This article focuses on one of the aspects of LNG bunkering that has received the most attention from many of the involved stakeholders: permitting. Although the specific details and workflow for obtaining an LNG Bunkering Permit vary by country, they all share similar elements and common parts.

- Permitting Process

- General Permitting Process Map

- Elements for LNG Bunkering General Permit

- Life Cycle of LNG Bunkering Projects

- Concept Project

- Letter of Intent

- Letter of Recommendation

- EIA Screening

- Seveso Notification

- Other Permits

- LNG Bunkering General Permit

- Inspections

- Measures for Time-Effective Permitting

It is the objective of the present section to define a general permitting process, based on the Life-Cycle of LNG bunkering projects. The permitting process here suggested as indicative cannot be taken directly as representing any actual procedure in practice, or directly representing the permitting process in any Member State.

For the present Section the permitting process will be typically that of an LNG bunkering fixed installation, with small scale LNG storage infrastructure. Other types of LNG bunkering typologies also require permitting and should be considered (remarkably those involving mobile LNG elements, such as Trucks, Barges or ISO–LNG containerized modules. Thus, for the purpose of making the concept as generic as possible “LNG bunkering project” means all LNG fuel handling facilities designed for the purpose of transferring LNG fuel to ships. This should encompass projects from fixed installations, to mobile LNG bunkering solutions which will, whenever in place, undertaking Guidance on HAZID and HAZOP for LNG bunkering operationsLNG bunkering operations, be subject to same levels of evaluation of fixed projects (environmental, safety and, where applicable, construction).

For aspects related to certification of LNG bunkering projects involving mobile units article Guide to Certification, Accreditation, and Equipment Standards for LNG Bunkering“Certification & Accreditation” should be consulted. Trucks and bunker vessels/barges follow very specific certification/approval references (ADR and IGC Code, respectively).

All aspects addressed in the present section should be read in conjunction with article “Regulatory Frame Best Practice – Applicability in the Bunkering InterfaceRegulatory Frame Best Practice“, where the relevant legal instruments are listed and summarized.

Permitting Process

Permitting is a key aspect in the development of LNG infrastructure. The current average duration of permitting procedures for energy infrastructure projects, from submission of application document to issuing of the permit can go up to 4 years. Public opposition to the project (via the mandatory stakeholder dialogue) is often the main reasons for delay/failure of the process, but this may often be due to insufficient information being made available to all stakeholders with an adequate advance.

The permitting processes in the different European countries for small-scale LNG infrastructure (i. e. LNG bunker station, LNG satellite plants, …) differ regarding the number of permits/processes in the permitting procedure, number of authorities responsible to deliver the permitting procedures, documents to be produced and delivered, timing, etc.

Two EU instruments strongly influence the permitting process for LNG bunkering facilities at national level: the EIA Directive and the Seveso Directive. For both directives it is important to underline that their transposition exercise in each Member State may have introduced aspects which are here not fully covered. It is important, when addressing this Guidance for reference at national level, to make clear which elements in national legislation may have introduced differences specific requirements.

The permitting process/requirements differ between countries, but there is strong similarity in the type of permits required at a national level. Often required permits are:

- Environmental permit;

- Permit to store dangerous goods;

- Handling of dangerous goods permit;

- Building permi.

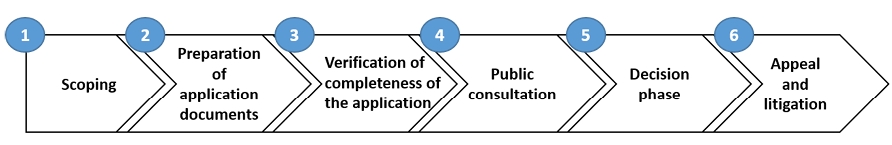

The average number of processes required in countries analysed to obtain all the required permits for the construction and operation of a project is 3 or more. A typical permit procedure consists of the steps presented in the diagram below, in figure 1 Permitting procedures for energy infrastructure projects in the EU: evaluation and legal recommendations, Roland Berger Strategy Consultants, Final report, EC DG Energy, July 31, 2011.x:

The following general phases of the Permitting Process are present in most LNG bunkering permitting processes.

- Scoping: process of determining the content of the matters to be covered in the environmental information to be submitted to the competent authorit.

- Preparation of application documents: the developer prepares the application documents based on the list of requirement.

- Verification of completeness of the application: ensure that application documents cover the scoping and enable a proper assessment of all potential impacts of the project.

- Public consultation: formal dialogue is established between responsible authorities, stakeholders and project developers.

- Decision phase: goal of this phase if to issue a permit.

- Appeal and litigation: after a permit has been issued, stakeholders may appeal.

The differences of the permitting processes of EU member states was one of the aspects covered by DNV-GL analysis and evaluation of identified gaps and of the remaining aspects for completing an EU-wide framework for marine LNG distribution, bunkering and use, mandated by the European Commission’s Directorate-General for Transport und Mobility (DG MOVE).

A typical common aspect of all permitting processes, regardless the country, is the involvement of several competent authorities, responsible for different parts of the project, either directly, or indirectly through consultation or special information/evaluation requests. There is potential for special complexity to be introduced only due to this fact, with the involvement of different authorities representing a potential complex document management control and sometimes unforeseen delays in the process which accumulate along the permitting chain.

Read also: LNG Bunkering Guide – What It Is and How to Use It

To address special complexity of some permitting processes, and the involvement of different competent authorities, some Member States have created “single-permits” or “single-desks” with a view to allow for simplification of processes, minimization of process length and complexity. At the same time a more customer-oriented service is the tone followed by most administrations.

The Permitting Process complexity is highly influenced by the number of intervening authorities, consultations, periods for analysis and, remarkably, by the number of different entities providing elements for granting the permit. The complex environment of a permitting process can today be made simpler through eh adoption of simple measures for procedural simplification or better management o information. Some of these measures are further discussed in Section “Measures for Time-Effective Permitting” below.

In specific for LNG bunkering projects it will be useful if PAAs adopt the facilitation approach, interacting with all stakeholders and, as far as reasonably possible, promote a consolidated overview of the process, intervening whenever a difficulty might be perceived.

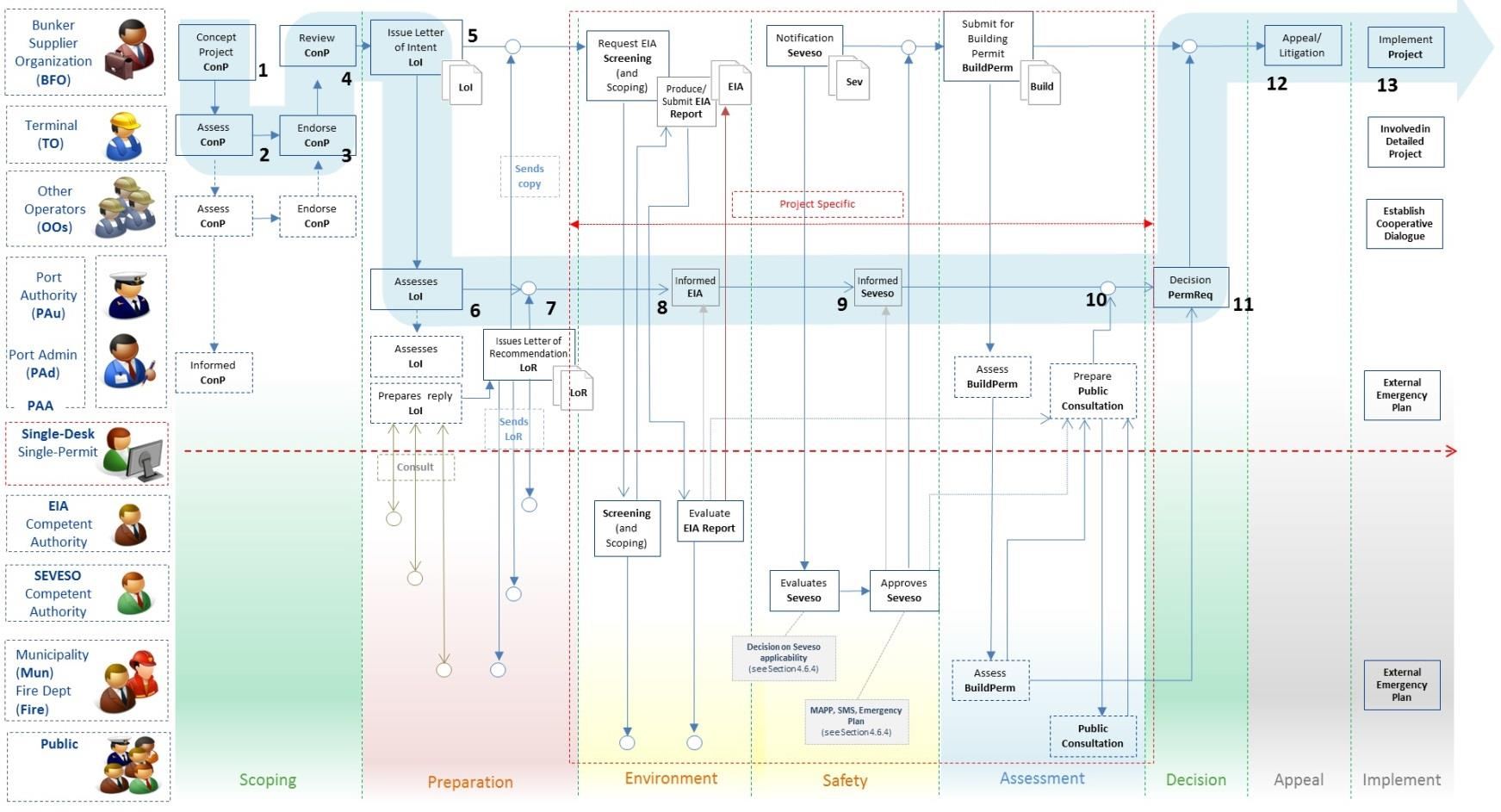

General Permitting Process Map

The General Permitting process map, suggested for LNG bunkering projects is presented in figure 2, in the next page, with table 1 identifying the main elements that can be taken into account, contributing collectively for permitting.

| Table 1. LNG bunkering General Permitting process (legend for figure 2) | |||||

|---|---|---|---|---|---|

| Nr (diagram in Figure 2) | Stage | Responsible | Description | ||

| 1 | Concept Project | BFO | The Concept Project is developed by the Operator(s) and submitted in advance to the beginning of the Permitting Process. | ||

| Submission to PAA, TO and Other Operators, for preliminary evaluation of technical/operational feasibility of the project. | |||||

| This possibility will allow different stakeholders to be engaged at the earliest opportunity, being able to provide relevant information for the project. | |||||

| Feasibility issues can be addressed at the earliest stage. | |||||

| BFO has here the opportunity to send as much information as possible for a good preliminary appreciation of the Project. | |||||

| At this stage, Concept Project sent to PAA for information. | |||||

| 2 | Assessment of Concept Project | TO | In those cases where a Terminal is involved it is important to have a first review of the Concept Project by the Terminal Operator. | ||

| Other Operators | At this stage it is relevant to check for any possible incompatible activities. | ||||

| 3 | Endorsement of Concept Project | TO | Following the preliminary assessment of the Concept Project the TO endorses the reviewed material reverting to the BFO. | ||

| Other Operators | Endorsement from other operators also possible to reinforce the operational feasibility of the project. | ||||

| Any relevant indications on possible incompatibilities, envisaged SIMOPS, safety concerns, major accident prevention policies, should here be shared with the BFO. | |||||

| 4 | Review Concept Project | BFO | Revision of the Concept Project, with due consideration to the feedback provided by TO and other operators. | ||

| Implementation of any possible modifications to the Concept Project. | |||||

| 5 | Issue Letter of Intent | BFO | Ref: Section 7.3.3 | Letter of Intent, covering revised Concept Project, to be sent to PAA. | |

| The Letter of Intent gives initiation to the Permitting Process. | |||||

| 6 | Assess Letter of Intent | PAA | PAA assesses the Letter of Intent (LoI), looking for elements that might have already indicated and rose in the preliminary evaluation, during SCOPING phase. | ||

| Complete evaluation of Concept/detailed project. | |||||

| 7 | Letter of Recommendation | PAA | Letter of Recommendation issued on the basis of Project evaluation, with the objective to facilitate the evaluation of other competent authorities. | ||

| Include formal assessment of Concept Project | |||||

| In issuing the Letter of Recommendation, PAAs may take preliminary information from respective competent authorities, municipality and other stakeholders. | |||||

| 8 See also article “Regulatory Frame Best PracticeEIA Directive“ | EIA Environmental Permit Request for Screening (possible request for Scoping if necessary) | BFO | BFO submits request for screening | ||

| NOTE: The applicability of the EIA is defined through the screening process and. There is no other | |||||

| Screening (and Scoping if requested) | EIA Competent Authority (On BFO request) | SCREENING: The Competent Authority makes a decision about whether EIA is required. At the end of this stage, a Screening Decision must be issued and made public. | |||

| SCOPING: The Directive provides that Developers may request a Scoping Opinion from the Competent Authority which identifies the content and the extent of the assessment and specifies the information to be included in the EIA Report. | |||||

| EIA Report | BFO | The BFO carries out the assessment. | |||

| EIA Report contains: information regarding the project, the Baseline scenario, the likely significant effect of the project, the proposed Alternatives, the features and Measures to mitigate adverse significant effects as well as a Non-Technical Summary and any additional information specified in Annex IV of the EIA Directive. | |||||

| Information and Consultation | EIA Competent Authority | The Competent Authority makes the EIA Report available to authorities with environmental responsibilities, local and regional authorities affected Member States and to other interested organisations and the public for review. They are given the opportunity to comment on the project and its environmental effects. | |||

| Decision Making and Development Consent | EIA Competent Authority | The Competent Authority examines the EIA report including the comments received during consultation and issues a Reasoned Conclusion on whether the project entails significant effects on the environment. This must be incorporated into the final Development Consent decision. | |||

| Information on Development Consent | EIA Competent Authority | The public is informed about the Development Consent decision. | |||

| Monitoring (as appropriate) | BFO | During construction and operation phase of the project the Developer must monitor the significant adverse effects on the environment identified as well as measures taken to mitigate them. | |||

| 9 See also “Regulatory Frame Best PracticeSeveso III Directive – Major Accident Prevention Directive“ | SEVESO Notification (Safety/Risk Assessment) Safety Permit | BFO | Submit Notification Formal Notification, including all elements prescribed in Article 7 of Seveso Directive (Directive 2012/18/EU). Include, as a good practice element, also information on: | Onsite storage capacity | |

| Bunkering frequencies | |||||

| Operation detail | |||||

| Assessment of SEVESO applicability | SEVESO Competent Authority | CA assesses whether site is already Seveso establishment or, in the context of additional information, whether it should merit becoming a Seveso establishment in view of the following information provided under Article 7: Data to be used for CA evaluation of: | Operator information and assessment confirming intended LNG bunkering location. | ||

| Calculation of the anticipated presence of Hazardous Substances (LNG + any other Annex I substances) | |||||

| Determination of possible multi-operator implications | |||||

| Input data for domino-effects evaluation | |||||

| SEVESO applicable (Lower-Tier and Higher-Tier) Development of Major Accident Prevention Policy (MAPP) and decide on suitable Safety Management System (SMS) | BFO | Development of Major Accident Prevention Policy and adequate setting up of a Safety Management System that is able to demonstrate that all possible major accident scenarios are addressed. | |||

| In particular for Lower tier establishments it is important that MAPP and SMS are adequately aligned with the Risk Assessment and Emergency Response Plan drafted as a consequence of ISO 201519 where the same accident scenarios must be evaluated and the risk mitigation measures adequately outlined. | |||||

| SEVESO applicable (only Upper-Tier) Development and submission of a Safety Report | BFO | One of the distinct requirements for Higher Tier establishments is the production of a Safety Report, following the terms of Article 10 of Directive 2012/18/EU and covering all elements listed in its Annex II (Minimum data and information to be considered in the safety report referred to in Article 10). | |||

| For LNG bunkering projects for facilities falling under Seveso, ISO 20519 and ISO/TS 18683 represent a set of technical measures that should be incorporated in addition to the requirements established in the Seveso III Directive for the Safety Report and Emergency Plan, as applicable. | |||||

| In fact it is here important to note that the requirements for the Safety Report, as contained in Annex II of Directive 2012/18/EU are only providing a framework for the actual study to be developed and produced. | |||||

| SEVESO not-applicable For Non-Seveso, and also for Lower-Tier establishments, PAA to set requirements for Risk Assessment and Emergency Response Plan. | BFO (on PAA request) | PAA receives indication from the CA to detail the requirements for Risk Assessment and Emergency Response Plan. | |||

| The role of the PAA holds the overview of the multi-operator scenario in the port area and holds the external ERP. The involvement of the PAA in the setup of the essential framework for Risk Assessment and ERP is here an important good practice note. | |||||

| PAA should define the applicable Risk Criteria and minimum Hazard Scenarios to evaluate in the context of a Risk Assessment (with reference to ISO/TS 18683 and EN ISO 201519). | |||||

| Requirements should apply to both Non-Seveso and Seveso Lower-Tier establishment as the Risk Assessment and Emergency Response Plan are not required by the Seveso III Directive for lower tier establishment. | |||||

| Building Permit | BFO | Following positive conclusion of Environmental and Safety Permits, the Building Permit is the next step in the permitting process. | |||

| Not all LNG bunkering projects will have construction/ infrastructure elements or actual physical installations in the port area. This would be the case of LNG projects which involve mobile LNG units such as LNG trucks and barges. | |||||

| Submission of the relevant elements for the Building Permit can be made well in advance, even before the Safety or Environmental permits. This should allow land-use issues to be cleared as soon as possible, allowing the detail of any constructive elements to be discussed and further detailed to include any results from a risk assessment. | |||||

| 10 | Public Consultation | PAA | For SEVESO establishments Public consultation for all Lower-Tier and Upper-Tier, according to Article 15 of Seveso Directive, subject to national legislation on the matter. | ||

| For LNG bunkering projects, in particular for any small-scale LNG storage incorporating the need for specific land-use arrangement affecting the Public, PAAs may provide support to operators, making available all elements to support public consultations, including the support media for its launching. | |||||

| The integration of the Port with the local community and any existing channels of good synergies with local population should be here explored for public consultation. | |||||

| 11 | LNG Bunkering Permit Decision/Licensing | PAA to issue the permit for LNG bunkering within the port area based on the outcomes from: | EIA | ||

| SEVESO/Risk Assessment | |||||

| Building Permit | |||||

| Certification of any mobile units | |||||

| Public Consultation (if required) | |||||

| Permitting Decision from PAA will be based on the elements provided throughout the process. | |||||

| It is particularly important to ensure all elements derived from the Risk Assessment have been implemented in the detailed project. | |||||

| All project elements should be in preparation for the issuing of the permit. | |||||

| 12 | Appeal/Litigation | BFO | In the context of existing national legislation, operators should be given the opportunity to appeal. All information on procedures and channels to appeal should be made available. | ||

| 13 | Implement Project | BFO | |||

| Detailed Project | BFO | ||||

| External Emergency Plan | PAA and competent authorities | External Emergency Plan to be updated | |||

As indicated previously the General Permitting Process gives an indicative reference for the LNG bunkering permitting process. It is not intended to be used as a standard process. Different countries will have specific processes implemented which may, or may not, resemble the process in figure 2.

Fig. 2 LNG Bunkering – General Permitting Process

Elements for LNG Bunkering General Permit

Having the General Permitting Process (Section “General Permitting Process Map”) as reference, the present section outlines with more detail some of the elements featured in figure 2 and Table 1. The complete life-cycle of LNG bunkering projects is presented in “Life Cycle of LNG Bunkering Projects” below.

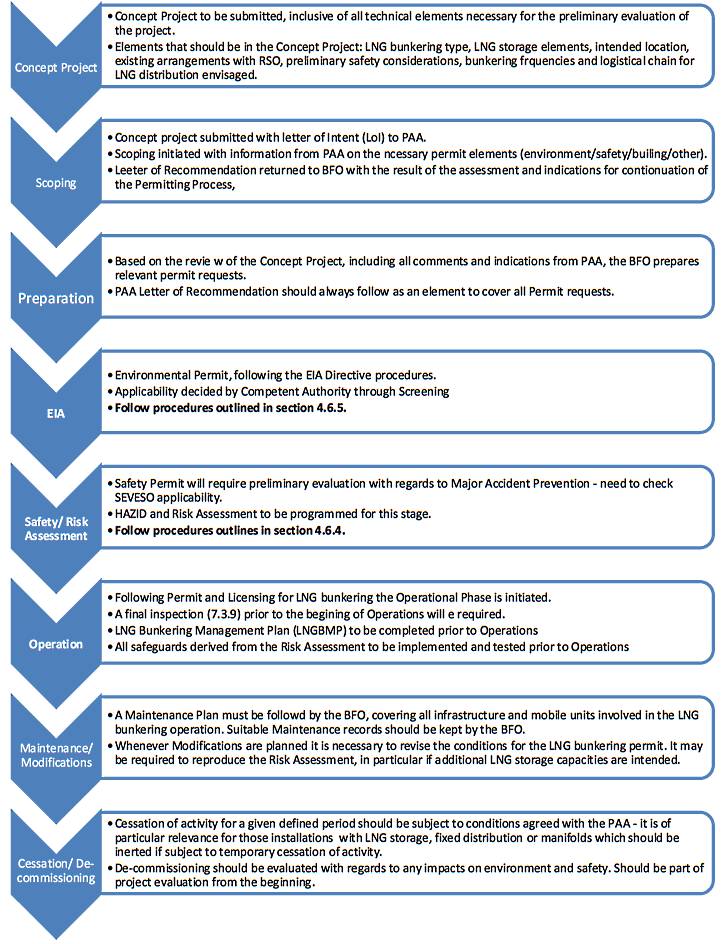

Life Cycle of LNG Bunkering Projects

Concept Project

The Concept Project should define all technical elements of the LNG bunkering project, including:

- LNG Storage elements, mobile units involved, fixed installation elements.

- Identification of stakeholders involved.

- LNG bunkering mode.

- Intended location for LNG bunkering.

- Logistical aspects: Loading of LNHG prior to bunkering, distribution, temporary storage.

- Frequency estimated for bunkering operations (including any possible agreement/contracts with RSOs).

- Intended range of operating parameters for LNG bunkering.

- LNG Vapour Management (BOG management).

- Onsite pipeline routing (if applicable).

- Required Staff Competencies / Envisaged Trainin.

- Preliminary Risk Assessment elements.

- Preliminary Nautical Risk/Suitability evaluation (pre-NRE).

- Indication in Port Map/Nautical Chart of the location, intended manoeuvring points, approach by sea, traffic routing, parking, bunkering are, hazardous zones, preliminary proposed safety zone.

The Concept Project will not yet include elements related to the Risk Assessment, unless this has been preliminarily conducted. It should however be sufficiently complete to provide the basis for the HAZID workshop.

Letter of Intent

Operators intending to develop a new LNG bunkering project, or operators planning to expand or modify existing Developing LNG Bunkering Facilities in Ports: Governance and Good PracticeLNG bunkering facilities and/or activities, where the construction, expansion, or modification would result in an increase in the size and/or frequency of LNG bunkering operations, should submit a Letter of Intent (LoI) to the PAA of the port in which the facility is or will be located. The LoI must meet the requirements in this section.

The BFO must submit the LoI to the PAA prior to the initiation of the Permitting process. It is suggested to consider sending the LoI to PAA at least 1 (one) year prior to the intended beginning of construction and. This should then encompass the whole General Permitting Process as described in the previous section.

An owner or operator intending to reactivate an inactive existing facility must submit an LoI that meets the requirements listed in this section, remarkably in terms of contents. In this case the BFO should submit the LoI at leat 6 (six) months prior to reactivation of existing LNG bunkering facility.

The LoI should contain all elements listed in the Concept Project, as outlined in “Concept Project”.

As indicated in “Concept Project” the LoI should include a preliminary Nautical Risk/Suitability Evaluation. This is especially relevant for the cases where waterborne LNG bunkering units are used (LNG bunker vessels/barges, platforms. Charts showing waterway channels and identifying commercial, industrial, environmentally sensitive, and residential areas in and adjacent to the waterway used by the LNG waterborne units, heading to/from the LNG bunkering location, within at least 10 km of the facility.

The pre-NRE, where an assessment of the port waterways suitability is made, should:

- Be submitted to the PAA as part of the Concept Project and LoI;

- and Provide an initial (as detailed as possible) explanation of the following:

- Port characterization;

- Characterization of the LNG bunkering facility, indicating in particular the routes intended for any waterborne LNG mobile units;

- Risk assessment for maritime safety and security;

- Risk management strategies;

- and Resource needs for maritime safety, security, and response.

The LoI should also include, as an appendix, a draft emergency response plan which should allow PAA to plan in advance the necessary integration of internal-external emergency plans (see article LNG Emergency, Preparedness & Response: Implementing a Robust Response Plan and OECD Guiding Principles“Emergency, Preparedness & Response”).

Letter of Recommendation

Based on the evaluation of the Letter of Intent, should the LNG bunkering project merit due consideration, PAAs should issue a Letter of Recommendation (LoR) commenting on the suitability of the location, both waterways and port infrastructure, to the competent authorities having jurisdiction for siting, construction, and operation, sending, at the same time, copy to the BFO, based on the:

1 Information submitted in the LoI;

2 Technical references provided in the Concept Project;

3 Density and character of marine traffic in the waterway;

4 Locks, bridges, or other waterway infrastructure elements;

5 Factors adjacent to the facility such as:

- Depths of the water;

- Tidal range;

- Protection from high seas;

- Natural hazards, including reefs, rocks, and sandbars;

- Underwater pipelines and cables;

- Distance of berthed vessel from the channel and the width of the channel;

6 Operational aspects related to Terminals operating within the port area;

7 Preliminary risk assessment aspects already included in the Concept Project/LoI.

8 Other safety and security issues identified.

EIA Screening

See article “EIA Directive” and “General Permitting Process Map” for EIA application. Screening should determine whether a given LNG bunkering project is subject to EIA provisions. Screening should be requested by BFOs to EIA Competent Authority well in advance to intended construction or initiation of LNG bunkering activities.

Seveso Notification

See Section “Seveso III Directive – Major Accident Prevention Directive” and “General Permitting Process Map” for SEVESO applicability.

It will be interesting: Balancing Cleaner Fuel and Environmental Impact in LNG Emissions

Following Notification should determine whether a given LNG bunkering project is subject to EIA provisions.

Screening should be requested by BFOs to EIA Competent Authority well in advance to intended construction or initiation of LNG bunkering activities.

Other Permits

PAAs should inform on any other relevant Permits that should be considered by Operators/BFO. It is important, in particular, to indicate the relevant Points of Contact for those Competent Authorities which are responsible for issuing the different permits.

LNG Bunkering General Permit

The LNG Bunkering General Permit should be issued in the end of the Permitting process, following the issuing of the Environmental, Safety and Building Permit (as applicable).

Source: Pixabay.com

The Permit, to be issued by PAA, should contain all relevant restrictions imposed at Port level and any other indications of technical, safety or operational nature, of the responsibility of the PAA.

The LNG Bunkering General Permit should be issued, in addition, upon the completeness of the following elements:

- LNG Bunkering Management Plan.

- Implementation of safeguards derived from Risk Assessment.

- Insurance and Liability guarantees (as applicable) Not covered in the present Guidance, subject to national requirements.x.

Inspections

A suitable inspection regime should be implemented by PAAs, preferably in conjunction with the relevant competent authorities at national level, to ensure that the conditions evaluated and verified during the permitting process are maintained and that the evaluated safety levels are kept throughout the life of the LNG bunkering project.

The Inspection regime should be designed at national level, reflecting the national and port requirements for LNG bunkering installations and activities. Inspections should be carried out by competent professionals, using check-lists developed for the specific inspections procedures implemented.

PAAs should ensure that, for any LNG bunkering project type, a suitable inspection regime is implemented where the characteristics verified and approved during the permitting process can now be verified in and after implementation.

Read also: LNG (Liquefied Natural Gas) as Fuel

The present Guidance does not specify a detailed inspection regime as this should, in principle, be subject to the definition by different competent authorities. PAAs are, ultimately, the one interested in the guarantee that the Resource Reserve Estimate in LNG Project Development PhasesLNG bunkering project is not implemented or activities initiated without having the necessary programmed inspections carried out.

Not all LNG bunkering projects will include constructive elements. LNG trucks and LNG barges/vessels are an example of LNG bunkering mobile units which will not directly imply infrastructure at the bunkering location. In this case, inspections should focus on operational aspects and equipment certification.

General information about inspections

Before starting to use a new bunkering installation and following alterations and repairs, an inspection (final inspection) should always be carried out to ensure that the installation is fit for purpose and safe.

Installations should be inspected periodically during the operational phase to ensure that the technical conditions remain satisfactory (a systematic condition inspection).

Source: AI generated image

The person carrying out the inspection should have the required competence according to article LNG Bunkering Training Matrix: Competence Alignment Across Maritime and Port Operations“Qualification & Training”. As a rule, someone should not carry out an inspection of their own work, nor should this be carried out by any company related in any way to the BFO activity. Conflict of Interest declarations may be considered in this regard.

An inspection report should be prepared, documenting what was inspected, how it was inspected and the result of the inspection. The report should be clear and provide an assessment of the results/deviations, so that the owner/user is able to assess which measures must/ought to be initiated.

An inspection before starting to use the installation (final inspection) and a systematic condition inspection of installations should be done by an independent inspector. An independent inspector means, in this context, a technical inspection body, user inspectorate or an accredited inspection body.

Accredited inspection bodies that are used must be accredited for inspection of such installations.

Inspection Prior to Installation

A construction inspection should ensure that drawings, specifications, etc. that form the basis of the construction of the installations are in accordance with the body of rules, standards and the relevant specifications and descriptions.

A receiving inspection of Accidents Involving LNG and LPG Storage Tanksstorage tanks, components, pipes and other equipment should be done.

Prior to putting down the pipeline system and equipment that should be covered, they should be inspected to ensure that they are not damaged and that the corrosion protection is intact. The inspection should be documented with photos with sufficient resolution so that all relevant details can be verified.

An inspection of the work and associated documentation must be carried out. This will, among other things, apply to risk assessments, drawings, the location of main components, distance requirements, descriptions, procedures and qualification requirements for the specialist personnel, as well as fitting guidelines.

Inspection during installation

Inspections during installation shall ensure that the work is done in accordance with the work and associated documentation.

Deviations uncovered during installation in relation to existing provisions and the planned construction of the installations should be rectified before starting to use the installations. Anyone involved in the installation is responsible for this and is subject to the regulations on the handling of hazardous substances.

A non-destructive essay (NDE) program should be implemented to verify, amongst other things, the quality of welding in pressure equipment and pipe welded joints.

Inspection following installation (final inspection)

Before LNG is brought into the installations, a final inspection should be done to ensure that the equipment and installations have been fitted and assembled in relation to permits, the body of rules and norms and specifications. A final inspection should ensure that the fitting and assembly documentation is updated in relation to any alterations that occur during construction. A final inspection should also be done after repairs and alterations to the installations.

Pressure testing and leakage testing of the entire installations should also be done. Pipeline systems that will be concealed should be pressure tested and leak tested before they are covered or encased. The entire length of pipeline that will be pressure and leak tested should be accessible for the inspection.

It will be interesting: LNG IMO Tanks/Containment Systems

Pressure testing and leakage testing should be done according to recognised standards, written procedures and set acceptance criteria for testing. Regarding the selection of a test pressure medium, please see the pressure equipment regulations. For leakage testing, all connections should also be visually inspected for leaks.

In cases where pressure testing of storage tanks, devices, pipeline systems and standard equipment has already been done in accordance with the requirements of the pressure Gas Tanker Equipment and Instrumentationequipment regulations, these should be accepted.

A functional inspection should ensure that the equipment and installations work as specified in the design documentation. Safety valves should be tested within three months of starting to use the installations.

A functional check of inspection, control and securing devices, valves, regulators, etc. should be done. Where such a functional check has already been done in accordance with the requirements of the pressure equipment regulations, for example as part of a conformity assessment again in accordance with the requirements of the pressure equipment regulations, this should be accepted.

A final inspection of individual bunkering installations should be done by an independent inspector. For serious safety deviations, the inspector shall send a copy of the inspection report to the relevant supervisory authority.

The same above shall apply to LNG bunkering projects involving bunker vessels/barges or LNG trucks. A rehearsed LNG bunkering operation should be performed for the purpose of a Final Inspection. During this inspection all the procedures in the LNGBMP should be checked. Leakage tests of the bunkering lines should be performed with real operating conditions.

Systematic Condition Inspections

To ensure that the technical conditions of installations and equipment remain satisfactory, in addition to ordinary maintenance, owners and users must ensure that a systematic condition inspection is done according to the set plan. A systematic condition inspection is thus an in-depth safety inspection of the installations that is done in addition to any service or regular maintenance.

The scope and frequency of the systematic condition inspection must be adapted to the operating conditions and risk potential for installations and equipment and any experience of similar equipment to ensure that satisfactory operating safety and protection against undesirable incidents are maintained.

Systematic condition inspection should preferably be done by an independent inspector. There should be a written plan for all inspections activities (frequency and scope) as well as written procedures for how the inspections should be done. Where several contractors are involved, individual areas of responsibility should be clearly defined.

Read also: The Role of LNG Bunkering Infrastructure

A systematic condition inspection of bunkering installations should be done at least every five years. The scope and recommended inspection interval can be adjusted in relation to the operating conditions, surroundings and operating experience, etc. of the installations and equipment.

Inspection and safety functions that have major safety implications should be inspected and tested in accordance with established procedures in accordance with the test programme that the enterprise has prepared. Standard EN IEC 61508 can be used to establish an inspection interval; see also Part 2, Chapter 7.6 of the standard. However, such inspections should be done at least every two years. Valves that have important safety functions should be tested in accordance with established procedures and the prepared testing programme.

If safety valves are removed for testing during operation, the remaining valves should be able to withstand depressurisation. An alternative to inspection and testing will be replacement. For serious or repeated safety deviations, the inspector should send a copy of the inspection report to the relevant supervisory authority.

Operation

Safety deviations uncovered during operation must be rectified immediately. If necessary, use of the installations and equipment must cease until the deviations have been satisfactorily rectified.

There should be operating and maintenance instructions that are adapted to operating conditions for the installations and equipment. The instructions must also include abnormal operating situations. All these operating and maintenance instructions should be included in the LNGBMP, subject to approval by the PAA.

Safety and operating instructions should be in a convenient language suitable to the understanding of all BFO and third-party staff. An emergency preparedness and response plan with associated procedures should also be prepared.

All instructions and plans should be regularly updated including for any alterations. Operating personnel (including bunkering operators) should have had training in regard to the installations and the specific operations with LNG and Inert Gas bunkering installations. They should be familiar with existing instructions, relevant user manuals and recognised norms that form the basis of operation and maintenance of the installations.

For installations where LNG is stored between bunkering but is not serviced between bunkering, an agreement with competent personnel who can quickly handle abnormal operating situations should be established.

Maintenance

The owner or user must ensure that maintenance of the installations, mobile units and equipment is carried out to ensure a continued high safety level.

Maintenance must be carried out by personnel who have the required technical competence and experience and are familiar with relevant methods of systematic maintenance. If the owner or user themselves do not have the required competence for carrying out maintenance, such competence must be obtained. Maintenance should be carried out according to the manufacturer’s instructions. Using checklists that specify checkpoints and intervals will make the work easier and clearer. Maintenance should be documented.

Modifications/Retrofitting

All intended modifications/retrofitting of the LNG bunkering facilities or operations should be subject to a renewal of the permitting. A new Letter of Intent (LoI) should be sent by the BFO to the PAA, containing all relevant modification/retrofit concept project elements.

For all purposes, a concept project for modification/retrofitting should follow all the steps as indicated in the General Permitting Process. Modification may have a significant impact in risk and therefore, safety and environmental impact should be assessed by the relevant competent authorities.

Temporary Cessation

The BFO should ensure that installations that are no longer in use are removed or properly secured to avoid unintentional use, or possibly maintained as if they were in normal operation. Before starting to use the installations again, a new systematic condition inspection must be done.

On those cases where fixed installation elements are present it should be guaranteed that a specific procedure for inerting of all installations is followed.

De-Commissioning

De-commissioning should be evaluated with regards to any impacts on Health, Environment and Safety Management for LNG Transportenvironment and safety. Should be part of project evaluation from the beginning of the permitting process, in the early stages of project evaluation.

As part of a life-cycle approach for LNG bunkering project developments it is important to take de-commissioning into account, especially with regards to end-of-life aspects for equipment, systems and installations.

Measures for Time-Effective Permitting

A “Good practice” Permitting process is something that is very difficult to suggest. The present Guidance proposes instead a General Permitting Process without calling it a “good practice” especially due to the fact that different countries will have different distribution of competencies amongst different national authorities.

Instead of “good practice” the present section lists relevant elements which are likely to improve the time-efficiency of permitting processes. The elements listed are, in principle, applicable to projects other than LNG bunkering. In the context of the present Guidance focus is however given to LNG bunkering.

It will be interesting: Loading Arms (Hard-Arms) – Specifications, Operation, and Maintenance

The length of LNG bunkering permitting processes has, in fact, been one of the main points indicated by Operators as being demotivating for new developments. Even if it can be taken into account that LNG bunkering is still taking early developing steps, with an ongoing learning curve to all stakeholders involve, it is still possible to suggest measures for process efficiency which may even be derived from permitting experience with.

Table 2 includes 6 (six) measures that will very likely have a direct potential reflection in efficiency of the permitting process. The different measures have already, to some extent, been experimented in different countries with significant advantages for the permitting process efficiencies.

| Table 2. Seven Measures for Time-Efficient Permitting | |||

|---|---|---|---|

| Measure | Description | ||

| 1 | Build Mutual Understanding | PAAs may find ways to break down communication barriers and build understanding between local permitting departments, applicants, consultants, related local and state agencies, elected leaders, and the general public. Building mutual understanding of land development permitting and the construction and inspection processes levels the playing field. Mutual understanding tends to create more open communication which allows participants to discover or explore opportunities for improving the process together. The result, overall, is a more predictable and efficient permit review process. | |

| 3 (three) approaches are possible: | Technical Forum/Seminars for industry and permitting departments to get to know each other and better understand each other’s requirements and objectives. | ||

| Training for Permitting Staff, including all competent authorities, preferably coordinated by PAAs | |||

| Common Platform for technical information, where all stakeholders may access relevant elements and information relevant for a levelling of understanding between all stakeholders involved. | |||

| 2 | Develop Single-Desk/ Single-Permit | In trying to introduce measures for the efficiency of LNG bunkering permitting processes it is a possible option to develop a Single-Desk/Single-Permit approach consisting of a set of different Administrative procedures to encapsulate the different permits applicable to one project. On either definition, for “single-desk” or “single-permit” the objective is to ensure that Operators/BFO would only need to approach PAAs and the relevant competent authorities through a simplified procedure. The routing of the permitting application would follow the path towards the different competent authorities through designated mapped flow of information, designed for best efficiency. PAAs could provide the physical point of entry for all applications, in a single-desk approach, providing, in addition, mediation throughout the whole process and allowing the best understanding between all parties involved. | |

| 3 | Engage All Reviewers and Stakeholders Early | Early engagement provides reviewers an opportunity to see what the applicant proposes, discuss requirements that would influence project design, and discuss options for avoiding and minimizing adverse impacts. For LNG bunkering projects a pre-application meeting is recommended. Some jurisdictions require pre-application meetings. Promote early engagement of all parties for preliminary meeting. To be effective pre-application conferences must clarify all application information requirements and detail the process (including timelines) through which the application, once submitted will be reviewed and acted upon. Contact persons must be identified and their contact information provided. Project proponents must be warned of potential red flags and the persons/agencies to contact for working out problems. It may be noted here that in order for a pre-application meeting to provide the information described above, an applicant must submit detailed information about the proposed site, initial project objectives, and at least a start on project design. | |

| 4 | Ensure Complete Applications | PAAs, working as facilitators for a prospective LNG bunkering project, should define what constitutes a complete application for LNG bunkering projects and verify that all elements have been included with each application at the time of submittal. A useful format for conveying these requirements is through a reception check-list. The check-list should indicate what must be presented at submittal for different types of LNG bunkering projects (from TTS proposal to PTS, involving onsite LNG storage and distribution). A good reception check-list identifies the information that staff need for conclusive review. The specific items vary based on the type of permit and the characteristics of the local jurisdiction. Only complete applications should be accepted. Incomplete applications should not be accepted, with all outstanding elements or deficiencies explained at the reception meeting. | |

| 5 | Analyse Process, Performance, and Costs | Another measure to promote time-effective permitting processes would be to analyse permitting procedures, performance, and costs of service. Analysis of the process and performance trends reveals and allows prioritization of opportunities for improved predictability, efficiency, speed, and collaboration. When the whole process is visible, inefficiencies become better revealed. Permitting, for a variety of projects other than LNG bunkering, uses a variety of methods and models for process mapping. The most successful models reach to a very detailed level of analysis and provide information about who carries out each task, how much actual work time is required for the task, and how much total time or work-time is associated with the task. When one task cannot be completed until another task is started or completed, these dependencies are indicated and may also be mapped. | |

| The analysis should include an assessment of what options exist for changing or removing constraints as well as eliminating, consolidating, or rearranging tasks in the process. | 1. Build detailed flowchart “process models“ of your existing process. | ||

| 2. Include measurements of work time, wait time, and overall performance. | |||

| 3. Analyse the results, looking carefully at low value and/or high wait time tasks; also identifying constraints such as staff availability or required notice and appeal periods. | |||

| 4. Develop change recommendations that respond to opportunities identified in the process maps and account for local circumstances and priorities. | |||

| 5. Implement changes and measure results. | |||

| Process mapping should be done by a team with direct experience in all aspects of the review process directly related to LNG bunkering projects. All participants in the review process should have an opportunity to contribute to development of the map. This investment in time improves the accuracy of the flowcharts, reveals variations in the ways particular reviewers approach the same review, and eases implementation and changes because the reasons for change become apparent to participants in the review process. Initially, it is important to map how the actual process flows, not how you want or think it ought to work. PAAs should mediate/facilitate the production of process maps, including the participation of all different competent authorities involved in the permitting decision. | |||

| For Performance Analysis, once process mapping is concluded, it is suggested to develop performance indicators to measure the efficiency of the mapped permitting process. Amongst these indicators it is possible to outline a few: | 1. Total calendar days to reach a decision on LNG bunkering projects. | ||

| 2. Number or percent of days when the application is on hold awaiting new information from the applicant, and conversely, number of days of the total when the jurisdiction is on the “clock“. | |||

| 3. The number of comment or correction cycles necessary to correct deficient applications. | |||

| 4. Response times or cycle times for first reviews, second reviews, and so-on. | |||

| 5. Backlog of pending applications and inspections by type of permit or decision. | |||

| In developing options or recommendations for change, the process maps and measurements link to a local jurisdiction’s overall goals. These goals may be specifically focused on improving permit turnaround time or may seek to improve customer experiences by clarifying application requirements or improving response times to telephone or email inquiries. | |||

| 6 | Use Information Technology | Use technology such as electronic permit tracking systems, geographic information systems (GIS), and the interconnection of these systems online to improve communication, reduce paperwork and build easily accessible project record. Make the best use of computers and information technology (IT). These tools are helping many jurisdictions and applicants operate more efficiently and provide better service. The uses of information technology range from in-house electronic permit tracking systems to online access for the general public to a range of permit records and reports, to social networking sites or blogs to keep stakeholders updated on project status. Online access to departmental forms, codes and standards is also a possibility, as well as online maps and aerial photos. An increasing number of competent authorities use workflow or project management software, as well as wireless or remote access to department records and systems for field inspectors and other staff. A few other authorities accept and review certain types of applications on-line. These have largely been limited to simpler engineering permits, along with very simple or standard building permit plans, but interest is growing in online submittal and review based on applicant and agency time savings and other customer service benefits. Electronic permit tracking systems could be a relevant approach to develop adequate information to applicants on the status of the permitting process. They provide a real-time tool for reviewers and inspectors to enter their findings, archive supporting documents, and indicate when they are waiting for additional information. Current web design tools make it easy to put these references into an applicant’s hands miles away from the permit counter. Some jurisdictions substitute on-demand printing for traditional inventories of lobby forms. Online files can allow applicants to complete forms with their computers, producing a cleaner result that is easier for everyone to understand. In some cases, they also have an electronic record of their completed application form. Many authorities (municipalities, port authorities and others) also provide online access to their in-house geographic information system (GIS). GIS provides applicants a preliminary indication of the environmental, land use, and other considerations a development project needs to consider. This reduces surprise during permit review and increases efficiency when the project designs incorporate these considerations at the beginning. This approach can be particularly beneficial for countries where LNG bunkering would fall into multiple departments involved in the permitting process. Managing and financing IT systems at an enterprise level does not happen overnight and requires a significant leadership commitment from all institutional stakeholders. | |

Bringing different stakeholders together, in particular different competent authorities may be one of the most challenging tasks. PAAs have here a remarkable opportunity to act as facilitators and provide the common ground for LNG bunkering projects to develop in a collaborative environment.

The measures proposed, as part of this Section, can be implemented partially or in a combination. To measure how efficiency has been improved by their implementation it is important to develop and adopt specific performance indicators (such as overall waiting time between reception of the permit request and conclusion of the process).