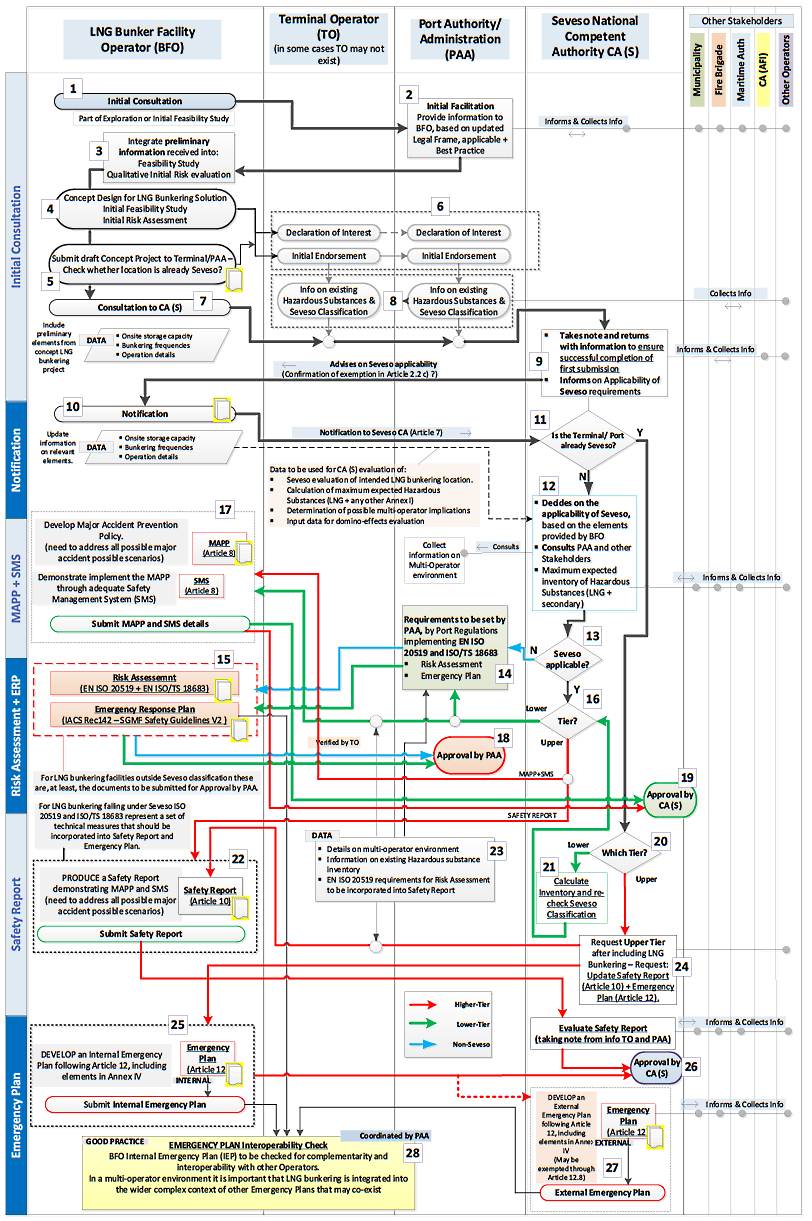

PAAs can, from a very early stage in the process, as indicated in the best practice flow-chart in figure 6, assume the role of facilitator in the context of the permitting process. Applicability of Seveso III Directive provisions in the classification of a given LNG bunkering location should also represent the indication of important action points to PAAs.

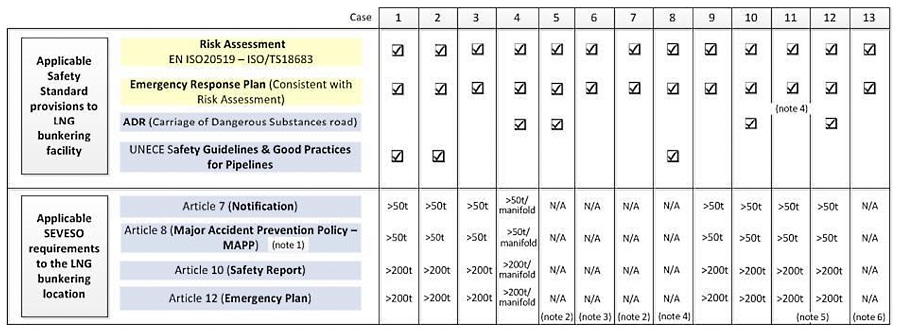

In the context of Seveso III Directive applicability it is important to note and distinguish the concept behind the relevant framework safety provisions. Table 1 below indicates for different establishments which requirement applies. In the context of LNG bunkering also non-Seveso locations/projects are included. In this category would fall a large number of LNG bunkering facilities based on spot LNG bunkering via trucks or LNG bunkering vessels or barges to which a different regulatory framework applies.

| Table 1. Seveso III framework requirements | |||

|---|---|---|---|

| Seveso Upper-Tier | Seveso Lower-Tier | Non-Seveso | |

| Major Accident Prevention Policy (MAPP) | Yes | Yes | Other |

| For upper tier establishments: SMS – in accordance with Annex III – is one of the means by which the operator has to demonstrate that a MAPP has been properly implemented. | For lower-tier establishments, the obligation to implement the MAPP may be fulfilled by other appropriate means, structures and management systems, proportionate to major-accident hazards, taking into account the principles set out in Annex III of Seveso III Directive. | For Non-Seveso LNG bunkering facilities the application of EN ISO 20519 (Section 7) would set the reference to Safety Management System. Compliance with EN ISO 20519 shall list conformance with this that as a management objective in the Operator/BFO management system. Management systems that can be used are ISO 9001, ISO 14001, ISM, ISO/TS 29001 and API Spec Q1. | |

| Safety Management System (SMS) | Yes | Yes | |

| The MAPP shall be implemented by appropriate means and a safety management system. SMS is not part of the Safety Report. | The MAPP shall be implemented by appropriate means and a safety management system. | ||

| Safety Report (SR) | Yes | Other | |

| Required to demonstrate actual implementation of the MAPP. SMS is not part of the Safety Report. Safety Report outlines the measures taken and demonstrates that all relevant aspects have been taken into account Can include, for LNG bunkering establishments, the technical requirement for a Risk Assessment in the terms of EN ISO 20519 and ISO/TS 18683. | For Lower-Tier and Non-Seveso LNG bunkering facilities, the applicability of EN ISO 20519 and ISO/TS 18683 may be considered as best practice. For this requirement to be implemented is important to ensure that compliance with these standards is inscribed in objectives of the BFO. | ||

| Emergency Plan | Emergency Plan | Emergency Response Plan | |

| (Article 12 Seveso III) Internal Emergency Plan to be developed applied and tested. Elements to be included in the Emergency plan as in Annex IV | (Reference to IACS Rec. 142 and SGMF LNG Bunkering Guidelines) Emergency Response Plan as part of the LNG Bunkering Management Plan (IACS Rec.142) Emergency Response Plan focused on the equipment and procedural aspects related to the LNG bunkering operation. | ||

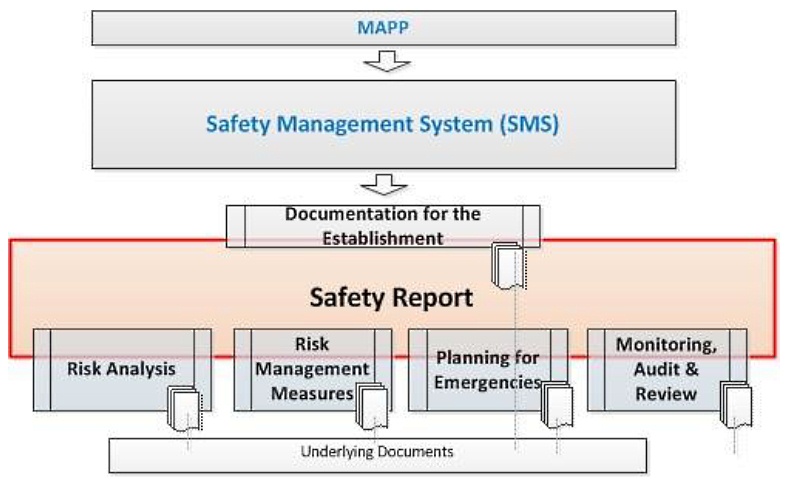

Referring to Table 4.14, above, for Upper Tier establishments both MAPP and Safety Report apply, whilst for lower tier only MAPP is required. An important note is however to be made, to clarify that these are, in essence, framework provisions, and not detailed technical requirements. It is quite likely and possible that the current safety practice, or national/local/port regulations, for LNG bunkering projects, facilities and locations, already include similar provisions in place, further detailed at national level, either on the technical or administrative levels. PAAs should make sure that the framework requirements in Table 1 are structured in detail at the technical level.

It will be interesting: Balancing Cleaner Fuel and Environmental Impact in LNG Emissions

PAAs should in all cases require BFOs have a management system; lower and upper tier Seveso establishments a SMS, or non-Seveso establishments, at least some type of management system where, as a minimum the requirements from EN ISO 20519 and ISO/TS 18683 can be included as objectives. Each system has to be in accordance with Annex III. Each system has to be proportionate to the major-accident hazards.

Management Systems that should be considered:

- SCC (Safety Certificate for contractors);

- BS 8800 OHSAS 18001, 18002 (Occupational Health and Safety Assessment System).

- ISO 9000 – 9004;

- ISO/TS 29001;

- ISM;

- API Spec Q1. API Spec Q1 Definition – API Spec Q1 is a company level certification based on the standard developed and published by the American Petroleum Institute (API) titled “Specification for Quality Management System Requirements for Manufacturing Organizations for the Petroleum and Natural Gas Industry”.x

- EMAS;

- ISO 14001.

It should be possible to ascertain the implementation of the MAPP by appropriate means and a SMS applied for permitting. Whilst the content and issues to be addressed in the SMS are laid down in Annex III of the Directive, it is again important to note that this instrument in itself is only specifying the framework minimum requirements for the safety management system. It should in essence allow the verification of a management loop (plan – do – check – act).

As per Annex III the SMS should include the part of the general management system which includes the organizational structure, responsibilities, practices, procedures, processes and resources for determining and implementing the MAPP.

The following issues shall be addressed by the SMS:

- Organization and personnel – the roles and responsibilities of personnel, identification of training needs, involvement of employees and subcontractors;

- Identification and evaluation of major hazards – procedures for systematically identifying major hazards, likelihood and severity;

- Operational control – adoption and implementation of procedures and instructions for safe operation;

- Management of change – adoption and implementation of procedures for planning modifications;

- Planning for emergencies – adoption and implementation of procedures to identify foreseeable emergencies by systematic analysis, to prepare, test and review emergency plans to respond to such emergencies;

- Monitoring performance – adoption and implementation of procedures for the ongoing assessment of compliance with the objectives set by the operator’s major-accident prevention policy and safety management system;

- Audit and review – adoption and implementation of procedures for periodic systematic assessment of the MAPP and the effectiveness and suitability of the SMS.

In all requirements related to the framework provisions in Seveso Directive, PAAs should integrate correctly the hierarchy of the different elements, as depicted in figure 2, below. The Safety Report, being a central element of the requirements applicable to the Operators, following the interpretation leading to Seveso framework applicability.

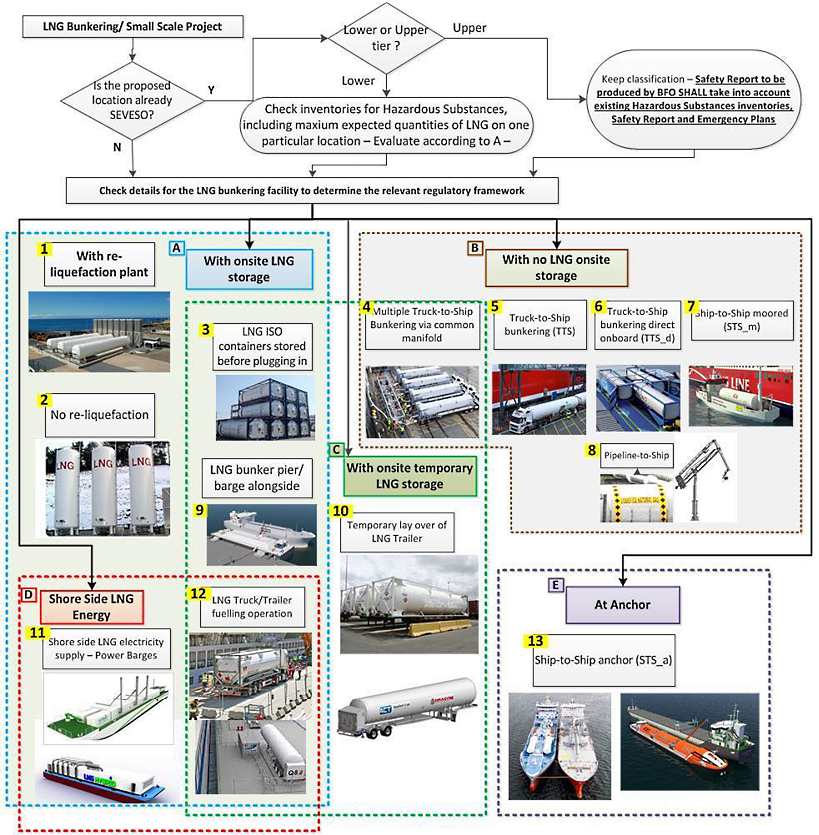

Following the previous point, and again with the focus on figure 3 in the next page, a suggestion is made for grouping LNG bunkering solutions into 4 (four) different groups, depending on the possibility of onsite LNG storage.

The following groups are defined:

A Fixed LNG bunkering solution with onsite storage.

B Mobile Units in LNG bunkering, without onsite intermediate storage.

C Mobile Units in LNG bunkering, with onsite intermediate storage.

D Shore-side LNG energy, either as direct fuelling The use of fuels with flashpoint lower than 60 °C is not permitted as per SOLAS 1989/1990 Amend / Chapter II-2 / Reg. 15.x or LNG-electricity supply.

E Ship-to-ship LNG bunkering, out of area. Ship-to-ship LNG bunkering can take place in the port area (at berth or at anchor) or out of area, at sea.x

- For lower-tier establishments, the obligation to implement the MAPP may be fulfilled by other appropriate means, structures and management systems, proportionate to major-accident hazards.

- Not applicable where Article 2(2)(c) applies:

- Possible major accident prevention provisions (similar to Seveso) to be judged by Seveso Competent Authorities, in light of the following relevant elements;

- Possible existing Seveso classification for the intended bunkering location;

- inventory of other possible hazardous substance, already in the area (possibly even below LOWER TIER threshold);

- Technical solution proposed for LNG bunkering;

- Quantity of LNG on-site;

- Frequency of LNG bunkenng operations.

- Evaluation based on the permanence of ISO LNG containers ashore, waiting to be loaded onto LNG fuelled ship (case 3).

- Not applicable where Article 2(2)(c) applies / pipelines outside establishments are exempt from Seveso application / Good practice to follow UNECE Safety Guidelines.

- The case of LNG power floating units is outside the scope of applcation of ISO 20519 or ISO/TS 18683. Similar measures, in particular for Risk Assessment, are mentioned here as important best practice.

- It is important to be certain that a transport or temporary storage situation can still be verified. If not, even for a ship, used for LNG storage, Seveso provisions can apply.

The division in the mentioned group in the previous point reflects and is aimed to capture the level of prevalence of a given LNG quantity close to the receiving ship or at any point with the port area. It reflects the need to address safety of LNG bunkering projects on the basis of how much LNG is onsite, and for how long. To this end PAAs should liaise with national Seveso competent authorities at the earliest possibility, as suggested in R4.18, accounting for the need to determine the necessary provisions, either from direct application of Seveso III Directive or, alternatively, for those cases falling within its Article 2.2.(c), by adopting the best practice suggested in this Guidance.

Sub-division presented in figure 3 is only indicative and should be taken as an example. It only suggests the need to differentiate between LNG bunkering solutions.

Read also: LNG (Liquefied Natural Gas) as Fuel

Fixed LNG bunkering installations, with small scale storage of LNG (with or without refrigeration/re-liquefaction), constituting Group A in figure 3, should be directly considered as eligible for Seveso III Directive application. Falling outside the derogation in Article 2.2.(c), fixed installations are subject to all provisions in Seveso III and, even if the intended location for LNG bunkering is already a Seveso classified area, it will require an update of all information, with the new hazardous substance (LNG) quantities reflected in the Emergency Procedures on Terminal and First Aid to VictimsEmergency Plan procedures and Safety Report.

To use the definition in the Seveso III Directive, Article 3.1, the whole location under the control of an operator” needs to be considered. This encompasses the storage site and the area adjacent to it, including all infrastructure and equipment elements connected to the storage tank downstream to the to the bunkering location/connection point (figure 4 and 5).

Seveso III Directive provisions are not applicable to the transport of dangerous substances and directly related intermediate temporary storage by road, rail, internal waterways, sea or air, outside the establishments covered by this Directive, including loading and unloading and transport to and from another means of transport at docks, wharves or marshalling yards. Seveso III – Directive 2012/18/EU – Article 2.2.c) x

For this reason, LNG tank trucks, railcars, and other mobile units, are not considered under the scope of Seveso III Directive, as Seveso establishments as long as they fulfil the conditions of Article (2)(2)(c). However, when these mobile units are used as a means for transferring LNG to a marine vessel, the location where the transfer occurs (i. e., any area on shore immediately adjacent to such waters, used or capable of being used to transfer liquefied natural gas, in bulk, to or from a vessel) can become subject, to Seveso III Directive provisions, depending on the circumstances.

PAAs should nevertheless be aware that LNG tank trucks, railcars, and other mobile units are subject to additional, existing international or local requirements.

Following R3.9, and considerations in Section “LNG Regulatory Framework International and European Maritime Safety OverviewEurope“, table “LNG Regulatory Framework International and European Maritime Safety OverviewSeveso III Directive-applicability to LNG bunkering“, the applicability of Seveso III Directive requirements to possible intermediate storage situations, as the ones presented in Table “Balancing Cleaner Fuel and Environmental Impact in LNG EmissionsLNG Bunker vessel/barge – Methane release mitigating measures” (situation 1, 2 and 3) is subject to a case-by-case assessment from PAAs and Seveso III competent authorities, which should, in the best interest of safety, have the following elements into consideration:

a. Actual or anticipated quantities of LNG in bunkering location/intermediate storage, taking into consideration also other dangerous substances present in the location.

b. Part of the distribution/transport chain where the bunkering /intermediate storage element is integrated.

c. Duration and frequency of the bunkering or intermediate storage at the location.

d. Other risk factors at the location or in its proximity such as the intermediate storage of other hazardous substances.

In the case that the location where LNG bunkering is being proposed is already a Seveso establishment the classification of that location should be subject to a revision, including careful consideration for the full aggregation of hazardous substances, in addition to the LNG storage/intermediate storage. For a Lower-Tier establishment, even if outside the scope for a Safety Report (Article 10) or an Emergency Response Plan (Article 12), it is advised as a good practice to also require the application of the technical provisions already in ISO/TS 18683 and EN ISO 20519. Requirements for Risk Assessment and reference to an Emergency Plan are already part of both ISO/TS 18683 and EN ISO 20519. There is however an important difference between what is prescribed as a Safety Report in Seveso III Article 10, and an actual Risk Assessment. The Safety Report is more representative of a Risk Study, where Risk is not a specific figure to be calculated. Assessment against relevant criteria is, in this sense, not possible. Whereas the Safety Report provisions from the Seveso directive provide the framework for the overall Safety Study, the Risk Assessment provisions, from ISO technical standards, provide for the Technical provisions relevant to evaluate Risk.x

Apart from the total volume of hazardous substance, in this case LNG, other elements should be taken into account which will be relevant for the Safety Report. ANNEX II in Seveso III Directive (Minimum data and information to be considered in the safety report referred to in Article 10) lists the minimum elements to be considered. It is important however to underline that requirements for Risk Assessment will very likely already be in place, whether it is a fixed installation or a mobile unit. Even if Seveso III Directive may, on a first analysis, exempt mobile units, requirements from other instruments may be in place and Risk Assessment and Emergency Plan may be already part of the requisite for the LNG bunkering project to be developed in the first place. Port Regulations play here a fundamental role in bringing the non-binding provisions from International Standards such as ISO/TS 18683 and EN ISO 20519, into an enforceable status.

The process to determine the applicability of Seveso III Directive to a given LNG bunkering location, independently of the LNG bunkering solution designed, will be very much dependent on a case-by-case assessment by the operator, ideally in cooperation with the competent authorities regarding the proposal as described in the LNG bunkering Concept Project and Letter of Intent, to be submitted by the prospective BFO and possibly endorsed by the TO. The diagram in figure 6, below, proposes a procedure for confirmation of possible Seveso classification for the intended LNG bunkering location. A short description of the process is presented in Table 3, with explanations to the diagram in figure.

As an alternative good practice approach it is possible to define a more simplified way of segmenting Major Accident Prevention application accounting for a staged application of different instrument provisions, following the outline of table 2, in the next page.

| Table 2. Risk, Emergency Plan, Management System and Major Accident Prevention requirements (simplified scheme) | |||||

|---|---|---|---|---|---|

| RISK ASSESSMENT | EMERGENCY RESPONSE PLAN (ERP) | MANAGMENT SYSTEM | MAJOR ACCIDENT PREVENTION Seveco | ||

| With No Onsite Storage | LNG Bunkering by mobile units Groups B, D and E in figure 3 | ISO/TS 18683 EN ISO 20519 Important to nite the scope of these standarts is focused on the LNG bunkering interface and, applicable to all LNG bunkering solutions. | ERP To reflect key aspects of Risk Assessment Following indicative scope as per IACS Rec.142/SGMF Guidelines. | Quality Managment System EN ISO 20519 Section 7.1 Objectives for LNG Bunkering compliance with EN ISO 20519 to be inscribed in QMS. | In principle not applicable Article 2.2(c) Seveco Directive) May have implications for location, (evaluation by Competent Autority). |

| Pipeline | ERP To reflect key aspects of Risk Assessment | Pipeline Integrated Managment System (PIMS) UNECE | In principle not applicable Article 2.2.(d) Seveco | ||

| With Onsite Intermediate temporary Storage | LNG Bunkering by mobile units With onsite intermediate storage elements Groups C, D and E in figure 3 | ISO/TS 18683 EN ISO 20519 Scope of these standards is focused on the LNG bunkering interface and, applicable to all LNG bunkering solutions. | ERP To reflect key aspects of Rick Assessment Following indicative scope as per IACS Rec.142/SGMF Guidelines. | Quality Managment System En ISO 20519 Section 7.1 Objective for LNG Bunkering compliance with EN ISO 20519 to be inscribed in QMS. | Subject to evaluation by Competent Authority as to which extent relevant Major Accident Prevention Provisions may apply to location. – As a minimum Good Practice a Rick Assessment should be conducted to demonst rate rick mitigation to ALARP levels |

| With Onsite Storage | LNG Bunkering With onsite storage elements < 50 ton | ISO/TS 18683 EN ISO 20519 Scope of these standards is focused on the LNG bunkering interface and, applicable to all LNG bunkering solutions. (it is important to note the Risk Assessment and scope of both ISO standards is for the “bunkering interface” (see figure “Maritime Standards ExplainedScope of EN ISO 20519“) | ERP To reflect key aspect of Rick Assessment Following indicative scope as per IACS Rec.142/SGMF Guidelines. | Quality Managment System EN ISO 20519 Section 7.1 Objective for LNG Bunkering compliance with EN ISO 20519 to be inscribed in QMS. | |

| LNG Bunkering With onsite storage elements > 50 ton | Emergency Response Plan as part of MAPP+SMS | Safety Management System EN ISO 20519 Section 7.1 Need to demonstrate that all MAPP Hazard Scenarios have been addressed | Seveco LOW-TIER – Notification (Article 7) – MAPP+SMS (Article 8) – Public Consultation (Article 13) – Information to Public (Article 14) | ||

| LNG Bunkering With onsite storage elements > 200 ton | Emergency Response Plan (Article 12) | Safety managment System Need to demonstrate that all MAPP Hazard Scenarios have been addressed | Seveco UPPER-TIER – Notification (Article 7) – MAPP+SMS (Article 8) – Safety Report (Article 10) – Emergensy Response Plan (Article 12) – Public Consultation (Article 13) – Information to Public (Article 14) | ||

| LNG Shore-side energy | Shore Side Electricity LNG power supply | No fuel transfer interface, Risk Assessment for the | ERP To reflect key aspects of Risk Assessment ERP applicable as a minimum Good Practice for both cases. | Quality Managment System Reflecting the specific service objectives to be defined and inscribed in QMS. | Subject to evaluation by Competent Authority as to which extent relevant Major Accident Prevention Provisions may apply to location. |

| LNG fuel direct to onboard generator LNG fuel supply | ISO/TC 18683 EN ISO 20519 Fuelling interface to be considered within scope. | ||||

Fig. 6 LNG bunkering – Seveso applicability (see table for legend)

| Table 7. Table legend for diagram in Figure 6 | |||

|---|---|---|---|

| Item in diagram figure 6 | Who? | Observation/ Note/ Guidance | |

| 1 | Initial Consultation | BFO | BFO consults PAA on the relevant aspects that need to be accounted for before initiating the process. Important to detail the main lines of the concept, share ideas on preferred bunkering location and outline the permitting process adequately. |

| 2 | Initial Facilitation | PAA | PAA, as a Good Practice approach, can be constituted as an initial facilitator the process. This would support all parties involved in having a single focal provider for initial information. |

| 3 | Collection of preliminary information | BFO | Resulting from initial consultations the BFO is here able to gather all the necessary information to develop the adequate permitting process, including in particular Risk Assessment and Major Accident Prevention aspects. |

| 4 | Development of Concept Design | BFO | Development of initial Concept Design to include elements of Qualitative Risk Assessment, Feasibility Analysis and, in particular, incorporating relevant elements from TO and PAA consultation. A dialogue with the PAA should be established at this point on the technical level. Non-disclosure agreements may be considered for adequate level of information sharing at this point. |

| 5 | Draft Concept Project for Peer Consultation | BFO | Submission, of the Concept Design for intended LNG bunkering facilities and operations, to the Terminal Operator (TO) and PAA. |

| 6 | Declarations of Interest and Initial Endorsements | TO/PAA | Should the TO and PAA be also interested parties in the setting of the LNG Bunkering project/service this information should be here subject to declaration. This is considered to be an important initial step for transparency purposes. |

| 7 | Consultation with Seveso Competent Authority | BFO | Include preliminary elements from concept LNG bunkering project, including 1) Onsite storage capacity, 2) Bunkering frequencies, 3) Operation details, 4) Possible temporary storage elements, 5) information on existing Seveso III Directive classification, including in particular aspects related to the proximity of populations as required by art 7 of the Seveso III Directive. |

| 8 | Information on existing Hazardous Substances onsite and potential existing Seveso classification | TO/PAA | Relevant information on possible Seveso classification for the intended LNG bunkering facilities location. Information on existing Hazardous Substances storage elements or handling location. |

| 9 | Preliminary information package | CA | In the best interest of a complete submission, relevant for the LNG bunkering project being proposed, it is important to have a consolidated information package from the CA. It is advised that CA informs on applicability of Seveso requirements. |

| 10 | Notification | BFO | Formal Notification, including all elements prescribed in Article 7 of Seveso Directive (Directive 2012/18/EU). Include, as a good practice element, also information on: – Onsite storage capacity – Bunkering frequencies – Operation detail |

| 11 | Evaluation of previous Seveso classification for intended LNG Bunkering facilities location | CA | CA assesses whether site is already Seveso establishment or, in the context of additional information, whether it should merit becoming a Seveso establishment in view of the following information provided under Article 7: Data to be used for CA (S) evaluation of: – Operator information and assessment confirming intended LNG bunkering location. – Calculation of the anticipated presence of Hazardous Substances (LNG + any other Annex I substances) – Determination of possible multi-operator implications – Input data for domino-effects evaluation |

| 12 | (Case where location is not a Seveso Establishment) Need to build the case to evaluate adequately Seveso provisions applicability. | CA | Decision of Seveso applicability to be based on the elements provided by the BFO, following consultation with PAA and Terminal Operator. Pursues aggregation of maximum expected inventory of Hazardous Substances at any time. Information on multi-operator environment to be obtained from PAA CA to determine accident prevention based on national legislation/standards. |

| 13 | Decision on Seveso applicability, for new LNG Bunkering projects | CA | Following evaluation of elements obtained in (12) CA decides on Seveso applicability to the detailed LNG bunkering project. Exact requirements following on the BFO will follow from this early evaluation of project details. |

| 14 | For Non-Seveso outcome from (13), and also for Lower-Tier establishments, PAA to set requirements for Risk Assessment and Emergency Response Plan. | PAA | Following determination of Seveso non-applicability in (13) the PAA receives indication from the CA to detail the requirements for Risk Assessment and Emergency Response Plan. The role of the PAA is here fundamental as it holds the overview of the multi-operator scenario in the port area and holds the external ERP. The involvement of the PAA in the setup of the essential framework for Risk Assessment and ERP is here an important good practice note. As applicable, the PAA should define the applicable Risk Criteria and minimum Hazard Scenarios to evaluate in the context of a Risk Assessment (with reference to ISO/TS 18683 and EN ISO 201519). It is important also to note here that the requirements should apply to both Non-Seveso and Seveso Lower-Tier establishment as the Risk Assessment and Emergency Response Plan are not required by the Seveso III Directive for lower tier establishment. |

| 15 | Production and submission of Risk Assessment and Emergency Response Plan | BFO | Development of Risk Assessment and Emergency Response Plan following requirements from PAA (as good practice the minimum is to be established by ISO/TS 18683 and EN ISO 201519). There should however be a reference to these Standards in Port Regulations. For HAZID assessment the PAA should be involved in the workshop team. For SIMOPs Risk Assessment evaluation the multi-operator environment should be adequately defined, with representative information of all relevant activities and stakeholders involved. |

| 16 | On the situation that the intended location is not a Seveso establishment already (11) and having confirmed the applicability of Seveso, CA defines Tier for location. | BFO (possibly in cooperation with CA) | CA to determine Tier for Seveso classification of location-establishment. It is here important to integrate all possible Hazardous Substances in addition to LNG bunkering storage elements. The distinction between Lower and Upper Tier is to be made here on the exact basis of the threshold values present in Annex I to the Seveso III Directive. |

| 17 | Development of Major Accident Prevention Policy (MAPP) and decide on suitable Safety Management System (SMS) | BFO | Requirement for both Lower and Upper tier establishments. Development of Major Accident Prevention Policy and adequate setting up of a Safety Management System that is able to demonstrate that all possible major accident scenarios are addressed. In particular for Lower tier establishments it is important that MAPP and SMS are adequately aligned with the Risk Assessment and Emergency Response Plan drafted as a consequence of ISO 201519 where the same accident scenarios must be evaluated and the risk mitigation measures adequately outlined. |

| 18 | Approval of Risk Assessment and Emergency Response Plan by PAA | PAA | As a good practice measure the approval of Risk Assessment and Emergency Response Plan is to be made at PAA level, drafted as a consequence of ISO/TS 18683 and EN ISO 201519. PAAs should have the best overview perspective of the entire operational scenario and land planning, including multi-operator relevant aspects that are important to the adequate integration of all emergency response. |

| 19 | Approval of MAPP by CA | CA | MAPP and SMS for approval by CA – applicable to Lower and Upper tiers. |

| 20 | For Seveso outcome from (11), i. e. following positive confirmation from (11) it is here made the decision on which tier would result from LNG bunkering facilities implementation. | BFO (possibly in cooperation with CA) | For the situations where the intended location is already a Seveso establishment, the main objective at this stage is to evaluate, based on existing tier classification, what would the result be after the addition of the new LNG bunkering facility, considering not only the relevant LNG storage elements but also the details of the intended LNG bunkering operations. Should the location be Lower-tier, the objective for the evaluation should be to decide whether the location would need to be updated for Higher-tier or if, otherwise the classification of the location could remain unchanged. |

| 21 | For the cases where a Lower Tier has been determined following evaluation in (20), calculate inventory and re-check Seveso classification. | CA | In the case the location is already a Lower-tier establishment a re-calculation of the aggregated quantities of hazardous substance(s) including the LNG would have to be made, as this may bring the establishment into the upper-tier range, following the terms outlined in Seveso III Directive. The process diagram, following (21) indicates then the need to re-assess the tier for the location by connecting with (16) in the diagram. |

| 22 | Development and submission of a Safety Report | BFO | One of the distinct requirements for Higher Tier establishments is the production of a Safety Report, following the terms of Article 10 of Directive 2012/18/EU and covering all elements listed in its Annex II (Minimum data and information to be considered in the safety report referred to in Article 10). For LNG bunkering projects for facilities falling under Seveso, ISO 20519 and ISO/TS 18683 represent a set of technical measures that should be incorporated in addition to the requirements established in the Seveso III Directive for the Safety Report and Emergency Plan, as applicable. In fact it is here important to note that the requirements for the Safety Report, as contained in Annex II of Directive 2012/18/EU are only providing a framework for the actual study to be developed and produced. The Safety Report should reflect directly the elements comtained in the MAPP, SMS and, amongst other aspects, it should be able to address all the identified possible Hazardous Scenarios whilst, at the same time, listing the relevant mitigation measures. |

| 23 | Data provision for the following: – Details on multi-operator environment – Information on existing Hazardous substance inventory – EN ISO 20519 requirements for Risk Assessment to incorporated into Safety Report | BFO/PAA | Ports are typically multi-operator environments and that should be well taken into account in the definition of Emergency Plans, Risk Assessment, Safety Report, amongst other relevant instruments contributing to Permitting and Major Accident prevention. Relevant information regarding existing Hazardous substances already on site is also fundamental for the adequate classification of the location in the context of the Seveso Directive. Potential for Domino Effects to be evaluated according to Article 9 of Directive 2012/18/EU. |

| 24 | Update on “Upper-Tier” classification – following evaluation in (20) | BPO (possibly in cooperation with CA) | Request Upper Tier after including LNG Bunkering – Request: Update relevant documentation and procedures. The update of an already Upper tier establishment should focus in particular on the update of the Safety Report to reflect adequately the addition of the LNG bunkering facility/project. Potential for Domino Effects to be evaluated according to Article 9 of Directive 2012/18/EU. |

| 25 | Internal Emergency Plan | BFO | Develop an Internal Emergency Plan following Article 12, including elements in Annex IV |

| 26 | Approval Safety Report by CA | CA | Approval of the Safety Report including the following good practice procedure: – Check for completeness, according to Annex II of Directive 2012/18/EU. – Cross check with elements in the MAPP – Evaluate if all Hazardous scenarios are covered, incorporating elements which are relevant for the situational scenario in the intended LNG bunkering location. – Check if other onsite Hazardous Substance storage elements are considered. – Consult with the PAA |

| 27 | External Emergency Plan | CA/PAA | Having information as submitted by the BFO, under Article 12(1)(b), it is up to the authorities designated for that purpose by the Member State to draw up an external emergency plan for the measures to be taken outside the establishment (Article 12.1, c)) The concept of the External Emergency Plan is of great importance in the actual design of the Safety concept for the whole LNG Bunkering facility. In fact, a potential LNG release scenario could very likely require the involvement of actions from other operators on site, emergency services, either from the Port or external, amongst several other entities. It is important that the External Emergency Plan is prepared in close observation of the Internal Emergency Plan and that they both work together to ensure the preparedness and response capability in the best time frame possible, as well as ensuring good communication and cooperation between the operator and external emergency services. It is suggested as a good practice that the PAA should be responsible for the preparation of the External Emergency Plan, consulting all possible entities involved to optimize the amount of hazardous scenarios covered and response measures designed. Emergency plans shall contain, at least, the information set out in Annex IV. |

| 28 | Testing Emergency Plans and Interoperability Check | PAA | Emergency Plans are to be tested at least every three years. It would constitute good practice to also check the interoperability between internal and external emergency plans and where relevant with neighbouring operators. BFO Internal Emergency Plan (IEP) to be checked for complementarity and interoperability with other Operators. In a multi-operator environment it is important that LNG bunkering is integrated into the wider complex context of other Emergency Plans that may co-exist. In exact terms there should be the sufficient flexibility to PAAs to bring the wider operators community to the process. It should here be possible to design wider scale Exercises to test and evaluate how well adapted Emergency Plans are, in terms of continuity of response. Continuity of Response is a term further explored in Section “Emergency, Preparedness & Response” of this Guidance, accounting for the need to have both external and internal ERPs sized and developed for a continuous response both in terms of Firefighting, Evacuation, Command and Control and External Emergency services.x |

EIA Directive

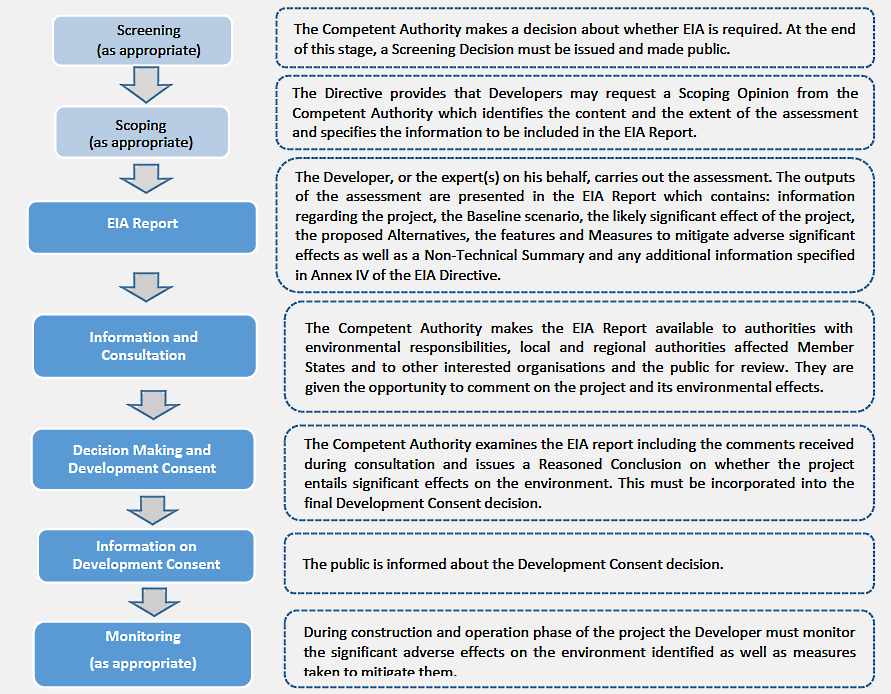

The EIA Directive is, together with the Seveso Directive, an instrument with a strong potential to influence and shape the permitting process for LNG bunkering projects.

Having this in mind, and following the previous section where the applicability of Seveso was addressed, it is now important to highlight that LNG bunkering projects fall under the scope of the EIA Directive (Annex II) and have to undergo a screening by the national authorities to determine whether they need to be subject to an EIA procedure. PAAs should here exercise an important role in conveying updated and accurate information to prospective BFOs.

It will be interesting: LNG IMO Tanks/Containment Systems

EIA Directive (2011/92/EU as amended) The initial Directive of 1985 and its three amendments have been codified by DIRECTIVE 2011/92/EU of 13 December 2011. Directive 2011/92/EU has been amended in 2014 by DIRECTIVE 2014/52/EUx applies to a wide range of public and private projects, which are defined in Annexes I and II. For projects listed in Annex II, the EIA competent authorities have to decide whether an EIA is needed.

The EIA also specifies the requirements on public participation in the process. This, together with the Public Consultation and information from Seveso Directive provisions, underlines the importance of the public involvement in the process. PAAs should be well informed and, consequently, inform adequately prospective BFOs, which applicable criteria is in place for EIA application. The indicative process is presented below, in figure 7.

IGF Code

For ships certified according to the IGF Code (IGF Code ships) the application of a specific LNG Bunkering Plan “LNG Bunkering Plan” should here be understood in the exact terms. The concept extends from the IACS LNG Bunkering Guidelines (Rec.142), where it is defined as “LNG Bunkering Management Plan”.x should meet all the requirements outlined in Chapter 8, Sections 18.4, 15.4 and 15.5 of the Code. Being all provisions specifically included in the code to ensure safe bunkering equipment, control and operations, it is important that, to the extent possible, all other parties involved in the LNG bunkering operation share the safety concept, terminology and procedures. National or local regulations for LNG Bunkering Operations should be adapted to IGF Code Goals, Functional Requirements and requirements outlined for the control and safety on LNG bunkering operations.

Where different terminology is found, coexisting in the LNG bunkering interface, all parties involved should, as a best practice approach, align the operation and safety concept with the requirements of the IGF Code. Functional requirements are extracted from the IGF Code and included in table LNG Regulatory Framework International“IGF Functional Requirements – Applicability to Bunkering Interface”. IGF functional requirements should also be respected, wherever applicable, in the whole bunkering interface.

For non-IGF Code ships, i. e. for ships built or converted to LNG as fuel before the entry into force of the Code (1st January 2017), the safety principles followed in bunkering should follow the same IGF regulations outlined in 18.4, especially in terms of responsibilities, pre-bunkering verification procedures, control systems, and all other requirements related to LNG bunkering operation.

LNG Bunkering Guidelines and Standards

PAAs should have the LNG Bunkering Guidelines listed in Section Maritime Standards Explained“Guidelines” as the relevant documents where industry best practice is reflected, resulting from a significant number of stakeholders in the Industry with experience in LNG. Functional requirements for LNG bunkering equipment, where listed, are also the reflection of current experience and good practice, not only in terms of the LNG Transfer System equipment but also regarding operational aspects. PAAs should nevertheless be aware that these documents are not mandatory in nature and should, in the context of a legal framework, be incorporated as references into national or Ports, Terminals and Jetties – Role and Significanceport regulations.

Read also: The Role of LNG Bunkering Infrastructure

For the particular case of ISO/TS 18683 or EN ISO 20519 a possible incorporation by reference into national or port regulations, would have to take into account the different nature of these two documents. Whilst some parts are repeated in both documents, there are very relevant aspects which can only be found in one or the other. This is the case with “Risk Assessment” (where ISO/TS 18683 includes a more thorough list of considerations) or with “Management system/quality assurance” where only EN ISO 20519 includes provisions that can be considered relevant. Reference to Section 7 in EN ISO 20519x

PAAs should note that EN ISO 20519 does not constitute a full substitute to ISO/TS 18683. Notwithstanding the repetition of some elements (as highlighted in section Balancing Cleaner Fuel and Environmental Impact in LNG Emissions“Methane Release Mitigation” and Balancing Cleaner Fuel and Environmental Impact in LNG Emissions“Good Environmental Practice for LNG Bunkering”) both documents should be read together. As a Technical Specification ISO/TS 18683 contains elements which are relevant to design and procedures.

Existing LNG Bunkering Guidelines contribute collectively to the safe development of LNG bunkering, helping to promote safety though harmonization and shared responsibility. Provisions established by port regulations should, as far as reasonable and practicable, conform to the relevant technical aspects with the Guidelines, making reference, first, to international standards and, secondly, wherever more convenient or applicable, to industry guidance documents.

EN ISO 20519 is referred to throughout this Guidance as the standard that should serve as a basis for certification, accreditation and quality assurance for all stakeholders. The EN notation is here essential to ensure that, at least in the EU the standard is incorporated in to all EU Member States as a national standard.

This standard represents an instrument of direct support to the IGF Code, providing the frame for implementation of IGF Section 18.4 provisions on bunkering operations.

Summary of Applicable Instruments

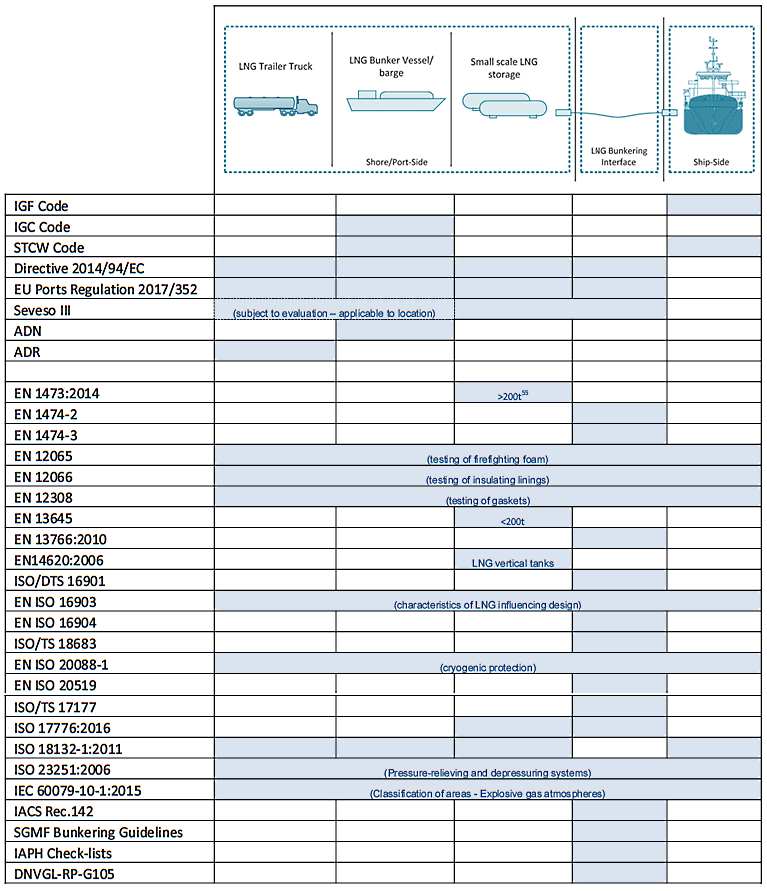

Table 4, below, provides an informative summary of applicable regulatory instruments, standards and guidelines in the context of LNG bunkering. Port Authorities should have the summary below as reference when having to quickly decide on the scope of application of each reference.

For the particular case of ISO/TS 18683 or EN ISO 20519 a possible incorporation by reference into national or port regulations, would have to take into account the different nature of these two documents. Whilst some parts are repeated in both documents, there are very relevant aspects which can only be found in one or the.