Following the previous Developing LNG Bunkering Facilities in Ports: Governance and Good Practicearticle, where the Ports Role could be explored in support of Gas bunkering development, the present section is focused of the Feasibility Analysis of LNG Bunkering projects from the perspective of PAAs. The multi-dimensional structure of Feasibility Analysis is here addressed without, however, focusing in depth the economic aspects, considered outside the scope of the present Guidance.

Aspects related to Economic Feasibility of LNG nevertheless highly relevant in the establishment of LNG bunkering business models and should be a great attention by Operators. In generic terms the aspects covered in this Section relate to the Technical and Operational Feasibility of prospective LNG Bunkering projects, with the outline of elements considered relevant to PAAs in the evaluation of these projects within the frame of their jurisdiction and competencies.

Having PAAs involved in the Feasibility Evaluation of LNG bunkering projects, from a very preliminary stage, either at concept or front end engineering development (FEED) it will be possible to early mitigate any risks of incompatible or unrealistic solutions, failing to meet PAAs requirements or to address any possible technical or operational constraints imposed by the administrative, physical or safety environment within the port.

The present section includes:

- Elements to be considered by PAAs for Feasibility Analysis;

- Main elements with a potential impact on Feasibility for a given LNG bunkering project;

- SWOT and Multi-Criteria Analysis as tools for Feasibility Analysis and, finally, a set of recommended good practice elements that PAAs may use to support prospective LNG bunkering projects, towards the improvement of the feasibility prospects for a given project.

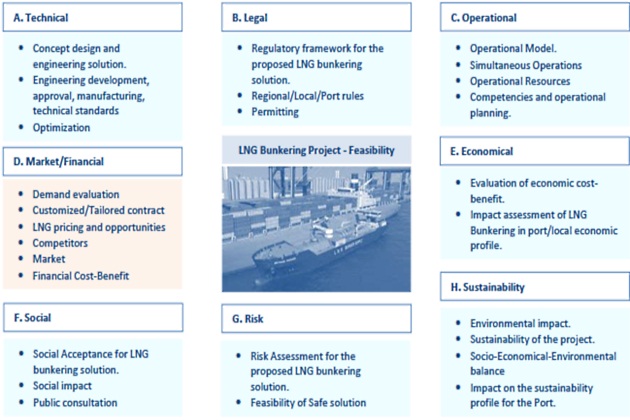

LNG Bunkering Project dimensions

There are several distinct dimensions for an LNG bunkering project that need to be included into a Feasibility Study, as presented in the diagram in figure 1, below.

A complete Feasibility Analysis of LNG bunkering projects will be the analytical, qualitative and, where possible, quantitative, evaluation of proposed projects covering at least the dimensions presented in the diagram of figure 1, all collectively contributing to the development and implementation of LNG bunkering projects and should be taken into consideration by PAAs at the earliest possible moment from the presentation of the project.

Addressing adequately all dimensions will be, primarily, of interest to the Bunker Facility Operator and associated direct/indirect economic operators. Whether an LNG bunkering project initiative is more or less successful will, in fact, impact first on those who commit to capital investment and initiate the venture towards implementation. Notwithstanding this may be the first relevant perception from the feasibility prospects of LNG bunkering projects it is not the only side. PAAs should also be not only implied but also, perhaps moreover, involved in the early evaluation of these specific projects. LNG bunkering constitutes an important add-on service to any Port’s service portfolio. It has the potential to differentiate any Port in a positive way, to attract further investment, defining new ship routes and increasing the potential options for local air quality improvement, in support of shipping and local, near-port populations. LNG bunkering as an economic differentiator for ports should here be regarded as a fundamental driver that may lead Ports to support such projects from an early Feasibility Analysis approach.

Read also: LNG Bunkering Guide – What It Is and How to Use It

For a Port, the Feasibility Analysis, divided into each one of its dimensions (as presented in figure 1), will provide an early evaluation study on the prospects of any LNG bunkering project. It is also possible to demonstrate through this structured exercise whether the proposed project will aggregate value to the Port service portfolio, along with an indication on risk, economical cost-benefit, and Energy consumption Optimization and Improvements in the Natural Gas Liquefaction Processoperational process optimization, amongst other important indicators.

Being involved from early stages in the Feasibility Analysis for an LNG bunkering project will allow PAAs to provide input, indicate potential restrictions, provide relevant statistical data, and even promoting the alignement between private, or public-private, initiatives with the port strategic vectors. These may vary significantly from one port to another, remarkably so if we acknowledge that ports have very different sizes, management models, operational and market contexts. Ports may be located in the overlapping between ocean-borne navigation, inland and other relevant multi-modal transportation hubs. LNG is a relevant fuel for transport on a wider perspective. PAAs may find therefore relevant and advantageous to integrate the wider scope in the early stage of LNG bunkering feasibility studies.

It is nevertheless important to underline that Feasibility Analysis will, in principle, represent an instrument to support business decision from the BFO side, including or not agreement with specific RSOs. When, how and to which extent PAAs are consulted in the context of Feasibility Studies will depend largely if a first contact/initiative have been established by the economic operators. The platform for this initiative should be created by PAAs. Promoting the early collaborative environment will allow the opportunity for PAAs to work closely with the BFO for the onset of an optimized permitting process.

Cumulative involvement of other competent authorities would further allow minimizing any elements in the concept design that could potentially impose delays in the permitting process, other than those already related to the administrative process flows. How, and how much, PAAs should support LNG bunkering operators is, in summary, a function of the level of involvement allowed during the concept definition and early project development stages.

Information on location or operational restrictions, big-data Big data is a term that describes a large volume of data – both structured and unstructured – that results from any monitored system, process or operation.x, Comprehensive Guide to Risk Assessment and Process Safety Managementrisk acceptance criteria or other relevant elements that can be provided to operator are likely to have a significant impact in the early stages of concept exploration and project development.

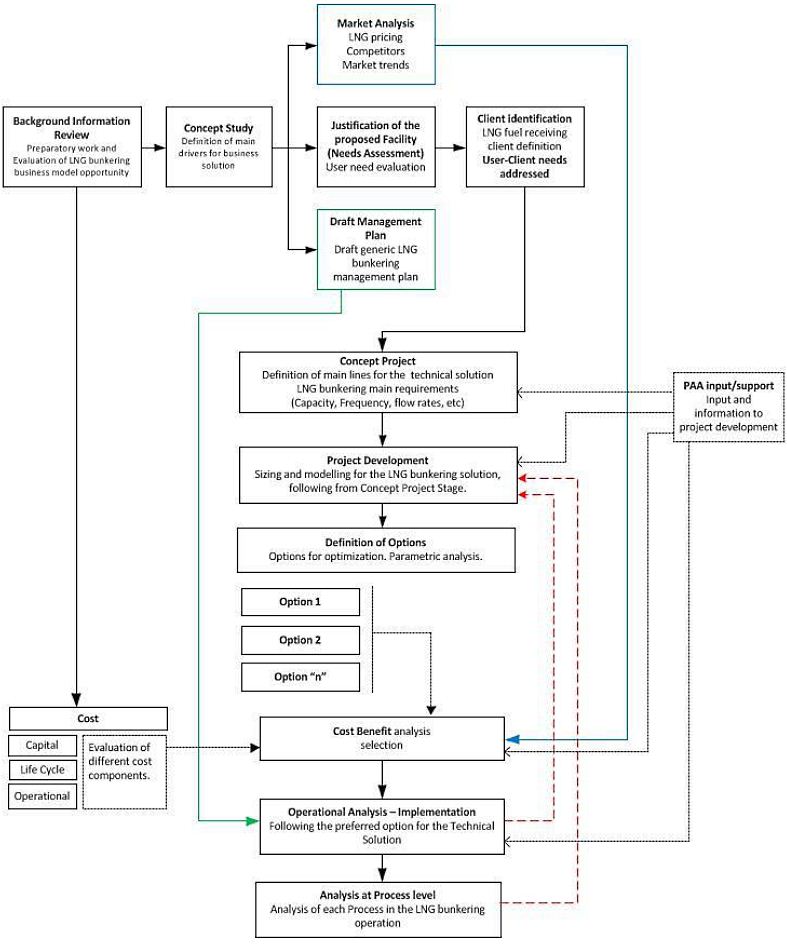

Figure 2, in the next page, includes a suggested generic LNG bunkering project development flow diagram which is included to highlight the different stages where PAAs are likely to play a very relevant role. Feasibility of an LNG bunkering project can, as expressed in the diagram, develop from concept study down to operational and process analysis through staged typical project development logic, with the support from PAAs being possible in different stages, depending how successful has been the establishment of a collaborative environment between operators and competent authorities. In LNG bunkering projects, as with other projects of relevance to the port’s service portfolio, the outcome of collaboration between operators and PAAs will derive in positive outcomes for all parties involved.

Collaboration and integration are very likely to pay dividends to all parties even if it may be considered that commercial/industry sensitive information is sometimes not shared in advance. Information and transparency, together with non-disclosure agreements should be able to allow for the necessary early trust and engagement to be developed.

Elements for Feasibility Analysis

Following the different dimensions presented in figure 1, defining LNG bunkering project dimensions, table 1, below, lists some suggested elements that PAAs may use not only in the support of Feasibility Analysis studies but also as a direct contribution to the feasibility prospects for any LNG bunkering project.

| Table 1. LNG bunkering projects – elements for Feasibility Analysis | |||

|---|---|---|---|

| Project Dimension (figure 1) | Elements for Feasibility Analysis (elements that should be observed for Feasibility Analysis of LNG bunkering projects) | Support from PAAs (elements where PAAs support may have a direct impact in Feasibility) | |

| A. Technical | LNG source/availability – distance to LNG import/LNG storage from break-bulk distribution. | Mapping of existing LNG facilities, storage and distribution infrastructure. | |

| Facilitation in the development of the logistic chain. | |||

| LNG bunkering option (STS, PTS, TTS, ISO – LNG containerized unit) | Share with operators the main restrictions imposed either by port area layout or activities. | ||

| Onsite storage for LNG fuel – requirement for consideration of local LNG storage facility for PTS bunkering (or PTS filling of LNG bunkering mobile units – barges, vessels or trucks). | Provide operators with proposed location options for LNG fixed storage elements. | ||

| Support with land use elements relevant for possible building permits or land-use classification. | |||

| Bunkering parameters required by specific LNG fuelled ships – LNG flow rate, pressures, temperatures may be some of the more important parameters to be fixed for a given LNG bunkering solution. (typically related to required turn-around times and operational constraints). | Should there be any restrictions on possible bunkering parameters, make them available and clear to operators from the early concept development stages. | ||

| Together with the relevant restriction elements, give indication of any possible risk-based review of those restrictions.(bunkering parameters are a fundamental aspect of the LNG bunkering service, in particular accounting for ships that will require increasingly shorter turn-around times, such as RO-PAX ferries)Together with the relevant restriction elements, give indication of any possible risk-based review of those restrictions. | |||

| Cooling services – requirement for cooling services may be derived from the need to fill otherwise warm LNG fuel tanks. | PAAs should define restrictions for “hot LNG” bunkering and enforce adequate temperature control for LNG trucks or other mobile LNG bunkering units. | ||

| Inerting – Both before and after LNG transfer, inerting is a requirement for safety of operation, preparing the bunkering lines prior to LNG filling and clearing them of LNG vapours immediately after drainage. Technical option for inerting should designate whose responsibility is it for inerting operations. Which resources are to be used, together with the operational and Process level evaluation. | PAAs should make clearly available any specific requirements regarding inerting of: | Bunkering lines | |

| LNG bunkering rigid arm fixed installations | |||

| LNG distribution lines | |||

| Vapour return lines | |||

| NG lines | |||

| Inerting is a fundamental safety aspect in LNG bunkering facilities and operations. PAAs should consider, in particular for fixed installations there may be large extensions of LNG lines that require inerting prior and after operation. | |||

| Displaced LNG vapours, in the end of operation must have a declared fate. What will be drainage sump? It is important to avoid all operational venting considerations. | |||

| PAAs should make clear requirements for inerting and, with this, support the early feasibility for LNG bunkering projects, defining clearly the baseline that should be considered for the technical concept project. | |||

| Communications – A variety of different options may be considered for communications during LNG bunkering. | Communications are an important element for technical feasibility analysis, in particular with regards to the necessary communication channels for operational aspects such as authorization procedures. | ||

| Radio frequencies, encrypted data, digital, web-based communications, SATCOM, emergency communication, and any other technical aspects relevant for the technical/operational feasibility of the project. | |||

| PAAs should make available all possible options for communications’ planning within the context of any prospective LNG bunkering facility project. | |||

| An important aspect to take into account is the interoperability of systems and, in the particular case of emergency, the possibility to have communication channels shared by the wider multi-operator community in the port area. | |||

| Standardization – Are the different LNG bunkering solution elements to be certified according to relevant international standards? | A key rule in the context of certification for a prospective LNG bunkering facility will be standardization. | ||

| PAAs should consider the identification of standardization elements as positive aspects towards feasibility of a given LNG bunkering project. | |||

| The relevant standards for LNG bunkering facilities and operations are listed and summarized in article Maritime Standards Explained. A Focus on EN ISO 20519, ISO/TS 18683, and Supporting Guidelines“Standards” with Regulatory Frame Best Practice – Applicability in the Bunkering Interface“LNG Bunkering Guidelines and Standards” underlining suggest good practice in the reference to these standards. | |||

| PAAs should make clear reference to the relevant standards for LNG bunkering in their requirements for certification of LNG bunkering facilities. Legally binding requirements for standardization must be inscribed either in national legislation of port-specific regulations. | |||

| Certification – will the LNG bunkering facility proposed meet all the requirements for certification? | PAAs should adopt structured certification schemes for LNG bunkering projects and operations. With guidance for certification, making reference to specific standards it will be, in principle, easier to assess the feasibility for a prospective project. | ||

| Technical Maturity of the proposed project – Has the solution presented for implementation been tested in operation before? For how long? For solutions that have already been implemented, prospective LNG bunkering projects should provide as many elements as necessary to support in the evaluation of their technical feasibility. | For solutions that have already been implemented it is important to check for evidence and elements of reference projects. | ||

| For new technology elements, in order to support technical maturity for a prospective LNG bunkering project PAAs can, as appropriate, establish connection points with other ports and initiatives, seeking for any possibility of technology transfer. | |||

| In the particular case of public funded projects, it should be possible for prospective LNG bunkering initiatives to get information and demonstrated results which belong partially LNG bunkering and small scale LNG projects, when supported by some type of public funding, will typically be under the obligation to provide some type of results report for public information. Technology elements and non-commercially sensitive information may very likely be sourced from these elements in support for prospective and ongoing LNG bunkering projects.x to the public domain. PAAs may play an important role in the dissemination and availability of these results, establishing the link with the public funding competent authorities. | |||

| Automation – What is the degree of automation in the proposed LNG bunkering solution? Is supervision considered. | Automation elements may be present in some LNG bunkering projects. The degree of automation, however, will inevitably be different from project to project, with LNG fuelling or LNG bunkering via rigid/automated arms being likely to incorporate elements of automation for reduced human intervention. | ||

| It is important, in this context, that PAAs may define what the minimum requirements are for manning of LNG bunkering installations, even in the case where full automation is considered. | |||

| Any automated elements in LNG bunkering solutions must be provided for with manual over-ride options that allow for manned operation. | |||

| In the particular case of LNG fuelling, where the LNG delivery is provided for by LNG mobile units alongside the receiving vessel throughout its whole stay at port. | |||

| B. Legal | National legislation – What are the applicable legislative references to the proposed LNG bunkering solution? (Taking the whole supply chain into consideration By taking the whole supply chain into consideration, for the appreciation of the applicable legislative frame, it will be possible to evaluate the feasibility of the different possible options for LNG delivery, transport and handling representing the complete chain for a given LNG bunkering solution.x). | PAAs should, as appropriate and reasonably possible, provide an information package to prospective LNG bunkering operators including all legal references that may be relevant for the definition of the concept project, supporting from an early stage in the definition of a feasible solution. | |

| Port Regulations – Are any specific requirements for LNG bunkering inscribed in the Port Regulations? | In the case of early consultation by prospective BFO/Operators, PAAs should assess any specific details of the proposed LNG bunkering project and provide the relevant legal references applicable to that case. | ||

| From the early evaluation of the proposed project, along with the relevant legal references, PAAs may issue a first indication regarding the feasibility for the presented solution. | |||

| Permitting – Are all steps for permitting being observed? Permitting can represent a significantly burdensome process if all aspects are not accounted for in a preliminary phase. Feasibility of any LNG bunkering projects should address, in advance, all different parts of the permitting process to ensure that no major obstacles are posed to the good realization of the project. | Provide operators with all the relevant elements for permitting, making them available in a transparent and informative manner. | ||

| Assuming the position of a “facilitator” in the permitting process, PAAs should provide operators with the relevant mapping and points of contact for the different parts of the permitting process. | |||

| The establishment of a “single-desk” approach, where all relevant permits could be initiated and monitored, would be a highly relevant initiative. One of the main factors of success for such measure would be the level of collaboration between different competent authorities. | |||

| C. Operational | Operational Restrictions. The adequate design of operations should take into account any restrictions possible/likely to be imposed by any given PAA. | Operational restrictions should be clearly expressed in Port Regulations. | |

| In addition, as a way to support the feasibility of prospective LNG bunkering projects, PAAs should also consider alternative options, possibly risk-based, where excursions beyond the operational restrictions would be possible. | |||

| Operational Envelopes. Similarly to the Operational Restrictions, the Feasibility Analysis of LNG bunkering projects should take into account the Operational Envelopes imposed by possible local weather restrictions (wind/temperature/other). | Provide information to operators on local conditions that may result in operational envelopes to be accounted for in LNG bunkering operations. | ||

| Inform on the local characteristic weather patterns, with local weather office data for a typical year-round chart (wind, temperature). | |||

| Make available to operators all operational information found relevant to the feasibility analysis of new LNG bunkering projects. | |||

| PAAs should also consider alternative options, possibly risk- based, where excursions beyond the operational envelope restrictions/limitations would be possible. Justification to be presented on the basis of specific risk assessment. | |||

| Simultaneous Operations (SIMOPS) – Any consideration regarding possible Simultaneous Operations should be considered well in advance as these may impact significantly on the Feasibility prospects of any LNG bunkering project. Some Ports may have more or less strict requirements regarding SIMOPS. Whether these are inscribed in specific Port Regulations or derived from a later Risk Assessment, they will highly relevant to the feasibility analysis of LNG bunkering projects. Can SIMOPS be considered? Under which conditions? Are there technical implications for the proposed solution? These are some of the questions that need to be answered in the context of a feasibility study for any proposed LNG bunkering project. With RSOs being, ultimately, the main interested party in having short turnaround times they should also, in principle, take part in the proposed solution. | PAAs should define under which conditions Simultaneous Operations (SIMOPS) are allowed. | ||

| SIMOPS will represent a fundamental aspect in the feasibility prospects for any prospective LNG bunkering project/facility. In some cases it may be that the LNG bunkering will only represent a viable option if some degree of SIMOPs is allowed. | |||

| Establish and inform operators, relevant stakeholders and involved parties, of a specific procedure to plan and approve SIMOPS. This should be inscribed in the Port Regulations or, alternatively, be issued as guidance or stand-alone documents as Circulars or Memos. | |||

| Define clearly the staged approach in the authorization for SIMOPS. | |||

| Evaluate the prospective project in the light of its preparation for SIMOPS, providing input under the form of recommendations. | |||

| D. Market/Financial | Aspects such as LNG price, competition, demand, opportunities and other important market related variables are taken into consideration as primary factors for feasibility. They will also impact necessarily on the technical solution through life-cycle cost analysis. NOTE: Market/Financial aspects may well be the main aspects typically evaluated in a Feasibility Study. These are however aspects that are not considered within the scope of the present Guidance document. | Not applicable | |

| E. Economical | Multi-Operator Environment. Other Port Service operators will have to be considered in advance as important factors affecting the feasibility of proposed LNG bunkering projects/facilities. Interaction between operators and potentially incompatible activities within the port area are some of the aspects that should be considered at the earliest opportunity. | PAAs may provide useful data on other activities within the port area which are likely to have some impact in the prospective LNG bunkering project. | |

| Local Port Economy factors. In a variety of different aspects, LNG bunkering will impact and be impacted from the local port economy. | Depending on the level of exchange with LNG bunkering project proponents and operators, PAAs may provide elements related to local port economy development. | ||

| Some of the main relevant aspects regarding the economic factors will be: | Future prospects for LNG/Energy developments in the port area, potential for growth, fees and incentive schemes are some of the support information that can be provided. | ||

| Potential for LNG multi-client hub development. | How the different information will impact on feasibility of different LNG bunkering projects will depend on a case-by-case evaluation. | ||

| Potential for growth (increasing number of LNG fuelled ships and bunkering operations) | |||

| Local “green economy” trends | |||

| Existing LNG bunkering operators | |||

| Schemes for Port Fees and incentives for alternative fuels and clean power solutions. | |||

| Economic Cost-Benefit. An Economic cost- benefit may, in a way, be regarded as more relevant to the port and local economy than to the LNG bunkering operator. | The economic cost-benefit of an LNG bunkering development in the port area may be evaluated in the early stages of the project. | ||

| How PAAs may support operators in this regard is very dependent on the exact nature of the business and solution proposed. | |||

| The essential note should be, in this context, that PAAs have the opportunity to evaluate the feasibility of LNG bunkering projects also from the perspective of port economy development, associating opportunities generated by the LNG bunkering development into the evaluation of the project feasibility itself. | |||

| F. Social | Public Consultation. Only in some specific cases Public Consultation will be required (remarkably where imposed as a SEVESO requirement for higher tier establishments (see article Regulatory Frame Best Practice – Applicability in the Bunkering Interface“Seveso III Directive – Major Accident Prevention Directive”). There is however a significant role that can be played by PAAs in the facilitation of local public/communities-consultation. This can be a relevant factor to take into account to support the feasibility of a given LNG projects, remarkably where LNG bunkering operation is envisaged for a location situated close to densely populated areas. | On the cases where Public Consultation needs to be accounted for (see article Regulatory Frame Best Practice – Applicability in the Bunkering Interface“Seveso III Directive – Major Accident Prevention Directive”), PAAs may liaise with local authorities to support with additional information, facilitating the public consultation, especially on those element which may be more related to risk & safety. | |

| PAAs may use the privileged knowledge of local communities to facilitate the consultation process, clarifying any elements where transparency and clarity may be of support for a better informed consultation process. | |||

| Information campaigns. In itself information to public and general information campaigns are not a fundamental factor for the feasibility of LNG bunkering projects. They have however the ability to enhance and facilitate the acceptance of LNG as fuel and associated projects. | PAAs may support social feasibility of LNG bunkering projects through information on different channels targeting the following communities: | Local authorities | |

| Port operators | |||

| Service providers within the port area. | |||

| Ship Agents | |||

| Information is particularly important in defining the risk & safety perception of LNG as fuel for ships. PAAs choosing to enforce LNG perception with information campaigns will improve directly the social feasibility prospects of LNG bunkering projects. | |||

| Examples of such initiatives may be found in the shape of informative websites such as the EC or the WPCI. | |||

| Opportunities. Social perception of LNG as an alternative fuel for ships will greatly depend on the ability of the proposed projects to highlight the new opportunities created by LNG as an alternative cleaner fuel, including benefits for the environment, new and more specialized jobs, together with a strong possibility for improvement of the local economy in a wider scale. | It is important to build the case for LNG bunkering projects, including as important factors the potential direct benefits for environment and economy. | ||

| PAAs may support feasibility of new LNG bunkering projects through the exploration of new opportunities, immediate or with through-life relevance. | |||

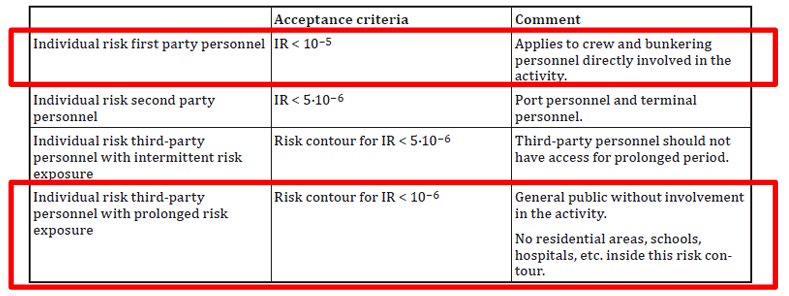

| G. Risk | Risk Assessment. The evaluation of risk for an LNG bunkering project is likely to be the most relevant document to be used not only for permitting but also, especially in the initial stages of concept or project development, an important tools to reassess the concept or project in itself. Risk Assessment is more likely to introduce modification into the proposed solution than to deem it to a negative feasibility prospect. It will be able to introduce elements which can then be used to detail the engineering solution, inclusive of any identified necessary safeguards to improve the evaluated safety risk level for the proposed project. Assessment of risk will be made either following a quantitative or qualitative approach. In both cases there are elements that can be considered fundamental drivers for an adequate feasibility evaluation derived from a risk assessment: | Risk Criteria (will be the most relevant element for QRA Risk Analysis). PAAs must clearly define Risk Criteria wherever Quantitative Risk Assessment is required. There must be a clear understanding, promoted by PAAs, that the usefulness of QRAs is only best explored where LNG bunkering risk criteria. In the absence of national framework for such risk criteria, ISO/TS 18683:2015 suggested risk criteria example (Annex-A) should be taken as the biding reference. | |

| Participate in HAZID workshops. Participation in HAZID workshops for prospective LNG bunkering projects will give PAAs the possibility to support operators in the definition of risk scenarios, underlining the most critical situations and supporting, through the drafting of relevant safeguards, the project feasibility. | |||

| Adequate representation of the LNG bunkering facility and operation in the risk assessment. | Data on Incidents and near-misses related to bunkering, eventually held by PAAs, should be used to draft recommendations or specific requirements for PAAs, improving in this way the feasibility prospects for the project. | ||

| HAZID team composition (experience, proven competency, number of participants). | Should the HAZID represent the first step before the development of more thorough Risk Assessment (QualRA or QRA), PAAs should take the opportunity of participation to provide elements considered relevant for feasibility. | ||

| Number of different risk case scenarios considered (including the complete scope of operations). | Involvement of third-party risk evaluation professionals should be regarded positively by PAAs, as an indication of transparency in the risk study/assessment process. For prospective LNG bunkering projects PAAs should underline the need for independent risk study (at least as much as reasonably possible). In this regard “independency” is to be understood as a good guarantee for feasibility of the prospective LNG bunkering project. | ||

| Safety Distances/ Control Zones. One of the direct results of Risk Assessment will be the definition of the Safety Zone and additional control zones (such as the security zone or navigation exclusion zone (see articles LNG Bunkering Hazardous Zone: Safety, Classification, and Control“Control Zones”, Security Zones in LNG Bunkering: A Guide to Meaningful Protection“Security Zone” and Key Aspects and Recommendations for the Safety Zone for LNG Bunkering“Safety Zone”). Focusing primarily on the Safety Zone it is important to evaluate if the intended location, adjacent infrastructure and proposed Safety Distance are compatible. If not entirely possible to eliminate potential ignition sources, gas trapping spots and conflicting activities, within the proposed Safety Zone, the feasibility of the project will be inevitably affected. This should be subject to continuous review. Since the Safety Zone, by definition, should encompass the elimination of potential ignition sources and other activities/ operations inside the defined zone, it will be important to ensure that no conflicts arise. | As a first-principle in the interpretation of proposed safety distances PAAs should consider that no Safety Distance is the “right” Safety Distance (see articles LNG Bunkering Hazardous Zone: Safety, Classification, and Control“Control Zones”, Security Zones in LNG Bunkering: A Guide to Meaningful Protection“Security Zone” and Key Aspects and Recommendations for the Safety Zone for LNG Bunkering“Safety Zone”). | ||

| PAAs should provide support with the indication of any baseline minimum required safety distances for LNG bunkering, underlining the concept of Meaningful Protection (articles LNG Bunkering Hazardous Zone: Safety, Classification, and Control“Control Zones”, Security Zones in LNG Bunkering: A Guide to Meaningful Protection“Security Zone” and Key Aspects and Recommendations for the Safety Zone for LNG Bunkering“Safety Zone”). | |||

| Feasibility analysis, based on suggested safety distances, should be based on the evaluation of meaningful protection for persons and infrastructure. | |||

| Dispersion studies should be regarded as a good indication on positive risk feasibility, resulting, in principle, in the definition of more realistic safety distances, based in numeric gas dispersion calculations. | |||

| Assumptions used in all numeric/computational gas dispersion calculations should be assessed by PAAs as indicators on how accurate is modelling of local conditions. | |||

| H. Sustainability | Air Emissions. The use of LNG as fuel is one of the main options available to ship operators to improve/reduce air pollution, reducing sulphur oxides, particulate matter and nitrogen oxides emissions to the atmosphere. The use of LNG as fuel is therefore a direct measure to improve the environmental performance of ships using this fuel, but not only. It may also represent a direct factor contributing to the improvement of any port’s environmental performance. A direct and sustainable reduction in emissions (SOx, NOX and PM) should be assessed together with a relevant set of measures to mitigate the risk of any methane emissions to the atmosphere (see article Balancing Cleaner Fuel and Environmental Impact in LNG Emissions“Environment”). Purging, Inerting, cooling and filling procedures should all be detailed with explicit reference to the measures considered relevant to PAAs evaluation. | Air Emissions from LNG bunkering operations are the main fundamental aspect in the field of Sustainability for the use of LNG as marine fuel. On one hand using LNG as an alternative fuel will immediately reflect in lower emissions of SOx (by more than 95 %), NOx (to an extent directly related to the engine technology, that can go up to 70 % in lean gas burning engines) and Particulate Matter (also by more than 95 %). On another hand CO2 emissions may outbalance the very positive figures from above, with methane (CH4) representing a GHG emission which is 25 times worse than CO2 on a 100 years scale. With the above in consideration PAAs should look for all elements related to prevention and mitigation of LNG vapour emissions through venting, pressure release or incorrect BOG management. | |

| Purging and inerting procedures should be revised and the fate of post-bunkering LNG in the bunkering lines questioned. Emission to the atmosphere, as a result of quick temperature increase and pressure build-up in the bunkering line should not be acceptable in the context of feasibility analysis. | |||

| Environment. The feasibility of the LNG bunkering solution as a sustainable environmental project should be assessed from the early stages of the concept project. The following stages of the Environmental Impact Assessment are relevant for the Feasibility Analysis: 1) Screening; 2) Scoping and; 3) Prediction and Mitigation (see diagram in figure Regulatory Frame Best Practice – Applicability in the Bunkering Interface“Environmental Impact Assessment – General reference process”). | PAAs should ensure that EIA related feasibility is successfully addressed, in preparation for the permitting process. | ||

| Logistics and Supply. How far is LNG sourced from for the proposed LNG bunkering facility? Which logistic routes are followed for LNG distribution? The footprint of LNG distribution chain in the port area, and its supply routes (road/sea) should be evaluated, in particular with regards to possible conflicting and congestion points. | PAAs should assess the impact on access to the port and within the port area. | ||

| To support feasibility of the LNG bunkering project PAAs may provide alternative options and design logistic solution in close cooperation with operators. | |||

For each selected project dimension the suggested elements indicate which aspects PAAs may provide support with.

All elements from the table above should be addressed in the context of the desired earliest involvement of PAAs in the feasibility discussion of prospective LNG bunkering projects. This may not always be possible, and LNG bunkering proposed solutions may be presented in a stage of development such that less flexibility to accommodate proposed recommendations may become a problem in the permitting and/or implementation stages. PAAs have here an opportunity to engage early, participate and through collaborative support be able to potentiate the Resource Reserve Estimate in LNG Project Development PhasesLNG bunkering project as a port service adding value to a specific port economy profile.

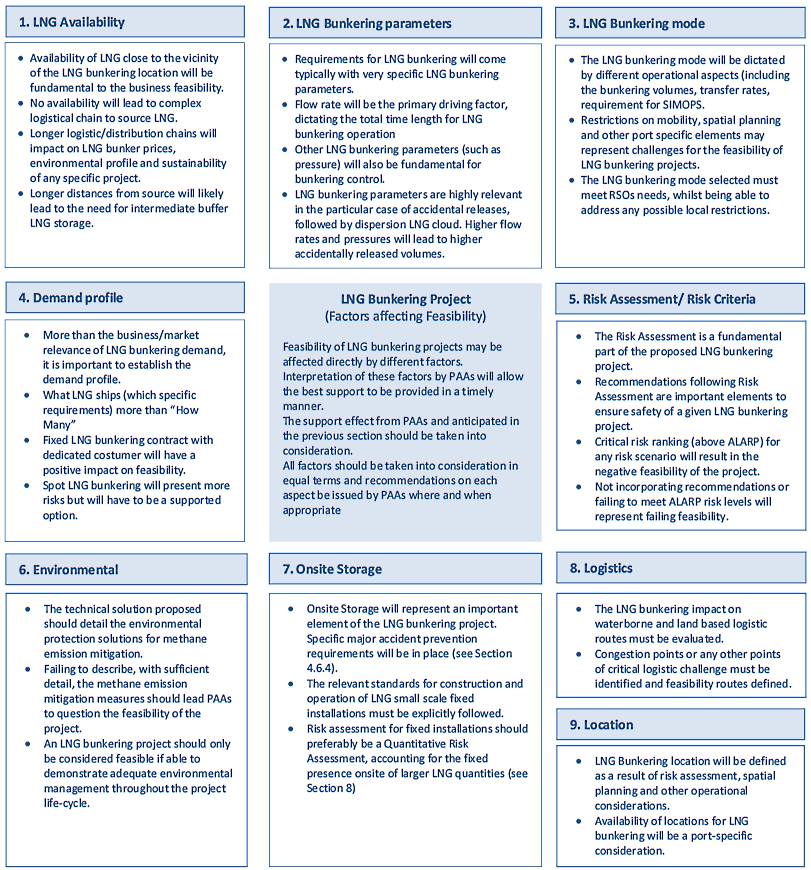

Factors affecting LNG Bunkering feasibility in the Port Area

Following from the previous section, where the main elements for Feasibility Analysis where listed and detailed, for each LNG bunkering project dimension, it is now possible to identify the essential aspects which can be either relevant aspects or “showstoppers” in the development of prospective LNG bunkering facilities. PAAs may take this for reference when evaluating LNG bunkering projects and should, in principle, be able to provide support in the clarification of any possible restrictions and, at the same time, support with the possible drafting of alternative options/possibilities.

The diagram in figure 3, below, presents the main factors and how they can, potentially, pose a negative impact in the Feasibility of LNG bunkering projects.

Whilst the diagram in figure 3 identifies some of the most relevant challenges to feasibility of LNG bunkering projects, it is important to note that today there are many technical options available to operators. As the market moves from smaller capacities (typically TTS mode) to higher LNG volumes (STS or PTS modes) there is a change in paradigm which will inevitably reflect in future LNG bunkering projects. Feasibility of different LNG bunkering projects will therefore be a characteristic to evaluate in increasingly relevant solution, remarkably in terms of the LNG quantities involved.

It will be interesting: LNG (Liquefied Natural Gas) as Fuel

How PAAs should support operators, and when, is difficult to define. The only possible guidance advice is that it should happen at the earliest possibility in the project development, with operators having to disclose early concept lines of the projects, in exchange for support from PAAs with aspects related to the feasibility prospects of each project.

Analytical Tools

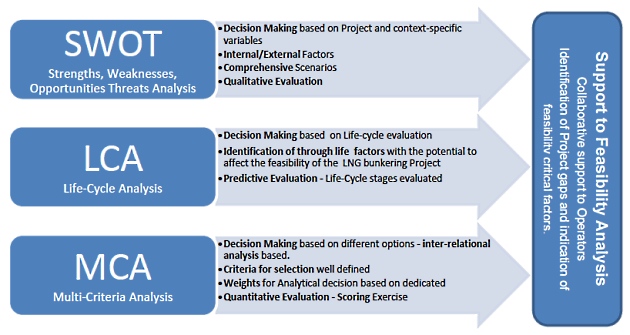

Whilst the previous sections listed the different dimensions in LNG Bunkering Projects, together with the different factors affecting Feasibility Analysis, the present section features three different analytical tools that may be helpful in the evaluation, decision-making and support to prospective LNG bunkering projects:

- SWOT Analysis (Strengths, Weaknesses, Opportunities and Threats);

- Life-Cycle Analysis (LCA) and;

- Multi Criteria Analysis (MCA):

- The SWOT analysis has the potential to identify different critical aspects of the LNG bunkering, considering the external and internal factors which may impact on the feasibility of any specific project. Intrinsic strengths and weaknesses of the project are also identified and a SWOT matrix is built to support the analysis.

- The LCA analysis focuses on the structured life-cycle evaluation of the LNG bunkering project as any other engineering development, incorporating:

- Concept,

- Development,

- Implementation,

- Operation and,

- Decommissioning.

- The MCA analysis used in decision-making, which may be regarded as particularly useful for PAAs faced with different options for LNG bunkering projects (such as deciding which bunkering mode to allow, bunkering parameters, and others).

To which extent PAAs may get involved in the feasibility evaluation of LNG bunkering projects will depend on the level of understanding and collaboration between competent authorities and operators.

SWOT, LCA and MCA tools will be some of the possible instruments for a transparent and structured evaluation of LNG bunkering projects feasibility, in all project’s dimensions.

SWOT Analysis

SWOT is a typical strategic planning tool used to evaluate the strengths, weaknesses, opportunities, and threats to a project. It involves specifying the objective of the project and identifying the internal and external factors that are favourable and unfavourable to achieving that objective. The strengths and weaknesses usually arise from within the project details and organisation, and the opportunities and threats from external context. SWOT analysis is adopted from strategic planning to project feasibility analysis but, in practice, it can be used widely in many other practical applications.

The SWOT analysis is, in this sense, an important part of the project planning and feasibility analysis process:

- Strengths: attributes of the project and operator(s) that are understood to have a direct impact in the feasibility of the project.

- Weaknesses: attributes of the project and operator(s) that have to potential to stop, or significantly diminish, the achievement of the project objective/implementation.

- Opportunities: external conditions, including port-specific conditions, which help achieve the LNG bunkering project objective.

- Threats: external conditions, including port-specific conditions, which have the potential to endanger the full achievement of the LNG bunkering project objectives/ implementation.

Table 2, below, represents a SWOT matrix, with a few examples of what can be considered in the context of LNG bunkering projects. The qualitative approach of a SWOT allows for the analysis to be used in a multi-variable context.

| Table 2. LNG bunkering projects – elements for Feasibility Analysis | ||||

|---|---|---|---|---|

| Positive | Negative | |||

| Internal | Strengths | Weaknesses | ||

| 1 | Maturity (similar successes and evidence of technological maturity for LNG bunkering solution). | 1 | Gaps in knowledge and expertise, with evident lack of previous experience in the field. | |

| 2 | Resource availability (LNG Terminal close). | 2 | Insufficiently detailed technical solution. (Lack of details for any part of the LNG storage, distribution or bunkering segments. | |

| 3 | LNG chain owned by BFO (Terminal and distribution). | 3 | Timescale and deadlines, for project implementation which may be regarded as non-realistic. | |

| 4 | Skill levels (demonstrated competence of personnel). | 4 | Financial capability, in particular regarding the lack of demonstration for capital investment. | |

| 5 | Processes and systems (properly mapped LNG bunkering process). | 5 | Certification challenges, in particular if standardization is not well clarified. | |

| 6 | Reputation (built references from operation in other ports or other sides of the LNG activity). | 6 | One-Client solutions, when LNG bunkering solution is customized taylor-made to one ship – poor flexibility. | |

| 7 | Complete and Independent Risk Assessment (including variety of risk scenarios and quantitative calculations, including gas dispersion modelling). | |||

| External | Opportunities | Threats | ||

| 1 | Technology and infrastructure development (development of a new terminal, standards for LNG bunkering). | 1 | Environmental factors, with methane emissions becoming a major focus of attention, particularly sensitive if no adequate methane emission mitigation is included in the project. | |

| 2 | LNG fueled ships uptake – more ships and increase in LNG fuel capacities – increasing number of ships suitable for the technology offered. | 2 | Competition/Competitor projects. | |

| 3 | Multimodal LNG hub – How adequate is the project proposed to respond to multi-modal LNG hub opportunities. | 3 | Risk Assessment in ALARP borderline. Variation of external factors potentially leading to unacceptable risk levels. | |

| 4 | New innovations (R&D). | 4 | LNG bunkering demand not compatible with the proposed solution (either in capacity or technical specification). | |

| 5 | Market demand. | |||

| 6 | Financing Opportunities. | |||

PAAs, in the course of a SWOT-assisted feasibility analysis for any given LNG bunkering project, should, as far as possible and appropriate, Common LNG Support Systemssupport operators in the adequate definition of the external environment factors (a large majority of them likely to be port-specific).

LCA Analysis

Every engineering project, or product development, will have in principle to be evaluated on the basis of its anticipated Life-Cycle. Not only are the costs a relevant aspect to evaluate through the life of the project but also the performance, environmental impact and other operational aspects. For LNG bunkering projects the same will apply and a Life-Cycle Analysis (LCA) may be one of the instruments to support the evaluation of feasibility for any prospective LNG bunkering project. The table 3, below, proposes an indicative structure for LCA of LNG bunkering projects, suggesting a few relevant questions to be asked by PAAs for each different phase.

MCA Analysis

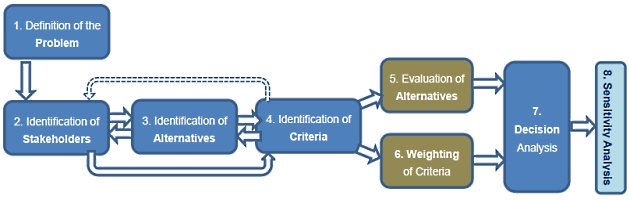

Whilst SWOT is a typical tool, adapted from strategic planning, used to evaluate the strengths, weaknesses, opportunities, and threats, the Multi Criteria Analysis (MCA) stands for a project-focused analysis establishing a comparative framework for different parametric options for the same project. In the case of LNG bunkering this may be useful in particular for PAAs to support operators in the location selection for a prospective LNG bunkering facility.

Multi-Criteria Analysis (MCA), or Multi-Criteria Decision Analysis (MCDA), is a discipline aimed at supporting decision makers who are faced with making numerous and conflicting evaluations. MCA aims at highlighting these conflicts and deriving a way to come to a compromise in a transparent process. MCA methods have been developed to improve the quality of decisions involving multiple criteria by making choices more explicit, rational and efficient. The goal is to create a structured process to identify objectives, create alternatives and compare them from different perspectives.

Read also: The Role of LNG Bunkering Infrastructure

MCA may be of particular interest, for instance, in the selection of alternatives for a designated LNG bunkering location. In this context MCA can be used to establish a clear and structured decision-support to the selection, with the impact of the analysis depending on a wider involvement of stakeholders and on the consensus reached for the selection of evaluation criteria. The MCA for site selection will, in the case of LNG bunkering, be inevitably related to Risk Assessment, Logistics and Operations.

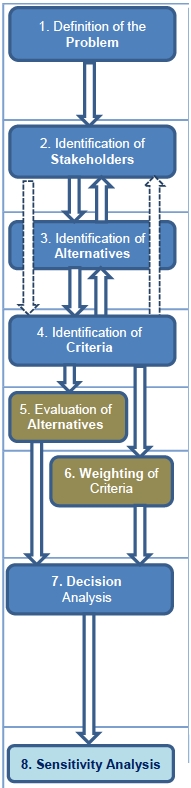

General steps in an MCA process adapted to risk assessment, selection of alternatives and site selection are an adaptation of the standard MCA frame, fully adapted. The steps in a general MCDA and spatial MCDA are similar. First, the objective of the analysis is defined (step 1). Next, the key stakeholders that should be involved in the analysis process are identified (step 2). The following steps involve defining all possible alternatives under consideration (step 3) and all of the relevant criteria for evaluating these alternatives (step 4). These steps are interchangeable and may lead to an iterative process of refining which stakeholders to involve. Next, the alternatives are assessed based on the identified criteria (step 5). Performance indicators or decision variables are created for each intersecting pair of alternative and criteria.

For spatial MCA, evaluation criterion maps are generated to evaluate the performance of alternatives. Constraint maps can also be generated to display the limitations of the values that decision variables may assume. Following this, all criteria are weighted by participating stakeholders in order to reflect the preference values of those involved (step 6). It should be noted that not all MCDA approaches make use of weighting; other ordering techniques such as pair-wise comparison can be used. Next, a mathematical combination of the criteria is performed using a decision rule and effectively combines the results of the preceding four steps (step 7). The combined criteria produce an ordering of alternatives.

Finally, a sensitivity analysis is performed to examine the robustness of the ranking outcome (step 8).

The end result of the MCA process is a recommendation consisting either of the best-ranked alternative or group of alternatives.

The diagram below, in figure 5 identifies the different steps in MCA Analysis, whilst Table 4, structures the adaptation of the MCA tool to LNG bunkering site selection.

The use of MCA methodology, adapted to any decision in LNG bunkering projects (location for LNG bunkering, in the case presented above, used as an example) is possible to scale and adapt to other decision-making aspects (such as deciding on the LNG bunkering mode). The adoption of such tool by PAAs will be limited to the type of cooperation established with operators. It will enable not only a more transparent decision-process but also allow for a structured approach in a complex multi-variable context.

The tool, as presented in the present Guidance, can in itself be also significantly helpful for operators in a variety of other decision making contexts. The approach is multi-disciplinary.

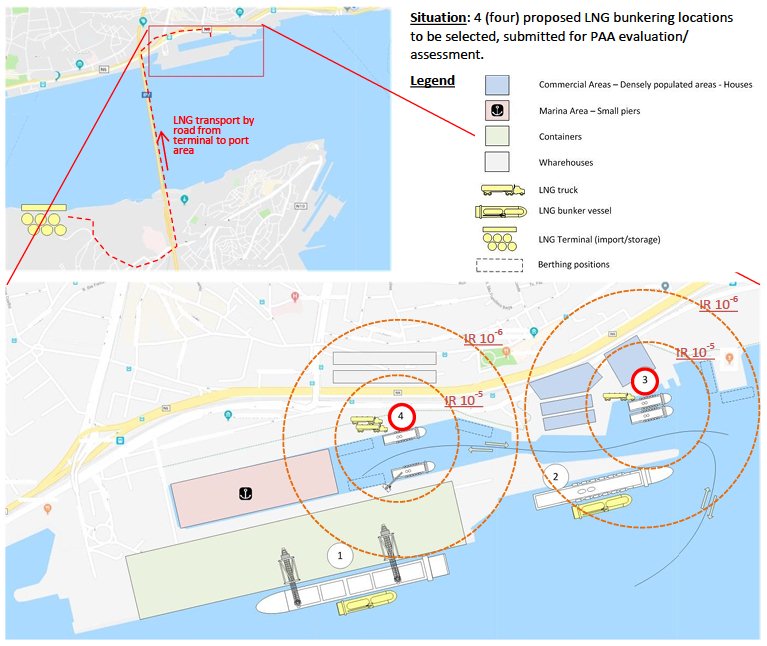

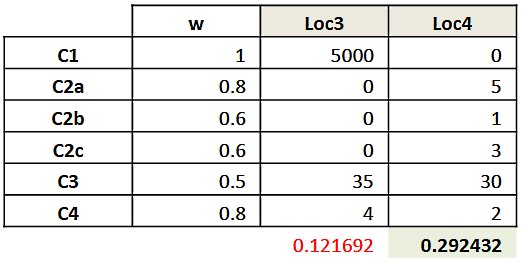

In the way of illustrating how the MCA can be used as an instrument by PAAs, an example is demonstrated below, including only a limited set range of parameter and criteria, with 4 (four) LNG bunkering locations subject to analysis, all defined options by applicant operator for the establishment of a wide LNG bunkering service in the Ports, Terminals and Jetties – Role and Significanceport area.

The example in table 5 illustrates some practical aspects behind MCA methodology. Notwithstanding its simplicity, the example illustrates the flexibility of MCA, its structured workflow, and the ability to integrate several alternative solutions, to be assessed by different criteria, weighted according to stakeholders review and assessment of the situation.

Important final additional notes regarding the example demonstrated:

- The example is the result of several simplifications, only valid for the demonstration of the MCA methodology for decision-making support.

- Locations 1 and 2 are the example of LNG bunkering locations which are dictated by the operational profiles of the ships at berth (containerships and cruise ships). SIMOPS are, for these ships inevitable operational aspects to address. In the case for locations 1 and 2, the choice/selection of a preferred bunkering location is not the central problem – it is rather more on how to make the;

- Locations 3 and 4 are indicated already with individual risk contours, following from risk quantification/ risk assessment in support of decision-making. This will not always be the case, even if the baseline for an adequate comparison of the proposed locations should preferably be risk-based.

Good Practice in the evaluation and support to prospective projects

Feasibility Evaluation of prospective LNG bunkering projects is a relevant step of every project development, with the objective of verifying whether a given LNG bunkering facility/service will, in one hand, be supported by sound, feasible and demonstrated technical/engineering aspects and, on the other hand, representing a safe and sustainable activity as a relevant port service.

A complete Feasibility Analysis of LNG bunkering projects will be the analytical, qualitative and, where possible, quantitative, evaluation of proposed projects covering at least the dimensions presented in the diagram of figure 1, all collectively contributing to the development and implementation of LNG bunkering projects and should be taken into consideration by PAAs at the earliest possible moment from the presentation of the project.

It will be interesting: LNG IMO Tanks/Containment Systems

PAAs should get involved in the Feasibility Evaluation of LNG bunkering project at the earliest possibility. This will greatly increase the possibilities for early mitigation of any risks of incompatible or unrealistic solutions, failing to meet PAAs requirements or to address any possible technical or operational constraints imposed by the administrative, physical or safety environment within the port.

This involvement will, despite all good practice indications, be subject to multi stakeholder initiative, disclosure and to the establishment of an early collaborative environment, favourable to sharing of information related to concept project stage. The initial stages of an LNG bunkering project (as shown in figure 2) are fundamental for the adequate shaping of a feasible solution. PAAs should, to the extent adequate and possible, participate and support operators with information, data sharing, facilitation with the wider community of stakeholders, competent authorities and other service providers within the port area.

Direct support from PAAs to prospective LNG bunkering feasibility can be materialized through the provision of different elements, relevant to the different project dimensions.

These are listed in table 1, and can be summarized in the following categories:

a. Rules and Regulations – through clear Port Regulations, where LNG bunkering related provisions are included, PAAs support prospective projects through transparency. In addition to design codes, standards, it is possible that port-specific requirements may have to be considered at the earliest stage by operators in order to avoid negative impact further down towards development stages.

b. Restrictions – Any restrictions that may apply to LNG bunkering (or fuelling) scenarios should be made very clear, along with possible alternatives that may ensure the safe and necessary development of alternative fuels infrastructure within the port area.

c. Data – In the initial stages of concept and project development, data availability is one of the key success factors for LNG bunkering developments. Risk Studies require data for probabilistic calculations. Data on bunkering related incidents and near-misses is, in this regard, important to be available. Demand forecast and compatibility will require data on the profile of the different ships visiting the port and, finally, spatial planning, existing risk contours and area classification will further assist operators in the design of a feasible LNG bunkering location.

d. Information – Informative elements should be made available actively or on request, regarding:

- possible incentives, funding, special conditions for the establishment of potential environmental sound technologies;

- administrative aspects related to permitting procedure;

- general port service portfolio, with specific information on any specific service which might be of interest in the context of LNG bunkering.

e. Facilitation – PAAs may develop support vectors to prospective LNG bunkering projects through facilitation between all relevant stakeholders, in particular throughout the permitting process.

f. Analysis – In support to operators, in the early stages of LNG bunkering project development, PAAs may.

PAAs, whenever engaged in the evaluation of prospective LNG bunkering project LNG bunkering projects may be supported through one or more of the following methodologies:

- SWOT Analysis (Strengths, Weaknesses, Opportunities and Threats);

- Life-Cycle Analysis (LCA) and;

- Multi Criteria Analysis (MCA):

a. The SWOT analysis to identify different critical aspects of the LNG bunkering, considering the external and internal factors which may impact on the feasibility of any specific project. Intrinsic strengths and weaknesses of the project are also identified and a SWOT matrix is built to support the analysis.

b. The LCA analysis focused on the structured life-cycle evaluation of the LNG bunkering project as any other engineering development, incorporating:

a) Concept,

b) Development,

c) Implementation,

d) Operation and,

e) Decommissioning.

c. The MCA analysis, to be used in direct support to decision-making, which may be regarded as particularly useful for PAAs faced with different options for LNG bunkering projects (such as deciding on proposed bunkering location, which bunkering mode to allow, Examples and Methods Liquefied Natural Gas Bunkeringbunkering parameters, and others).