The present Section highlights the role of Port Authorities and Administrations in the context of LNG bunkering, throughout the entire life-cycle of these projects, from concept to development and actual implementation, as differentiated Port Services.

- LNG bunkering for Ports

- LNG small scale and bunkering scenarios

- Ports Good Governance for LNG Bunkering

- Port Authorities and Port Administrations

- Definitions

- Port Roles and Responsibilities in LNG Bunkering

- Spatial Planning

- The Role of Ports in the development of LNG bunkering facilities

- Landlord function

- Regulator function

- Operator function

- Community manager function

- Ports Good Practice approach for LNG bunkering

- LNG bunkering for Ports – Good Practice for Transparency

- Good Practice in the evaluation of LNG small scale and bunkering scenarios

- Ports Good Governance for LNG Bunkering

- Port Roles and Responsibilities in LNG Bunkering

- The Role of Ports in the in Developing of LNG Bunkering Facilities

How to incorporate LNG as fuel, and in particular LNG bunkering, into the different management policies for PAAs, is a fundamental aspect for the incentive and development of LNG bunkering. On a different formulation it is furthermore important to adapt management principles, policies and strategies to support the development of LNG bunkering projects.

The following aspects are covered in the present Section:

- Different LNG bunkering scenarios (in the context of existing Port activities).

- Good Governance and the role of port authorities in the development of LNG as a ship fuel, with a reference to the different implications of LNG bunkering for Ports managerial practice.

- Directive 2014/94 on the deployment of an alternative fuel infrastructure implementation.

- Suggested Best Practice for PAAs in the context of LNG bunkering development as a differentiated Port Service.

The present section does not prescribe any elements for port management, nor is it intended to qualify governance models and ownership structures. Diversity is an important feature of the European port system, with no two ports operating in exactly the same way. The present Guidance, in line with European Port Policy

COM(2013) 295 – Ports: An Engine for Growth.x respects that diversity and does not seek even to suggest a uniform model for ports.

LNG bunkering for Ports

The diagram in Figure 1, below presents the interaction areas between PAAs, LNG bunkering supply organizations and costumer LNG fuelled ships.

Ports are today characterized by fast-developing multi-operator environments, evolving increasingly to corporatized and highly specialized service portfolio, where LNG bunkering is now becoming a relevant addition.

Figure 1 identifies the general areas of interaction between the 3 (three) main stakeholders in the LNG bunkering service development and implementation. The areas of interaction are not mutually exclusive but, instead, they complement each other in the implementation of LNG bunkering projects and sustainable services. The following three-partite generic arrangement can be identified (some variations may occur in the context of different port management and organization models):

- LNG bunkering supply organization (other organizations can be involved or directly related, such as the gas supplier, liquefaction or storage services, transport and distribution. Cooling, inerting, or even gas recycling can be also provided by other parties).

- Port Authority & Administration (Port Authority and Port Administration can be the same or different entities – see section “Ports Good Governance for LNG Bunkering” below).

- Costumer LNG Fuelled Ship (representing ultimately the demand side for LNG bunkering)

The 3 parties have, different interests and their inter-relations are characterized by different levels of communications and potential partnerships. Safety is expressed as an objective by all parties, but how much commitment to safety must be defined in clear regulations. Also on the subject of Safety it is furthermore important to establish measures of acceptability but also of credibility and independency. If Risk Criteria is used to define an “acceptable level” of risk, other criteria could be used to ascertain credibility and independency of risk evaluation results. This example for Safety is relevant also for other aspects of the LNG bunkering, such as compatibility assessment and other. To help identifying the relevance of “independency“, figure 2 below, based in the diagram of 1, highlights the important separation vectors that must be observes to directly ascertain the adequate level of independency in LNG bunkering.

On the basis of the above, a fundamental principle that should govern the inter-relationship vectors in LNG bunkering is the one of “Transparency“. The distances “A“, “B” and “C” should always be observed, in the best interest of “Transparency“. In this sense, and following the same approach, whenever one of the distances could not be observed a potential conflict of interests could be claimed.

Figure 3, below presents a particular case where the LNG Bunkering Supply is totally or part-owned by the PAA. The absence of distance “A” leads to the potential conflict of interest situation when the Port Regulator function may be affected resulting in a less than ideal scenario that can affect transparency in the LNG bunkering process.

The situation below represents a case where BFO and RSO are the same company.

Situations like those presented in 3 and 4 are very specific in nature and, of course they do not immediately translate a situation where a conflict of interests could inherently result in a compromise, for instance, in safety. They represent however an illustration of the importance to keep the triangular formulation in LNG bunkering as an indicator (or measure) of transparency on the process.

Growing towards complex hubs in a multi-operator context, with management and organizational systems which differ significantly from port to port, PAAs should give a particular relevance to the need to ensure transparency in processes, with the involvement of the wider stakeholders’ community inside and in interaction with the port.

Examples of processes where transparency is a fundamental pillar in LNG bunkering:

- Vessel compatibility Assessment.

- Risk Assessment (whenever performed to ascertain ALARP Risk levels).

- Permitting.

- Simultaneous Operations.

- Safety Distances.

When deciding or intervening on any of the above aspects BFO, RSO and PAA will interact within a specific regulatory frame (see article “LNG Regulatory FrameworkLNG Regulatory Framework International and European Maritime Safety Overview“) which can only be enforced to an adequate level if the processes are conducted with the necessary independency.

Compliance with EN ISO 20519, as introduced in article “Regulatory Frame Best Practice – Applicability in the Bunkering Interface“, declared and inscribed as an objective within an appropriate Safety/Quality Management System should be the basis for the minimum requirement advisable as best practice. Enforcement is made easier through the provision of adequate “external audits” by a competent authority, whilst allowing planning and continuous development of processes by the Operators.

LNG small scale and bunkering scenarios

The above is even more relevant if we take into account the wide variety of Port activities that can involve LNG bunkering or, on a more widely scoped approach, small scale LNG applications and developments within the wider port area. Figure 5, below, and table 1 feature some of the possible LNG bunkering activities that may take part in a port, highlighting the need for good governance.

| Table 1. LNG bunkering Activities in the wider port area (legend to Figure 5) – LNG bunkering situations are indicated with (LNG bunkering). Other situations are also described that do not fall within the context of LNG Bunkering but contribute to complete the small scale LNG frame within the port area. Even though the present Guidance is focused on LNG Bunkering, other small scale LNG elements within the port also need to be considered as, to some extent, they will be part of the LNG bunkering chain in the port area | |||

|---|---|---|---|

| ID | Generic Port configuration (Figure 2) | LNG bunkering mode/ observations/ business model | |

| A | Large LNG terminal, break bulk terminal | Import, export, gas to the grid, loading of LNG tank trucks, LNG tankers and LNG bunker vessels | LNG Terminals are fundamental in the feasibility evaluation of LNG bunkering projects. The proximity of an LNG terminal may represent a good indicator to the LNG bunkering potential for a given port. Should the Terminal be located within the port area it is important to take into account the wide variety of LNG break-bulk services that are also possible (e. g. LNG truck loading, bunker barge/vessel loading, re-gasification, etc.) |

| B | Maritime traffic | Including inland – and seagoing LNG tankers, LNG bunker vessels, LNG fuelled inland vessels and LNG fuelled seagoing vessels | Considerations on maritime traffic within the port basins, canals and navigable waters, should take into account the possible traffic of LNG fuelled vessels and LNG bunkering barges/vessels. Control, or potential restrictions, over maritime traffic, during bunkering operations, should be responsibility of the PAA. Adequate measures to control maritime traffic should be put in place. |

| C | Inland vessel bunkering from a tank truck (LNG bunkering) | LNG tank truck, bunkering of a LNG fuelled inland vessel or port service vessel | LNG bunkering by truck is typically associated to low flow-rates and low volume capacities. Smaller LNG fuelled vessels, such as inland vessels, with reduced LNG fuel storage capacities, will still be typical demand for LNG bunkering by TTS mode. |

| D | Seagoing vessel bunkering with a large bunker vessel (LNG bunkering) | Ship to ship LNG bunkering of large container ships or large crude oil carriers with a large LNG bunker vessel | In “D” the particular situation of a large containership being bunkered by an LNG bunker vessel is represented. This offers an interesting view on how large LNG fuelled containerships, in particular, will most likely receive LNG fuel. On one hand LNG bunker vessels will be able to deliver higher transfer rates and capacities. On the other hand, bunkering from the side opposite to the quay will favour potential SIMOPS, with the LNG being bunkered from the opposite side to the cranes operating, loading on/off. |

| E | Large seagoing vessel bunkering from the shore (LNG bunkering) | Shore bunkering of large container ships or large crude oil carriers from a local LNG buffer storage | Bunkering from shore, or the so designated PTS mode, will inherently involve fixed storage of larger LNG quantities, a distribution system with some way of fixed LNG pipeline and a fixed bunkering location with manifold or mechanical bunkering arm. Fixed bunkering locations represent high throughput solution at the cost of losing some flexibility. |

| F | Lay by berth for inland LNG (bunker) tankers | One cone berth for waiting inland LNG tankers | Location for LNG bunker vessels to berth whilst waiting for bunker delivery service. This can either be a designated lay-by position or coincident with the loading berth, where the LNG bunker vessel loads LNG. |

| G | Port service/ maintenance/repair for LNG fuelled ships | LNG-cryogenic maintenance, repairs on LNG tankers or LNG fuelled ships, cooling and de-gassing of LNG installations etc. | A large variety of maintenance/repair works are typically needed on board ships, both for corrective or planned maintenance purposes. LNG fuelled ships are not different in this regard. Maintenance needs may be directly related or not with LNG fuel systems onboard. It is important that any permits for work within the port are subject to a specific procedure and that all relevant details for the works are given to the PAA. It is important here to distinguish between 1) Maintenance/repair conducted in designated shipyards or 2) in normal berthing location. Both cases should be regarded separately, with different considerations to be made. |

| H | Lay by berth for LNG fuelled ships | Lay by location | Lay by berth for LNG fuelled vessels should, in principle, deserve attention with regards to possible exposure to passing maritime traffic. |

| I | Bunkering from a bunker pontoon (LNG bunkering) | LNG bunkering from a bunker pontoon of inland LNG fuelled vessels, small seagoing LNG fuelled vessels, LNG fuelled port service vessels | LNG bunkering from a bunkering pontoon may seem, at first, a PTS bunkering mode. Careful attention should however be given to the fact that the pontoon may be considered a mobile unit, with implications to the applicable regulatory frame. The good practice approach advised in the current Guidance is to consider the LNG bunkering pontoon as semi-fixed infrastructure, to be considered within the adequate regulatory scope regarding major accident prevention. It is advised to evaluate the location where the LNG bunkering pontoon is moored as a potential Seveso establishment, taking the storage capacity of the LNG bunkering pontoon as the main indicative criteria for the classification of the location. Major accident prevention with regards to floating structures, such as pontoons, should lead to considerations that are likely to affect the adjacent port are surrounding the mooring location.x |

| J | Ship to Ship (STS) LNG transfer | LNG transfer between seagoing LNG tanker, floating storage, Inland LNG tankers and LNG bunker vessels | The example in “J” represents a ship undertaking LNG bunkering whilst moored inside the port basin area. This STS arrangement can be achieved within the port area, in protected waters, as long as the maritime traffic is not impaired and due consideration has been given to navigational/collision risk. This should typically be a restricted possibility to authorized anchorages. |

| K | STS LNG bunkering of an inland LNG fuelled vessel (LNG bunkering) | LNG bunkering of an inland LNG fuelled vessel with a small LNG (inland) bunker vessel | STS bunkering of an inland LNG fuelled vessel, with a small LNG inland bunker vessel represents the situation where none of the vessels has to be a SOLAS vessel and, therefore, to which the IGF Code does not apply as a mandatory requirement. It is nevertheless important to assess the certification of such vessels according to their respective regulatory frame, with due consideration for the need to have these vessels certified, at least for bunkering of LNG fuel, with requirements that are at least equivalent to those of the IGF. Adequate compatibility to be assessed. |

| L | Distribution of LNG tank containers | Container vessel loading of LNG tank containers for distribution | Loading on/off of LNG containers is, in all aspects, a cargo handling operation. The important aspect to consider is the potential implication for the classification of the location in the port with regards to major accident prevention. LNG containers holding time is limited, therefore special consideration needs to be made with regards to the waiting times for such containers in the port area. |

| M | Sailing STS LNG bunkering (LNG bunkering) | LNG bunkering of an inland LNG fuelled vessel with a small LNG (inland) bunker vessel during sailing | Again, as in situation “K” this represents a case where none of the vessels has to be SOLAS. Similar concerns with regards to IGF equivalent requirements are to be made. Regarding the LNG bunkering operation itself, STS during sailing, within the port basin, it is at least possible to mention that very careful consideration needs to be made especially with regards to the need for careful collision risk analysis, accounting in particular for the local traffic conditions. |

| N | STS LNG bunkering of a Short Sea / Feeder vessel (LNG bunkering) | LNG bunkering of a LNG fuelled short sea / feeder vessel with a small LNG (inland) bunker vessel | Similarly to “D” the situation here represented highlights the favourable aspect of STS as an LNG bunkering mode with the potential to allow for SIMOPS, with a feeder container vessels loading/offloading containers whilst bunkering from the outside. It is, of course, purely representative, and SIMOPs should follow a specific procedure, potentially based on a dedicated risk assessment. The operational advantage of SIMOPs is however, especially for containerships with very limited turn-around times at port, a very important aspect that PAAs should be sensible to. |

| O | Loading of a local LNG (buffer) storage | LNG transfer from a LNG tanker to a local LNG storage or bunker pontoon | Not an LNG bunkering operation. The represented situation, in the context presented, is more related to LNG break-bulk cargo operation. The relevance of the presented case is however directly related to the LNG small scale infrastructure within the port area. LNG storage onsite (local LNG (buffer) storage) is an important element of the fixed LNG bunkering solution (PTS LNG bunkering mode). |

| P | Ferry or Ro/Ro bunkering (LNG bunkering) | LNG bunkering from the shore, with an LNG tank truck or STS from a small bunker barge | RO-PAX is another typical example of ships with very limited turn-around times in port. For this reason SIMOPs are very important, with the potential need for LNG bunkering whilst passenger embarkation/disembarkation or vehicle roll-on/off is taking place. Typically location for RO-PAX operation is fixed in the port and, therefore, it is possible to implement dedicated mitigation measures to allow for SIMOPS to be potentially considered (e. g. enclosed passenger gangway). Management of vehicle flow is very important to avoid congestion traffic in the way of potential LNG trucks on site. |

| Q | Ro-Ro ship re-fuelling by tank container (LNG bunkering) | Unloading (empty) and loading trailers with LNG tank container for the ship propulsion | The case presented in “Q” is the particular case were LNG fuel is bunkering in a special containerized unit mode, with the LNG containers embarking via vehicle ramp to be plugged-in onboard. Specific requirements for the use of containerized LNG ISO units are present on the IGF Code. Aspects related to the control of access to LNG trucks are however to be dealt with by PAAs. As an opposite observation to the case represented in “P“, in this particular situation the important point to make is that roll on-off of vehicle cargo movement should be restricted during onboard containerized bunkering, unless very specific mitigation safeguards are in place. |

| R | Container ship re-fuelling by tank container (LNG bunkering) | Unloading (empty) and loading LNG containers for the ship propulsion | The situation represented in this case is different from the one presented in “L“. The case now presented is a special LNG bunkering operation, using LNG ISO containerized units. In this case containers are loaded-on from the shore using a crane and plugged-in onboard. Similar concerns for the waiting of LNG containers ashore can be mentioned. Holding time for LNG in the container is limited and due consideration to that fact should be given by PAAs whenever authorizing this type of LNG bunkering to take place within the port area. |

| S | LNG bunkering of a cruise vessel | LNG bunkering of a Cruise Ship with a tank truck or LNG bunker vessel | LNG bunkering for a large cruise ship will have to take, again, as in previous cases presented in “D” and “P” to take into consideration the short turn-around times for such ships. In addition to this the very likely large number of passengers onboard will add another important factor to take into consideration. The risk assessment for any potential LNG bunkering with embarkation/ disembarkation of passengers will have to take these factors into consideration. Replenishment of goods, short port maintenance services amongst others, are typical services that concur during the short stay of cruise ships in a given port. It is very important that PAAs have in consideration the need to coordinate any LNG bunkering operation in the context of multi-operator scenario. |

| T | Floating Storage Unit | Floating Storage Unit (FSU) for the storage of LNG away from shore berthing position. For buffer storage and/or LNG bunkering. | The use of FSU solutions for LNG bunkering is a possible option within the port area. Aspects related to the following aspects need to be carefully observed: 1) Regulatory frame It is important to determine which regulatory frame best applies to this specific case. MODU or IGC Code would not be mandatory in case of inland FSU. Requirements can however be used to assess certification as good practice. 2) Major accident prevention Applicability of major accident prevention measures will depend on elements such as LNG storage capacity of the FSU and its location. Even if this is, in practice, a floating unit, it should be assessed with regards to possible impact on port area location. 3) Risk Assessment Aspects related to LNG FSU unit, its location and intended bunkering operation profiles should be subject to risk assessment under agreed conditions by all parties. Aspects related to the Risk Assessment need to take into consideration assumptions It is very important to define the anchoring location for the FSU taking into account collision risk analysis and the particular maritime traffic profile in the area. |

| U | Bunkering (commissioning) at a dock yard (LNG bunkering) | Following planned repair period, at a dock yard, the first filling of the LNG storage tanks onboard requires special attention. | Commissioning of LNG storage tanks will require inerting and cooling services to be provided. The first filling of the tanks involves a complex procedure where it needs to be guaranteed that no air is present in the LNG tanks for the loading of LNG fuel (inerting) and that the tanks are sufficiently cool to avoid excessive boil-off (cooling). |

| V | Multi-truck bunkering (LNG bunkering) | TTS bunkering mode where several LNG trucks bunker an LNG fuelled vessel through a common manifold. | The situation represented in “V” offers a view of a possible variation from the TTS LNG bunkering mode where several LNG trucks are used to bunker an LNG fuelled vessel. The number of LNG trucks is only limited by the number of plug-in connection in the manifold structure and, in practice the LNG bunkering capacity and possible flow rate will depend on the exact manifold arrangement. The multi-truck bunkering solution should deserve careful consideration from PAAs, especially in terms of bunkering procedures, including inerting of the manifold connections, piping and hoses and considerations for connection/disconnection of successive trucks onto the manifold. |

| W | LNG fuelled dredger | LNG fuelled service vessel. | Operation on LNG with significant improvements for local air quality, especially for energy intensive ships like dredgers. Tugs are likely to adopt the same principle, favouring the use of cleaner fuels in the port area. Having service ships fuelled with LNG is part of a strategy to improve the quality of the port as an LNG hub, diversifying and increasing demand. |

| X1 | Electrical Energy supply to a feeder containership | Electric power supply by floating LNG driven generator set (at a distance from the supplied ship) | Electrical energy supply from an LNG “power barge“. Electrical energy is supplied to the receiving ship as “shore side electricity“. No LNG transfer occurs between power barge and receiving vessel. This may represent a new advantage from the use of LNG to produce energy in ports, reducing the footprint from ships at berth (any type of ship), allowing for electrical energy supply for all hotel load and services whilst at berth. Considerations with regards to the LNG capacity stored onboard the “power barge” can be made, especially if the amounts of LNG stored onboard are in excess of 50 t (lower tier threshold for Seveso. |

| X2 | Electrical Energy supply to a feeder containership | Electric power supply by shore-side mobile LNG driven generator. | Electrical energy supplied from an LNG fuelled shore-side generator. In all things similar to shore-side electricity supply, with the particular case that LNG storage onsite may have to be considered, even if attached to modular containerized unit. Risk assessment to be performed in order to identify possible risks from solution presented. |

| X3 | Electrical Energy supply to a cruise ship | Electric power supply by floating LNG driven generator set (alongside the supplied ship) | Electrical energy supplied by LNG “power barge” from location alongside the receiving ship. The substantial differences in comparison with “X2” are in essence that in this case we have a cruise ship and the proximity of the LNG “power barge” is very close to the receiving vessel. On one hand the risk from potential LNG hazardous event would be higher and, on the other hand, the proximity of the “power barge” would also represent that any potential LNG hazard in the barge could potentially escalate to the receiving ship. This is merely indicative and a specific risk assessment would have to be made taking these factors into account. |

| X4 | LNG fuel supply directly to Generator onboard the ship | LNG fuelling operation, with LNG directly feeding dual fuel engine onboard a cruise ship. | For a ship with no onboard LNG storage, but with engine(s) that are prepared to run on natural gas/dual fuel, it is possible, at berth, to feed in this fuel from an external LNG storage unit. Even though it may look like normal LNG bunkering, involving the transfer of LNG to a receiving ship, there are a few distinctive features that should be taken into account: – Transfer of very low LNG fuel volumetric rates, mainly dictated by the onboard engine fuel consumption rate. Unless a buffer tank exists onboard the rate of transfer will correspond to the engine consumption. When compared to the volumes transferred in bunkering this should be much less. – Delivery unit (LNG truck, barge or ISO container) stay close to the ship for longer periods. In fact the presence of the LNG supply/storage will last for the whole visit of the ship, with the energy at berth coming from the LNG fuelled onboard generator. – Regasification can occur either at the delivery or inside the ship, through a dedicated evaporator. Different configurations are possible depending on how technically prepared the ship is to undertake such type of operation. PAAs should take into consideration particular elements for this type of operation, such as: i. Regulatory frame. Even though not a typical LNG bunkering operation it is important to frame LNG fuelling into the existing instruments for LNG bunkering (EN ISO 20519, ISO/TS18683, IACS Rec.142). ii. Risk Assessment to be conducted, as indicated in the diagram in figure “LNG bunkering options, operations and Seveso III applicability“, where agreed possible hazardous scenarios must be reflected. iii. Safeguards to implements, derived from RA above, or others, such as 1) physical barriers, 2) Detection and Alarm, 3) access restriction, 4) Emergency response measures, 5) Dispersion mitigation measures, amongst others. iv. Manned attendance of the LNG delivery point. Taking into account that this is a type of operation that may extend for several hours, it is important to have consideration for the possible need to ensure manned attendance of the LNG delivery point/storage. This should be an important point focused at the RA. v. Credible release scenarios. In the context of the RA it is important to determine what would be a credible release scenario from such an LNG fuelling operation. |

Ports Good Governance for LNG Bunkering

Good governance in LNG Bunkering development in Ports, like in other activities, has 9 major characteristics. It is participatory, consensus oriented, accountable, clear, transparent, responsive, effective and efficient, equitable and inclusive, and follows the rule of law. Good governance is responsive to the present and future needs of the organization, exercises prudence in policy-setting and decision-making, and that the best interests of all stakeholders are taken into account.

In the specific context of LNG as fuel PAAs will have the overall responsibility for the good governance and the safety framework for LNG bunker operations in the port. Decisions and requirements for LNG bunkering should be based on a risk analysis carried out in advance, and in the early-involvement of all parties. In this way the port can conduct public affairs and manage public resources. Again, as introduced in the previous section, transparency plays a major role as one of the Good Governance Principles listed.

Table 2, lists the relevant principles of Good Governance in LNG bunkering that should serve a safe, sustainable and harmonized development of this activity as an important multi-operator and relevant activity in the port area and service portfolio.

| Table 2. Principles for Good Governance in LNG Bunkering | |||

|---|---|---|---|

| Good Governance principle | Description of Good Governance Principle | Good Governance for LNG bunkering development in Ports | |

| 1 | Rule of Law | Good governance requires fair legal frameworks that are enforced by an impartial regulatory body, for the full protection of stakeholders | Imperative to follow: |

| – International Regulatory frame (IGF Code, IGC Code, EU Regulations and Directives) | |||

| – Both ship-side and shore-side regulatory context. | |||

| Particular attention to be given to EU Directives as transposition into national law leads to different implementation exercise between EU Member States. | |||

| Develop adequate Port Regulations/ bye-laws, inclusive of LNG bunkering. | |||

| Refer Standards in regulations to allow legally binding reference for Operators to follow. Standards are not mandatory instruments unless they are included/ indicated in mandatory instruments. | |||

| Ensure adequate level of information to all stakeholders on the applicable regulatory frame to LNG Bunkering. | |||

| Ensure that all Competent Authorities implied in LNG bunkering are involved and that no conflicting requirements exist. | |||

| 2 | Clarity | The framework, its rules and their justification, the governing principles and schemes, should be clear to all stakeholders. | In addition to the points above, the framework for the application of law should be clear and understandable to all stakeholders, in particular to Operators. |

| Scope and applicability of regulations should be clear, with particular consideration for the different characteristic modes of LNG bunkering. Notwithstanding the fact that more general provisions can be applicable to all modes, it is important to realize and be clear in the rules as to which particular measures/requirements apply to each particular LNG bunkering mode. | |||

| 3 | Transparency | Transparency means that information should be provided in easily understandable forms and media; that it should be freely available and directly accessible to those who will be affected by governance policies and practices, as well as the outcomes resulting therefrom; and that any decisions taken and their enforcement are in compliance with established rules and regulations. | Easy access to rules and requirements for LNG bunkering operation in a specific port is fundamental. |

| Web-based information access should be privileged, without prejudice to other potential communication media where access to other stakeholder is found to be more adequate. | |||

| 4 | Responsiveness | Good governance requires that organizations and their processes are designed to serve the best interests of stakeholders within a reasonable timeframe. | The ability to respond to the needs from operators, within an adequate timeframe is fundamental for the confidence in the processes and competencies of the port. |

| NG bunkering, as in other oil fuel bunkering operations is a highly time-sensitive business. LNG is to be delivered on-time, as scheduled, to ships which are often under the pressure of time. This should not only be taken into account by PAAs, it should motivate PAA to develop mechanisms to swiftly respond to concrete technical, operational or administrative needs from Operators, in the frame of their competencies. | |||

| Permitting is another aspect of LNG bunkering which is highly time-critical, notwithstanding on a different time scale. Responsiveness in the particular context of LNG bunkering permitting is one of the factors that may contribute most to the reduction of inefficiencies in permitting processes. | |||

| 5 | Consensus Oriented | Good governance requires consultation to understand the different interests of stakeholders in order to reach a broad consensus of what is in the best interest of the entire stakeholder group and how this can be achieved in a sustainable and prudent manner. | Within the applicable legal frame reaching consensus and common understanding in LNG bunkering is essential for the success of projects, implementation and operations. |

| The width and ambition of consensus should be adequate to the complexity of the LNG bunkering solution and to the impact of that project to other operators within the Terminal or Port area. | |||

| Consensus with the wider public community is also fundamental, as applicable and necessary, and should not be limited to public consultations required by legal instruments. | |||

| A permanent platform for dialogue should be established. | |||

| 6 | Equity and Inclusiveness | The organization that provides the opportunity for its stakeholders to maintain, enhance, or generally improve their well-being provides the most compelling message regarding its reason for existence and value to society. | Equal opportunities to operators wishing to initiate LNG bunkering projects should be given, in the particular context of the Port, with due consideration to operational and spatial limitations. |

| Equity and Inclusiveness should be exercised, as a priority, in the access to information and support to permitting initiation. | |||

| All operators should receive the same level of information, same level of opportunity to demonstrate the concept projects and feasibility for a given intended LNG bunkering development. | |||

| 7 | Effectiveness and Efficiency | Good governance means that the processes implemented by the organization to produce favorable results meet the needs of its stakeholders, while making the best use of resources – human, technological, financial, natural and environmental – at its disposal. | Processes should be mapped. Criteria and Key Performance Indicators should be defined for an adequate measurement of Effectiveness and Efficiency. |

| All the life-cycle of an LNG bunkering project should here be subject to adequate measurements of effectiveness and efficiency (regarding the action of the PAA): | |||

| i. Concept Project | |||

| ii. Permitting | |||

| iii. Implementation | |||

| iv. In –service | |||

| v. Surveys | |||

| vi. Modifications | |||

| vii. Surveys | |||

| viii. Temporary Cessation | |||

| ix. Decommissioning | |||

| 8 | Accountability | Accountability is a key of good governance. Who is accountable for what should be documented in policy statements. In general, an organization is accountable to those who will be affected by its decisions or actions as well as the applicable regulations. | PAAs are accountable to Operators in the exact measure of the applicable legislation. |

| In addition to Mission Statement and other Quality related instruments, PAAs should identify clearly who, and in which areas, is responsible and accountable, in all areas of the Port Administration, including LNG Bunkering, Safety, Emergency, and other related responsibility areas. | |||

| For the sake of Good Governance the adequate channels for complaints, appeals and suggestions should be clear, accessible and included as part of a Quality Management System. | |||

| Independent investigation of incidents should be ensured. | |||

| 9 | Participation | Participation is a key cornerstone of good governance. Participation needs to be informed and organized. | In the interest of a sound port operating environment, all interested stakeholders should be given the opportunity to participate, comment and interact. |

| Participation of the wider public community is also fundamental, as applicable and necessary, and should not be limited to public consultations required by legal instruments. | |||

| A permanent platform for dialogue and participation should be established. | |||

Good governance is an ideal which is difficult to achieve in its totality. Governance typically involves well-intentioned people who bring their ideas, experiences, preferences and other human strengths and shortcomings to the policy-making table. Good governance is achieved through an on-going exercise that attempts to capture all of the considerations involved in assuring that stakeholder interests are addressed and reflected in policy initiatives. It should be all-inclusive and drawn in respect to an existing regulatory frame which is well understood by all parties.

In the same way that different Ports will have different management models, also Good Governance is different for every port so the list of items above is just guidance. It depends on your customers’ needs and LNG availability. Some ports only will be in need of the distribution of LNG to Small River crafts, other ports only will have LNG fueled seagoing vessels to be bunkered at anchorage. Most ports will have a mix of customers, all with their own LNG bunker needs.

Port Authorities and Port Administrations

Definitions

Ports usually have a governing body referred to as the port authority, port management, or port administration. Port authority is used widely to indicate any of these three terms.

It is, in the particular context of this Guidance, important to underline the definition used for Port Authority & Administration (PAA). The concept contains, in practice, a “two-in-one” definition: The “Port Authority” and the “Port Administration”. Even though merged together in the present Guidance, the two concepts have distinct definitions, with one responsible for the enforcement of the applicable legal provisions, and the other for the management of the port. Today’s management models followed by some ports have however merged these two, in fact, allowing for the corporatization of port authorities, serving the interest of an increasingly dynamic port activities’ environment.

In Regulation (EU) 2017/352 Port Authority and Port Administration are defined, respectively, through the concepts of “competent authority” and “managing body of the port”. Definitions given as per table below.

| Table 3. Port Authority and Port Administration definitions | ||

|---|---|---|

| Regulation (EU) 2017/352 | EMSA Guidance | Description (from Regulation (EU) 2017/352) |

| Competent authority | Port Authority | Any public or private body which, on behalf of a local, regional or national level, is entitled to carry out, under national law or instruments, activities related to the organisation and administration of port activities, in conjunction with or instead of the managing body of the port; |

| Managing body of the port | Port Administration | Any public or private body which, under national law or instruments, has the objective of carrying out, or is empowered to carry out, at a local level, whether in conjunction with other activities or not, the administration and management of the port infrastructure and one or more of the following tasks in the port concerned: the coordination of port traffic, the management of port traffic, the coordination of the activities of the operators present in the port concerned, and the control of the activities of the operators present in the port concerned; |

Adequate implementation of LNG bunkering will depend on the good coordination of both Port Authority and Administration core activities, especially bearing in mind that other authorities play an important part also in facilitation, permitting, emergency response, amongst other aspects. From the adequate and well-structured regulatory frame, taking into account international, regional and local/port aspects, to the execution of different approval and control activities it is the responsibility of PAAs to coordinate the necessary efforts to allow the best development of LNG bunkering activity within the port area.

Good practice Guidance in this document is applicable to the different parts of the LNG bunkering activity, throughout the different stages of its life cycle.

Port Roles and Responsibilities in LNG Bunkering

Table 4, below, outlines the main Port Roles and responsibilities, in the context of LNG bunkering, integrating both “competent authority” and “administration” aspects and highlighting the challenges that should be met by PAAs.

| Table 4. Port Authority and Port Administration roles and responsibilities in LNG bunkering | |||

|---|---|---|---|

| Port Role/Responsibility | Main Aspects to Consider (reference to section in the Guidance) | Port Authority Role | Port Administration Role |

| Develop a regulatory framework for LNG bunkering in the ports | As indicated in article “LNG Regulatory Framework International EU ComplianceLNG Regulatory Framework International and European Maritime Safety Overview” the development of an adequate Port Regulation that is inclusive of LNG bunkering, is the fundamental instrument for the development of this activity. Ensure adequate integration of different LNG bunkering standards. (Refer to article “LNG Regulatory Framework International EU ComplianceLNG Regulatory Framework International and European Maritime Safety Overview“) | х | х |

| Allow for adequate information on LNG bunker activities within the port by reporting procedures | Implementation of well-documented permitting procedures, including relevant provisions for management of modifications. Definition of adequate channels for communications, with the identification of the responsible Port representative(s), electronic address, or other that should be taken into account by RSO, BFO or other interested parties. Adequate information channel for reporting of incident and near-misses in LNG bunkering. (Refer to articles Navigating the Complexities of an LNG Bunkering Permit“Permitting”, Strategies for Effective LNG Bunkering Operations and Their Execution“Bunkering Operation”, Guide LNG Bunkering Incident Reports Land Sea and Port Levels“Incident Reporting” and Guide to Certification, Accreditation, and Equipment Standards for LNG Bunkering“Certification & Accreditation”) | х | |

| Develop restrictions on bunkering operations if necessary | Restrictions on bunkering operations can be of several types and dependent on different factors: | х | |

| – Risk Assessment based Restrictions and limitations may be the practical result from risk assessment results. These may be restrictions on bunkering parameters (pressure, flow rate, hose diameter) or restriction in other operational aspects. | |||

| – Weather based Weather elements, such as wind, rain, temperature can determine possible operational envelopes. | |||

| – Local harbour/maritime traffic Special local maritime traffic conditions can dictate restrictions to bunkering. PAAs should be able to aim for a balance of normal operating profiles within the port, whilst ensuring the sufficient safeguards for the LNG bunkering location. | |||

| – Security restrictions Restrictions on LNG bunkering may arise from possible security related elements. | |||

| Ports should avoid, to the extent possible, to favour restrictions in looking for safe LNG bunkering operations. It should be important to develop a favourable environment for this type of operations, based on a minimum restriction approach (Refer to article Strategies for Effective LNG Bunkering Operations and Their Execution“Bunkering Operation”) | |||

| Approval of Safety Zone in way of the bunkering area | The safety zone is an important parameter that should be calculated by the BFO and approved by the PAA. It is important, as good practice, to allow sufficient freedom to the BFO to elaborate on LNG bunkering parameters, local safeguards and to submit the proposal to the PAA for evaluation and approval. It should be avoided, also in the terms of a good practice approach, a fixed safety distance applicable to all situations. This approach is not consistent with the mechanism that justifies the fixation of the safety distance, based on considerations on gas dispersion. Since this is fundamentally affected by environmental and local conditions, it is important to evaluate a proposed safety distance also in the light of these parameters. (Refer to articles LNG Bunkering Hazardous Zone: Safety, Classification, and Control“Control Zones”, Security Zones in LNG Bunkering: A Guide to Meaningful Protection“Security Zone” and Key Aspects and Recommendations for the Safety Zone for LNG Bunkering“Safety Zone”) | х | х |

| Definition of Security Zone around bunkering location | The definition of the Security zone should be a responsibility of the PAA (eventually defined by the Administration and approved by the Port Authority. The fundamental objective of the Security Zone is to allow control of any possible element that may cause interference with the LNG bunkering operation. Maintenance of the Security Zone should be a responsibility of the PAA, allowing for an alternative security maintenance scheme if so agreed between all parties, subject to approval of the Port Authority. (Refer to articles LNG Bunkering Hazardous Zone: Safety, Classification, and Control“Control Zones”, Security Zones in LNG Bunkering: A Guide to Meaningful Protection“Security Zone” and Key Aspects and Recommendations for the Safety Zone for LNG Bunkering“Safety Zone”) | х | х |

| Confirmation of Hazardous Zone | Surrounding the LNG bunkering manifold connections a hazardous area shall be defined at the responsibility of the BFO and RSO. Port Authorities should confirm by inspection that all personnel working and equipment used inside Hazardous Zones is adequately certified for the area in consideration. PPE and EX-proof material should be used. Even though a responsibility of the parties involved, the maintenance of the permitting should be based on periodic confirmation by PAAs that all safety procedures and measures are well kept in place and ensured by parties involved. (Refer to articles LNG Bunkering Hazardous Zone: Safety, Classification, and Control“Control Zones”, Security Zones in LNG Bunkering: A Guide to Meaningful Protection“Security Zone” and Key Aspects and Recommendations for the Safety Zone for LNG Bunkering“Safety Zone) | х | |

| Approve and enforce additional control zones (in addition to Hazardous, Safety and Security Zone) | In addition to Safety Zone and Security Zone, other Control Zones may be defined to ensure the safe execution of LNG bunkering operations, These may involve navigation restricted areas or other control zones. It is important that the definition of relevant control zones is effective and adequately enforced. The definition of the relevant zones should take into account the local conditions and infrastructure that may influence the access control to these areas. (Refer to articles LNG Bunkering Hazardous Zone: Safety, Classification, and Control“Control Zones”, Security Zones in LNG Bunkering: A Guide to Meaningful Protection“Security Zone” and Key Aspects and Recommendations for the Safety Zone for LNG Bunkering“Safety Zone”) | х | |

| Establish passing distances for other ships during LNG bunkering | Either in context with Safety or Security zones, or even separately, the control of passing navigational traffic should be a concern of PAAs. The necessary measures should be developed, implemented and adequately enforced in order to restrict navigational traffic in the way of the LNG bunkering location. The need for control of passing navigational traffic will also vary according to the LNG bunkering type into consideration (STS at berth, STS at anchor, PTS, TTS) with all STS modes deserving the closest attention. Similarly to all control zones, also in the definition of passing distances for other ships the main objective is to avoid any external interference on the LNG bunkering operation. (Refer to articles LNG Bunkering Hazardous Zone: Safety, Classification, and Control“Control Zones”, Security Zones in LNG Bunkering: A Guide to Meaningful Protection“Security Zone” and Key Aspects and Recommendations for the Safety Zone for LNG Bunkering“Safety Zone”) | х | |

| Mooring requirements | Safe mooring during LNG bunkering operations is a fundamental element to allow a stable and secure LNG bunkering interface. It should be the role of the PAA to define the standard requirements for mooring, including under which conditions reinforced or special mooring should be considered. Mooring of the receiving ship and bunker facility, industry standards may be referenced (e. g. OCIMF Effective Mooring 3rd Edition 2010) (Refer to article Strategies for Effective LNG Bunkering Operations and Their Execution“Bunkering Operation”) | х | |

| Develop environmental protection requirements | As mentioned in Section “LNG Emissions Understanding the Environmental ImpactEnvironment“, LNG bunkering operations should deserve careful attention with regards to potential negative environmental impact. The adequate prevention of any methane release in connection/disconnection, inerting/purging, or even in pressure relief, depends mostly on the definition of good procedures for pre-bunkering, bunkering and post-bunkering phases, including consideration for equipment compatibility. It is important that PAAs establish as a minimum requirement that no venting is allowed. Adequate measures for control should also be developed. (Refer to Sections 3, article Strategies for Effective LNG Bunkering Operations and Their Execution“Bunkering Operation”) | х | |

| LNG bunkering checklists | The implementation of LNG bunkering checklists is an important measure to ensure adequate documentation of important aspects of LNG bunkering operations. IAPH check-lists, ISO 20519 or their adaptation as include in the present Guidance, can be used for this purpose. It is the role of the Port Administration to ensure that adequate verification and treatment of validated check-lists is adequately done. This may be either part of the port regulations or a requirement derived from the permitting process. (Refer to article Process Map & Organization of the LNG Bunkering“Proccess Map & Organization”) | х | |

| Develop proposals for spatial planning and bunker locations | Concurrently with other competent authorities with responsibilities for land planning, use, classification and administration, PAAs should consider the need to integrate possible LNG bunkering locations into the spatial planning of the port. A possible approach is to determine pre-destined locations for LNG bunkering, allowing for easier prospective permitting processes. Important elements to take into account for spatial planning: | х | |

| – Waterways accessibility | |||

| – Proximity of locations handling/storing hazardous substance | |||

| – Emergency response facilitie | |||

| – Proximity of Populated areas and commercial services Commercial | |||

| – Areas of restricted securit | |||

| (Refer to article Navigating the Complexities of an LNG Bunkering Permit“Permitting”) | |||

| Approve Spatial planning elements and LNG bunkering location | Based on elements developed in the proposal for spatial planning, above, it should be the role of the Port Authority, following the administrative proposal, to assess the compliance of the proposal with respect to major accident prevention requirements and other national port authority regulations. (Refer to article Navigating the Complexities of an LNG Bunkering Permit“Permitting”) | х | |

| Develop measures to allow possible simultaneous activities and operations (SIMOPs) during LNG bunkering | (SIMOPs) during LNG bunkering Simultaneous Operations (SIMOPs) are an important aspect to consider especially in LNG bunkering of larger ships with short turn-around times (such as passenger vessels and container ships). PAAs should be involved and dialogue with interested parties, from the beginning, in the development of the necessary measures to allow SIMOPs to be conducted in the safest operational environment possible. Port Administrations, as a good practice approach, can be involved with the role of finding and developing the necessary solutions, in support to BFO and RSO, that can support SIMOPs to take place (Refer to article How to Conduct Simultaneous Operations during LNG Bunkering“Simultaneous Operations”) | х | |

| Approve SIMOPs | Port Authorities should be responsible for the approval of SIMOPs. This approval can however be distinguished in two levels: 1) Permitting and 2) Approval. In the first the BFO and RSO may be certified, within a given permit for operation, to undertake SIMOPs. On the second, Approval, the Port Authority should confirm that all necessary and agreed elements in the permit are well in place. (Refer to article How to Conduct Simultaneous Operations during LNG Bunkering“Simultaneous Operations”) | х | |

| Develop general procedures for traffic control and restrictions in case of an LNG bunkering | Both to ensure the integrity of the Safety and Security zones (and any other control zones defined by the PAA) it is important to define relevant traffic control and restrictions. Amongst the measures for traffic control the following can be considered: | х | |

| – Visual signals and traffic indication | |||

| – Speed limit (with possibility to vary speed limit indication depending on operational context) | |||

| – Barriers to restrict traffi | |||

| – Traffic lights for temporary restrictio | |||

| – Active manned traffic contro | |||

| – Traffic diversio | |||

| The adequate degree of authority should be ensured to implement and enforce the defined Traffic restrictions. (Refer to article Strategies for Effective LNG Bunkering Operations and Their Execution“Bunkering Operation”) | |||

| Establish clarity on the roles and responsibilities between the involved parties | The adequate definition of responsibilities between all parties involved should be a central aspect of Port Regulations. In the absence of definition in relevant port instruments the responsibilities to be defined should take EN ISO 20519, the present guidance and Industry relevant guidelines. PAAs should also define clear internal division of responsibilities (permitting, inspections, emergency, amongst others) (Refer to article Strategies for Effective LNG Bunkering Operations and Their Execution“Bunkering Operation”) | х | |

| Emergency Response Plan (external) Approve external emergency plan | In cooperation with other relevant competent authorities, Port Authority should approve the external ERP, taking into account all relevant ERPs existing in the multi-operator context of the port. The Port Authority should, in particular for this approval, and whenever major accident prevention aspects are relevant, liaise directly with the competent authorities responsible for that particular area. (Refer to article LNG Emergency, Preparedness & Response: Implementing a Robust Response Plan and OECD Guiding Principles“Emergency, Preparedness & Response”) | х | |

| Emergency Response Plan (training) Develop and implement an LNG fuel training program adequate for port personnel directly or indirectly with LNG bunkering. | In order to ensure adequate implementation of the Emergency Response Plan, PAAs should develop and put in practice an adequate training program to be undertaken by all relevant members of the emergency response organization. It is the responsibility of the PAA to ensure that all staff members directly or indirectly involved are aware of their roles in emergency. Training in LNG bunkering emergency & response should consider the involvement of all relevant operators involved in LNG bunkering. (Refer to article LNG Emergency, Preparedness & Response: Implementing a Robust Response Plan and OECD Guiding Principles“Emergency, Preparedness & Response”) | х | |

| Build adequate Enforcement capacity Initiate an enforcement system by LNG trained enforcements officers | Enforcement is an important factor to ensure that the relevant requirements are well implemented and complied with by the relevant parties involved in LNG bunkering. Requirements and relevant legal/technical provisions should therefore be enforceable, clear and well understood by all parties. It is also very important that the enforcement exercise takes into account the practical aspects, both in terms of equipment and cost-benefit of possible safeguard solutions. (Refer to articles Navigating the Complexities of an LNG Bunkering Permit“Permitting”, LNG Bunkering Hazardous Zone: Safety, Classification, and Control“Control Zones”, Security Zones in LNG Bunkering: A Guide to Meaningful Protection“Security Zone” and Key Aspects and Recommendations for the Safety Zone for LNG Bunkering“Safety Zone”, Guide to Certification, Accreditation, and Equipment Standards for LNG Bunkering“Certification & Accreditation”) | х | х |

| Approve risk acceptance criteria | In the absence of relevant directly applicable risk acceptance criteria, the BFO, RSO or Port Administration may propose relevant risk criteria to be adopted. As a good practice approach, where better procedure is not available, the risk criteria should be subject to approval by the Port Authority. In approving the risk criteria, Port Authority should liaise in close cooperation with other relevant competent authorities involved in prevention of major accidents, or with responsibilities on civil and port protection. (Refer to article Assessing the Safety Risks of LNG Bunkering“Risk & Safety”) | х | |

| Accreditation of the BFO Authorize /accredit bunkering facilities, once they have demonstrated that they are compliant and prepared | In pursuit of a transparent and equitable regulatory and administrative framework for the development of LNG bunkering in ports, PAAs should develop an LNG bunkering accreditation scheme. The scheme should be clear and allow for equal opportunities to all those that present intention or projects for LNG bunkering within the port. The following factors should be taken into account for the accreditation scheme: | х | |

| – Certification of LNG bunkering Equipment | |||

| – Qualification of BFO personnel | |||

| – Safety Management System implemented by the BFO | |||

| – Number of available hours per yea | |||

| – Results of periodic in-service inspection | |||

| (Refer to article Guide to Certification, Accreditation, and Equipment Standards for LNG Bunkering“Certification & Accreditation”) | |||

| Qualification of the Person-in-Charge (PIC) | Define the main elements to consider for the qualification of the Person-in-Charge (PIC). What competencies should be derived from the already IGF-defined responsibilities for the PICs should be a responsibility of PAAs. As a minimum it should be here considered that the RSO and BFO PICs should have equivalent qualification for LNG bunkering operation. (Refer to article Guide to Certification, Accreditation, and Equipment Standards for LNG Bunkering“Certification & Accreditation”) | ||

| Restrictions for repairs and maintenance on LNG installations on board of ships | (Not directly related to LNG bunkering) Repairs and maintenance of LNG fuelled ships, either planned or non-planned, in designated areas or other locations within the port should be subject to consideration of the PAA. Subject is not related to LNG bunkering but it is of great relevance and importance in the context of operations with LNG fuelled ships. It is included in the present article under article Guide to Certification, Accreditation, and Equipment Standards for LNG Bunkering“Certification & Accreditation”, on Certification/Permit to Work. | х | х |

| Safety requirements for LNG propelled ships on (dock)yards | Not directly related to LNG bunkering) Even if the repairs of LNG fuelled ships take part in dedicated shipyards, PAAs should be reassured that relevant precautions and procedures are followed in both unloading-inerting and commissioning-cooling-loading operations. Shipyards should be required to have relevant procedures in place to allow for safe repair works in LNG fuelled ships. Subject is not related to LNG bunkering but, for the same reason as the previous point, it is included in the present Guidance under Section 15, on Certification/Permit to Work. | ||

| Safety requirements for LNG propelled ship on a lay bye berth to avoid a BOG problem | In the context of the development and implementation of relevant provisions for methane release mitigation, PAAs consider the development of all necessary measures to reduce the amount of NG release to the atmosphere. Should an LNG fuelled ship be on a lay bye berth it should be possible to ensure that adequate measures are put in place to avoid difficult BOG management situations, in particular when LNG vapour pressures are such that PRVs are actuated allowing the pressure relief at cost of environmental impact of methane release to the atmosphere. | х | |

As indicated in table 4, above, PAAs, either in the Port Authority or in Port Administration context, take stake of a considerable amount of roles and responsibilities. The listed elements in the table include the main aspects that need to be to be considered by PAAs. Different aspects can be taken either by the Port Authority or Administration, depending on the specific port management model and on specific national contexts. Table 4 provides only for an indicative structure of different port roles and responsibilities in LNG bunkering.

It should not be the role of the Port Authority to interfere with the normal operations during LNG bunkering. Once the adequate Authorization procedure (see section Strategies for Effective LNG Bunkering Operations and Their Execution“LNG Bunkering Process”) is concluded, for a given LNG bunkering operation, PAAs should implement a suitable inspection and verification model (see section Navigating the Complexities of an LNG Bunkering Permit“Inspections”) to ensure that the conditions established during the permitting procedure are kept in-service, throughout the life-cycle of the LNG bunkering facility.

Spatial Planning

From table 4, in the previous section, one of the most relevant responsibilities of PAAs is the proposal and approval of spatial planning within the port area, accounting for the development of a new LNG bunkering facility or operation.

To approve a bunker location for an LNG bunkering among other things PAAs can consider different elements that collectively may contribute to the definition of the most suitable location for the LNG bunkering operation:

- the different types of ships to bunker with LNG;

- the expedience of the terminal with LNG bunker operations;

- the planned simultaneous operations during the LNG bunkering;

- the water depth;

- availability of proper anchoring, mooring and fendering appliances;

- double banking possibilities (dolphins, buoys or bollard loads);

- nautical accessibility;

- nautical safety, including maneuvering basin area’s;

- frequency and type of passing vessels (collision risk);

- the space for the passing of vessels taking into account safety zone and ship exclusion zone.

- Water movements due to tidal amplitudes, swell, passing ships etc.

- the quay maximum admissible load in case of a truck to ship bunkering;

- enough safety distance to populated areas (in line with national legislation).

- Impact on other activities, both waterborne or on the shore side.

- Security, accessibility by public.

In order to minimize the risk of a collision during bunkering, the bunker location should ideally not be located in waterways with high vessel traffic intensity levels or complicated nautical situations, including basins dedicated to maneuvering; In addition to the elements above it is also important to note that Spatial Planning is done to incorporate the possibility of LNG bunkering in the existing spatial layout of a given port. Different concurring factors may contribute for this, some safety related and others of a more operational and economical nature.

This would be the case of Safety Distances and proximity of LNG, respectively. Notwithstanding this fact, planning for a new LNG bunkering location will be an exercise that will be done concurrently with already existing factors, within sometime restricted boundaries and in a context which may present several challenges.

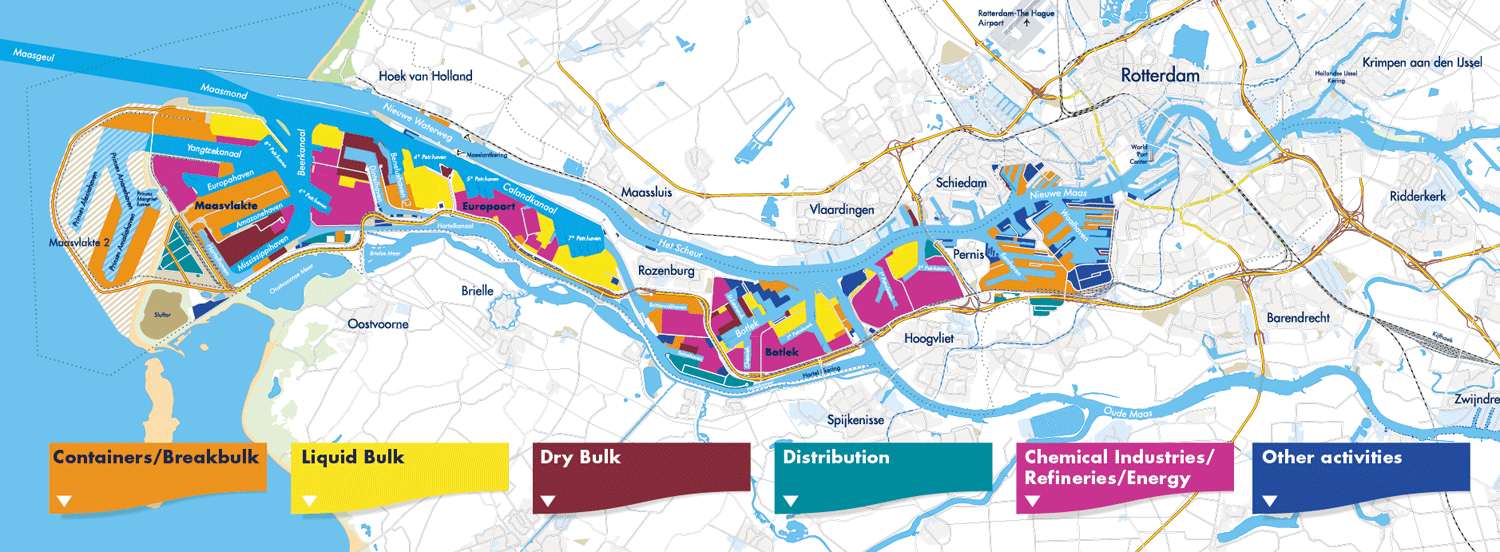

Figure 6, below, presents a graphical image of the spatial planning in the Port of Rotterdam, an extreme example of a very large port, dealing with a large variety of ship types and cargoes.

Assuming that LNG bunkering can be a potential operation for any ship type it can be easily concluded that it will be very likely to have LNG bunkering areas superimposed with other areas with necessary judgement to be taken into account, not only in the context of potential SIMOPS but, most certainly, in those cases where hazardous substances other than LNG are present.

The Role of Ports in the development of LNG bunkering facilities

Whilst the previous section outlined the more operational roles for PAAs, in the context of LNG bunkering, the present Section aims to provide the same entities with options to promote and support the use of LNG as a marine fuel and develop bunkering facilities in full length. The elements contained in this particular section are based on a study published by the World Maritime University in 2015, where 8 (eight) relevant Ports, recognized as first-movers for LNG bunkering, were analysed with regards to the aspects related to direct or indirect support to this activity. The study, based on questionnaires and evaluation of the different Ports (all inside ECA) allows a summary of the different initiatives to support the development of LNG bunkering.

Regardless the management structure of a port and the corporatization level of both port authority and administration bodies, the development of LNG bunkering can be characterized across the four main functions of a Port:

- Landlord function;

- Regulator function;

- Operator Function and, finally,

- Community Manager Function.

These are outlined below to provide PAAs a generic Menu-Portfolio of the policy-vectors and strategies that are available to support development of LNG bunkering potential.

Landlord function

The typical landlord function of port authority in the development of LNG bunkering facilities refers to the provision of land for an LNG bunkering terminal, the construction of quay walls, jetties, or other possible basic infrastructure for maritime access, and the associated development policies. Most port authorities go beyond the traditional landlord function by adopting “proactive” and “cooperative” policies to speed up the development progress of this new application. These policies relate to:

- a proactive coordinating role in conducting feasibility studies on LNG bunkering in cooperation with various stakeholders (i. e., local government, competent authorities, private actors, etc.),

- the development of a comprehensive location selection policy,

- the forging of strategic partnerships with private industrial players and even with other ports for developing LNG bunkering and, finally,

- the adoption of an adequate infrastructure investment policy.

The above policy-vectors are structured in the diagram of figure 6, showing the main trends on how PAAs enact the landlord function in order to play a proactive coordinating role in performing feasibility studies on LNG bunkering (e. g., technical, regulatory, and market dimensions) together with various stakeholders in order to obtain confidence among market players to kick-start the business. The selection of a location for LNG infrastructure currently is a key problem faced by the ports. The LNG bunkering facilities would be better built close to the customers (e. g., shipping lines), while considering the safety issue of handling LNG as a dangerous cargo, some ports prohibit LNG operations in populated port area. Other ports are however developing dialogue platforms with the general public on the construction of LNG facilities near residential areas.

Fig. 7 Policy Options for LNG Bunkering development in ports

Regulator function

The traditional regulator function of port authorities is to apply and enforce rules and regulations set by regulatory bodies. The current scenario for LNG bunkering in ports is however characterized by the lack of a set of unified harmonized rules and standards for a number of different aspects in this activity (Safety Distances, SIMOPS, Permitting, Risk Acceptance criteria, amongst others). In this particular context, the development of relevant rules and standards for such new application is a key for the wide diffusion of the LNG technology. Below is presented a summary of the regulatory role of that may be followed by ports in the development of LNG bunkering. Port authorities mainly adopt a stronger regulatory role in the following ways:

1 By actively assisting regulatory authorities to enforce air emission standards, underlining the relevance of an adequate control that mitigates the risk of non-compliances, also promoting in that way the option for EAMs such as LNG as fuel.

2 By proactively coordinating and facilitating the development of regulations on the maritime use of LNG and by setting corresponding port bylaws. Relevant regulations and rules on LNG bunkering have already been developed by a significant number of ports, remarkably by those located in ECA areas. The challenges, whilst developing such instruments, are diverse and PAAs should be prepared to develop the relevant port regulations in a collaborative manner with other ports and competent authorities.

3 By developing LNG bunkering checklists and establishing appropriate Risk Criteria. Initiatives like the World Ports Climate Initiative (WPCI) – have allowed the participation of Ports in a dedicated working group to jointly develop an LNG bunkering checklists Check-lists included in Annex-A, adapted to include relevant aspects to Port Authorities and Administrations. The baseline check-lists used are IAPH and ISO.x for different significant bunkering solutions (e. g., ship to ship, truck to ship, etc.). The definition of adequate risk criteria is further relevant in the context of LNG bunkering allowing risk evaluation studies to be properly assessed, promoting transparency and defining clearly the acceptance frame.

4 By setting a differential port tariff on ships fuelled by LNG or other clean fuels.

Operator function

Looking at the three traditional functions of port authorities, i. e., the landlord, regulator, and operator functions, it can be concluded that, as operators, port authorities gradually moved away from providing services of cargo handling, stevedoring and bunkering, etc. These have in most cases been privatized. A common best-rated strategic option for port authorities is today to enact an active control and supervision of concessions to stimulate intra-port competition and market contestability as well as sustainable and efficient operations of private operators. Thus, LNG bunkering services are supposed to be mainly operated by private actors, although at the beginning of market development, the port authorities might adopt incentive policies promoting investments in the maritime application of LNG.

The Operator function by PAAs, in the context of LNG Bunkering, similarly to the example of other relevant port services, is not expected to be privileged. Exception to this may however be considered in the cases where the business case for LNG bunkering is not yet fully developed or secured, leading in the extreme situation where PAAs may take the lead in the development of an LNG bunkering service infrastructure.

Community manager function

The function of community manager assumes a coordinating role of the port authority to solve collective problems in and outside the port perimeters, for instance, marketing and promoting innovations, etc. It is a common function of port authorities today acting as community managers in promoting LNG as a ship fuel.

- Marketing and promotion on the maritime use of LNG. PAAs may use different ways to promote and market the maritime use of LNG by organizing conferences, seminars, and workshops or by sending handbooks or arranging meetings with the interested parties.

- Learning and sharing knowledge and skills with port stakeholders and even other ports. Possibility to enhance interactive learning and knowledge sharing with port stakeholders by establishing various workshops or stakeholder platforms or developing strategic alliances with other ports in/or across the regions.

- Establishing a close dialogue with government and raising public awareness.

Ports Good Practice approach for LNG bunkering

Sections “LNG bunkering for Ports” to “Spatial Planning” addressed several and different aspects related to Ports in the context of LNG Bunkering. In “LNG bunkering for Ports” the main principles that should assist PAAs in the development of control mechanisms for LNG bunkering are derived and discussed, with a triangle established with the following vertices:

- LNG Bunkering Facility Organization (BSO).

- Port Authority & Administration (Port Authority and Port Administration can be the same or different entities – see Section “Ports Good Governance for LNG Bunkering”).

- Receiving LNG Fuelled Ship (Receiving Ship Organization – RSO).

In addition, contained in the same section and making use of a generic port layout, different LNG bunkering scenarios are presented. For each scenario different considerations are outlined, highlighting some of the main particulars for each situation. Table 1 provides this list of possible LNG bunkering scenarios, including some particular small scale LNG cases possible within ports. No such thing as “Good Practice” can be indicated for the presented scenarios. They are typically developed in the operational context and, notwithstanding the list in Table 1 being considered extensive, it will still be possible to have new concepts for LNG Bunkering, or even small-scale LNG bunkering solutions being developed. For this reason it is important to note that good practice should not be derived from the list of possible LNG Bunkering Scenarios. Instead, a sound Good Practice approach for Ports to deal with LNG bunkering operations should be supported by adequate Good Governance principles (Section “Ports Good Governance for LNG Bunkering”), clear definition of the responsibilities falling on PAAs (on both Port Authorities and Administrations) (Section “Port Authorities and Port Administrations”) and, finally, by adequately defining the position of PAAs regarding the development of LNG bunkering (Section “The Role of Ports in the development of LNG bunkering facilities”). Spatial Planning, one of PAAs responsibilities also included in Section “Port Authorities and Port Administrations” is also mentioned separately accounting for the details and complex port-specific considerations that can be derived in this particular point.

LNG bunkering for Ports – Good Practice for Transparency

Transparency is, in the context of LNG Bunkering as in others related to relevant port services, a primary principle that should be privileged by PAAs.

Accounting for the three main vertices of a triangle, mentioned above and in “LNG bunkering for Ports” (BFO, RSO and PAA) it is, in the best interest of transparency, important to ensure that adequate separation and absence of conflict of interests is ensured between all parties.

Different interests can be derived for all parties and their inter-relations may be characterized by different levels of communications and potential partnerships. Safety can be expressed as an objective by all parties, but how much commitment to safety must be defined in clear regulations.

Growing towards complex hubs in a multi-operator context, with management and organizational systems which differ significantly from port to port, PAAs should give a particular relevance to the need to ensure transparency in processes, with the involvement of the wider stakeholders’ community inside and in interaction with the port.

Examples of processes where transparency is a fundamental pillar in LNG bunkering:

- Vessel compatibility Assessment/

- Risk Assessment (whenever performed to ascertain ALARP Risk levels).

- Permitting/

- Simultaneous Operations.

- Safety Distances.

In Section “LNG bunkering for Ports” a specific approach is presented to determine adequate independency of all parties involved in LNG Bunkering. Independency between all the parties identified has there been identified as a marker for transparency. It is however important to note that other stakeholders may also be involved in ancillary tasks (such as inerting, cooling, amongst others) from service providers other than the BFO.

PAAs should have a clear overview of all the parties involved in the LNG bunkering operations, looking for the identification any less transparent situations and questioning, in particular, how, and by whom, are provided the elements for safety of operations (risk assessment, supervision, compatibility assessment, definition of safety distances, etc, as listed above).